Warehouse Business Plan Template

Written by Dave Lavinsky

Warehouse Business Plan

You’ve come to the right place to create your Warehouse business plan.

We have helped over 1,000 entrepreneurs and business owners create business plans and many have used them to start or grow their Warehouse businesses.

Below is a template to help you create each section of your Warehouse business plan.

Executive Summary

Business overview.

FlexiStore Warehousing is a startup warehousing business located in Tulsa, Oklahoma. The company is founded by Martin Snow, a warehouse manager who has an extensive number of customers who have appreciated his service in the past ten years of his employment with a national chain warehouse company. Martin consistently went out of his way to accommodate the particular and sometimes, unique, needs of his customers in moving goods of all types into and out of the appropriate warehousing; the perfect sized facility, warehousing that was renovated to meet customer needs, and other specific solutions for customers. Whether large inventory or small, Martin Snow was known in the chain as the “Go To” solution-provider.

FlexiStore Warehousing will provide an advanced technology infrastructure, including barcode scanning, RFID tracking, and automated inventory management systems. These systems will ensure goods are brought in as properly tracked, sorted, managed and, finally, sent out without errors or issues involved.

Product Offering

The following are the services that FlexiStore Warehousing will provide:

- Logistics management

- State-of-the-art facility

- Advanced technology infrastructure

- Highly-skilled team

- Clear access to major transportation hubs

- Timely entry/exit management

- Fulfillment options

- Value-added options

- Technology-driven security system

Customer Focus

FlexiStore Warehousing will target e-commerce companies. They will also target medium-to-large manufacturers. They will target regional wholesale companies. They will also target medium-to-large retail outlets, chains and other stores needing warehousing for overstocks or ancillary goods.

Management Team

FlexiStore Warehousing will be owned and operated by Martin, “aka Marty,” Snow. He recruited his former warehouse associates, Roger Hartwell and Kenny Jones, to assist in the management of the startup business.

Marty Snow is a veteran of over fifteen years of warehousing experience, five of those years in management. His former employer was a national chain, which meant that Marty was limited in some areas where he could see that improvements to inventory, storage and processing could have been a factor in gaining or retaining customers. For these reasons, and with a large following of customers who’ve already agreed to move their warehousing to his startup, Marty has made the decision to form FlexiStore Warehousing.

Roger Hartwell, formerly a warehouse team member with Marty, will take on the role of Inventory Control Manager. In this role, he will exercise his depth of knowledge using the advanced technology tools installed to perfect the process of inventory control. Roger has a background in the U.S. Marines as a Staff Sergeant in the logistics department of a nearby station.

Kenny Jones, a former team warehouse member with Marty, will take on the role of Operations Manager, overseeing the movement of goods in, through, and out of the warehousing process. His keen eye for detail and depth of warehousing knowledge has earned him this role.

Success Factors

FlexiStore Warehousing will be able to achieve success by offering the following competitive advantages:

- Friendly, knowledgeable, and highly-qualified team of FlexiStore Warehousing

Financial Highlights

FlexiStore Warehousing is seeking $200,000 in debt financing to launch its FlexiStore Warehousing. The funding will be dedicated toward securing the office space and purchasing office equipment and supplies. Funding will also be dedicated toward three months of overhead costs to include payroll of the staff, rent, and marketing costs for the print ads and marketing costs. The breakout of the funding is below:

- Office space build-out: $20,000

- Office equipment, supplies, and materials: $10,000

- Three months of overhead expenses (payroll, rent, utilities): $150,000

- Marketing costs: $10,000

- Working capital: $10,000

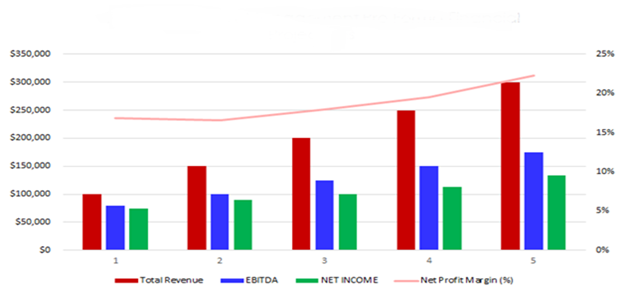

The following graph outlines the financial projections for FlexiStore Warehousing.

Company Overview

Who is flexistore warehousing.

FlexiStore Warehousing is a newly established, full-service warehouse business in Tulsa, Oklahoma. FlexiStore Warehousing will be the most reliable, cost-effective, and efficient choice for commercial enterprises throughout Tulsa and the surrounding communities. FlexiStore Warehousing will provide a comprehensive menu of warehousing and inventory control services for any client to utilize. Their full-service approach includes a comprehensive array of technology-driven processes that guarantee inventory control, logistics movements, and security.

FlexiStore Warehousing will be able to warehouse goods for any medium-to-large manufacturer or other entity. The team of professionals are highly qualified and experienced in logistics, inventory control and warehousing solutions. FlexiStore Warehousing removes all headaches and issues of common warehousing issues and ensures service and reliability are included in the best customer service.

FlexiStore Warehousing History

Since incorporation, FlexiStore Warehousing has achieved the following milestones:

- Registered FlexiStore Warehousing, LLC to transact business in the state of Oklahoma.

- Has a contract in place at one of the nearby buildings to set up its 10,000 square foot office space.

- Reached out to numerous contacts and former clients to refer FlexiStore Warehousing to associates in their industry.

- Began recruiting a staff of ten warehousing team members and office personnel to work at FlexiStore Warehousing.

FlexiStore Warehousing Services

The following will be the services FlexiStore Warehousing will provide:

Industry Analysis

The warehousing industry is expected to grow over the next five years to over $1,007 billion. The growth will be driven by the increased number of goods imported into the U.S. which require either distribution or warehousing until clients schedule shipments. The growth will also be driven by increasing demand for efficient logistics and supply chain management The growth will also be driven by an increasing need for advanced security systems as warehouse thefts continue to be problematic The growth will also be driven by e-commerce, which will call for more fulfillment capabilities, upsell options and other consumer offers that will necessitate warehousing special services. Costs will likely be reduced as shipments increase and supply chain issues are resolved from years past. Costs will likely be reduced as improved shipping times increase the regulation of delivery of goods, implementing a smoother process for inventory and logistics control.

Customer Analysis

Demographic profile of target market, customer segmentation.

FlexiStore Warehousing will primarily target the following customer profiles:

- Medium-to-large manufacturers

- Regional wholesale companies

- Medium-to-large retail outlets and chains

- Stores needing overstock facilities

Competitive Analysis

Direct and indirect competitors.

FlexiStore Warehousing will face competition from other companies with similar business profiles. A description of each competitor company is below.

Swift Logistics

Swift Logistics is a warehouse business located in Claremore, thirty miles from Tulsa, Oklahoma. The business is owned by Jack Parsons, an entrepreneur who has determined the warehousing market is a viable and profitable venture. Jack Parsons has instituted previously-unknown technology systems into the warehouse company, where the results have been mixed success throughout. The company owns five warehouses, soliciting small to medium-sized businesses as clients.

Jack Parsons has an extensive list of clients that has grown from the past ventures he has initiated. He has a mixed amount of success in these ventures, but has a dedicated following of supporters willing to continue investing in each venture. Former startups include Rent-a-Place LLC, a traveler’s rental business; HowsAboutThat, Inc., a company that sells unusual toys and novelties; and TeddyBear Wonders, Inc., a company that imports teddy bears of all kinds.

Exceptional Service Wearhouse Co.

Exceptional Service Warehouse Company has five warehouse units of 120,000 square feet each. It is located in Fort Worth, Texas, about 180 miles from Tulsa, Oklahoma. As a direct competitor, Exceptional Service Warehouse is a large-scale service with multiple options for customers who need a vast array of services. The organization has over 300 team members with multiple offices and functions within the general administration of the company.

Exceptional Service Warehouse has a strategic initiative to include the very largest inventory supplies in the nation within their warehousing facilities. Toward this end, the company does not solicit any business from medium or small-sized companies, nor does the company allow any exceptions to their stated policies. This somewhat limits the participation of smaller companies and does not offer solutions when potential clients present unusual circumstances or emergency requests.

Thomas & Harris Warehouse

The Thomas & Harris Warehouse company is located in Tulsa, Oklahoma in the southeastern portion of the city. The company targets small businesses specializing in grocery items, including refrigerated and frozen goods. This specialty ensures a steady stream of grocery store clients and other large chains who need emergency supplies for overstocks or other grocery items. Overall, the team of six people run the warehousing and operate the administrative side of the business. There is no technology for inventory control or distribution and there are no options for added value packaging or fulfillment of orders. The targeted customers are grocery stores or wholesalers to grocery stores or chains.

Competitive Advantage

FlexiStore Warehousing will be able to offer the following advantages over their competition:

Marketing Plan

Brand & value proposition.

FlexiStore Warehousing will offer the unique value proposition to its clientele:

- Highly-qualified team of skilled employees who are able to provide a comprehensive array of services

- Technology-driven systems that manage inventory, logistics and cost controls throughout the warehousing system

- High-tech security systems that guarantee the safety of warehouse goods

- Fulfillment and upsell options; logistics RFID controls and other options

- Unbeatable pricing to its clients; they will offer the lowest pricing in Tulsa.

Promotions Strategy

The promotions strategy for FlexiStore Warehousing is as follows:

Word of Mouth/Referrals

FlexiStore Warehousing has built up an extensive list of contacts over the years by providing exceptional service and expertise to their former clients. Marty Snow has multiple former clients who have announced to him they are following him to the new company and will also help spread the word of FlexiStore Warehousing.

Professional Associations and Networking

Marty Snow will be involved in networking during industry associations and trade shows related to warehousing, technology solutions, and related subjects. He will also offer to speak or exhibit the successful processes of his new startup to others to help spread the word of efficiencies that can be offered to all new customers.

Website/SEO Marketing

FlexiStore Warehousing will extensively utilize their website. The website will be well organized, informative, and list all their services that FlexiStore Warehousing provides. The website will also list their contact information and list their available square footage for rent on any given day and date. The up-to-the-minute information will help clients immediately identify the capabilities they need for warehousing. The website presence will contain SEO marketing tactics so that anytime someone types in the Google or Bing search engine “warehouse company” or “warehouse near me”, FlexiStore Warehousing will be listed at the top of the search results.

The pricing of FlexiStore Warehousing will be moderate and on par with competitors so customers feel they receive excellent value when purchasing their services.

Operations Plan

The following will be the operations plan for FlexiStore Warehousing. Operation Functions:

- Martin Snow will be the Owner and President of the company. He will oversee all staff and manage client relations. Martin has spent the past year recruiting the following staff:

- Roger Hartwell, formerly a warehouse team member with Marty, will take on the role of Inventory Control Manager. In this role, he will exercise his depth of knowledge using the advanced technology tools installed to perfect the process of inventory control.

- Kenny Jones, a former team warehouse member with Marty, will take on the role of Operations Manager, overseeing the movement of goods in, through, and out of the warehousing process.

Milestones:

FlexiStore Warehousing will have the following milestones completed in the next six months.

- 5/1/202X – Finalize contract to lease office space

- 5/15/202X – Finalize personnel and staff employment contracts for the FlexiStore Warehousing

- 6/1/202X – Finalize contracts for FlexiStore Warehousing clients

- 6/15/202X – Begin networking at industry events

- 6/22/202X – Begin moving into FlexiStore Warehousing office

- 7/1/202X – FlexiStore Warehousing opens its office for business

Marty Snow will be the owner and operator of the FlexiStore Warehousing company. He has recruited his former warehouse associates, Roger Hartwell and Kenny Jones, to assist in the management of the startup business.

Financial Plan

Key revenue & costs.

The revenue drivers for FlexiStore Warehousing are the fees they will charge to clients for their services.

The cost drivers will be the overhead costs required in order to staff FlexiStore Warehousing. The expenses will be the payroll cost, rent, utilities, office supplies, and marketing materials.

Funding Requirements and Use of Funds

FlexiStore Warehousing is seeking $200,000 in debt financing to launch its warehousing business. The funding will be dedicated toward securing the office space and purchasing office equipment and supplies. Funding will also be dedicated toward three months of overhead costs to include payroll of the staff, rent, and marketing costs for the print ads and association memberships. The breakout of the funding is below:

Key Assumptions

The following outlines the key assumptions required in order to achieve the revenue and cost numbers in the financials and in order to pay off the startup business loan.

- Number of Clients Per Month: 26

- Average Revenue per Month: $78,000

- Office Lease per Year: $100,000

Financial Projections

Income statement, balance sheet, cash flow statement, warehouse business plan faqs, what is a warehouse business plan.

A warehouse business plan is a plan to start and/or grow your warehouse business. Among other things, it outlines your business concept, identifies your target customers, presents your marketing plan and details your financial projections.

You can easily complete your Warehouse business plan using our Warehouse Business Plan Template here .

What are the Main Types of Warehouse Businesses?

There are a number of different kinds of warehouse businesses , some examples include: Distribution centers, Climate-controlled warehouses, Smart warehouses, Bonded warehouses, and Consolidated warehouses.

How Do You Get Funding for Your Warehouse Business Plan?

Warehouse businesses are often funded through small business loans. Personal savings, credit card financing and angel investors are also popular forms of funding.

What are the Steps To Start a Warehouse Business?

Starting a warehouse business can be an exciting endeavor. Having a clear roadmap of the steps to start a business will help you stay focused on your goals and get started faster.

1. Develop A Warehouse Business Plan - The first step in starting a business is to create a detailed warehouse business plan that outlines all aspects of the venture. This should include potential market size and target customers, the services or products you will offer, pricing strategies and a detailed financial forecast.

2. Choose Your Legal Structure - It's important to select an appropriate legal entity for your warehouse business. This could be a limited liability company (LLC), corporation, partnership, or sole proprietorship. Each type has its own benefits and drawbacks so it’s important to do research and choose wisely so that your warehouse business is in compliance with local laws.

3. Register Your Warehouse Business - Once you have chosen a legal structure, the next step is to register your warehouse business with the government or state where you’re operating from. This includes obtaining licenses and permits as required by federal, state, and local laws.

4. Identify Financing Options - It’s likely that you’ll need some capital to start your warehouse business, so take some time to identify what financing options are available such as bank loans, investor funding, grants, or crowdfunding platforms.

5. Choose a Location - Whether you plan on operating out of a physical location or not, you should always have an idea of where you’ll be based should it become necessary in the future as well as what kind of space would be suitable for your operations.

6. Hire Employees - There are several ways to find qualified employees including job boards like LinkedIn or Indeed as well as hiring agencies if needed – depending on what type of employees you need it might also be more effective to reach out directly through networking events.

7. Acquire Necessary Warehouse Equipment & Supplies - In order to start your warehouse business, you'll need to purchase all of the necessary equipment and supplies to run a successful operation.

8. Market & Promote Your Business - Once you have all the necessary pieces in place, it’s time to start promoting and marketing your warehouse business. This includes creating a website, utilizing social media platforms like Facebook or Twitter, and having an effective Search Engine Optimization (SEO) strategy. You should also consider traditional marketing techniques such as radio or print advertising.

Learn more about how to start a successful warehouse business:

- How to Start a Warehouse Business

Warehouse Business Plan Template [Updated 2024]

Warehouse Business Plan Template

If you want to start a warehouse business or expand your current warehouse business, you need a business plan.

The following Warehouse business plan template gives you the key elements to include in a winning Warehouse business plan.

You can download our Business Plan Template (including a full, customizable financial model) to your computer here.

Warehouse Business Plan Example

I. executive summary, business overview.

[Company Name] is a new warehouse facility located in [location]. Our warehouse will specialize in storing products for various industries and companies located within a 50-mile radius of [location]. We provide everything a business needs when storing its products, from climate-controlled facilities to loading and unloading services. We aim to be the most dependable warehouse chain in the local area that can be trusted to store and secure any kind of product.

[Company Name] will store products for local businesses located within a 50-mile radius of [location]. We will provide many services to ensure all products are secure and stay in perfect condition. Some of the services our warehouse offers include:

- Bulk floor storage

- Palletized rack storage

- Five bay truck doors

- Two ramp doors

- Climate controlled facilities

- Inventory control

- Monitored alarm system

- Mail acceptance and delivery services

- Container loading or unloading

Customer Focus

[Company Name] will primarily service businesses within 50 miles of [location]. There are approximately 20,000 businesses within this area, which gives us a large client base to work with. Our primary customer focus is on small and medium-sized businesses that serve the local area. We are open to servicing most industries but plan to get the most business from the following sectors:

- Agribusiness

- Food and beverage

- Retail and consumer goods

Management Team

[Company Name] is headed by [Founder’s Name], who graduated from [University] with a degree in Business Administration. Prior to starting [Company Name], [Founder’s Name] worked as an operations manager at a logistics and warehousing company for [X] years. During his career, he was able to learn all aspects of the industry, including the operations (e.g., running day-to-day operations) and management (e.g., staffing, marketing, etc.) sides. His experience will be invaluable to the business.

Success Factors

[Company Name] is uniquely qualified to succeed for the following reasons:

- [Company Name] will focus primarily on the local region (about a 50-mile radius from [location]). Many small local businesses are overlooked or underserved by larger national warehousing companies.

- We surveyed the target market and received extremely positive feedback saying that they explicitly want to make use of our services when launched.

- The [location] region has a robust business environment with a large number of businesses needing warehousing services like ours.

- The management team has a track record of success in the warehousing services industry.

Financial Highlights

[Company Name] is currently seeking $2,000,000 to launch. Specifically, these funds will be used as follows:

- Warehouse design/build: $1,000,000

- Vehicle and machinery purchase and maintenance: $500,000

- Equipment and supplies: $250,000

- Working capital: $250,000 to pay for marketing, salaries, and lease costs until [Company Name] reaches break-even

Top line projections over the next five years are as follows:

II. Company Overview

Who is [company name].

[Company Name] is a new warehouse facility located in [location]. Our warehouse will specialize in storing products for various industries and companies located within a 50-mile radius of [location]. We provide everything a business needs when storing its products, from climate-controlled facilities to loading and unloading services. Though we are open to helping most businesses located near [location], we will primarily focus on local small and medium businesses in the food and beverage, consumer goods, and agribusiness sectors.

[Company Name] is run by [Founder’s Name], who graduated from [University] with a degree in Business Administration. Prior to starting [Company Name], [Founder’s Name] worked as an operations manager at a logistics and warehousing company for [X] years. During his career, he was able to learn all aspects of the industry, including the operations and management sides. His experience will be invaluable to the business.

After working in the industry for [X] years, [Founder’s Name] decided to open up his own warehouse that would cater to local small and medium-sized businesses. [Founder’s Name] has lived in [location] for his whole life and wanted to run a business that helped the local community and economy. Therefore, [Company Name]’s goal will always be to serve the local supply chain and regional business owners.

[Company Name]’s History

[Founder’s Name] incorporated [Company Name] as an S-corporation on [date of incorporation]. The company is currently being run from [Founder’s Name]’s home but will move to the warehouse once it is built and furnished.

Upon incorporation, [Company Name] was able to achieve the following milestones:

- Found a location to build and hired a construction company

- Developed the company’s name, logo, and website located at [website]

- Determined equipment and fixture requirements

- Identified required vehicles and machinery

- Began recruiting key employees

[Company Name]’s Products/Services

- 5-bay truck doors

- 1 ramp door

- Climate controlled warehousing

III. Industry Analysis

Warehousing has never been in greater demand. Between the dependence on e-commerce and the supply chain crisis, more and more companies are depending on warehousing facilities to store their products. Many businesses cannot afford to build their own warehouses, but they also can’t depend on warehouses that are located far away. Therefore, many businesses are looking to local warehousing solutions to carry their products and supplies. Local warehouses like [Company Name] help improve the local supply chain and offer valuable services that keep the local economy thriving.

Therefore, warehouses have never been so valuable. In fact, the industry is currently growing without any signs of stopping. According to Expert Market Research, the industry is expected to grow at a compound annual growth rate of 4.5% over the next five years. The industry was valued at $428 billion last year and is expected to be valued at $557 billion in five years.

IV. Customer Analysis

Demographic profile of target market.

[Company Name] will serve the local businesses and industries located within a 50-mile radius of [location]. The area is home to more than 20,000 businesses across a variety of industries.

Customer Segmentation

Though we are open to working with most local businesses and industries, we expect we will primarily work with the following segments:

- Retail and consumer goods : Most local small businesses fall into the consumer goods industry. Small retailers rarely have the space to store their goods but also need a local warehouse that is easily accessible on short notice. [Company Name] will be easily accessible and can provide the warehousing services they need.

- Agribusiness : [Location] consists of a large agribusiness that is essential to the nation’s food supply. This industry needs proper storage for food and equipment and quick shipping to prevent spoilage. Since this is such an important industry, we will work closely with local agribusinesses to provide them with all their warehousing needs.

- Food and beverage industry : [Company Name] will also offer storage space and refrigeration to carry perishable and non-perishable food items for local food and beverage businesses. This is the second biggest local industry behind consumer goods, so we expect many businesses will need our warehouse space.

V. Competitive Analysis

Direct & indirect competitors.

The following companies offer extensive warehousing services locally and nationwide and therefore provide either direct or indirect competition to our business:

Warehouse USA Warehouse USA has been the #1 warehousing solution in the United States for [X] years, catering to a variety of industries and businesses, both big and small. They provide ample warehouse space across dozens of warehouses across the country and provide unique services depending on the industry served. Some of their services include climate-controlled storage, bulk floor storage, and rack storage.

Though Warehouse USA will remain a large nationwide competitor, it has a minimum storage requirement that most small businesses can’t meet. Therefore, local small businesses will be much more interested in utilizing our warehouse services.

Pine City Food Storage Pine City Food Storage is the #1 storage facility for all businesses in the food and beverage sector. The facility offers great climate-controlled storage as well as refrigeration to store any form of food or beverage product. With ample space and excellent customer service, clients can expect a great warehousing experience from day one.

Though Pine City Food Storage will continue to thrive, their prices keep away many small businesses that cannot afford their fees. Our prices will be more moderate, which provides a more affordable option for small food and beverage businesses that are just starting out.

NW Warehousing Solutions NW Warehousing Solutions has been a popular warehouse company since 1978. They cater to a variety of industries in the local area, including food and beverage, consumer goods, and healthcare. Clients can be assured that their products will be secured and protected while stored at NW Warehousing Solutions.

Though NW Warehousing Solutions will continue to thrive, their pricing turns many local businesses away. [Company Name] will be more moderately priced to ensure local businesses can afford their warehousing needs.

Competitive Advantage

[Company Name] enjoys several advantages over its competitors. These advantages include the following:

- Location : [Company Name]’s business is local and will cater to regional businesses.

- Client-oriented service : [Company Name] will have 24/7 customer service and a strong team to fully cater to our clients’ needs.

- Management : [Founder’s Name] has been extremely successful working in the industry and will be able to use his previous experience to provide the best sales and customer service experience. His unique qualifications will serve customers in a much more sophisticated manner than [Company Name]’s competitors.

- Relationships : [Founder’s Name] knows many of the local leaders, business managers, and other influencers within [location]. With his [X] years of experience and good relationships with business leaders in the area, he will be able to develop an initial client base.

VI. Marketing Plan

The [company name] brand.

The [Company Name] brand will focus on the Company’s unique value proposition:

- Client-focused warehouse services that treat each client individually and get the job done right the first time

- Service built on long-term relationships

- Thorough knowledge of our clients and their varying needs

Promotions Strategy

[Company Name] expects its target market to be businesses operating within 50 miles of [location]. [The Company’s] promotions strategy to reach these businesses includes:

Website/SEO [Company Name] will develop a professional website that showcases pictures of the warehouse and the services we provide. It will also invest in SEO so that the company’s website will appear at the top of search engine results.

Social Media [Founder’s Name] will create the company’s social media accounts and invest in ads on all social media platforms. The company will use targeted marketing to appeal to our target demographics.

Publications [Company Name] will announce its launch several weeks in advance through publicity pieces in multiple newspapers and publications. Regular advertisements will run to maintain exposure to relevant markets.

Commuter Advertising We will drive attention toward [Company Name] by renting billboard ad spaces along routes or highways that hold heavy traffic. Advertising on heavily traveled commute routes is an opportunity to alert large numbers of businesses of our opening.

Client Referral Programs [Company Name] will create an aggressive client referral program that gives discounts to existing clients for every successful referral.

Direct Mail [Company Name] will blanket businesses with direct mail pieces. These pieces will provide general information on [Company Name], offer discounts and/or provide other enticements for businesses to use our services.

Pricing Strategy

[Company Name]’s pricing will be moderate, so customers feel they receive great value when working with us. Our customers can expect to receive quality services at a more affordable price than what they pay for larger warehouse providers.

VII. Operations Plan

Functional roles.

In order to execute [Company Name]’s business model, the company needs to perform many functions, including the following:

Administrative Functions

Inventory and Warehouse Functions

- Stock and organize products

- Count inventory for accuracy

- Keep warehouse clean and organized

- Inspect products often to ensure quality

- Maintain temperatures in refrigerated and climate-controlled facilities

- Provide excellent customer service

- Accept and mail out parcels for clients

VIII. Management Team

Management team members.

[Founder’s Name] will serve as the Chief Executive Officer and is in the process of hiring other C-suite professionals to help run the business.

Hiring Plan

[Founder’s Name] will serve as the Chief Executive Officer of the company. In order to launch, it needs to hire the following personnel:

- Warehouse Manager

- Inventory Manager

- Administrative Assistants (2 to start)

- Chief Finance Officer

- Head of Marketing

- Warehouse Associates (6 to start)

- Sales Representatives (2 to start)

- Security Staff (2 to start)

IX. Financial Plan

Revenue and cost drivers.

[Company Name]’s revenues will come primarily from the warehouse fees charged to our customers.

The major costs will consist of salaries, vehicle and machinery maintenance costs, and ongoing marketing expenditures.

Capital Requirements and Use of Funds

Key assumptions.

5 Year Annual Income Statement

Comments are closed.

- Sample Business Plans

- Retail, Consumers & E-commerce

Warehouse Business Plan

High demand and a recurring revenue model make starting a warehouse business a lucrative and rewarding profession.

Anyone can start a new business, but you need a detailed business plan when it comes to raising funding, applying for loans, and scaling it like a pro!

Need help writing a business plan for your warehouse business? You’re at the right place. Our warehouse business plan template will help you get started.

Free Business Plan Template

Download our free warehouse business plan template now and pave the way to success. Let’s turn your vision into an actionable strategy!

- Fill in the blanks – Outline

- Financial Tables

How to Write A Warehouse Business Plan?

Writing a warehouse business plan is a crucial step toward the success of your business. Here are the key steps to consider when writing a business plan:

1. Executive Summary

An executive summary is the first section planned to offer an overview of the entire business plan. However, it is written after the entire business plan is ready and summarizes each section of your plan.

Here are a few key components to include in your executive summary:

- Introduce your Business: Start your executive summary by briefly introducing your business to your readers.This section may include the name of your warehouse business, its location, when it was founded, the type of warehouse business (E.g., general warehousing, cold-storage warehousing, distribution centers, bonded warehouses), etc.

- Market Opportunity: Summarize your market research, including market size, growth potential, and marketing trends. Highlight the opportunities in the market and how your business will fit in to fill the gap.

- Products and Services: Highlight the warehouse services you offer your clients. The USPs and differentiators you offer are always a plus.For instance, you may include storage, inventory management, and order fulfillment as services.

- Marketing & Sales Strategies: Outline your sales and marketing strategies—what marketing platforms you use, how you plan on acquiring customers, etc.

- Financial Highlights: Briefly summarize your financial projections for the initial years of business operations. Include any capital or investment requirements, associated startup costs, projected revenues, and profit forecasts.

- Call to Action: Summarize your executive summary section with a clear CTA, for example, inviting angel investors to discuss the potential business investment.

Ensure your executive summary is clear, concise, easy to understand, and jargon-free.

Say goodbye to boring templates

Build your business plan faster and easier with AI

Plans starting from $7/month

2. Business Overview

The business overview section of your business plan offers detailed information about your company. The details you add will depend on how important they are to your business. Yet, business name, location, business history, and future goals are some of the foundational elements you must consider adding to this section:

Describe what kind of warehouse company you run and the name of it. You may specialize in one of the following warehouse businesses:

- General Warehouse

- Cold storage warehouse

- Distribution centers

- Bonded warehousing

- Specialized warehousing

- Public warehousing

- Private warehousing

- Describe the legal structure of your warehouse company, whether it is a sole proprietorship, LLC, partnership, or others.

- Explain where your business is located and why you selected the place.

- Owners: List the names of your warehouse company’s founders or owners. Describe what shares they own and their responsibilities for efficiently managing the business.

- Mission Statement: Summarize your business’ objective, core principles, and values in your mission statement. This statement needs to be memorable, clear, and brief.

Additionally, If you have received any awards or recognition for excellent work, describe them.

This section should provide a thorough understanding of your business, its history, and its future plans. Keep this section engaging, precise, and to the point.

3. Market Analysis

The market analysis section of your business plan should offer a thorough understanding of the industry with the target market, competitors, and growth opportunities. You should include the following components in this section.

- Competitive Analysis: Identify and analyze your direct and indirect competitors. Identify their strengths and weaknesses, and describe what differentiates your warehouse services from them. Point out how you have a competitive edge in the market.

- Regulatory Environment: List regulations and licensing requirements that may affect your warehouse company, such as occupational safety & health, labor laws & employment regulations, data protection & privacy, licensing & permits, etc.

Here are a few tips for writing the market analysis section of your warehouse business plan:

- Conduct market research, industry reports, and surveys to gather data.

- Provide specific and detailed information whenever possible.

- Illustrate your points with charts and graphs.

- Write your business plan keeping your target audience in mind.

4. Warehouse Services

The product and services section should describe the specific services and products that will be offered to customers. To write this section should include the following:

- Inventory management

- Order fulfillment

- Distribution & shipping

- Cross-docking services

- Customs and compliance

- Describe specialized storage: Give an outline of the storage options your warehouse will offer. Describe the things you can store, the amount of space you have, and any specialized storage alternatives you might have (such as cold storage or hazardous material storage).

- Additional Services: Mention if your warehouse company offers any additional services. You may include services like, reverse logistics, quality control & inspection, packaging & labeling, inventory financing, etc.

In short, this section of your warehouse plan must be informative, precise, and client-focused. By providing a clear and compelling description of your offerings, you can help potential investors and readers understand the value of your business.

5. Sales And Marketing Strategies

Writing the sales and marketing strategies section means a list of strategies you will use to attract and retain your clients. Here are some key elements to include in your sales & marketing plan:

- Pricing Strategy: Describe your pricing strategy—how you plan to price your services and stay competitive in the local market. You can mention any discounts you plan on offering to attract new customers.

- Marketing Strategies: Discuss your marketing strategies to market your services. You may include some of these marketing strategies in your business plan—social media marketing, Google ads, email marketing, content marketing, etc.

- Sales Strategies: Outline the strategies you’ll implement to maximize your sales. Your sales strategies may include partnering with other businesses, offering referral programs, etc.

- Customer Retention: Describe your customer retention strategies and how you plan to execute them. For instance, introducing loyalty programs, personalized service, etc.

Overall, this section of your warehousing business plan should focus on customer acquisition and retention.

Have a specific, realistic, and data-driven approach while planning sales and marketing strategies for your warehouse business, and be prepared to adapt or make strategic changes in your strategies based on feedback and results.

6. Operations Plan

The operations plan section of your business plan should outline the processes and procedures involved in your business operations, such as staffing requirements and operational processes. Here are a few components to add to your operations plan:

- Staffing & Training: Mention your business’s staffing requirements, including the number of employees or warehouse staff needed. Include their qualifications, the training required, and the duties they will perform.

- Operational Process: Outline the processes and procedures you will use to run your warehouse business. Your operational processes may include inventory management, storage & organization, order fulfillment, etc.

Adding these components to your operations plan will help you lay out your business operations, which will eventually help you manage your business effectively.

7. Management Team

The management team section overviews your warehouse business’s management team. This section should provide a detailed description of each manager’s experience and qualifications, as well as their responsibilities and roles.

- Founders/CEO: Mention the founders and CEO of your warehouse company, and describe their roles and responsibilities in successfully running the business.

- Organizational structure: Explain the organizational structure of your management team. Include the reporting line and decision-making hierarchy.

- Compensation Plan: Describe your compensation plan for the management and staff. Include their salaries, incentives, and other benefits.

This section should describe the key personnel for your warehouse services, highlighting how you have the perfect team to succeed.

8. Financial Plan

Your financial plan section should provide a summary of your business’s financial projections for the first few years. Here are some key elements to include in your financial plan:

- Profit & loss statement: Describe details such as projected revenue, operational costs, and service costs in your projected profit and loss statement . Make sure to include your business’s expected net profit or loss.

- Cash flow statement: The cash flow for the first few years of your operation should be estimated and described in this section. This may include billing invoices, payment receipts, loan payments, and any other cash flow statements.

- Balance Sheet: Create a projected balance sheet documenting your warehouse business’s assets, liabilities, and equity.

- Financing Needs: Calculate costs associated with starting a warehouse business, and estimate your financing needs and how much capital you need to raise to operate your business. Be specific about your short-term and long-term financing requirements, such as investment capital or loans.

Be realistic with your financial projections, and make sure you offer relevant information and evidence to support your estimates.

9. Appendix

The appendix section of your plan should include any additional information supporting your business plan’s main content, such as market research, legal documentation, financial statements, and other relevant information.

- Add a table of contents for the appendix section to help readers easily find specific information or sections.

- In addition to your financial statements, provide additional financial documents like tax returns, a list of assets within the business, credit history, and more. These statements must be the latest and offer financial projections for at least the first three or five years of business operations.

- Provide data derived from market research, including stats about the industry, user demographics, and industry trends.

- Include any legal documents such as permits, licenses, and contracts.

- Include any additional documentation related to your business plan, such as product brochures, marketing materials, operational procedures, etc.

Use clear headings and labels for each section of the appendix so that readers can easily find the necessary information.

Remember, the appendix section of your warehouse business plan should only include relevant and essential information supporting your plan’s main content.

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks and automatic financials make it easy.

This sample warehouse business plan will provide an idea for writing a successful warehouse plan, including all the essential components of your business.

After this, if you still need clarification about writing an investment-ready business plan to impress your audience, download our warehouse business plan pdf .

Related Posts

Courier Business Plan

Delivery Service Business Plan

AI Business Plan Generators

How to Find a Good Location for Business

Frequently Asked Questions

Why do you need a warehouse business plan.

A business plan is an essential tool for anyone looking to start or run a successful warehouse business. It helps to get clarity in your business, secures funding, and identifies potential challenges while starting and growing your business.

Overall, a well-written plan can help you make informed decisions, which can contribute to the long-term success of your warehouse company.

How to get funding for your warehouse business?

There are several ways to get funding for your warehouse business, but self-funding is one of the most efficient and speedy funding options. Other options for funding are:

- Bank loan – You may apply for a loan in government or private banks.

- Small Business Administration (SBA) loan – SBA loans and schemes are available at affordable interest rates, so check the eligibility criteria before applying for it.

- Crowdfunding – The process of supporting a project or business by getting a lot of people to invest in your business, usually online.

- Angel investors – Getting funds from angel investors is one of the most sought startup options.

Apart from all these options, there are small business grants available, check for the same in your location and you can apply for it.

Where to find business plan writers for your warehouse business?

There are many business plan writers available, but no one knows your business and ideas better than you, so we recommend you write your warehouse business plan and outline your vision as you have in your mind.

What is the easiest way to write your warehouse business plan?

A lot of research is necessary for writing a business plan, but you can write your plan most efficiently with the help of any warehouse business plan example and edit it as per your need. You can also quickly finish your plan in just a few hours or less with the help of our business plan software .

How detailed should the financial projections be in my warehouse business plan?

The level of detail of the financial projections of your warehouse business may vary considering various business aspects like direct and indirect competition, pricing, and operational efficiency. However, your financial projections must be comprehensive enough to demonstrate a comprehensive view of your financial performance.

Generally, the statements included in a business plan offer financial projections for at least the first three or five years of business operations.

What key components should a warehouse business plan include?

The following are the key components your warehouse business plan must include:

- Executive summary

- Business Overview

- Market Analysis

- Products and services

- Sales and marketing strategies

- Operations plan

- Management team

- Financial plan

Can a good warehouse business plan help me secure funding?

Indeed. A well-crafted warehouse business will help your investors better understand your business domain, market trends, strategies, business financials, and growth potential—helping them make better financial decisions.

So, if you have a profitable and investable business, a comprehensive business plan can help you secure your business funding.

About the Author

Upmetrics Team

Upmetrics is the #1 business planning software that helps entrepreneurs and business owners create investment-ready business plans using AI. We regularly share business planning insights on our blog. Check out the Upmetrics blog for such interesting reads. Read more

Turn your business idea into a solid business plan

Explore Plan Builder

Plan your business in the shortest time possible

No Risk – Cancel at Any Time – 15 Day Money Back Guarantee

Create a great Business Plan with great price.

- 400+ Business plan templates & examples

- AI Assistance & step by step guidance

- 4.8 Star rating on Trustpilot

Streamline your business planning process with Upmetrics .

Warehouse Business Plan Template

Written by Dave Lavinsky

Warehouse Business Plan

Over the past 20+ years, we have helped over 500 entrepreneurs and business owners create business plans to start and grow their warehouse companies.

If you’re unfamiliar with creating a warehouse business plan, you may think creating one will be a time-consuming and frustrating process. For most entrepreneurs it is, but for you, it won’t be since we’re here to help. We have the experience, resources, and knowledge to help you create a great business plan.

In this article, you will learn some background information on why business planning is important. Then, you will learn how to write a warehouse business plan step-by-step so you can create your plan today.

Download our Ultimate Business Plan Template here >

What is a Warehouse Business Plan?

A business plan provides a snapshot of your warehouse business as it stands today, and lays out your growth plan for the next five years. It explains your business goals and your strategies for reaching them. It also includes market research to support your plans.

Why You Need a Business Plan for a Warehouse Business

If you’re looking to start a warehouse business or grow your existing warehouse company, you need a business plan. A business plan will help you raise funding, if needed, and plan out the growth of your warehouse business to improve your chances of success. Your warehouse business plan is a living document that should be updated annually as your company grows and changes.

Sources of Funding for Warehouse Businesses

With regards to funding, the main sources of funding for a warehouse business are personal savings, credit cards, bank loans, and angel investors. When it comes to bank loans, banks will want to review your business plan and gain confidence that you will be able to repay your loan and interest. To acquire this confidence, the loan officer will not only want to ensure that your financials are reasonable, but they will also want to see a professional plan. Such a plan will give them the confidence that you can successfully and professionally operate a business. Personal savings and bank loans are the most common funding paths for warehouse companies.

Finish Your Business Plan Today!

How to Write a Business Plan for a Warehouse Business

If you want to start a warehouse business or expand your current one, you need a business plan. The guide below details the necessary information for how to write each essential component of your warehouse business plan.

Executive Summary

Your executive summary provides an introduction to your business plan, but it is normally the last section you write because it provides a summary of each key section of your plan.

The goal of your executive summary is to quickly engage the reader. Explain to them the kind of warehouse business you are running and the status. For example, are you a startup, do you have a warehouse business that you would like to grow, or are you operating a chain of warehouse businesses?

Next, provide an overview of each of the subsequent sections of your plan.

- Give a brief overview of the warehouse industry.

- Discuss the type of warehouse business you are operating.

- Detail your direct competitors. Give an overview of your target customers.

- Provide a snapshot of your marketing strategy. Identify the key members of your team.

- Offer an overview of your financial plan.

Company Overview

In your company overview, you will detail the type of warehouse business you are operating.

For example, you might specialize in one of the following types of warehouse businesses:

- Distribution centers: These types of warehouse businesses are usually large facilities that hold high quantities of goods for short periods of time from multiple suppliers to be transported to customers quickly.

- Climate-controlled warehouses: These types of warehouse businesses specialize in storing temperature-sensitive products such as frozen foods, fruits and vegetables, and other perishable goods.

- Smart warehouses: These types of warehouse businesses run on artificial intelligence to automate the process of storing, organizing, and transporting products.

- Bonded warehouses: These types of warehouses specialize in storing imported goods.

- Consolidated warehouses: These types of warehouses specialize in the intake of small shipments from various suppliers and grouping them together into a larger shipment to be distributed to buyers.

In addition to explaining the type of warehouse business you will operate, the company overview needs to provide background on the business.

Include answers to questions such as:

- When and why did you start the business?

- What milestones have you achieved to date? Milestones could include the number of customers served, the number of shipments processed, and reaching $X amount in revenue, etc.

- Your legal business Are you incorporated as an S-Corp? An LLC? A sole proprietorship? Explain your legal structure here.

Industry Analysis

In your industry or market analysis, you need to provide an overview of the warehouse industry.

While this may seem unnecessary, it serves multiple purposes.

First, researching the warehouse industry educates you. It helps you understand the market in which you are operating.

Secondly, market research can improve your marketing strategy, particularly if your analysis identifies market trends.

The third reason is to prove to readers that you are an expert in your industry. By conducting the research and presenting it in your plan, you achieve just that.

The following questions should be answered in the industry analysis section of your warehouse business plan:

- How big is the warehouse industry (in dollars)?

- Is the market declining or increasing?

- Who are the key competitors in the market?

- Who are the key suppliers in the market?

- What trends are affecting the industry?

- What is the industry’s growth forecast over the next 5 – 10 years?

- What is the relevant market size? That is, how big is the potential target market for your warehouse business? You can extrapolate such a figure by assessing the size of the market in the entire country and then applying that figure to your local population.

Customer Analysis

The customer analysis section of your warehouse business plan must detail the customers you serve and/or expect to serve.

The following are examples of customer segments: individuals, schools, families, and corporations.

As you can imagine, the customer segment(s) you choose will have a great impact on the type of warehouse business you operate. Clearly, individuals would respond to different marketing promotions than corporations, for example.

Try to break out your target customers in terms of their demographic and psychographic profiles. With regards to demographics, including a discussion of the ages, genders, locations, and income levels of the potential customers you seek to serve.

Psychographic profiles explain the wants and needs of your target customers. The more you can recognize and define these needs, the better you will do in attracting and retaining your customers.

Finish Your Warehouse Business Plan in 1 Day!

Don’t you wish there was a faster, easier way to finish your business plan?

With Growthink’s Ultimate Business Plan Template you can finish your plan in just 8 hours or less!

Competitive Analysis

Your competitive analysis should identify the indirect and direct competitors your business faces and then focus on the latter.

Direct competitors are other warehouse businesses.

Indirect competitors are other options that customers have to purchase from that aren’t directly competing with your product or service. This includes other types of warehouses, order fulfillment service providers, or in-house storage and distribution operations. You need to mention such competition as well.

For each such competitor, provide an overview of their business and document their strengths and weaknesses. Unless you once worked at your competitors’ businesses, it will be impossible to know everything about them. But you should be able to find out key things about them such as

- What types of customers do they serve?

- What type of warehouse business are they?

- What is their pricing (premium, low, etc.)?

- What are they good at?

- What are their weaknesses?

With regards to the last two questions, think about your answers from the customers’ perspective. And don’t be afraid to ask your competitors’ customers what they like most and least about them.

The final part of your competitive analysis section is to document your areas of competitive advantage. For example:

- Will you make it easier for customers to acquire your product or service?

- Will you offer products or services that your competition doesn’t?

- Will you provide better customer service?

- Will you offer better pricing?

Think about ways you will outperform your competition and document them in this section of your plan.

Marketing Plan

Traditionally, a marketing plan includes the four P’s: Product, Price, Place, and Promotion. For a warehouse business plan, your marketing strategy should include the following:

Product : In the product section, you should reiterate the type of warehouse company that you documented in your company overview. Then, detail the specific products or services you will be offering. For example, will you provide long-term storage, temperature control, third-party logistics, or order fulfillment services?

Price : Document the prices you will offer and how they compare to your competitors. Essentially in the product and price sub-sections of your plan, you are presenting the products and/or services you offer and their prices.

Place : Place refers to the site of your warehouse company. Document where your company is situated and mention how the site will impact your success. For example, is your warehouse business located in a busy retail district, a business district, or a standalone warehouse? Discuss how your site might be the ideal location for your customers.

Promotions : The final part of your warehouse marketing plan is where you will document how you will drive potential customers to your location(s). The following are some promotional methods you might consider:

- Advertise in local papers, radio stations and/or magazines

- Reach out to websites

- Distribute flyers

- Engage in email marketing

- Advertise on social media platforms

- Improve the SEO (search engine optimization) on your website for targeted keywords

Operations Plan

While the earlier sections of your business plan explained your goals, your operations plan describes how you will meet them. Your operations plan should have two distinct sections as follows.

Everyday short-term processes include all of the tasks involved in running your warehouse business, including answering calls, scheduling shipments, billing and collecting payments, etc.

Long-term goals are the milestones you hope to achieve. These could include the dates when you expect to acquire your Xth customer, or when you hope to reach $X in revenue. It could also be when you expect to expand your warehouse business to a new city.

Management Team

To demonstrate your warehouse business’ potential to succeed, a strong management team is essential. Highlight your key players’ backgrounds, emphasizing those skills and experiences that prove their ability to grow a company.

Ideally, you and/or your team members have direct experience in managing warehouse businesses. If so, highlight this experience and expertise. But also highlight any experience that you think will help your business succeed.

If your team is lacking, consider assembling an advisory board. An advisory board would include 2 to 8 individuals who would act as mentors to your business. They would help answer questions and provide strategic guidance. If needed, look for advisory board members with experience in managing a warehouse business or a small order fulfillment operation.

Financial Plan

Your financial plan should include your 5-year financial statement broken out both monthly or quarterly for the first year and then annually. Your financial statements include your income statement, balance sheet, and cash flow statements.

Income Statement

An income statement is more commonly called a Profit and Loss statement or P&L. It shows your revenue and then subtracts your costs to show whether you turned a profit or not.

In developing your income statement, you need to devise assumptions. For example, will you make 20 sales per day, and will your average inventory be 500 units? And will sales grow by 2% or 10% per year? As you can imagine, your choice of assumptions will greatly impact the financial forecasts for your business. As much as possible, conduct research to try to root your assumptions in reality.

Balance Sheets

Balance sheets show your assets and liabilities. While balance sheets can include much information, try to simplify them to the key items you need to know about. For instance, if you spend $50,000 on building out your warehouse business, this will not give you immediate profits. Rather it is an asset that will hopefully help you generate profits for years to come. Likewise, if a lender writes you a check for $50,000, you don’t need to pay it back immediately. Rather, that is a liability you will pay back over time.

Cash Flow Statement

Your cash flow statement will help determine how much money you need to start or grow your business, and ensure you never run out of money. What most entrepreneurs and business owners don’t realize is that you can turn a profit but run out of money and go bankrupt.

When creating your Income Statement and Balance Sheets be sure to include several of the key costs needed in starting or growing a warehouse business:

- Cost of equipment and office supplies

- Payroll or salaries paid to staff

- Business insurance

- Other start-up expenses (if you’re a new business) like legal expenses, permits, computer software, and equipment

Attach your full financial projections in the appendix of your plan along with any supporting documents that make your plan more compelling. For example, you might include your warehouse lease or a list of key performance indicators (KPIs) you track.

Warehouse Business Plan Template PDF

You can download our warehouse business plan PDF to help you get started on your own business plan.

Writing a business plan for your warehouse business is a worthwhile endeavor. If you follow the template above, by the time you are done, you will truly be an expert. You will understand the warehouse industry, your competition, and your customers. You will develop a marketing strategy and will understand what it takes to launch and grow a successful warehouse business.

Don’t you wish there was a faster, easier way to finish your Warehouse business plan?

OR, Let Us Develop Your Plan For You

Since 1999, Growthink has developed business plans for thousands of companies who have gone on to achieve tremendous success. See how a Growthink business planning consultant can create your business plan for you.

Other Helpful Business Plan Articles & Templates

- hello waredock.com

New Fulfilment Magazine

A complete guide to warehouse planning.

Table of Contents

Deciding to remodel or plan a new warehouse is no easy task and it requires planning that businesses are often not accustomed to. Yet, going through the planning process will result in an optimized warehouse with lean warehouse operations . It will help make better use of your resources in the long run and has a positive domino effect on your business.

Remember, effective fulfillment warehouse planning requires careful consideration of your inventory, space, equipment, and processes, as well as an understanding of your operational goals and priorities.

How Do I Start Warehouse Planning?

Warehouse design projects can be split into initiation phase, followed by planning, implementation and closing. Taking a project management approach to your warehouse planning and redesign by breaking it down into smaller task can make the job less intimidating

In case you’re starting this project on your own, consider project management solutions like Trello, Monday, or Microsoft Project.

At high level planning for a fulfillment warehouse requires the following steps:

- Define your inventory: Determine the types and quantities of products you will store in the warehouse.

- Determine your storage needs: Decide on the types of storage solutions you will use for your products, such as pallet racking, shelving, or mezzanine flooring.

- Assess your space: Measure the physical space available in your warehouse and decide how much of it will be dedicated to storage, receiving, and shipping areas.

- Evaluate your equipment needs: Decide what material handling equipment, such as forklifts or conveyor systems, you will need to efficiently store and retrieve your products.

- Plan your layout: Develop a layout of the warehouse that maximizes storage space and allows for efficient product flow.

- Establish processes and procedures: Decide on the processes and procedures for receiving, storing, and shipping products, and train your staff on these procedures.

- Implement technology: Consider using warehouse management software or barcoding systems to improve accuracy and efficiency in your fulfillment operations.

Order- & stock management for sellers and fulfillment centers

Automate your inventory and order process with Waredock

Initiation Phase: Identify the Problems You Want to Solve

First step: identify the problem you’re trying to solve. If you simply rearrange a few shelves and clean up some work areas without a clearly defined objective, you’ll be disappointed with the results.

Think about the major problems within your warehouse. For instance, is your facility struggling with:

- Inefficient placement of equipment? If you consistently use one piece of equipment after another, but the two are located incredibly far away from each other, you’re wasting your workers’ time and your company’s resources. Inefficiencies are frustrating and tedious for workers who have to take twenty steps to handle a task that could be completed in four.

- Poor placement of products? If you follow the Pareto Principle , 80% of your warehouse movements come from 20% of your products. If this 20% of products is located in a hard-to-reach area of your warehouse or behind other goods, it’ll take your workers longer to store, pick, and pack fast-moving products.

- Disorganized flow of people and equipment? People and equipment are constantly moving through your warehouse, and bottlenecks or traffic jams can lead to missed deadlines, decreased productivity, injuries, and even deaths. A warehouse layout designed with a traffic management plan helps mitigate these risks.

Want to quickly understand where your warehouse’s challenges lie? You’ve got two main options.

Option 1: Hold Consultations

Consult with your warehouse workers to identify inefficiencies. There may be elements of your warehouse operations that you’d never considered a problem before, but that are actually causing undue stress for your workers. Addressing these concerns is important. One study shows that useless or inefficient tasks have a negative effect on the mental health of workers . If your warehouse layout can eliminate some of these concerns, it’s worth incorporating them into your plans.

Option 2: Use Technology to Assess Your Warehouse’s Current State

If your warehouse management system ( WMS ) uses mobile scanners or radio frequency identification (RFID) technology, you can readily assess your data to understand the flow of goods through your warehouse. This analysis will identify your most frequently moved goods, the areas with the most traffic in your warehouse, and how long it takes to store, pick, pack, and ship goods.

More specifically, you can understand your warehouse’s operations (and plan your layout redesign accordingly) using statistics from your WMS technology , like total landed cost.

Knowing the total landed cost of each item allows you to understand which particular items are driving your revenue. Conversely, you understand which items aren’t driving your revenue, allowing you to strategically reorganize your warehouse space so that fast-moving items are easily accessible and slow-moving items are placed in the less-convenient spots.

Planning Phase: Detail the Work to Be Done

In the planning phase, you outline the work to be done, the tasks and resources needed, and timeframes. By the end of this phase in your warehouse redesign project, you should have:

- Listed and described all the tasks to be completed

- Drafted the schedule

- Estimated the project costs

Create a Map of Your Warehouse

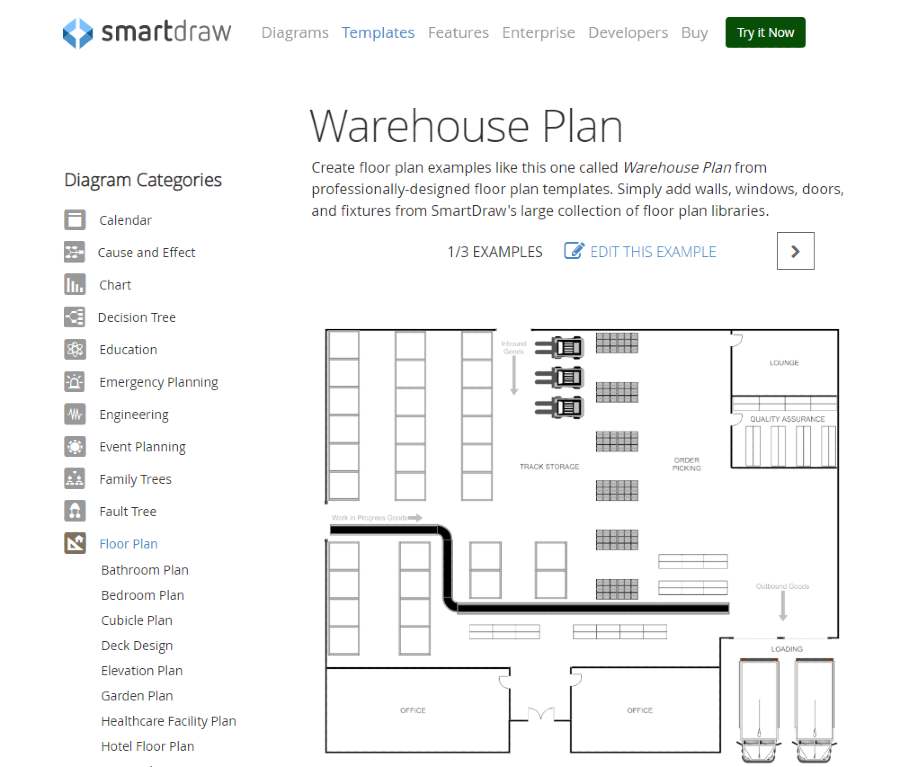

Once you’ve committed to specific areas of improvement, create a map of your warehouse. You can either use an existing map, manually draw a map, or use technology such as the warehouse layout and design software SmartDraw.

Whichever method you use, your map should clearly illustrate elements like:

- Docks doors

- Height restrictions

- Columns/supports

- Overhead doors

- Installed equipment

- Office areas (with indication of which direction the door opens to avoid blocking entrances/exits)

Furthermore, identify the operational locations of your warehouse on your map. Laying them out clearly will allow you to consider every movement and activity within your warehouse. Examples of operational activities include:

- Inbound staging area

- Back-to-back racks

- Packing desks

- Outbound shipment area

- Damaged product area

Consider The Unique Requirements of Your Warehouse

Your planning efforts will depend on your unique business. Generally, every warehouse layout redesign effort should consider the following elements:

- Equipment and Surrounding Workspace. As a warehouse, your key units may consist of items like pallet racks, shelving, and equipment.

- Production Zones and Workflow Areas. A warehouse manager needs to think about the space between shelves. Since your primary objective is receiving, stocking, and shipping, efficiently accessing goods is of the utmost importance. It should be easy for forklifts and people to navigate aisles. You’ll also want to plan a specific location for packing and receiving. Failing to allocate enough space for these essential, non-storage activities can lead to bottlenecks and damaged goods.

- Storage Areas. The types of items you store impacts your warehouse layout planning. If you’re moving pallets with pallet jacks or a forklift, you’ll need wider aisles and shelving. If your goods are hand-picked, you won’t need as much space. The type of items you’re storing also impacts the type of shelving you purchase, so be mindful of any particular requirements related to safety (e.g. chemicals) or temperature (e.g. perishable goods) when deciding where to store certain goods.

Add Your Warehouse Flow to Your Map

Start by listing your key processes, and then draw the workflow directions of those operations. Use different colors – either on paper or in your software – to draw the secondary operations that follow these main processes.

Use your earlier conversations with warehouse workers or the information from your WMS to create an accurate representation of the different workflows.

Overall, your planning should account for these 6 basic warehouse workflows:

- The putaway flow from the inbound receiving area to back-to-back racks or free areas

- The walking paths and directions for the pickers

- The picking path or direction for the forklift drivers

- The outbound flow for picked orders

- The movement of returned products to the damaged area or inventory

- The flow of packed and labeled boxes to outbound shipment area

Analyze Your Warehouse Map and Consider Opportunities to Optimize

Carefully analyze the data on operational locations, shipping, receiving, assembly, special handling lines, and quality and inspection areas along with the warehouse flow you have drawn. Clear product and location identification are critical to receiving, picking, and putaway efficiency and accuracy.

Storage area and staging lane identification is another must. Go through your notes on inbound and outbound operations and value-added processes with your team and make sure nothing is missing. Keep in mind that even relatively minor activities can dramatically affect warehouse efficiency. So be sure you’ve covered all of the locations and operations in your warehouse.

While analyzing your data, or circling back to your team, use this general checklist to ensure you’ve covered all bases:

- Diagrammed every possible movement in your warehouse

- Highlighted the main paths (those with the most movements)

- Reserved enough space for forklift movements

- Partitioned off a multi-purpose free area for staging, moving, etc.

- Created separate locations for inbound shipments and outbound shipments (if possible)

- Reserved the first 2 levels of back-to-back racks for pickers

- Created a dedicated space for damaged items

- Considered smaller shelves for small items (if applicable)

- Considered drawers for smaller items which cannot be barcoded (unless implementing RFID technology)

Once you’ve identified priority areas for optimization, you can start making a shopping list and budget for your revamped warehouse.

Use Computer-Aided Design (CAD) to Visualize Your Ideal Warehouse Layout

Depending on your comfort level with technology and your budget, you can use computer-aided design (CAD) tools to design the optimal warehouse layout.

The use of CAD tools in warehouse applications—where designers could assess various layout options including “building shape, equipment selection, and operational conditions” —is still emerging, and most commercially available tools are not specifically designed for warehouses.

As a result, warehouse designers who want to build photorealistic, 3D renderings of their warehouses need experience working in software like AutoCAD or the willingness to tackle the steep learning curve.

Alternatively, warehouse managers can use basic sketching tools, like SketchUp, to create 3D models of their dream warehouse and even realistic 3D renderings.

If you hire a warehouse design consultant, they will likely be able to create photorealistic 3D models for you.

Draft a List of Required Equipment and Associated Costs

Depending on the scope of your warehouse layout design, you may need to simply move a couple things around, add some new equipment, or buy everything new, including:

- Pallet racks

- Industrial shelving

- Cantilever racks

- Pallet jacks

- Hand trucks

- Service carts

- Dock plates/boards

Once you’ve made a list of desired equipment, assign prices and list them in order of importance so you can focus your budget on high-priority items.