To read this content please select one of the options below:

Please note you do not have access to teaching notes, lean management in universities: a systematic literature review.

International Journal of Lean Six Sigma

ISSN : 2040-4166

Article publication date: 10 June 2021

Issue publication date: 28 January 2022

Implementing lean management (LM) provides universities with a variety of benefits and utilities. The purpose of this study is to systematically analyze the existing literature on the implementation of LM in universities.

Design/methodology/approach

A systematic literature review is undertaken to identify, select and evaluate the literature. A total of 68 articles were identified in Web of Science and Scopus, analyzed and synthesized from the first article published on the topic (2003) to mid-2020.

Literature analysis and evaluation have enabled us to offer a novel literature classification based around four research lines that summarize the empirical evidence on LM implementation in universities, namely, lean applied to academic management processes; lean applied to administrative management processes; factors that facilitate lean implementation and results obtained with lean. Finally, the gaps and challenges for future research into LM in universities are presented.

Originality/value

This study provides a characterization of the research carried out into LM implementation in universities, which facilitates the work of both scholars wishing either to begin or to dig deeper into this sphere and university professionals and managers pursuing the best outcomes from LM.

- Systematic literature review

- Higher education

- Lean management

Acknowledgements

The authors acknowledge the financial support of Spanish Ministry of Science, Innovation and Universities (Research Project PID2019-106577GB-I00/AEI/10.13039/501100011033) and University of Jaén Research Support Plan 2019-2020.

Gómez-Molina, D.-L. and Moyano-Fuentes, J. (2022), "Lean management in universities: a systematic literature review", International Journal of Lean Six Sigma , Vol. 13 No. 1, pp. 156-177. https://doi.org/10.1108/IJLSS-12-2020-0224

Emerald Publishing Limited

Copyright © 2021, Emerald Publishing Limited

Related articles

We’re listening — tell us what you think, something didn’t work….

Report bugs here

All feedback is valuable

Please share your general feedback

Join us on our journey

Platform update page.

Visit emeraldpublishing.com/platformupdate to discover the latest news and updates

Questions & More Information

Answers to the most commonly asked questions here

Do a more advanced search »

Search for dissertations about: "lean management"

Showing result 1 - 5 of 101 swedish dissertations containing the words lean management .

1. Lean Visual Management of Deviations in Product Development and Production - Coining Physical, Digital, and Hybrid Pulse Methodology

Author : Onur Kaya ; Chalmers tekniska högskola ; [] Keywords : TEKNIK OCH TEKNOLOGIER ; ENGINEERING AND TECHNOLOGY ; lean management ; Visualization ; visual management ; lean tools. ; issue management ; deviation management ; disturbance management ; lean ;

Abstract : Lean is a relatively new trend, and every company strives for lean aiming for creating more output while using less input by focusing on the customer via eliminating non-value adding waste. Lean started at Toyota within its production system. From production, it started to be used in product development, and later on to other various sectors. READ MORE

2. Human Lean : Combining Sense of Coherence and Lean to achieve productivity and health

Author : Bengt Halling ; Lars Bengtsson ; Katarina Wijk ; Jörgen Eklund ; Bonnie Poksinska ; KTH ; [] Keywords : TEKNIK OCH TEKNOLOGIER ; ENGINEERING AND TECHNOLOGY ; barriers ; health promotion ; implementation ; Lean ; leadership ; management ; organizational change ; productivity ; sense of coherence ; supportive factors ; Technology and Health ; Teknik och hälsa ;

Abstract : The purpose of this thesis is to identify barriers to and supportive factors for Lean implementation and to investigate how application of the Sense of Coherence (SOC) theory combined with Lean philosophy may affect health and productivity. The thesis is based on five studies. READ MORE

3. Senior Management Lean Practice : A Team-Based Approach to Facilitate Learning

Author : Jonas Renström ; Lars Bengtsson ; Camilla Niss ; Jörgen Eklund ; Anders Fundin ; KTH ; [] Keywords : SAMHÄLLSVETENSKAP ; SOCIAL SCIENCES ; Lean ; leadership ; management ; cross-functional teams ; senior managers ; Lean implementation ; Lean ; ledarskap ; management ; tvärfunktionella grupper ; senior ledning ; Lean implementation ; Technology and Health ; Teknik och hälsa ;

Abstract : In order to improve organizational performance, organizations within both production and servicesectors keep turning to the Lean concept with hopes of finding a productive approach to theirchallenges. This tendency appears to remain in spite of reports indicating that the Lean concept isfar from easy to develop, implement and sustain. READ MORE

4. Lean contracting : relational contracting influenced by lean thinking

Author : Bengt Toolanen ; [] Keywords : TEKNIK OCH TEKNOLOGIER ; ENGINEERING AND TECHNOLOGY ; Construction Engineering and Management ; Byggproduktion ;

Abstract : The construction sector represents a most vital proportion of Swedish society through its main task of meeting the demands regarding buildings and infrastructure needed, among other things, for living, work, leisure time, education and communication. That this is executed in an effective manner is an important issue for a sustainable development of society. READ MORE

5. Lean Implementation : the significance of people and dualism

Author : Halling Bengt ; Lars Bengtsson ; Jörgen Eklund ; Lars Medbo ; KTH ; [] Keywords : SAMHÄLLSVETENSKAP ; SOCIAL SCIENCES ; SAMHÄLLSVETENSKAP ; SOCIAL SCIENCES ; Lean ; leadership ; management ; implementation ; barriers ; comparison ; development ; health care ; manufacturing ;

Abstract : Lean, with its origins at the Toyota Motor Company, is a concept that is known to increase effectiveness in manufacturing. The Lean concept is now argued to be relevant not only in manufacturing but in service and health-care delivery as well. The reported results of Lean implementation efforts are divided. READ MORE

Searchphrases right now

- Joakim P. Hansen

- fingerprint enhancement

- Magnus Löfstrand

- management of customers

- Perfect Absorption

- 111In-octreotide

Popular searches

- competition law.

- heart failure

- timber construction

- TRADE MODELS

- energy Dissertations

- thesis using solar energy

- merger and acquisitions

- Computer model

Popular dissertations yesterday (2024-06-16)

- Computational Terminology Exploring Bilingual and Monolingual Term Extraction

- Studies on the biological functions of interaction between components in Wnt, TGF-? and HIF pathways for cancer progression

- Land Use, Freshwater Flows and Ecosystem Services in an Era of Global Change

- Ecosystem Services and Disservices in an Agriculture–Forest Mosaic : A Study of Forest and Tree Management and Landscape Transformation in Southwestern Ethiopia

- Two Optimization Problems in Genetics : Multi-dimensional QTL Analysis and Haplotype Inference

- Polycystic ovary syndrome and pregnancy complications : Focus on hyperandrogenism and comorbidity

- Charge Transport in Single-crystalline CVD Diamond

- Innate and acquired immunity to Leishmania in humans : the role of the host versus the parasite

- Degradation Mechanisms of Heat Resistant Steel at Elevated Temperatures : In an Iron Ore Pelletizing Industry

- Sol-gel Synthesis and Photocatalytic Characterization of Immobilized TiO2 Films

- Popular complementary terms: essays, phd thesis, master thesis, papers, importance, trend, impact, advantages, disadvantages, role of, example, case study.

See yesterday's most popular searches here . Dissertations.se is the english language version of Avhandlingar.se .

Analyzing the state and evolution of lean management in Russia

FEATURE ARTICLE - It is always fascinating to learn about the evolution of lean in other countries. This piece gives us the lowdown on the state of lean in Russia, a late adopter where interest is now growing fast in all sectors, from government to agriculture.

Words: Vyacheslav Boltrukevich , 'MBA-Production System' Program Director at Lomonosov Moscow State University Business School; Pavel Rabunets , Editor-in-Chief of www.leaninfo.ru and Development Manager of ICSS Publishing

At a recent Cabinet meeting, Alexey Ulyukayev, Minister of the Economic Development, said: "Russia is lagging behind. The levels of productivity in OECD countries are twice as a high as they are in Russia, while in the US they are 2.6 times higher."

Mr Ulyukayev is not the only one who worries about Russia's struggle to keep up. According to a 2009 study by McKinsey, the performance of Russian organizations was very low: in the five key sectors of the economy, Russia averaged a meagre 26% of the level of productivity of the United States. Even Prime Minister Dmitry Medvedev has made it a priority of the Government to increase the productivity of labour by 150% by 2018.

The economic sanctions imposed on Russia after the Crimea crisis have complicated things even further. We badly need to raise productivity and quality levels, which is why lean is more important than ever for us.

Despite the figures we just shared seem to suggest otherwive, lean-like production systems that are based on efficiency exist here too, as the experience of several Russian companies shows.

Two companies really stand out: Gorky Automobile Plant (GAZ) and Bratsk Aluminum Smelter (RUSAL Bratsk). The former implemented TPS principles in their classic form (on the assembly line) and is one of the most advanced lean organizations in Russia and beyond, while the latter is often considered as the first Russian company in which a production system has had a system-wide scope, covering everyone from operator to managing director. Actually, all RUSAL employees (not only those of the Bratsk smelter), or at least the vast majority of them, understand what the production system is and are involved in improvement activities. The company has achieved production levels of 250 tons per person per year, which corresponds to the output of leading global aluminum producers. At the same time, it has significantly improved working conditions and the quality of life of employees.

RUSAL's managing director, Sergey Filippov, published a book on the company's experience, the first title that described the adoption of lean principles in a Russian company. It became a bestseller, which indicates there is a lot of interest in this topic.

THE HISTORY OF LEAN IN RUSSIA

In Russia lean thinking has its roots in the development of industrial engineering that took place in the 1930s and in the successful experiments run by several state-owned military plants in the following 50 years to bring productivity and quality up to the level required (back in Soviet times, cost was not an issue).

The implementation of Lean/TPS principles as we know them began in the automotive and metallurgy industries in the early 2000s, after GAZ Group became a private enterprise. The company saw it as a no-brainer to follow Toyota's example on its assembly lines, in order to meet growing demand. At the same time, Russian metallurgical giants were entering the global market and were suddenly faced with strong competition. They had to find a way to reduce their costs and become more competitive.

There were a few other examples of companies that leaned out early, like Instrumrand (part of Ingersoll), which did so well that it became Mercedes Benz's only Russian supplier.

The populatization of lean ideas didn't start until 2002-2003. It's important to note that, as a rule, the early adopters were all very large, private businesses, which had no other choice but to change under the pressure of increasing global competition and had the resources to do so. However, since then the interest in lean has grown at a steady rate even among mid-size to large businesses, as indicated by the results of a survey of managers of industrial enterprises conducted by the Institute for Complex Strategic Studies between 2006 and 2012. It shows significant and steady increase in the number of Russian companies that are working on lean projects:

Graphic taken from Vera Kononova's (PhD, Institute for Complex Strategic Studies and Lomonosov Moscow State University Business School - [email protected]) article, Gaining the Competitive Advantages through the Development of Production System ; "The Future Competitiveness of EU and its Eastern Neighbors"

From a geographical perspective, it is not surprising to learn that lean organizations and plants are concentrated in the most heavily industrialized regions in the country – the Volga Federal District, Central Federal District, and Ural Federal District. More remote regions, like Siberia and the Far East, have only just appeared on the lean map of Russia.

LEAN "INFRASTRUCTURE" IN RUSSIA

One of the first books on lean in Russian was published by GAZ's shareholder Oleg Deripaska. It was Taiichi Ohno's Toyota Production System book , originally translated by Deripaska for internal use at GAZ in 2002.

Since then, things have changed and the lean literature has expanded. The number of books explaining basic lean concepts and the application of lean tools has increased substantially in the past decade. While initially early adopters of lean in the country only had access to books by Jim Womack, Taiichi Ohno and Jeffrey Liker (still the most popular), a variety of publications are now available. In our publishing house, ICSS (Institute for Complex Strategic Studies), we currently have 25 books on various aspects of lean manufacturing, for example.

As we know, the written word is not the only way to teach people about lean. As organizations' demand for lean capabilities increases, more and more universities are recognizing the importance of instilling the methodology in their students' minds (early experiments might soon be carried out in high schools as well). We are also noticing an increase in the number of scientific and graduate projects (final theses) dedicated to lean thinking and its many facets.

The number of lean programs taught in Russian universities is on the up, but they are mostly standalone courses within traditional management programs. At Lomonosov Moscow State University Business School, we have been running a unique educational program, an MBA in Production Systems, since 2005. Online courses are only just starting to appear, " Lean Thinking " being one of the few available.

The Internet is playing an increasingly big role in people's lives in Russia, so it will come as no surprise that in recent years the information provided online by pioneers of lean has grown in both quantity and quality: for example, our own Leaninfo.ru – launched in 2008 as the country's first blog on production management – has quickly grown into a very popular online source of information on lean for practitioners based all around Russia. The number of personal "lean blogs," mostly run by consultants, is also growing.

Speaking of consultants, it is interesting to see how more and more foreign consultancy firms are now actively entering the Russian market as a growing need for lean expertise is noticed and leveraged (when we didn't have a market to begin with, Russian companies scrambled to recruit Western or Japanese senseis).

Of course, we have a lot of lean events too. The most notable ones are the Lean Forum, taking place in November (this year it will be on the 10th), and the Lean Summit in the south of Russia, organized by our Business School and Kaizen Center (this year it was the third edition, with John Shook as one of the speakers).

There are also some regional activities, like the annual Lean without ties meeting, organized by Dmitry Stukalov (head of the Leanzone web forum), the Lean Club in Kaluga, and the Kaizen Club in Tomsk – just to name a few.

QUANTITATIVE AND QUALITATIVE CHANGES

Initially, companies understood lean manufacturing as a set of tools and selectively used its methods, such as 5s, SMED, VSM, kanban, to achieve local improvements. That, too, has changed, and it is great to see how managers are now realizing that lean is not just a toolbox, but an alternative management model that encompasses the whole enterprise. More and more organizations are now focusing their efforts and resources on the creation of the right relationship and on the development of people across all levels.

Experienced business leaders who have embraced lean are rethinking the speed at which they are developing their production systems. Until recently, many of them argued that a few months after a set of tools had been deployed on the shop floor and lean production introduced a fully lean enterprise would be born. Today, they understand what being on a lean journey really entails and recognize their organizations are just at the beginning of their transformation. More importantly, they now understand that the creation of an alternative production system and the implementation of lean manufacturing are associated with the development of people.

Lean in Russia may still be predominantly seen a manufacturing concept, but we would argue that the there is actually no sector of the economy that has not had any exposure to lean. The service industry is starting to show considerable interest in it, largely due to the work of Sberbank of Russia, the country's largest bank, which has been on a radical transformation of its processes since 2008 (the story of its journey was told in the book Elephant on the dance floor). To many service organizations, the experience of Sberbank has become proof of the fact that improvement is possible in any environment, even in one as complex as a bank.

In regions with a large concentration of lean enterprises, lean is spreading beyond manufacturing incredibly fast. For example, in the Kaluga region, where a powerful cluster of businesses operating in the automotive, aerospace and pharmaceuticals sectors operates, the local government has launched a lean initiative aimed at the provision of healthcare to citizens. Study missions for medical teams have been arranged in some of Europe's leading clinics.

There is also Tatarstan, of course, where lean has become a government-led regional development strategy: in several cities of the republic, projects on "lean municipalities" and "lean cities" have been launched. Khanty-Mansiysk even announced a "Lean Region" program! [Yalcin Ipbuken, President of Lean Institute Turkey, recently visited Tatarstan – here's what he saw .]

Lean construction principles have helped to build many of the buildings for the 2014 Sochi Olympics in a very short period of time, and even agriculture is making great strides in adopting lean. It is increasingly common to see agricultural organizations sharing their experience with lean with manufacturing companies that are starting out on their journeys. [Last year Planet Lean interviewed Anton Ulanov, CEO of Agroholding Kuban – check out the interview here .]

But we can't rest on our laurels just yet, as lean in still far from being a mass phenomenon in Russia.

The state of lean in our country was clearly outlined by Jim Womack during his visit in 2012. Here are his observations:

- Russia is a late adopter of lean thinking;

- Toyota was late to arrive to provide the example;

- There is a shortage of lean senseis;

- There is an expectation for low quality;

- Russia seems to be a hostile environment for lean in terms of government practices and local customs.

What advice did Jim give us, then? He suggested we learn the management principles and process methods we are currently lacking by running experiments in our organizations (the only real way to learn anything).

The trends we have identified in this article make us hopeful that the constraints to the dissemination of lean in Russia (lack of information, books, senseis, local expertise, and so on) and the misconceptions about its nature will be eliminated, and that more and more organizations in all sectors will embrace lean thinking.

In fact, we believe that the pace and reach of lean in Russia will grow substantially, because improvement has become a necessity: global competition is getting fiercer by the day, the economic sanctions are encouraging companies to find ways to work better and smarter, and the shortage of highly-skilled workers in the domestic market is putting people development in the spotlight. So the answer to the question "Will lean expand in Russia?" is very simple. It will. We have no other choice.

THE AUTHORS

Vyacheslav Boltrukevich , PhD is Assistant Professor of Operations Management and Director of the 'MBA-Production System' Program at Lomonosov Moscow State University Business School

Pavel Rabunets is the Editor in chief of Leaninfo.ru and the Development Manager and Publishing Editor at ICSS Publishing

INTERVIEW – With the Lean Global Connection just two weeks away, we learn more about the lean healthcare content available to attendees.

WOMACK’S YOKOTEN - When managed poorly and tied to the wrong performance metrics, financial rewards can seriously damage your organization, Jim Womack warns in his latest column.

CASE STUDY – This Barcelona hospital began its journey with ambitious projects and is starting to see the fruits of its labor, with the pandemic acting as an unexpected but powerful catalyst for change.

CASE STUDY - The Italian branch of Tokheim services about 3,000 gas stations in the central and northern parts of Italy. The general manager shares the story of how lean thinking changed everything, for the better.

Subscribe for our newsletter and get early access to all exclusive Planet Lean articles.

Guide: MoSCoW Method

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

The MoSCoW Method transcends being just a prioritization tool; it is a strategic approach for navigating the intricate decision-making in project management. This methodology excels by offering a structured framework, facilitating discussions among stakeholders to assess and align on the relative importance of various tasks and features in a project.

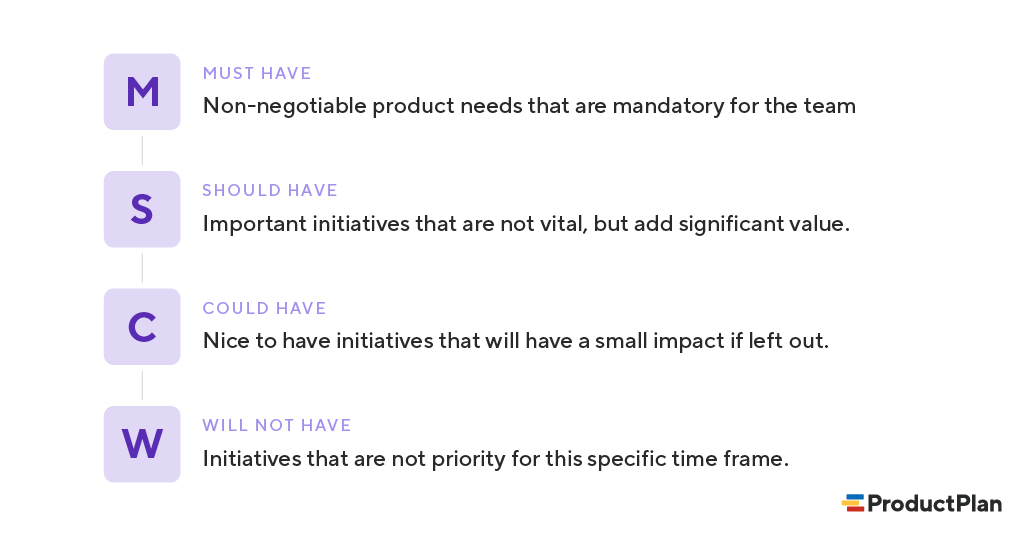

Central to MoSCoW is its acronym, denoting four priority categories – Must have, Should have, Could have, and Won’t have. This classification is crucial in managing stakeholder expectations, directing the project team’s focus towards critical elements, and charting a clear course for project advancement.

What is the MoSCoW Method?

The MoSCoW method is used as a prioritization tool, but it is more than just that; it is also a strategic approach to handling complex decision-making processes that you can encounter in project management. This method shines by offering a structured framework for stakeholders to discuss, debate, and ultimately agree on the relative importance of different tasks or features within a project.

The uniqueness of the MoSCoW method is within its acronym, which represents four priority categories. Must have, Should have, Could have, and Won’t have. This structure is key to managing stakeholder expectations and ensuring that a project team focuses on the most crucial elements first, setting a clear path for project progression.

The MoSCoW Categories

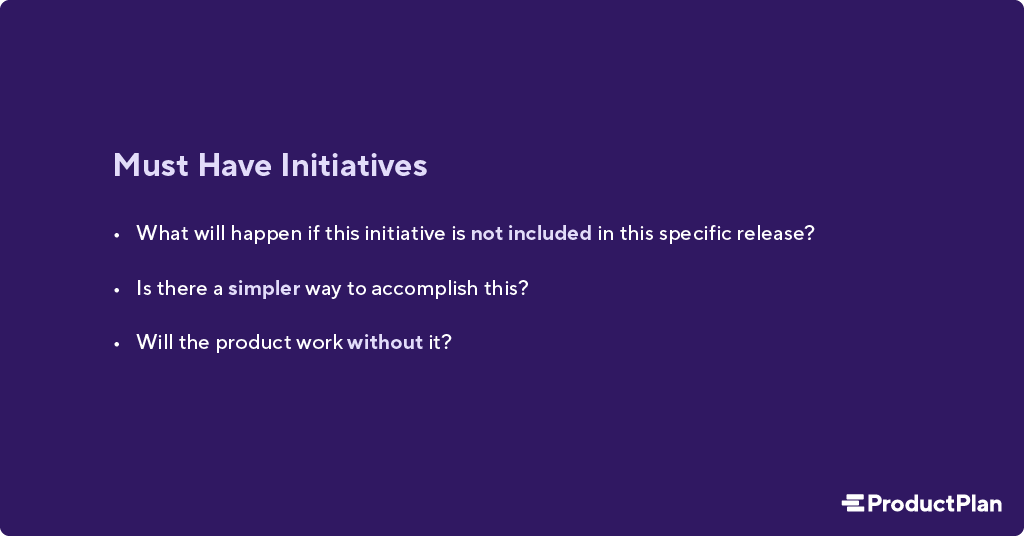

In the ‘ Must have ‘ category, you find the key activities that are essential to your project . These are non-negotiable and pivotal for the project’s success. This category often comprises items that, if omitted, would make the project irrelevant or non-compliant with essential criteria like legal standards or core objectives.

Should Have

Moving to the ‘ Should have ‘ category, we encounter important elements that, while not critical to the project’s existence, greatly enhance its value and effectiveness . These are features that stakeholders strongly desire, and their inclusion could significantly enhance the project’s outcome . However, their absence wouldn’t label the project a failure.

The ‘ Could have ‘ category is where you place desirable but less critical elements . These are often enhancements that would be nice to include but aren’t vital to the project’s success . The inclusion of these elements is usually subject to resource availability and project timelines.

The ‘ Won’t have ‘ category is often misunderstood but is crucial for setting realistic boundaries. It includes elements that, although potentially beneficial, are beyond the scope of the current project phase or constraints. This clear demarcation helps manage expectations and focus on what’s achievable within the project’s constraints.

How to Apply the MoSCoW Method: A Step-by-Step Guide

Implementing the MoSCoW Method in a project requires a systematic approach, ensuring that all aspects of the project are considered and aligned with the prioritization framework. Here’s a detailed look into each step of implementing this method:

Step 1: Gather Requirements

The first step in the MoSCoW method requires gathering a list of the tasks , activities, features, or requirements you need to prioritize in your project. For this step, you should engage with all relevant stakeholders , including project sponsors, end-users, and technical teams. This ensures that the requirements reflect a wide range of perspectives and needs.

To help decide the categorize of each task in a later step you should understand the overall goals of the project . You will also need to gain an understanding of technical, business, time, and resource constraints right from the start. This helps in setting realistic expectations for what can be achieved.

Step 2: Categories Each Requirement

The next step is to, as a team with the relevant stakeholders, run a categorization session . Doing this with the stakeholders involved will help to gain buy-in and support for the project as well as a shared understanding of priorities.

Each requirement’s placement in the MoSCoW categories should be a subject of discussion. Different stakeholders may have varying views on what is a ‘ Must have ‘ or ‘ Should have ‘, and these need to be reconciled.

For each decision, documenting the rationale behind the categorization can be valuable, especially for future reference or when explaining decisions to others not involved in the process.

Step 3: Review and Adjust

You will need to ensure the decisions of the categories are balanced and achievable within the scope once all are allocated. You may find that you still have too many must-haves and should-haves that either some activities need to be downgraded or a consideration to go back to decision-makers and create a case for more resources of time to achieve what is needed.

Step 4: Use as a Guiding Tool

You should continue to use the MoSCoW prioritization to inform decisions throughout the project lifecycle. This helps maintain focus on what’s most important . Prioritization can guide where to allocate resources and effort, especially when under constraints.

Step 5: Update as Necessary

Finally, regularly revisit the MoSCoW categorization , especially after major milestones or significant changes in the project environment. Also, be prepared to adjust the priorities in response to new information, stakeholder feedback, or changes in the external environment.

Implementing the MoSCoW Method is an exercise in strategic planning and adaptive management. It begins with a comprehensive gathering of project requirements, engaging a broad spectrum of stakeholders to ensure a multifaceted view of the project’s needs. The heart of the process lies in the collaborative categorization of these requirements, balancing differing perspectives to establish a shared priority framework.

As the project progresses, this method serves as a dynamic guide, directing resources and decision-making effectively. Regularly revisiting and adjusting these priorities ensures the project stays aligned with evolving objectives and constraints, making MoSCoW an indispensable tool for successful project management.

- Kuhn, J., 2009. Decrypting the MoSCoW analysis. The workable, practical guide to Do IT Yourself , 5 .

- Ahmad, K.S., Ahmad, N., Tahir, H. and Khan, S., 2017, July. Fuzzy_MoSCoW: A fuzzy based MoSCoW method for the prioritization of software requirements. In 2017 International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT) (pp. 433-437). IEEE.

Q: What types of projects is the MoSCoW method best suited for?

A: The MoSCoW method is versatile and can be used for various types of projects, ranging from software development and website redesign to manufacturing and logistics. It’s particularly useful for projects with multiple stakeholders and those that require a clear understanding of task priority.

Q: How often should the MoSCoW list be reviewed and updated?

A: The frequency of reviewing the MoSCoW list depends on the project’s complexity and how often its circumstances change. For fast-paced projects, a weekly or bi-weekly review might be necessary. For more stable projects, a monthly review could suffice.

Q: Can the MoSCoW method be integrated with other project management techniques?

A: Absolutely! The MoSCoW method can be used in conjunction with other project management methodologies like Agile, Scrum, or Lean Six Sigma. It serves as a prioritization tool that can easily be incorporated into other frameworks to make them even more effective.

Q: What should I do if stakeholders disagree on the categorization of tasks?

A: If there’s disagreement on task categorization, it’s useful to have a facilitated discussion to reach a consensus. You can also use a weighted scoring system to quantitatively assess each task’s importance, which can help in making more objective decisions.

Q: Are there any tools or software that can help in applying the MoSCoW method?

A: While the MoSCoW method can be applied using simple tools like whiteboards and Post-It notes, there are also specialized project management software that offer built-in MoSCoW categorization features. These tools can be particularly helpful for larger or more complex projects.

Daniel Croft

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website www.learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Was this helpful?

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

How AI Fits into Lean Six Sigma

- Matthias Holweg,

- Thomas H. Davenport,

It’s already being applied, and its usage promises to rapidly expand.

AI already is being used in some areas of process improvement, and the usage of this technology — including generative AI — promises to grow. That’s because it can perform tasks faster and much less expensively than humans alone. But it will never fully replace people — and that poses management challenges.

Most manufacturing and service operations repeat in one way or another, which provides the opportunity to experiment, learn, and continuously improve their underlying processes. Until recently, the methods for making these processes better and better were performed by human experts. That is rapidly changing thanks to artificial intelligence tools, including generative AI, that can perform tasks faster and much less expensively than humans alone.

- Matthias Holweg is the American Standard Companies Professor of Operations Management at Saïd Business School at the University of Oxford and a visiting professor at the Huntsman School of Business at Utah State University.

- Thomas H. Davenport is the President’s Distinguished Professor of Information Technology and Management at Babson College, a visiting scholar at the MIT Initiative on the Digital Economy, and a senior adviser to Deloitte’s AI practice. He is a coauthor of All-in on AI: How Smart Companies Win Big with Artificial Intelligence (Harvard Business Review Press, 2023).

- Ken Snyder is the executive director of the Shingo Institute and a senior lecturer at the Huntsman School of Business at Utah State University.

Partner Center

- Integrations

- Learning Center

MoSCoW Prioritization

What is moscow prioritization.

MoSCoW prioritization, also known as the MoSCoW method or MoSCoW analysis, is a popular prioritization technique for managing requirements.

The acronym MoSCoW represents four categories of initiatives: must-have, should-have, could-have, and won’t-have, or will not have right now. Some companies also use the “W” in MoSCoW to mean “wish.”

What is the History of the MoSCoW Method?

Software development expert Dai Clegg created the MoSCoW method while working at Oracle. He designed the framework to help his team prioritize tasks during development work on product releases.

You can find a detailed account of using MoSCoW prioritization in the Dynamic System Development Method (DSDM) handbook . But because MoSCoW can prioritize tasks within any time-boxed project, teams have adapted the method for a broad range of uses.

How Does MoSCoW Prioritization Work?

Before running a MoSCoW analysis, a few things need to happen. First, key stakeholders and the product team need to get aligned on objectives and prioritization factors. Then, all participants must agree on which initiatives to prioritize.

At this point, your team should also discuss how they will settle any disagreements in prioritization. If you can establish how to resolve disputes before they come up, you can help prevent those disagreements from holding up progress.

Finally, you’ll also want to reach a consensus on what percentage of resources you’d like to allocate to each category.

With the groundwork complete, you may begin determining which category is most appropriate for each initiative. But, first, let’s further break down each category in the MoSCoW method.

Start prioritizing your roadmap

Moscow prioritization categories.

1. Must-have initiatives

As the name suggests, this category consists of initiatives that are “musts” for your team. They represent non-negotiable needs for the project, product, or release in question. For example, if you’re releasing a healthcare application, a must-have initiative may be security functionalities that help maintain compliance.

The “must-have” category requires the team to complete a mandatory task. If you’re unsure about whether something belongs in this category, ask yourself the following.

If the product won’t work without an initiative, or the release becomes useless without it, the initiative is most likely a “must-have.”

2. Should-have initiatives

Should-have initiatives are just a step below must-haves. They are essential to the product, project, or release, but they are not vital. If left out, the product or project still functions. However, the initiatives may add significant value.

“Should-have” initiatives are different from “must-have” initiatives in that they can get scheduled for a future release without impacting the current one. For example, performance improvements, minor bug fixes, or new functionality may be “should-have” initiatives. Without them, the product still works.

3. Could-have initiatives

Another way of describing “could-have” initiatives is nice-to-haves. “Could-have” initiatives are not necessary to the core function of the product. However, compared with “should-have” initiatives, they have a much smaller impact on the outcome if left out.

So, initiatives placed in the “could-have” category are often the first to be deprioritized if a project in the “should-have” or “must-have” category ends up larger than expected.

4. Will not have (this time)

One benefit of the MoSCoW method is that it places several initiatives in the “will-not-have” category. The category can manage expectations about what the team will not include in a specific release (or another timeframe you’re prioritizing).

Placing initiatives in the “will-not-have” category is one way to help prevent scope creep . If initiatives are in this category, the team knows they are not a priority for this specific time frame.

Some initiatives in the “will-not-have” group will be prioritized in the future, while others are not likely to happen. Some teams decide to differentiate between those by creating a subcategory within this group.

How Can Development Teams Use MoSCoW?

Although Dai Clegg developed the approach to help prioritize tasks around his team’s limited time, the MoSCoW method also works when a development team faces limitations other than time. For example:

Prioritize based on budgetary constraints.

What if a development team’s limiting factor is not a deadline but a tight budget imposed by the company? Working with the product managers, the team can use MoSCoW first to decide on the initiatives that represent must-haves and the should-haves. Then, using the development department’s budget as the guide, the team can figure out which items they can complete.

Prioritize based on the team’s skillsets.

A cross-functional product team might also find itself constrained by the experience and expertise of its developers. If the product roadmap calls for functionality the team does not have the skills to build, this limiting factor will play into scoring those items in their MoSCoW analysis.

Prioritize based on competing needs at the company.

Cross-functional teams can also find themselves constrained by other company priorities. The team wants to make progress on a new product release, but the executive staff has created tight deadlines for further releases in the same timeframe. In this case, the team can use MoSCoW to determine which aspects of their desired release represent must-haves and temporarily backlog everything else.

What Are the Drawbacks of MoSCoW Prioritization?

Although many product and development teams have prioritized MoSCoW, the approach has potential pitfalls. Here are a few examples.

1. An inconsistent scoring process can lead to tasks placed in the wrong categories.

One common criticism against MoSCoW is that it does not include an objective methodology for ranking initiatives against each other. Your team will need to bring this methodology to your analysis. The MoSCoW approach works only to ensure that your team applies a consistent scoring system for all initiatives.

Pro tip: One proven method is weighted scoring, where your team measures each initiative on your backlog against a standard set of cost and benefit criteria. You can use the weighted scoring approach in ProductPlan’s roadmap app .

2. Not including all relevant stakeholders can lead to items placed in the wrong categories.

To know which of your team’s initiatives represent must-haves for your product and which are merely should-haves, you will need as much context as possible.

For example, you might need someone from your sales team to let you know how important (or unimportant) prospective buyers view a proposed new feature.

One pitfall of the MoSCoW method is that you could make poor decisions about where to slot each initiative unless your team receives input from all relevant stakeholders.

3. Team bias for (or against) initiatives can undermine MoSCoW’s effectiveness.

Because MoSCoW does not include an objective scoring method, your team members can fall victim to their own opinions about certain initiatives.

One risk of using MoSCoW prioritization is that a team can mistakenly think MoSCoW itself represents an objective way of measuring the items on their list. They discuss an initiative, agree that it is a “should have,” and move on to the next.

But your team will also need an objective and consistent framework for ranking all initiatives. That is the only way to minimize your team’s biases in favor of items or against them.

When Do You Use the MoSCoW Method for Prioritization?

MoSCoW prioritization is effective for teams that want to include representatives from the whole organization in their process. You can capture a broader perspective by involving participants from various functional departments.

Another reason you may want to use MoSCoW prioritization is it allows your team to determine how much effort goes into each category. Therefore, you can ensure you’re delivering a good variety of initiatives in each release.

What Are Best Practices for Using MoSCoW Prioritization?

If you’re considering giving MoSCoW prioritization a try, here are a few steps to keep in mind. Incorporating these into your process will help your team gain more value from the MoSCoW method.

1. Choose an objective ranking or scoring system.

Remember, MoSCoW helps your team group items into the appropriate buckets—from must-have items down to your longer-term wish list. But MoSCoW itself doesn’t help you determine which item belongs in which category.

You will need a separate ranking methodology. You can choose from many, such as:

- Weighted scoring

- Value vs. complexity

- Buy-a-feature

- Opportunity scoring

For help finding the best scoring methodology for your team, check out ProductPlan’s article: 7 strategies to choose the best features for your product .

2. Seek input from all key stakeholders.

To make sure you’re placing each initiative into the right bucket—must-have, should-have, could-have, or won’t-have—your team needs context.

At the beginning of your MoSCoW method, your team should consider which stakeholders can provide valuable context and insights. Sales? Customer success? The executive staff? Product managers in another area of your business? Include them in your initiative scoring process if you think they can help you see opportunities or threats your team might miss.

3. Share your MoSCoW process across your organization.

MoSCoW gives your team a tangible way to show your organization prioritizing initiatives for your products or projects.

The method can help you build company-wide consensus for your work, or at least help you show stakeholders why you made the decisions you did.

Communicating your team’s prioritization strategy also helps you set expectations across the business. When they see your methodology for choosing one initiative over another, stakeholders in other departments will understand that your team has thought through and weighed all decisions you’ve made.

If any stakeholders have an issue with one of your decisions, they will understand that they can’t simply complain—they’ll need to present you with evidence to alter your course of action.

Related Terms

2×2 prioritization matrix / Eisenhower matrix / DACI decision-making framework / ICE scoring model / RICE scoring model

Prioritizing your roadmap using our guide

Try productplan free for 14 days, share on mastodon.

IMAGES

VIDEO

COMMENTS

While lean management practices (LMP) helps small and medium sized enterprises (SMEs) to be efficient, sustainability oriented innovation (SOI) facilitates to adopt environmental and social practices.

A dissertation submitted to the Johns Hopkins University in conformity with the ... and enterprise resource management (ERP) tools such as SAP and Oracle to help manage and reduce resource costs (4). These safety ... Lean Thinking and Six Sigma have gone through parallel developments over the

the challenges they had in implementing Lean management. The theory of this thesis was based largely on published literature, such as books, journals, and theses, as well as a few websites on the subject of Lean and Lean management. The research method was a qualitative research in the form of an online questionnaire. The questionnaire was sent ...

Navarro (2021) argues that process management combined with lean management has provided companies with effective solutions and results in terms of economic, time, and material resources. The notion of process effectiveness is valid while it provides a measure of the actual effect of improvement efforts of management models and whether positive ...

2 UNIVERSITY OF VAASA School of Technology and Innovations Author: Gerda Saar Title of the Thesis: Process improvement with the use of Lean Management meth- ods Degree: Master of Science in Economics and Business Administration Programme: Industrial Management Supervisor: Ville Tuomi Year: 2021 Sivumäärä: 58 ABSTRACT: Today's business market is constantly changing, and industries are ...

A THESIS SUBMITTED TO THE FACULTY OF THE GRADUATE SCHOOL OF THE UNIVERSITY OF MINNESOTA BY Ryan Douglas Taylor ... recently implemented lean management into its supply chain by minimizing the number of suppliers in its system. The company has emphasized that in order to benefit during . chain Management

between Lean Manufacturing and Industry 4.0 al thesis, 2020:65 ... Lean manufacturing has for more than two decades been the most prominent methodology for ... operations management research field and investigates the relationship between lean manufacturing and Industry 4.0. We will look further into whether lean manufacturing is an

Part of the Management Information Systems Commons, and the Other Engineering Commons Recommended Citation Ellis, S. F.(2016). The Application Of Lean Six Sigma To Improve A Business Process: A Study Of The Order Processing Process At An Automobile Manufacturing Facility. (Master's thesis). Retrieved from https://scholarcommons.sc.edu/etd/3944

departments. Lean in healthcare has evolved over the past 15 years beyond implementation of tools alone to include implementation of Lean Management Systems. Methods A structured literature review of peer-reviewed articles on Lean Management in healthcare, published between 2000 and 2017, was conducted. The relationship between early stage Lean

THESIS SUBMITTED TO THE FACULTY OF THE VIRGINIA POLYTECHNIC INSTITUTE AND STATE UNIVERSITY ... David Earl Kline René Leendert Maria Catherine Aernoudts December 8, 2010 Blacksburg, VA Keywords: Lean Management, Lean awareness, Lean implementation, Lean support, wood products industry, furniture manufacturing industry, small and medium ...

• Only the term 'Lean' was used as opposed to previous literature reviews in which selected few terms amongst the various terms used to describe lean such as lean production, lean manufacturing, lean philosophy, Toyota Production system, lean thinking, lean management, lean techniques etc. were used to make the study more exhaustive. -304-

Title of master's thesis: A comprehensive review on Lean Project Management, transformation & Implementation methods, and its utilization in the construction industry (Lean Construction) Credits: 30 Keywords: Lean Thinking Lean Management Lean Construction Project Management Number of Pages: Stavanger, Norway 06.2021

across industries: Lean and Six Sigma. While Lean has a strong focus on value and eliminating waste from the production process, Six Sigma focuses on reducing defects and sources of variability. The unification of both philosophies is Lean Six Sigma (LSS), and it is characterized by finding the roots of the problems from a quantitative approach

Lean management (LM) has attracted the interest of scientists and practitioners since 1990, when Womack et al. (Womack, J.P., Jones, D.T. and Roos, D. (1990). The Machine that Changed the World. New York, NY: Rawson Associates) popularized the Japanese manufacturing approach aimed at eliminating waste to improve operational performance and ...

dr.nee nasinha@g mail.com, mi sha.math aru@gmail. com. Received: M arch 2019. Accepted: A pril 2019. Abstract: Purpose: Lean Manageme nt has evo lved in to an inter-discip linary subject with ...

This thesis seeks to find out the impact of Lean manufacturing (LM) on different sectors of process industries. The theory of this thesis was established mainly on published high-impact scholarly literature, such as books, journals, conferences and theses, as well as several online websites on the subject matters of LM.

Findings. Literature analysis and evaluation have enabled us to offer a novel literature classification based around four research lines that summarize the empirical evidence on LM implementation in universities, namely, lean applied to academic management processes; lean applied to administrative management processes; factors that facilitate lean implementation and results obtained with lean.

In this context, lean manufacturing is regarded as one of the most significant management initiatives for energy management, since it intensifies the effective utilization of resources via ...

Showing result 1 - 5 of 99 swedish dissertations containing the words lean management . 1. Lean Visual Management of Deviations in Product Development and Production - Coining Physical, Digital, and Hybrid Pulse Methodology. Abstract : Lean is a relatively new trend, and every company strives for lean aiming for creating more output while using ...

This document outlines the contents and objectives of a dissertation on lean supply chain management. It discusses key concepts like lean thinking, value stream mapping, and eliminating waste. It also describes a lean enterprise workshop conducted by a professional services firm. The workshop aims to train participants on assessing processes, implementing lean improvements, and evaluating ...

The number of lean programs taught in Russian universities is on the up, but they are mostly standalone courses within traditional management programs. At Lomonosov Moscow State University Business School, we have been running a unique educational program, an MBA in Production Systems, since 2005.

The MoSCoW Method transcends being just a prioritization tool; it is a strategic approach for navigating the intricate decision-making in project management. This methodology excels by offering a structured framework, facilitating discussions among stakeholders to assess and align on the relative importance of various tasks and features in a project. Central to MoSCoW is its…

AI systems, however, are better and faster at identifying "best performance" configurations in the performance data. What is more, whereas standardizing a process is the norm in Lean Six Sigma ...

Lean methodology facilitates an ongoing process of incremental adjustment, significantly accelerating product delivery by optimizing resources and effort and allowing teams to work efficiently and effectively. In this article, you will learn more about Lean methodology, its benefits, and how Jira can help your software team implement its ...

Innovation management; a literature review of. innovation process models and their implications. April 2010. Chris Eveleens. Abstract. The body of innovation management literature grew ...

MoSCoW prioritization, also known as the MoSCoW method or MoSCoW analysis, is a popular prioritization technique for managing requirements. The acronym MoSCoW represents four categories of initiatives: must-have, should-have, could-have, and won't-have, or will not have right now. Some companies also use the "W" in MoSCoW to mean "wish.".