Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- My Account Login

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Open access

- Published: 15 May 2024

Supply chain transformational leadership and resilience: the mediating role of ambidextrous business model

- Taiwen Feng 1 na1 ,

- Zhihui Si 1 na1 ,

- Wenbo Jiang 2 &

- Jianyu Tan 3

Humanities and Social Sciences Communications volume 11 , Article number: 628 ( 2024 ) Cite this article

Metrics details

- Business and management

The global prevalence of COVID-19 has caused many supply chain disruptions, which calls for firms to build resilient supply chains. Prior research primarily examined the effects of firm resources or capabilities on supply chain resilience (SCR), with limited attention given to the critical role of supply chain transformational leadership (SCTL). Based on social learning theory, we explore how SCTL impacts SCR via an ambidextrous business model and the moderating role of paradox cognition. We employ hierarchical regression analysis to verify the hypotheses with data from 317 Chinese firms. The results show that SCTL has a positive impact on proactive and reactive SCR, and the ambidextrous business model mediates this relationship. Furthermore, paradox cognition strengthens the effect of SCTL on the ambidextrous business model. This study contributes to literature and practices in the field of transformational leadership and SCR by providing unique insights into how to improve SCR from a leadership perspective.

Introduction

Affected by the global prevalence of COVID-19, frequent supply chain disruptions have occurred (Nikolopoulos et al., 2021 ; Jiang et al., 2023 ; Shen and Sun, 2023 ). Since supply chains are increasingly complex, firms are more likely to suffer from supply chain disruptions (Lechler et al., 2019 ; Spieske and Birkel, 2021 ; Xi et al., 2024 ). It will be difficult for a firm lacking resilient supply chains to survive and compete within a dynamic and uncertain condition. Supply chain resilience (SCR) reflects the capability of a system to maintain desirable functions before/during disruptions and/or timely recover to its normal functions after disruptive events (Gu et al., 2021 ). Understanding the enablers of SCR would help the firm better respond to potential risks caused by supply chain disruptions (Vanpoucke and Ellis, 2020 ).

Firm leaders could play critical roles in reducing disruption risk in supply chains and building a more resilient supply chain (Khunwishit et al., 2018 ). However, little research has checked the effect of transformational leadership within the supply chain context. We define supply chain transformational leadership (SCTL) as a continual influence that the focal firm demonstrates modeling values and reformative behaviors, which motivates its supply chain partners to act similarly with inspiration and close relationships.

While previous studies mainly focused on the roles of specific resources or capabilities on SCR, such as agility, redundancy, and collaboration (Al Naimi et al., 2021 ; Tukamuhabwa et al., 2015 ), the strategic role of SCTL has largely been ignored. Previous studies suggest that transformational leadership encourages employees’ reaction to changes in a firm (Peng et al., 2021 ) and increases team resilience (Dimas et al., 2018 ). Hence, high levels of SCTL could operate as role-modeling behaviors for the focal firm’s partners and foster a more resilient supply chain. According to social learning theory (Bandura, 1977 ; Brown et al., 2005 ), the focal firm with high levels of SCTL acts as a reliable role model whom its followers trust and attempt to emulate. That is to say, supply chain partners can learn transformative behaviors by observing the focal firm. As a result, the focal firm with high levels of SCTL acts as a benchmark for its supply chain followers to build a resilient supply chain. Therefore, we propose that SCTL may strengthen SCR.

Firms throughout supply chains often face conflicting objectives while implementing organizational learning to improve SCR (Lee and Rha, 2016 ). That is, they must balance different types of learning strategies, such as exploring potential opportunities to transform supply chains while also exploiting current resources to optimize supply chains. The tension of balancing exploitation and exploration is termed organizational ambidexterity (Kristal et al., 2010 ). According to an ambidexterity perspective (Aslam et al., 2022 ; Eng et al., 2023 ), the focal firm with high levels of SCTL prefers to deal with supply chain disruptions through both exploring external opportunities and exploiting internal resources. However, little is known about how SCTL affects SCR via organizational ambidexterity.

Our research devotes to filling this research gap through clarifying the mediating effect of an ambidextrous business model that encompasses both novelty and efficiency within the SCTL–SCR link. We define an ambidextrous business model as a firm’s boundary-spanning transaction mode developed to create and capture value by both balancing activities of redesigning a novel business model and reorganizing elements of an existing one. Specifically, a novelty-centered business model could help firms explore a new value proposition to meet changing demands in disruptions, whereas an efficiency-centered business model improves inter-organizational transaction efficiency by facilitating supply chain visibility and reducing transaction cost (Wei et al., 2017 ; Zott and Amit, 2008 ). Drawing on social learning theory (Ojha et al., 2018 ), the focal firm with high levels of SCTL may demonstratively build an ambidextrous business model by fostering a supportive organizational context. Then, the ambidextrous business model in the focal firm motivates other supply chain partners to emulate and actively take a similar business model, improving SCR through shared supply chain ambidexterity. In this manner, an ambidextrous business model may mediate the SCTL–SCR relationship.

Furthermore, the focal firm with paradoxical thinking and cognition could also influence its learning strategies (Brusoni and Rosenkranz, 2014 ). That is, paradoxical thinking and cognition would affect the focal firm’s attitude and identification towards tensions (explore or exploit) arising from its contrasting strategic agendas (Smith and Lewis, 2011 ). When the focal firm possesses high levels of paradox cognition, it is more likely to recognize and embrace tensions, making well-balanced strategic decisions through developing transformational leadership. Hence, we propose that paradox cognition enhances the impact of SCTL on an ambidextrous business model.

In sum, this study explores three questions to uncover the impact of SCTL on SCR. First, whether SCTL is positively related to SCR? Second, does ambidextrous business model mediate the SCTL–SCR relationship? Third, does paradox cognition strengthen the role of SCTL on ambidextrous business model? By answering the above questions, this study makes a contribution to research and practices in the field of transformational leadership and SCR.

Literature review and hypotheses development

Supply chain resilience.

Resilience, a multidisciplinary construct originating from engineering, ecology, and psychology (Holling, 1973 ; Novak et al., 2021 ). Although most scholars have viewed resilience as an ability to resist and/or rebound from disruptive events (El Baz and Ruel, 2021 ; Namdar et al., 2018 ), there still lacks a normative definition widely accepted. Later, resilience is extended and applied to the field of social sciences, such as supply chain management and operational management. Due to the prevalence of COVID-19, resilience is particularly valued in global supply chains as supply chains become increasingly complex (Spieske and Birkel, 2021 ).

The major divergences of SCR concentrate on two aspects: influencing scope and attributive level. With regard to the influencing scope, some authors only treat SCR as a reactive capability (Brandon-Jones et al., 2014 ; El Baz and Ruel, 2021 ), while others propose that both reactive and proactive components are indispensable (Gu et al., 2021 ). With regard to the attributive level, SCR is often viewed as a firm’s capability (Ambulkar et al., 2015 ); however, it is more acceptable to belong to a whole supply chain system (Scholten et al., 2020 ). Hence, we define SCR as the capability of a system to maintain its expected functions before disruptions and timely recover to its normal functions during facing interruptions.

SCR has been segmented into various dimensions corresponding to different nodes, disruptive phases, or sub-capabilities. For example, Pournader et al. ( 2016 ) argue that SCR could be divided by the organizational boundary into supplier, internal, and customer resilience. Han et al. ( 2020 ) suggest that SCR could be classified into stages of readiness, response, and recovery. Jüttner and Maklan ( 2011 ) propose that flexibility, velocity, visibility, and collaboration are essential sub-capabilities comprising SCR. Following Cheng and Lu’s study ( 2017 ), we divide SCR into two dimensions: proactive and reactive SCR. Proactive SCR is the capability of a supply chain system to mitigate shocks and keep its normal state before/during possible disruptions. Reactive SCR means the capability of a supply chain system to quickly respond and return to its normal state after experiencing disruptions.

Although previous research has revealed diverse factors in formulating SCR (Razak et al., 2023 ; Scholten and Schilder, 2015 ), transformational leadership is rarely discussed. Prior studies mainly examine the roles of four groups of resources and capabilities in building SCR, including reengineering, collaboration, agility, and risk management culture (Belhadi et al., 2022 ). First, supply chain reengineering is positively related to SCR. Resources and capabilities, such as network structure, security, redundancy, efficiency, innovation, contingency planning, and market position, usually contribute to the realignment of structures and processes within supply chains (Han et al., 2020 ; Tukamuhabwa et al., 2017 ), which could help firms deal with new changes. Second, supply chain collaboration is valuable to build SCR. By developing information sharing, risk and revenue sharing, trust, communication, coordination, and integration, the cooperation among different supply chain partners becomes mutually high-quality (Ali et al., 2017 ; Dubey et al., 2021 ; Zhu et al., 2024 ). Third, supply chain agility facilitates the construction of SCR. Flexibility, velocity, visibility, ambidexterity, market sensitiveness, and disruption mitigation (El Baz and Ruel, 2021 ; Gu et al., 2021 ; Jain et al., 2017 ; Kochan and Nowicki, 2018 ) can increase the responsiveness of a supply chain system when facing dynamic business environment. Fourth, supply chain risk management culture, which involves risk awareness, knowledge management, and training and development of a risk management team, can create a proper culture atmosphere in favor of SCR (Belhadi et al., 2022 ).

Beyond four fostering factors, some research has also identified the interactive effects of mixed resources or capabilities on SCR, like industry 4.0 technologies, social capital, leadership, and business model (Belhadi et al., 2024 ; Gölgeci and Kuivalainen, 2020 ; Shashi et al., 2020 ; Shin and Park, 2021 ). However, we still lack knowledge about the strategic role of transformational leadership in fostering SCR. Antecedents of SCR in existing literature are shown in Table 1 .

Supply chain transformational leadership and supply chain resilience

Transformational leadership refers to leaders’ suitable behaviors that drive their followers’ reformative behaviors through continuous motivation and partnership (Bass, 1985 , 1999 ). Existing literature demonstrates that transformational leadership could affect employee attitude (Peng et al., 2021 ) and team resilience in a firm (Dimas et al., 2018 ), while the strategic role of transformational leadership across an entire supply chain system needs more explanation. According to social learning theory (Brown et al., 2005 ), we regard the focal firm with high levels of SCTL as a credible role model whom other supply chain partners respect, trust, and emulate. In this manner, other supply chain partners are likely to learn transformative behaviors by observing the focal firm.

We view the development of SCTL as a role modeling-learning process. That is, the focal firm with high levels of SCTL has an exemplary influence on other supply chain partners via observing and learning from benchmarks. Specifically, SCTL includes three elements: inspiration, intellectual stimulation, and individualized consideration (Defee et al., 2010 ). Inspiration implies that the focal firm with high levels of SCTL often articulates a compelling vision about a desirable future for the supply chain system. The focal firm, with intellectual stimulation, tends to stimulate other supply chain partners to solve issues by adopting creative and innovative methods. Individualized consideration helps the focal firm understand differentiated demands of supply chain followers, and assists them respectively. Based on social learning theory (Bommer et al., 2005 ), the focal firm’s transformative behaviors benefit its followers by the conveyance of competence. Before/during disruptive events, the focal firm clarifies a reliable vision and motivates followers to observe what it does to improve firm resilience. Targeted support makes it easier for other supply chain partners to master and emulate the focal firm’s resilient actions. In addition, coordination and trust among firms are developed in the social learning process (Mostafa, 2019 ), constructing closer supply chain relationships. Therefore, SCTL could enhance the proactive dimension of SCR.

The focal firm with high levels of SCTL would not only strengthen the proactive dimension of SCR, but also contribute to the reactive dimension of SCR. Drawing on social learning theory (Bommer et al., 2005 ), the focal firm’s transformative behaviors increase the self-efficacy of other supply chain partners. After supply chain disruptions, the focal firm demonstrates its response and encourages followers to achieve quick recovery through their differentially new insights. Besides, as firms in the supply chain are closely connected, all members’ resilient actions would transform into SCR when there are common goals and effective interactions (Gölgeci and Kuivalainen, 2020 ). In this manner, SCTL contributes to the reactive aspect of SCR. Hence, we hypothesize:

H1: SCTL has a positive influence on (a) proactive dimension and (b) reactive dimension of SCR.

Supply chain transformational leadership and ambidextrous business model

Ambidexterity is a special dynamic ability balancing exploration and exploitation simultaneously (Kristal et al., 2010 ; Lee and Rha, 2016 ). Previous literature has identified that different leadership styles, such as transformational leadership, could foster ambidexterity in firms (Jansen et al., 2008 ; Tarba et al., 2020 ). Ambidextrous business model means a firm’s boundary-spanning transaction mode developed to create and catch business value by balancing activities of redesigning novel governance, content, and structure and reorganizing elements of an existing business model. Miller ( 1996 ) identifies that novelty and efficiency are classic themes of designing business models. Specifically, a novelty-centered business model aims to create value and catch potential opportunities by redesigning a new business model, while an efficiency-centered business model devotes to increasing efficiency and decreasing operational cost by reconstructing the current business model (Feng et al., 2022 ; Wei et al., 2017 ; Zott and Amit, 2008 ). Under the context of plurality, change, and scarcity, leaders in firms have more intentions to make decisions from an ambidexterity perspective (Smith and Lewis, 2011 ). According to social learning theory (Wang and Feng, 2023 ), leaders in the focal firm with high levels of SCTL tend to express a committed attitude and take exemplary actions to maintain balancing operations. In other words, employees would be guided to conduct certain transformative behaviors, raising a flexible organizational culture with their leaders’ values.

SCTL, which is viewed as a role model-building process, includes three components: inspiration, intellectual stimulation, and individualized consideration (Defee et al., 2010 ). First, the focal firm with high levels of SCTL often articulates a compelling vision and sets high-quality standards. Inspiration by the focal firm’s leaders shows necessary confidence in their subordinates’ abilities and encourages employees to recognize the importance of individual effort in creating and capturing value through exploring and exploiting business opportunities. Additionally, the focal firm’s leaders promote collective goal-setting and collaboration among employees based on a shared vision, creating a supportive organizational context characterized by discipline, stretch, and trust (Ojha et al., 2018 ; Xi et al., 2023 ). Second, the focal firm with high levels of SCTL pays much attention to meeting emerging challenges. Intellectual stimulation by the focal firm’s leaders demonstrates transformative ideas and stimulates their employees to provide new insights under a challenging but supportive atmosphere, increasing organizational creativity and contributing to a stretch context (Elkins and Keller, 2003 ). Third, the focal firm with high levels of SCTL actively understands and helps its internal members. Individualized consideration by the focal firm’s leaders offers differentiated support via one-to-one knowledge exchange and creates a heartwarming condition that promotes more assistance among employees, fostering a culture of support and trust (Bommer et al., 2005 ). While a supportive organizational context is developed (Pan et al., 2021 ), a firm with high levels of SCTL prefers to design an ambidextrous business model. Thus, we hypothesize:

H2: SCTL has a positive influence on an ambidextrous business model.

Ambidextrous business model and supply chain resilience

The development of an ambidextrous business model could be recognized as a role model-engaging process. According to social learning theory (Wang and Feng, 2023 ), the focal firm with high levels of ambidextrous business model would serve as an example that provides a flexible business model for its followers. Then, supply chain followers are likely to trust and attempt to emulate the focal firm’s business model when sensing or experiencing frequent supply chain disruptions.

In detail, the focal firm with a high level of ambidextrous business model shows its supply chain partners how to maintain agility before/during disruptions through a proper organization arrangement. A novelty-centered business model could help other firms realize that they must create and capture value through designing new activities of governance, content, and structure to predict/respond to changing environments before/during disruptions. An efficiency-centered business model guides followers to continuously change the current supply chain into a more robust system (Wei et al., 2017 ; Zott and Amit, 2008 ). Besides, when all firms with high levels of ambidextrous business models tend to balance novelty and efficiency simultaneously, they would contribute to a more robust supply chain by preventive supply chain ambidexterity. Therefore, the ambidextrous business model enhances the proactive dimension of SCR.

The focal firm with high levels of the ambidextrous business model provides other supply chain members a valuable frame to quickly react after disruptions as well. Specifically, a novelty-centered business model stimulates other firms to adopt new ideas and norms in solving issues after disruptive events, improving their adaptability and responsiveness. An efficiency-centered business model helps followers achieve greater transaction efficiency and lower transaction costs, facilitating the adjustment of actions and strategies to rapidly respond to disruptions. In addition, firms with high levels of ambidextrous business models jointly balance novelty and efficiency, establishing a more resilient supply chain through responsive supply chain ambidexterity. SCTL contributes to the reactive dimension of SCR. Hence, we hypothesize:

H3: Ambidextrous business model has a positive influence on (a) proactive dimension and (b) reactive dimension of SCR.

In sum, the ambidextrous business model serves as a proper mediator within the role modeling-learning process. Drawing on social learning theory, the focal firm with high levels of SCTL demonstrates an ambidextrous business model through fostering a supportive organizational context. And then other supply chain partners would actively learn and emulate the focal firm’s typical business model based on their trust and common values, improving SCR by supply chain ambidexterity. An ambidextrous business model could transform SCTL into proactive and reactive dimensions of SCR. Thus, we hypothesize:

H4: Ambidextrous business model mediates the relationship between SCTL and (a) proactive dimension and (b) reactive dimension of SCR.

The moderating role of paradox cognition

Paradox cognition refers to an epistemic framework and process recognizing and juxtaposing contradictory demands, which could make latent tensions within organizations more explicit (Smith and Tushman, 2005 ). The focal firm with paradoxical thinking and cognition could influence learning strategies (Brusoni and Rosenkranz, 2014 ; Sheng et al., 2023 ). That is, paradox cognition may affect the focal firm’s attitude and identification towards tensions (explore or exploit) arising from its contrasting strategic agendas (Smith and Lewis, 2011 ). Based on social learning theory (Bandura, 1977 ), when the focal firm possesses high levels of paradox cognition, it is more likely to recognize the importance of ambidexterity. In this manner, leaders’ transformative behaviors in the focal firm with high levels of SCTL would be more easily accepted and emulated by employees to balance both explorative and exploitive learning activities (Han et al., 2022 ), which may help build an ambidextrous business model. By contrast, when the focal firm has low levels of paradox cognition, it tends to choose either novelty or efficiency in designing a business model. The SCTL-ambidextrous business model relationship becomes less important because contradictions in the focal firm are latent. Hence, we hypothesize:

H5: Paradox cognition enhances the impact of SCTL on an ambidextrous business model.

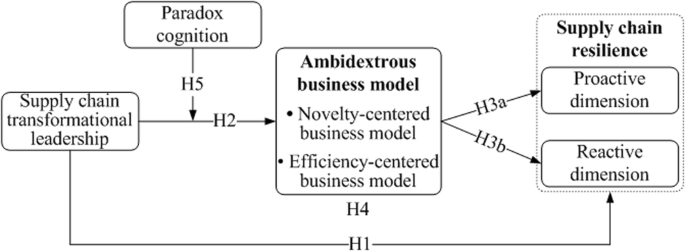

Combining the hypotheses above, we build a conceptual model to check the influence of SCTL on SCR (including proactive and reactive SCR), the mediating role of the ambidextrous business model within the SCTL–SCR relationship, and the moderating effect of paradox cognition. The conceptual model is illustrated in Fig. 1 .

This figure represents the hypothetical relationships among constructs.

Research design

Procedures and data collection.

We gathered data from Chinese manufacturers. Affected by the COVID-19 pandemic, manufacturing firms in China suffered from many supply chain disruptions, prompting leaders to realize the necessity of keeping a resilient supply chain (Lin et al., 2021 ; Shen and Sun, 2023 ). It is a challenging objective for manufacturing firms in China as they account for a large share of total exports in the global supply chains. Thus, China provided an appropriate context to explore the antecedents of SCR.

Due to the regional imbalanced characteristic of the Chinese economic force and transportation network (Feng et al., 2019 ; Hosseini et al., 2019 ), we selected sampling firms in five typical provinces: Guangdong, Jiangsu, Shandong, Henan, and Inner Mongolia. Guangdong, Jiangsu, and Shandong, in the eastern coastal areas of China, had relatively high levels of economic force and transportation networks. Henan, in the middle area of China, had average levels of economic force and transportation network. By contrast, Inner Mongolia, in the north and west of China, had relatively low levels of economic force and transportation network.

We adopted three steps to design a questionnaire. First, 12 firm executives, including the chief executive officer, general manager, or vice president, were interviewed to confirm the content validity of our study issue. All these individuals were required to be knowledgeable about their firms’ internal operations as well as external partnerships. Second, an initial questionnaire was developed through literature and expert review, translation, and back-translation. Third, a pre-test with another 20 executives was conducted to provide useful suggestions for modification, forming the formal questionnaire.

We randomly chose 200 firms in each province above and sought cooperation via a cover letter introducing the research intention. All participants were ensured confidentiality. Invitations were sent through emails or telephones, and 435 firms agreed to join our survey total. To mitigate common method bias (CMB), we split each questionnaire into two parts (including parts A and B) and invited different respondents in each firm to complete one part respectively. Part A featured demographic characteristics, competitive intensity, SCTL, novelty-centered business model, and SCR, whereas part B included paradox cognition and efficiency-centered business model.

We distributed and received back the questionnaires through emails from May 2020 to December 2020. 317 valid questionnaires were gathered, with an effective response rate of 72.9%. The final sample included 72 firms in Guangdong, 62 firms in Jiangsu, 67 firms in Shandong, 56 firms in Henan, and 60 firms in Inner Mongolia. The average working experience of 634 respondents was 7.19 years. 64.8% of our respondents held the posts of chief executive officer, general manager, or vice president, and 35.2% were operations directors. The detailed features of sampled firms are presented in Table 2 .

We utilized two steps to verify non-response bias (Armstrong and Overton, 1977 ). First, firm size and ownership were compared for the nonresponding and responding firms. Second, differences in firm size, firm age, industry, and ownership between the early and late responses were also examined. These results of the independent t -test suggested that non-response bias in this study was not a serious issue.

We selected the seven-point Likert scale adopted or adapted from previous studies to measure all constructs in the questionnaire (1 = strongly disagree, 7 = strongly agree).

Supply chain transformational leadership

A refined seven-item scale from Defee et al. ( 2010 ) was applied to measure SCTL. SCTL was operationalized as respondents’ perceptions of their firms’ influences, which are often the outcome of behavioral factors, including inspiration, intellectual stimulation, and individualized consideration.

Paradox cognition

A seven-item scale from Smith and Lewis ( 2011 ) was used to measure paradox cognition. Respondents were requested to evaluate the degree of their own firms’ dual awareness when making strategic decisions in the last three years.

Ambidextrous business model

A ten-item scale and a nine-item scale were adjusted by Zott and Amit ( 2007 ) to measure the novelty-centered business model and efficiency-centered business model in turn. Additionally, the average value of these two variables was calculated to measure the ambidextrous business model. This approach not only kept convenience to reserve and made logical interpretations for the useful information from both parts but reflected the nature of ambidexterity–seemingly contradictory yet coexisting tensions (Lubatkin et al., 2006 ; Zhang et al., 2015 ).

Following Cheng and Lu ( 2017 ), SCR was divided into two dimensions: proactive and reactive SCR Two altered four-item scales were adopted for proactive and reactive SCR separately (Ambulkar et al., 2015 ; Brandon-Jones et al., 2014 ; Wieland and Wallenburg, 2013 ).

Control variables

To mitigate the roles of other factors on analytical results as much as possible, we controlled five demographic characteristics, including firm size, firm age, industry, ownership, and competitive intensity (Ambulkar et al., 2015 ; Gölgeci and Ponomarov, 2015 ). Firm age and firm size were measured by the natural logarithm of the number of years since foundation and the natural logarithm of the number of employees, respectively (Li et al., 2008 ). One dummy variable was to control industry (1 = high-tech firm, 0 = otherwise), and two dummy variables (including state-owned and collective firms and private firms) were to control ownership. A four-item scale was adjusted by Jaworski and Kohli ( 1993 ) to measure competitive intensity.

Reliability and validity

First, we did a reliability test and explorative factor analysis (EFA). All constructs revealed high reliability with a Cronbach’s alpha value of more than 0.7 (Flynn et al., 1990 ). Seven principal components were extracted, which was consistent with constructs in the scales (Table 3 ). Second, we made a confirmatory factor analysis (CFA) by AMOS 24.0 to ensure validity. The results indicated that the measurement model had good fit indices: χ ²/d f = 2.034; RMSEA = 0.057; CFI = 0.928; NNFI = 0.923; SRMR = 0.038. All constructs’ composite reliability (CR) was more than 0.7, with item loadings varying from 0.760 to 0.939, and all average variance extracted (AVE) values were more than 0.5 (Table 3 ). Thus, the results indicated sufficient convergent validity. Besides, the comparison between shared variances of constructs and the square root of AVE demonstrated that all correlations were less than the corresponding square roots of AVEs (Table 4 ), identifying acceptable discriminant validity. Tables 3 and 4 reported the measure items, reliability, and validity assessment.

Common method bias

We utilized three means to test CMB. First, Harman’s single-factor test was conducted, revealing that there were seven principal components (Table 3 ), and no single factor accounted for most variances in these measures. Second, the fit indices of CFA between the actual seven-factor model and the one-factor model were compared, indicating that the one-factor model got significantly worse fit indices. Third, another common method factor was supplemented to the seven-factor CFA model above and it discovered that the fit indices did not change significantly. As a result, there was no serious CMB.

We adopted hierarchical regression analysis and the bootstrapping method by SPSS 23.0 to examine the research hypotheses. First, the effect of SCTL on SCR was examined. Then, the influence of SCTL on the ambidextrous business model, the effect of the ambidextrous business model on SCR, and the mediating impact of the ambidextrous business model within the SCTL–SCR link were tested. Finally, the moderating effect of paradox cognition in the SCTL–ambidextrous business model relationship was examined. Table 5 reports the results of the hierarchical regression model.

To minimize possible multicollinearity, we generated an interaction with mean-centering of both the independent variable and the moderating variable (Aiken and West, 1991 ). The maximal value of the variance inflation factor (VIF) is 1.739, which is much less than the recommended cut-off of 10. Thus, the multicollinearity is not serious.

H1a and H1b predict the positive impact of SCTL on both dimensions of SCR. Models 5 and 9 in Table 5 show that SCTL has a significantly positive effect on the proactive dimension ( β = 0.122, p < 0.05) and reactive dimension ( β = 0.166, p < 0.01). Therefore, H1a and H1b are supported.

H2 predicts the positive influence of SCTL on the ambidextrous business model. Model 2 in Table 5 indicates that SCTL has a significantly positive impact on ambidextrous business models ( β = 0.140, p < 0.05). Hence, H2 is supported.

H3a and H3b predict the positive role of the ambidextrous business model on both dimensions of SCR. Models 6 and 10 in Table 5 suggest that the ambidextrous business model has a positive effect on the proactive dimension ( β = 0.241, p < 0.001) and reactive dimension ( β = 0.256, p < 0.001). Therefore, H3a and H3b are supported.

H4a and H4b hypothesize that the ambidextrous business model mediates the relationships between SCTL and two dimensions of SCR. According to Baron and Kenny ( 1986 ), Models 2, 5, and 7 in Table 5 jointly demonstrate that the ambidextrous business model ( β = 0.228, p < 0.001) fully mediates the relationship between SCTL ( β = 0.090, p > 0.1) and proactive dimension, which supports H4a. Similarly, Models 2, 9, and 11 in Table 5 collectively exhibit that the ambidextrous business model ( β = 0.237, p < 0.001) partially mediates the relationship between SCTL ( β = 0.133, p < 0.05) and reactive dimension, which supports H4b.

To ensure the robustness of the results, we further used the PROCESS macro to conduct a bootstrapped mediation analysis. As depicted in Table 6 , the results keep consistency with the corresponding results in Table 5 , ensuring the effectiveness of analytical findings before.

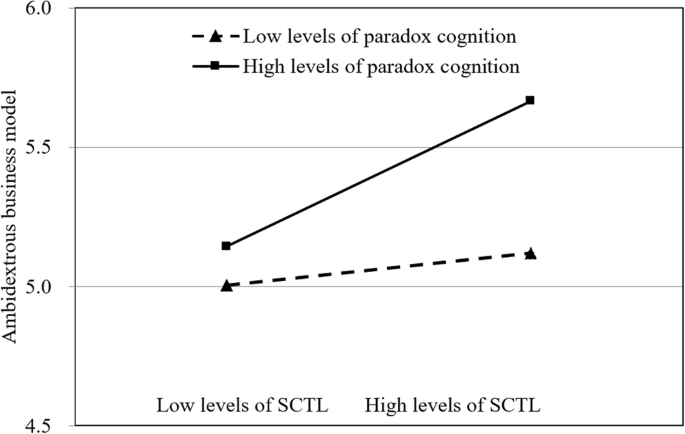

H5 hypothesizes that paradox cognition strengthens the impact of SCTL on the ambidextrous business model. Model 3 in Table 5 presents that the interaction of SCTL and paradox cognition is significantly positive ( β = 0.094, p < 0.1), which supports H5. Moreover, we applied a simple slope analysis to verify the moderating effect of paradox cognition so that a clearer explanation could be given. As illustrated in Fig. 2 , when levels of paradox cognition are higher, the role of SCTL in the ambidextrous business model becomes stronger. Hence, the result further supports a strengthened effect of paradox cognition in the SCTL–ambidextrous business model relationship.

This figure reflects the moderating effect of paradox cognition on the relationship between supply chain transformational leadership and ambidextrous business model.

Discussions and implications

Discussions.

This study intends to verify the impact of SCTL on both dimensions of SCR (including proactive and reactive SCR) through the ambidextrous business model and the moderating role of paradox cognition. Our results exhibit that SCTL has a positive influence on proactive and reactive SCR. This finding is similar to studies that explore the effect of leader–member exchange on network resilience performance in the supply chain context (Shin and Park, 2021 ) or the effect of transformational supply chain leadership on operational performance (Defee et al., 2010 ). However, these studies only emphasize the necessity of inter-organizational relationships and capabilities within the influential process of supply chain leadership on supply chain performance. Our results show that SCTL contributes to proactive and reactive SCR in a social learning process where both firm resilience and supply chain collaboration are indispensable parts.

Our results demonstrate that an ambidextrous business model mediates the impact of SCTL on SCR. This finding is inconsistent with existing studies about the antecedents or consequences of business models (Schoemaker et al., 2018 ; Shashi et al., 2020 ). One possible explanation is that the ambidextrous business model aims at designing new business models to capture and create value while also reconfiguring new combinations to improve transaction efficiency. Our results also indicate that the ambidextrous business model fully mediates the relationship between SCTL and proactive SCR while partially mediates the relationship between SCTL and reactive SCR. That is, the ambidextrous business model occupies a more important position in the SCTL-proactive dimension link. A possible reason could be that compared with intellectual stimulation, the influence of inspiration and individualized consideration is more dispersive within a longer time, improving the necessity of an ambidextrous business model. These results provide new insights to realize how SCTL enhances SCR.

In addition, we identify that paradox cognition strengthens the effect of SCTL on an ambidextrous business model. When the focal firm has high levels of paradox cognition, it tends to recognize the importance of ambidexterity. In this manner, the focal firm’s transformative behaviors would be more easily accepted and emulated by employees to balance both explorative and exploitive learning activities (Han et al., 2022 ), building an ambidextrous business model. This outcome verifies our research hypothesis, indicating the importance of paradox cognition in the SCTL–ambidextrous business model link.

Theoretical contributions

This study contributes to managerial research in three aspects. First, we enrich the antecedents of SCR by confirming the role of SCTL. Existing studies emphasize the impacts of specific resources or capabilities on SCR, such as agility, redundancy, and collaboration (Al Naimi et al., 2021 ; Tukamuhabwa et al., 2015 ), while the strategic effect of SCTL is rarely discussed. Previous literature has identified that transformational leadership could improve employee attitude (Peng et al., 2021 ) and team resilience (Dimas et al., 2018 ) at the firm level. Our research extends the concept of transformational leadership to the whole supply chain system and proposes that the focal firm with high levels of SCTL can improve proactive and reactive SCR. Hence, we contribute to the field of SCTL and SCR.

Second, we reveal the ‘black box’ of how SCTL impacts SCR by examining the mediating role of the ambidextrous business model. Existing studies reveal the influence of transformational leadership on organizational ambidexterity (Eng et al., 2023 ) and the impact of organizational ambidexterity on SCR (Aslam et al., 2022 ), while we still lack understanding of how SCTL affects SCR. Previous literature has demonstrated that redesigning a supply chain with high levels of concentration plays a significant role in protecting firm performance when suffering from disruptions (Liu et al., 2023 ). Hence, we contribute to the SCTL and SCR literature by showing a partial mediating effect of the ambidextrous business model in the SCTL–proactive SCR relationship and a fully mediating effect of ambidextrous business model in the SCTL–reactive SCR relationship.

Third, we clarify the boundary condition for the SCTL–ambidextrous business model relationship by examining the moderating effect of paradox cognition. Existing studies show that the efficiency of the learning process would be influenced by external stakeholders (Song et al., 2020 ; Wang and Feng, 2023 ), while the interactive role of internal factors is largely ignored. Previous literature has argued that organizational learning may be influenced by paradoxical thinking and cognition (Brusoni and Rosenkranz, 2014 ). Our findings suggest that paradox cognition would affect the focal firm’s attitude and identification towards tensions (explore or exploit) arising from its contrasting strategic agendas. Under high levels of paradox cognition, the focal firm is more likely to recognize and embrace tensions, making well-balanced decisions. Thus, the efficiency of social learning from SCTL to ambidextrous business model improves, which further emphasizes the necessity of developing paradox cognition within the learning process.

Managerial implications

This study offers three suggestions for managerial practice. First, managers should undertake leading roles and encourage member firms within the supply chain to improve SCR. In a dynamic and uncertain context, the focal firm with high levels of SCTL is effective to motivate its supply chain partners’ transformative behaviors. Managers should develop a reliable role model whom their followers trust and attempt to emulate. They should also develop two types of SCR, including proactive and reactive SCR. Additionally, they should articulate a compelling vision for all supply chain members, providing individualized training to meet the differentiated needs of firms and stimulating supply chain partners to create new insights with a supportive and challenging atmosphere.

Second, managers should establish an ambidextrous business model in firms. The focal firm with high levels of SCTL often demonstrates an ambidextrous business model by fostering a supportive organizational context. Managers should design an ambidextrous business model balancing both novelty and efficiency. Furthermore, they are suggested to motivate other supply chain followers to learn and emulate the focal firm’s transformative behaviors through a shared system vision, promoting communication and coordination among supply chain members.

Third, managers should foster a paradox cognition framework within their firms. Under high levels of paradox cognition, the focal firm is more likely to recognize the importance of ambidexterity and solve tensions from an ambidexterity perspective. Transformative behaviors of the focal firm would be more easily accepted and emulated by its employees. Managers should provide a proper organizational context for employees to improve their paradoxical thinking and cognition to quickly respond to disruptions.

Conclusion and limitations

Drawing on social learning theory, this study clarifies the impact of SCTL on SCR. Our findings reveal that SCTL has a positive influence on both proactive and reactive SCR. In addition, the ambidextrous business model fully mediates the relationship between SCTL and proactive SCR while also partially mediating the relationship between SCTL and reactive SCR. Paradox cognition strengthens the effect of SCTL on the ambidextrous business model.

This study has a few limitations, of course. First, we must demonstrate the effect of SCTL on SCR. Future research could try investigating the roles of other factors, such as transactional leadership to enrich antecedents of SCR. Second, this study only explores the mediating role of the ambidextrous business model between SCTL and SCR. In the future, other possible realization paths from the configurational perspective should be verified (Feng and Sheng, 2023 ). Third, we must identify the moderating impact of paradox cognition within the SCTL–ambidextrous business model relationship. Scholars are suggested to discover more possible boundary conditions like dynamic environment, and build a moderated mediation model to further explore the roles of potential moderators.

Data availability

All data generated and analyzed during the current study are included in this article and a supplementary Excel spreadsheet called ‘Dataset’ which contains all items’ values from questionnaires and other control variables’ values.

Aiken LS, West SG (1991) Multiple regression: testing and interpreting interactions. Sage, Newbury Park, CA

Google Scholar

Al Naimi M, Faisal MN, Sobh R, Uddin SMF (2021) Antecedents and consequences of supply chain resilience and reconfiguration: an empirical study in an emerging economy. J Enterp Inf Manag 34(6):1722–1745

Article Google Scholar

Ali A, Mahfouz A, Arisha A (2017) Analysing supply chain resilience: integrating the constructs in a concept mapping framework via a systematic literature review. Supply Chain Manag: Int J 22(1):16–39

Ambulkar S, Blackhurst J, Grawe S (2015) Firm’s resilience to supply chain disruptions: scale development and empirical examination. J Oper Manag 33-34(1):111–122

Armstrong JS, Overton TS (1977) Estimating nonresponse bias in mail surveys. J Mark Res 14(3):396–402

Aslam H, Syed TA, Blome C, Ramish A, Ayaz K (2022) The multifaceted role of social capital for achieving organizational ambidexterity and supply chain resilience. IEEE Trans Eng Manag https://doi.org/10.1109/TEM.2022.3174069

Bandura A (1977) Social learning theory. General Learning Press, New York

Baron RM, Kenny DA (1986) The moderator-mediator variable distinction in social psychological research: conceptual, strategic, and statistical considerations. J Personal Soc Psychol 51(6):1173–1182

Article CAS Google Scholar

Bass BM (1985) Leadership and performance beyond expectations. Free Press, New York

Bass BM (1999) Two decades of research and development in transformational leadership. Eur J Work Organ Psychol 8(1):9–32

Belhadi A, Kamble S, Fosso Wamba S, Queiroz MM (2022) Building supply-chain resilience: an artificial intelligence-based technique and decision-making framework. Int J Prod Res 60(14):4487–4507

Belhadi A, Mani V, Kamble SS, Khan SAR, Verma S (2024) Artificial intelligence-driven innovation for enhancing supply chain resilience and performance under the effect of supply chain dynamism: an empirical investigation. Ann Oper Res 333:627–652

Bommer WH, Rich GA, Rubin RS (2005) Changing attitudes about change: longitudinal effects of transformational leader behavior on employee cynicism about organizational change. J Organ Behav 26(7):733–753

Brandon-Jones E, Squire B, Autry CW, Petersen KJ (2014) A contingent resource-based perspective of supply chain resilience and robustness. J Supply Chain Manag 50(3):55–73

Brown ME, Treviño LK, Harrison DA (2005) Ethical leadership: a social learning perspective for construct development and testing. Organ Behav Hum Decis Process 97(2):117–134

Brusoni S, Rosenkranz NA (2014) Reading between the lines: learning as a process between organizational context and individuals’ proclivities. Eur Manag J. 32(1):147–154

Cheng JH, Lu KL (2017) Enhancing effects of supply chain resilience: Insights from trajectory and resource-based perspectives. Supply Chain Manag: Int J 22(4):329–340

Chowdhury MMH, Quaddus M (2017) Supply chain resilience: conceptualization and scale development using dynamic capability theory. Int J Prod Econ 188:185–204

Defee CC, Stank TPT, Esper T (2010) Performance implications of transformational supply chain leadership and followership. Int J Phys Distrib Logist Manag 40(10):763–791

Dimas ID, Rebelo T, Lourenço PR, Pessoa CIP (2018) Bouncing back from setbacks: on the mediating role of team resilience in the relationship between transformational leadership and team effectiveness. J Psychol 152(6):358–372

Article PubMed Google Scholar

Dubey R, Gunasekaran A, Childe SJ, Fosso Wamba S, Roubaud D, Foropon C (2021) Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. Int J Prod Res 59(1):110–128

El Baz J, Ruel S (2021) Can supply chain risk management practices mitigate the disruption impacts on supply chains’ resilience and robustness? Evidence from an empirical survey in a COVID-19 outbreak era. Int J Prod Econ 233:107972

Elkins T, Keller RT (2003) Leadership in research and development organizations: a literature review and conceptual framework. Leadersh Q 14(4-5):587–606

Eng TY, Mohsen K, Wu LC (2023) Wireless information technology competency and transformational leadership in supply chain management: implications for innovative capability. Inf Technol People 36(3):969–995

Feng T, Sheng H (2023) Identifying the equifinal configurations of prompting green supply chain integration and subsequent performance outcome. Bus Strateg Environ 32(8):5234–5251

Feng T, Wang D, Lawton A, Luo BN (2019) Customer orientation and firm performance: the joint moderating effects of ethical leadership and competitive intensity. J Bus Res 100:111–121

Feng T, Yang S, Sheng H (2022) Supply chain integration and novelty-centered business model design: an organizational learning perspective. Eur Manag J https://doi.org/10.1016/j.emj.2022.12.002

Flynn BB, Sakakibara S, Schroeder RG, Bates KA, Flynn EJ (1990) Empirical research methods in operations management. J Oper Manag 9(2):250–284

Gölgeci I, Ponomarov SY (2015) How does firm innovativeness enable supply chain resilience? The moderating role of supply uncertainty and interdependence. Technol Anal Strat Manag 27(3):267–282

Gölgeci I, Kuivalainen O (2020) Does social capital matter for supply chain resilience? The role of absorptive capacity and marketing-supply chain management alignment. Ind Mark Manag 84:63–74

Gu M, Yang L, Huo B (2021) The impact of information technology usage on supply chain resilience and performance: an ambidextrous view. Int J Prod Econ 232:107956

Han G, Bai Y, Peng G (2022) Creating team ambidexterity: the effects of leader dialectical thinking and collective team identification. Eur Manag J 40(2):175–181

Han Y, Chong WK, Li D (2020) A systematic literature review of the capabilities and performance metrics of supply chain resilience. Int J Prod Res 58(15):4541–4566

Holling CS (1973) Resilience and stability of ecological systems. Annu Rev Ecol Syst 4(1):1–23

Hosseini S, Ivanov D, Dolgui A (2019) Review of quantitative methods for supply chain resilience analysis. Transp Res Part E 125:285–307

Jain V, Kumar S, Soni U, Chandra C (2017) Supply chain resilience: model development and empirical analysis. Int J Prod Res 55(22):6779–6800

Jansen JJ, George G, Van den Bosch FA, Volberda HW (2008) Senior team attributes and organizational ambidexterity: the moderating role of transformational leadership. J Manag Stud 45(5):982–1007

Jaworski BJ, Kohli AK (1993) Market orientation: antecedents and consequences. J Mark 57(3):53–70

Jiang Y, Feng T, Huang Y (2024) Antecedent configurations toward supply chain resilience: the joint impact of supply chain integration and big data analytics capability. J Oper Manag 70(2):257–284

Jüttner U, Maklan S (2011) Supply chain resilience in the global financial crisis: an empirical study. Supply Chain Manag: Int J 16(4):246–259

Khunwishit S, Choosuk C, Webb G (2018) Flood resilience building in Thailand: assessing progress and the effect of leadership. Int J Disaster Risk Sci 9(1):44–54

Kochan CG, Nowicki DR (2018) Supply chain resilience: a systematic literature review and typological framework. Int J Phys Distrib Logist Manag 48(8):842–865

Kristal MM, Huang X, Roth AV (2010) The effect of an ambidextrous supply chain strategy on combinative competitive capabilities and business performance. J Oper Manag 28(5):415–429

Lechler S, Canzaniello A, Rossmann B, von der Gracht HA, Hartmann E (2019) Real-time data processing in supply chain management: revealing the uncertainty dilemma. Int J Phys Distrib Logist Manag 49(10):1003–1019

Lee SM, Rha JS (2016) Ambidextrous supply chain as a dynamic capability: building a resilient supply chain. Manag Decis 54(1):2–23

Li JJ, Poppo L, Zhou KZ (2008) Do managerial ties in China always produce value? Competition, uncertainty, and domestic vs. foreign firms. Strat Manag J 29(4):383–400

Lin Y, Fan D, Shi X, Fu M (2021) The effects of supply chain diversification during the COVID-19 crisis: evidence from Chinese manufacturers. Transp Res Part E: Logist Transp Rev 155:102493

Liu F, Liu C, Wang X, Park K, Fang M (2023) Keep concentrated and carry on: redesigning supply chain concentration in the face of COVID-19. Int J Logist Res Appl https://doi.org/10.1080/13675567.2023.2175803

Lubatkin MH, Simsek Z, Ling Y, Veiga JF (2006) Ambidexterity and performance in small-to medium-sized firms: the pivotal role of top management team behavioral integration. J Manag 32(5):646–672

Miller D (1996) Configurations revisited. Strat Manag J 17(7):505–512

Mostafa AMS (2019) Transformational leadership and restaurant employees customer-oriented behaviours: the mediating role of organizational social capital and work engagement. Int J Contemp Hosp Manag 31(3):1166–1182

Namdar J, Li X, Sawhney R, Pradhan N (2018) Supply chain resilience for single and multiple sourcing in the presence of disruption risks. Int J Prod Res 56(6):2339–2360

Nikolopoulos K, Punia S, Schäfers A, Tsinopoulos C, Vasilakis C (2021) Forecasting and planning during a pandemic: COVID-19 growth rates, supply chain disruptions, and governmental decisions. Eur J Oper Res 290(1):99–115

Article MathSciNet PubMed Google Scholar

Novak DC, Wu Z, Dooley KJ (2021) Whose resilience matters? Addressing issues of scale in supply chain resilience. J Bus Logist 42(3):323–335

Ojha D, Acharya C, Cooper D (2018) Transformational leadership and supply chain ambidexterity: mediating role of supply chain organizational learning and moderating role of uncertainty. Int J Prod Econ 197:215–231

Pan Y, Verbeke A, Yuan W (2021) CEO transformational leadership and corporate entrepreneurship in China. Manag Organ Rev 17(1):45–76

Peng J, Li M, Wang Z, Lin Y (2021) Transformational leadership and employees’ reactions to organizational change: evidence from a meta-analysis. J Appl Behav Sci 57(3):369–397

Pournader M, Rotaru K, Kach AP, Razavi Hajiagha SH (2016) An analytical model for system-wide and tier-specific assessment of resilience to supply chain risks. Supply Chain Manag: Int J 21(5):589–609

Razak GM, Hendry LC, Stevenson M (2023) Supply chain traceability: a review of the benefits and its relationship with supply chain resilience. Prod Plan Control 34(11):1114–1134

Schoemaker PJ, Heaton S, Teece D (2018) Innovation, dynamic capabilities, and leadership. Calif Manag Rev 61(1):15–42

Scholten K, Schilder S (2015) The role of collaboration in supply chain resilience. Supply Chain Manag: Int J 20(4):471–484

Scholten K, Stevenson M, van Donk DP (2020) Dealing with the unpredictable: supply chain resilience. Int J Oper Prod Manag 40(1):1–10

Shashi, Centobelli P, Cerchione R, Ertz M (2020) Managing supply chain resilience to pursue business and environmental strategies. Bus Strategy Environ 29(3):1215–1246

Shen ZM, Sun Y (2023) Strengthening supply chain resilience during COVID-19: a case study of JD.com. J Oper Manag 69(3):359–383

Sheng H, Feng T, Liu L (2023) The influence of digital transformation on low-carbon operations management practices and performance: does CEO ambivalence matter? Int J Prod Res 61(18):6215–6229

Shin N, Park S (2021) Supply chain leadership driven strategic resilience capabilities management: a leader-member exchange perspective. J Bus Res 122:1–13

Smith WK, Tushman ML (2005) Managing strategic contradictions: a top management model for managing innovation streams. Organ Sci 16(5):522–536

Smith WK, Lewis MW (2011) Toward a theory of paradox: a dynamic equilibrium model of organizing. Acad Manag Rev 36(2):381–403

Song M, Yang MX, Zeng KJ, Feng W (2020) Green knowledge sharing, stakeholder pressure, absorptive capacity, and green innovation: evidence from Chinese manufacturing firms. Bus Strategy Environ 29(3):1517–1531

Spieske A, Birkel H (2021) Improving supply chain resilience through industry 4.0: a systematic literature review under the impressions of the COVID-19 pandemic. Comput Ind Eng 158:107452

Article PubMed PubMed Central Google Scholar

Tarba SY, Jansen JJ, Mom TJ, Raisch S, Lawton TC (2020) A microfoundational perspective of organizational ambidexterity: critical review and research directions. Long Range Plan 53(6):102048

Tukamuhabwa B, Stevenson M, Busby J (2017) Supply chain resilience in a developing country context: a case study on the interconnectedness of threats, strategies and outcomes. Supply Chain Manag: Int J 22(6):486–505

Tukamuhabwa BR, Stevenson M, Busby J, Zorzini M (2015) Supply chain resilience: definition, review and theoretical foundations for further study. Int J Prod Res 53(18):5592–5623

Vanpoucke E, Ellis SC (2020) Building supply-side resilience-a behavioural view. Int J Oper Prod Manag 40(1):11–33

Wang J, Feng T (2023) Supply chain ethical leadership and green supply chain integration: a moderated mediation analysis. Int J Logist Res Appl 26(9):1145–1171

Article MathSciNet Google Scholar

Wei Z, Song X, Wang D (2017) Manufacturing flexibility, business model design, and firm performance. Int J Prod Econ 193:87–97

Wieland A, Wallenburg CM (2013) The influence of relational competencies on supply chain resilience: a relational view. Int J Phys Distrib Logist Manag 43(4):300–320

Xi M, Fang W, Feng T (2023) Green intellectual capital and green supply chain integration: the mediating role of supply chain transformational leadership. J Intellect Cap 24(4):877–899

Xi M, Liu Y, Fang W, Feng T (2024) Intelligent manufacturing for strengthening operational resilience during the COVID-19 pandemic: a dynamic capability theory perspective. Int J Prod Econ 267:109078

Zhang Y, Waldman DA, Han YL, Li XB (2015) Paradoxical leader behaviors in people management: antecedents and consequences. Acad Manag J 58(2):538–566

Zhu J, Feng T, Lu Y, Jiang W (2024) Using blockchain or not? A focal firm’s blockchain strategy in the context of carbon emission reduction technology innovation. Bus Strategy Environ 33(4):3505–3531

Zott C, Amit R (2007) Business model design and the performance of entrepreneurial firms. Organ Sci 18(2):181–199

Zott C, Amit R (2008) The fit between product market strategy and business model: implications for firm performance. Strateg Manag J 29(1):1–26

Download references

Acknowledgements

This work was partially supported by the National Natural Science Foundation of China (72172040), the Fundamental Research Funds for the Central Universities (HIT.HSS.ESD202333), and the Taishan Scholar Project of Shandong Province (tsqn201909154).

Author information

These authors contributed equally: Taiwen Feng, Zhihui Si.

Authors and Affiliations

School of Economics and Management, Harbin Institute of Technology (Weihai), Weihai, China

Taiwen Feng & Zhihui Si

School of Economics and Management, Dalian University of Technology, Dalian, China

Wenbo Jiang

College of New Energy, Harbin Institute of Technology (Weihai), Weihai, China

You can also search for this author in PubMed Google Scholar

Contributions

Taiwen Feng: Conceptualization, investigation, data curation, funding acquisition, supervision, writing-review and editing. Zhihui Si: Methodology, data curation, formal analysis, writing-original draft, and editing. Wenbo Jiang: Investigation, data curation, writing-review, and editing. Jianyu Tan: Data curation, writing-review, and editing.

Corresponding author

Correspondence to Wenbo Jiang .

Ethics declarations

Competing interests.

The authors declare no competing interests.

Ethical approval

The survey process and procedures used in this study adhere to the tenets of the Declaration of Helsinki. Ethics approval was obtained from the Professor Committee at the School of Economics and Management of Harbin Institute of Technology (Weihai), China. The ethical approval protocol number 2020-01.

Informed consent

The data collection process was conducted with strict adherence to ethical considerations. Informed consent was given to all respondents, and respondents were assured that data would be treated confidentially and used only for research purposes. They were also informed that all private information, including their names and companies’ names, would be anonymized in the study results.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Cite this article.

Feng, T., Si, Z., Jiang, W. et al. Supply chain transformational leadership and resilience: the mediating role of ambidextrous business model. Humanit Soc Sci Commun 11 , 628 (2024). https://doi.org/10.1057/s41599-024-03099-x

Download citation

Received : 21 November 2023

Accepted : 23 April 2024

Published : 15 May 2024

DOI : https://doi.org/10.1057/s41599-024-03099-x

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

- History of the SCRC

- SCRC Events

- Diversity, Equity and Inclusion

- Industry Engagement

- Current Partners

- Partner Successes

- Practicum Experience

- Client Project Showcase

- Student Engagement

- Undergraduate Opportunities

- Graduate Research Assistantship

- Graduate Opportunities

- Student Profiles

- Alumni Profiles

- Thought Leaders

- Executive Advisors

- SCM Resources

- SCRC Director’s Blog

- SCM Article Library

- Coronavirus and Supply Chain Management

- Ethical Apparel Index

- Poole Thought Leadership

The Origins and Growth of Supply Chain Management – and the Need for a Common Lexicon

The term “supply chain management” quickly exploded into the public lexicon during COVID, at which time people would often heard saying “blame it on the supply chain”! For the first time in my 35 year career, I was also inundated with calls from the media wanting to know what was going on with our supply chains. Indeed, supply chains were effectively shut down during COVID, and I was closely involved with several federal efforts to obtain critical materials like PPE, drugs, and other initiatives . Over time, the term has grown to the point where most business schools have a Department of Supply Chain Management, academics have expanded the topic to include a variety of specialized areas within the field of supply chain management, including human resources in SCM, urban logistics, transparency in software, human behavior, supply chain nethics, supply chain finance, supply chain analytics, and a host of other issues shown in Table 1. Indeed, the field has also exploded into an entire software industry devoted to a number of various areas, including Manufacturing Planning and Control, OPM, warehouse management systems, transportation management systems, retail assortment planning, and a variety of other areas that are now evaluated annually by Gartner . There is even a “Top Supply Chain Organizations” (which will be revealed for 2024 on May 22) and “Top Supply Chain Universities” competition every year, in which marketing groups scramble to get on the list.

Table 1 – Mapping the Landscape of Supply Chain Management (Handfield, Wieland, and Durach, 2016)

Where did the term supply chain management originate? And how has it become so popular?

The origins of the term was documented in an article by Tim Laseter and Keith Oliver, two consultants from Booz Allen, in 2003. Mr. Oliver claims that the term was born in a discussion with clients in the late 1970s:

Mr. Oliver was formulating his ideas through work with a number of clients, including SKF, Heineken, Hoechst, Cadbury-Schweppes, and Philips. Many of the ideas jelled during an engagement with Philips, the Dutch consumer electronics manufacturer. He began to develop a vision for tearing down the functional silos that separated production, marketing, distribution, sales, and finance to generate a step-function reduction in inventory and a simultaneous improvement in customer service. Looking for a catchy phrase to describe the concept, the consulting team proposed the term integrated inventory management. In a sure sign that consultants should not be allowed near promotional issues, the group expressed confidence that the world would adopt the sophisticated-looking abbreviation I2M .

Later, at a key steering committee meeting, the team shared the vision and introduced the new term and accompanying abbreviation. Eyes glazed over as the phrase failed to resonate with participants. One manager, a Mr. Van t’Hoff, challenged Mr. Oliver to explain what he meant by “I2M.”

“We’re talking about the management of a chain of supply as though it were a single entity,” Mr. Oliver replied, “not a group of disparate functions.”

“ Then why don’t you call it that?” Mr. Van t’Hoff said.

“ Call it what?” Mr. Oliver asked.

“ Total supply chain management. ”

The term was formally introduced to the public in an interview with Mr. Oliver published in a 1982 Financial Times . The term supply chain management (SCM) could have easily disappeared into the history of business jargon. IInstead, SCM rapidly passed into the public domain — a sure indication the concept holds meaning for executives wrestling with the endless challenges of procurement, logistics, operations, sales, and marketing activities that fall within its realm.

However, the term became widely adopted after the publication of the seminal book Introduction to Supply Chain Management i n 1998 which I wrote with my colleague Ernie Nichols , during the time I was at Michigan State. This was a thin paperback that sought to simplify the concepts of supply chain management into a practical framework, and was conceived as the two of us began a conversation around the lack of a common definition for supply chain management. (The book became a best seller, selling more than 25,000 copies and was translated into Japanese, Korean, Chinese, and Russian. It has been cited in almost 5000 different academic journal articles. Who would have thought?)

- In this book, we proposed that the field of supply chain management is based on three simple ideas. First, every organization must make a product or provide a service that someone values . Otherwise, why would the organization exist? Think about it. Manufacturers produce goods that are used directly by consumers or as inputs by other manufacturers. Transportation companies like Schneider provide valuable services by moving and storing these goods. Design firms such use their expertise to design products and create corporate images for customers. The need to provide a valuable product or service holds true for non-profit organizations as well. Consider the variety of needs met by government agencies, charities and religious groups, for example.

- The common thread is that each of the above organizations has an operations function, or operations for short. S imply put, operations is the collection of people, technology, and systems within a company that has primary responsibility for providing the organization’s products or services. Regardless of what career path a student might choose, you will need to know something about your company’s operations.

- As important as the operations area is to a firm, few organizations can – or even want to – do everything themselves. This leads to our third point : Most organizations function as part of larger supply chains . Supply chains encompass all activities associated with the flow of goods from the raw materials stage (extraction), through to the end user, as well as the associated information flows. Supply chains link the operations of many firms together.

I first introduced the concept of supply chains to a group of executives at Michigan State in 1998. I proposed the idea that multiple organizations would be connected together through integrated software systems, and would be able to look at inventory as if through a glass pipeline, being able to see where products were, if they were constrained, and where the bottlenecks were occurring. These executives stared at me as if I had been smoking something…they could never imagine that one day this vision would become a reality.

Although there has been an incredible amount of research in the field and massive advances in supply chain software solutions, there still remains many unsolved problems, and many areas for on-going discovery into research in the field. For instance, there are now different levels of maturity of supply chain performance, that document the progress that organizations are making towards a fully integrated supply chain. ..

The Need for a Standard Supply Chain Lexicon

One of the biggest challenges facing the field is the lack of a standardized lexicon that serves as the foundation for effective global trade communications across industries in different supply chains.

The ASTM F49 International Committee on Digital Information in the Supply Chain is focused on providing the data standards necessary for next generation efficiencies in the global supply chain process covering all major modes of transport: Ocean Full Container, Ocean Less-Than-Container, Short-Sea, Road, Rail and Air. Supply Chains face poor performance of logistics resulting from massive problems and disruptions caused by the current inadequate communication processes. F49 will deliver standardized common language, common processes, and information exchanges that will remove roadblocks to better performance of logistics and Supply Chains.

I am working on a F49 committee founded by the American Society for Testing and Materials, which is working on this very problem. Our early work reveals that there is indeed almost no match in terms between the major non-profit supply chain organizations, including ASCM, CSCMP, GS1 and others. We need supply chain experts to volunteer and help this effort! You will learn a lot, and get to interact with others in moving the field of supply chain management forward!

- Director's Blog

- Facts & Figures

- FLOW: How the Best Supply Chains Thrive

- Information Flows

- LIVING Supply Chain

- Physical Flows

- Relationships

- SCM Features

- SCM Supply Chain Management Definitions & Terms

Journal of Industrial Engineering and Management

Printed Edition

SJR (Scopus)

CiteScore Rank (Scopus)

See more: DOAJ, InRecs...

- For Readers

- For Authors

- For Librarians

- Submissions

- Publication fee

- Indexing & Statistics

Integration of machine learning in the supply chain for decision making: A systematic literature review

Purpose: This study presents a systematic literature review that provides a broad and holistic view of how machine learning can be used and integrated to enhance decision-making in various areas of the supply chain, highlighting its combination with other techniques and models.

Design/methodology/approach: An exhaustive literature review used three sets of keywords in the Scopus and Web of Science (WoS) databases. Through a rigorous filtering process, 70 articles were selected from an initial total of 410, focusing on those that specifically addressed the intersection of machine learning and decision-making in supply chain management.

Findings: Machine learning has proven to be an essential tool in the supply chain, with applications in inventory management, logistics, and transportation, among others. Its integration with other techniques has led to significant advances in decision-making, improving efficiency in complex environments. Combining machine learning methods with traditional techniques has been particularly effective, and integration with emerging technologies has opened up new application possibilities.

Originality/value: Unlike previous studies that focused on specific areas, this study offers a broad perspective on the application of machine learning in the supply chain. Additionally, combining machine learning techniques with other models is highlighted, representing added value for the scientific community and suggesting new avenues for future research.

This work is licensed under a Creative Commons Attribution 4.0 International License

Journal of Industrial Engineering and Management, 2008-2024

Online ISSN: 2013-0953; Print ISSN: 2013-8423; Online DL: B-28744-2008

Publisher: OmniaScience

Lean Supply Chain Management: A Systematic Literature Review of Practices, Barriers and Contextual Factors Inherent to Its Implementation

- First Online: 13 January 2018

Cite this chapter

- Satie Ledoux Takeda Berger 3 ,

- Guilherme Luz Tortorella 3 &

- Carlos Manuel Taboada Rodriguez 3

Part of the book series: Management and Industrial Engineering ((MINEN))

3174 Accesses

17 Citations

The objective of this chapter is to perform a systematic literature review to identify the main Lean Supply Chain Management (LSCM) practices, barriers to such implementation and contextual factors that influence it. Through this literature examination, it is expected to identify the main gaps related to LSCM implementation and discuss the relevance of research in this topic, indicating future research directions. A systematic literature review (SLR) was devised and adopted, which involved the selection, classification, and evaluation of the literature, resulting in a final portfolio of 60 research articles. It is worth noticing that no temporal delimitation of publications was defined. The content of extant LSCM literature was critically analyzed and synthesized from the perspective of the practices, barriers and contextual factors inherent to LSCM implementation. The analysis of extant literature shows that there is a significant increase in studies related to LSCM, especially after 2011. Based on an extensive systematic review of the literature, we consolidated 18 practices, 12 barriers and 8 contextual factors inherent to LSCM implementation. It is noteworthy that most of the studies published to date on LSCM have focused on outlining practices and their potential benefits, inferring that once companies adopt them the lean implementation would be automatically started. However, such implementation throughout the supply chain is extremely difficult and challenging. From the analysis of this portfolio, it was also verified that most researchers address the three topics (practices, barriers and contextual factors) in an isolated way, not correlating them from a holistic perspective. This research expands previous work on LSCM, strengthening of the body of knowledge on the subject and consolidating the main practices of LSCM, barriers and contextual factors inherent to its implementation. The clear identification of these topics may help researchers and practitioners to anticipate occasional difficulties and set the proper expectations along the LSCM implementation.

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

- Available as EPUB and PDF

- Read on any device

- Instant download

- Own it forever

- Compact, lightweight edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

- Durable hardcover edition

Tax calculation will be finalised at checkout

Purchases are for personal use only

Institutional subscriptions

Adamides, E. D., Karacapilidis, N., Pylarinou, H., & Koumanakos, D. (2008). Supporting collaboration in the development and management of lean supply networks. Production Planning and Control, 19, 35–52.

Article Google Scholar

Adebanjo, D., Laosirihongthong, T., & Samaranayake, P. (2016). Prioritizing lean supply chain management initiatives in healthcare service operations: A fuzzy AHP approach. Production Planning and Control, 27, 953–966.

Akkermans, H., Bogerd, P., & Van Doremalen, J. (2004). Travail, transparency and trust: A case study of computer-supported collaborative supply chain planning in high-tech electronics. European Journal of Operational Research, 153, 445–456.

Article MATH Google Scholar

Al-Aomar, R. (2012). A lean construction framework with six sigma rating. International Journal of Lean Six Sigma, 3, 299–314.

Alves Filho, A. G., Cerra, A. L., Maia, J. L., Sacomano Neto, M., & Bonadio, P. V. G. (2004). Pressupostos da gestão da cadeia de suprimentos: Evidências de estudos sobre a indústria automobilística. Gestão & Produção, 11, 275–288.

Anand, G., & Kodali, R. (2008). A conceptual framework for lean supply chain and its implementation. International Journal of Value Chain Management, 2, 313–357.

Ariffin, A. S., Abas, Z., & Baluch, N. H. (2015). Literature ratified knowledge based view of poultry supply chain integration concept. Jurnal Teknologi , 77 (27), 35–39.

Google Scholar

Arif-Uz-Zaman, K., & Ahsan, A. M. M. N. (2014). Lean supply chain performance measurement. International Journal of Productivity and Performance Management, 63, 588–612.

Arkader, R. (2001). The perspective of suppliers on lean supply in a developing country context. Integrated Manufacturing Systems, 12, 87–93.

Azevedo, S. G., Carvalho, H., Duarte, S., & Cruz-Machado, V. (2012). Influence of green and lean upstream supply chain management practices on business sustainability. IEEE Transactions on Engineering Management, 59, 753–765.

Baker, P. (2004). Aligning distribution center operations to supply chain strategy. The International Journal of Logistics Management, 15, 111–123.

Ballou, R. H. (2009). Gerenciamento da Cadeia de Suprimentos . Logística Empresarial Bookman Editora.

Behrouzi, F., & Wong, K. Y. (2011). An investigation and identification of lean supply chain performance measures in the automotive SMES. Scientific Research and Essays, 6, 5239–5252.