The importance of the purchasing function in a company

The corporate purchasing function is an emerging concept no more than thirty years old. This means that academic knowledge is still relatively young compared to other internal departments. For a long time, and still today, it has not been given the importance it deserves. However, the context is increasingly reversing, and purchasing is rising to its rightful status as a strategic function . Purchasing strategy is now being taken to the highest level, and purchasing departments, for example, are now part of the management committees of major corporations. In SMEs, general management is also paying closer attention to purchasing management within the company. On the one hand, this is due to the proposed areas of productivity , and on the other, to the legislative arsenals that are being built up over time: electronic invoicing, supplier compliance, ISO standards and quality controls. This article is a plea for the purchasing function in business, and lists its advantages, proving both its usefulness and its importance for structures in all sectors of activity.

- 1 A brief look at the purchasing function

- 2 Optimal management of resources

- 3 Essential for company performance

- 4 Creating the right conditions for a good purchasing function

A brief look at the purchasing function

The corporate purchasing function covers all aspects of purchasing management . Its main mission is to ensure that the entire purchasing process is properly implemented . It can be run from a purchasing department, or from within your general services department. With its broad scope of activity, it keeps a close eye on the total costs generated by the company’s purchasing policy . Good purchasing management guarantees the financial health of purchasing organizations. More than simply reducing costs on non-production purchases or raw materials, the purchasing function provides a strategic vision , monitoring the quality of products and services purchased, the reliability of supplier relations, areas for optimization, and consolidating strategic partnerships with long-term benefits.

The importance of the purchasing function is becoming more and more a reality within SMEs, as it contributes to economic performance . The attention paid to this function is proportional to the size of the company. It’s for this very reason that groups have set up purchasing departments.

Optimal management of resources

A company can’t function properly if it doesn’t have the resources it needs to run its business. The wider the range of products and services on offer, the greater the number of requirements. It is therefore necessary to make an effort to provide a good framework through a procurement function. Even for small companies, there are a minimum number of actions to be taken to ensure optimal purchasing:

- Keeping track of expenses allocated to purchasing categories, and of likely price variations according to the economic context,

- Knowledge of purchasing parameters such as volume, quality, delivery times, etc.

- Identification of technical skills to identify the levers for optimizing the purchasing process.

Finding the right purchasing strategy is a real necessity for any company. It enables them to master their environment and respond to any situation. A number of risks need to be anticipated , such as uncontrolled purchases, higher-than-anticipated expenditure or, worse still, a supply disruption, as was the case during the health crisis. It also means keeping an eye on the supplier market and the opportunities it provides for your business.

Essential for company performance

In addition to the criteria taken into account in purchasing management that do not directly affect the price of the product or service purchased, the purchasing function prioritizes cost optimization . It analyzes the composition of the price as well as the total cost of the purchase. This work is crucial, as it enables the company to identify the most suitable suppliers and offers . It helps to find the best value for money . In a responsible purchasing approach, it analyzes the supplier’s impact according to several criteria in order to meet CSR (Corporate Social Responsibility) challenges .

The purchasing function also determines the purchasing policy, which defines the line to be followed with regard to the company’s interests. This direction is important, as it reflects the company’s strategic ambitions : sustainable purchasing, social responsibility, ISO standards, etc. It is essential to bear in mind that a purchasing function that complements a sales function contributes to increasing the company’s results . A company that offers quality goods and services is a safe bet for its customers. Encouraging good-quality products is therefore one of the most effective promotional gestures a company can make.

Creating the right conditions for a good purchasing function

For a company to make the most of its purchasing departments, it must have reliable agents to entrust with this task. To achieve this, the search for talent must be carried out through human resources. Among the criteria they must meet is the ability to combine available data to accurately assess the company’s needs. Finally, it is essential that these employees have the data and tools they need to do their job properly . These days, it’s a mistake not to take advantage of digital solutions for the purchasing function. Tools as simple as Microsoft Word Excel spreadsheets are already sufficient for basic actions .

These tools then reach their limits when it comes to collaboration between company players. If a company is to grow, it must not minimize the importance of its purchasing function . It’s something for which it must deploy the necessary resources. That’s why purchasing management software like Weproc offers you a simple and effective service to meet these challenges, with an intuitive interface.

Want to learn more about our procurement management software Weproc? Contact us or request your free 15-minutes demo below!

Weproc is a SaaS software specialized in digitizing the procurement process of companies. From purchase requests to supplier invoicing, through the validation process, Weproc is designed to simplify the purchase management of SMEs and mid-sized companies by centralizing all purchase-related activities.

You may also like

Make or buy: the eternal dilemma.

Who hasn’t heard of Make or Buy, an American theory that is often rhetorical when applied to oneself, but which takes on […]

When should you outsource your procurement process?

There’s no better way to boost your company’s profitability than to adopt a better purchasing policy! The whole process needs to be […]

Implement an effective purchasing policy for your company

In an increasingly competitive economic climate, implementing an effective purchasing policy is essential to optimising expenditure and guaranteeing the long-term future of […]

Recevez chaque mois nos meilleurs articles ! En bonus, nous vous mettons à disposition nos nouveaux modèles de documents en avant première.

Alors, pas mal non ?

- SaaS Solution Weproc

- Free Ressources

- Discover our tool

Want to create or adapt books like this? Learn more about how Pressbooks supports open publishing practices.

1 Introduction to Procurement

Note . From ProPhotoStock, 2014. CC BY 3.0 .

Learning Objectives

- Define procurement and its purpose.

- Understand key procurement objectives.

- Explain procurement roles and activities.

- Analyze the key procurement procedures and processes.

- Evaluate the key steps carried out in managing the procurement process.

What do you know about the procurement process?

Procurement in the supply chain world.

The purpose of this book is to equip the learner with knowledge about the key aspects of procurement and supply management. The chapters are intended to provide an overview and definitions of supply management and procurement. Additionally, key policies, procedures, processes, and requirements for effective and efficient implementation are presented. The effective implementation of procurement activities is a critical function in the overall supply chain process. This chapter further describes the identification of requirements, identification, and qualification of suppliers, supplier bidding and negotiation, approval for purchases, and supplier performance monitoring and performance measurement.

Purchasing and Procurement

The terms procurement and purchasing are often used interchangeably; however, they have important similarities and differences between them. This certification track employs the following definitions for each term:

- Procurement : Procurement is the management of all processes involved in obtaining the goods and services necessary for manufacturing products and providing services to customers. Procurement focuses on sourcing activities, negotiation with suppliers, and the strategic selection of goods and services that enable an organization to maximize value from a select group of key supplier partners.

- Purchasing : Purchasing is a function within the procurement process that is largely transactional and associated with how goods and services are ordered. Purchasing involves receiving and processing purchase requisitions (requirements) and converting them to purchase orders (POs) (awards to suppliers).

A Procurement Example

Procurement professionals interact with a wide array of internal and external organizations; they work with suppliers, other functions in the supply chain, and other functions within the company, such as marketing and engineering. An example of a cereal manufacturing and supply chain process and the key role procurement plays to purchase grain and other raw materials, along with packaging and labelling products needed to make breakfast cereal, the finished product in this example.

In addition, to the raw materials, the company also purchases paperboard from a paper manufacturer and labels from a label manufacturer. In turn, the paper manufacturer purchases trees to make the paper, and the label manufacturer purchases semi-finished stock to make the labels. After making the cereal and packaging it, the cereal manufacturer sends the cereal to the distributor, which then ships the product to the grocery store at which the end customers purchase their cereal. Throughout this sample supply chain, the purchasing of goods and services takes place between various entities.

The example shows how materials and products move from one entity to another while information (e.g., specification, quantities, and desired receiving date) also flows between the various entities. This information flow is important because it is needed to ensure the right products are delivered at the right place, at the right time, and at the right price.

The Importance of Procurement

The procurement function plays a critical role in supporting the ongoing functioning of a firm by ensuring a continuous flow of materials, products, and services to support the firm’s operations while continually seeking opportunities to reduce costs, minimize supply risk, and maintain expected quality levels. The importance of the procurement department can be seen by the key inputs it provides firms, including:

- The raw materials and intermediate goods and services needed in the production of goods and services.

- Finished goods and services required for resale or for operational purposes.

- Capital goods and consumables are needed for the business.

These inputs are critical to a business. The procurement department plays a key role in obtaining these inputs at appropriate levels of cost, quality, and on-time delivery to ensure the continuity of inputs from suppliers. As noted previously, the procurement function plays a vital role in the supply chain; the following list describes several major benefits of effectively managing procurement.

- Cost reduction : Procurement represents an excellent opportunity for saving money because organizations can spend up to 50% or more of their revenues on raw materials, work in process, finished goods, spare parts, services, and other goods needed to keep operations going. Significant savings can be achieved by applying effective procurement techniques.

- Quality improvement : Procurement directly impacts the quality of the overall products sold by companies, because it is responsible for purchasing raw materials and other unfinished or finished goods. The quality of raw and other materials used in producing goods almost always affects the quality of the end products.

- Product enhancement : Procurement can also improve products and process designs by helping introduce new technologies into companies’ product and service offerings. For example, procurement can work with internal and external engineering personnel and suppliers to improve product reliability and performance while also reducing costs.

The 5 Procurement Functions

The main objective of the procurement function is purchasing materials and services at the lowest total cost possible while ensuring the required quality levels and meeting the needs of internal and external customers. Much of this effort entails identifying and negotiating with suppliers to reduce the costs of purchased products and services; however, procurement departments must also consider other items that add to the total cost of procurement, including transportation costs, payment terms, return policies, and warranties.

The five key objectives for a procurement department are: supporting operational requirements, working with other functional groups, partnering with suppliers, supporting organizational goals and objectives, and developing sourcing strategies.

1) Supporting Operational Requirements

Procurement supports the day-to-day operational requirements of a firm by acquiring raw materials, components, subassemblies, finished goods, maintenance, repair items, and services. Procurement aids supply chain elements like transportation and distribution centres (DCs) by ensuring that the end customers receive the replacement parts or finished products they need. Additionally, procurement supports the departments involved in developing new plants or products, installing and commissioning new machinery, and providing replacement parts by ensuring that parts, replacement parts, and machinery are available as needed in the required quantities, at the required quality, and at an appropriate cost.

2) Working with Other Functional Groups

Procurement plays a vital role in ensuring continuity of supply, reducing costs, sourcing from qualified suppliers, and ensuring that the quality of goods and services is maintained. However, procurement cannot accomplish these tasks without a close working relationship with several other functions within a firm, including top management, operations, engineering, marketing, quality assurance, and finance. Procurement works with top management to ensure that the procurement strategy is aligned with the overall organizational strategy and objectives. Procurement has a working relationship with the following functions within a firm shown in the list below.

- Make vs Buy

- Insight into Capacity, Materials, Service Needs

- Requirements in Quality, Cost, Cycle Times

- Insight into Specifications and Requirements

- Support in Value Analysis Exercises

- Insight into Evolving Technologies

- Insight into New Product Development

- Support in Total Cost Analysis

- Sales Forecasting

- Suppliers perform as expected

- Quality training

- Corrective action planning

- Supplier quality planning

- Material re-work costs

- The total cost of an item

- Making or buying products

- Capital acquisition decisions

3) Partnering with Suppliers

Partnerships and effective supplier management have become increasingly important to improve firms’ Supply Chain Management (SCM) competitiveness. For instance, forming partnerships, or strategic alliances, with suppliers allows them to focus on providing quality products and services. This comes about while working closely with key suppliers to develop long-term partnerships based on trust. Additionally, close buyer-supplier relationships offer numerous technical, financial, and strategic advantages, such as opportunities to work together to re-engineer products to lower costs while maintaining functionality. Many companies have adopted a strategy of using a smaller number of suppliers for key products and services rather than working with many suppliers. This strategy is adopted to allow companies to focus their efforts on improving performance and reducing costs with fewer, better suppliers.

Typically, a partnership with suppliers is required to ensure an adequate supply of quality materials overtime at an optimal total acquired cost. A strategic alliance is defined as a purposive relationship between two or more independent firms that involves exchanging, sharing, or co-developing resources and capabilities to achieve mutually relevant benefits (Kale & Singh, 2009). However, once formed, these strategic alliances must be developed through effective relationship management. For example, a company may provide warehouse layout and design services to multiple companies and may work together with a firm that provides the actual storage and handling equipment that support new warehouse designs.

Global competition has grown, and companies have developed supply chains that rely heavily on external suppliers. One well-known example is Apple, which outsources product and component manufacturing. This emphasis on concentrating on core competencies has seen a dramatic rise in outsourcing to, and reliance on, external suppliers to provide not only materials and products but also services (e.g., IT support and design services). As more emphasis is placed on the use of external suppliers, including global suppliers, procurement departments’ roles must also involve close support and management of these suppliers. The procurement function has a vital responsibility to meet the needs of both internal and external customers by choosing products and services with specific criteria. Products and services must come from the best sources of supply and be made to the correct specifications, have the desired levels of quality at a reasonable cost, and be made and delivered in the correct quantities. Products and services must be delivered at the right time and to the satisfaction of internal and external customers.

4) Supporting Organizational Goals and Objectives

In order for a company to grow and remain profitable, procurement can help increase revenues and reduce costs and expenses. Using effective procurement strategies, organizations can position themselves to be competitive on both the quality and pricing of their products and services. By helping to reduce the costs of materials and services, procurement thus improves corporate profit margins and return on assets. Additionally, procurement plays an essential role in ensuring the quality of the goods and services needed by an organization. Organizational goals and objectives can be described under four main categories: survival, growth, finances, and environment. However, procurement goals and objectives are typically expressed using other terms like quality and function, delivery, quantity, price, terms and conditions, and services. A critical first step in developing organizations’ strategies is to develop strategic goals, in which procurement plays a major role. The next step is to translate these goals into specific procurement objectives. According to Monczka, Trent, and Handfield (2005), procurement functions must ultimately support the strategic goals and objectives of the entire organization, including ensuring overall profitability and adequate return on investment for organizations’ shareholders.

5) Developing Sourcing Strategies

Many firms face the challenge of remaining competitive in the face of highly competitive world markets. A firm’s ability to effectively develop and execute strategic plans is a major factor in generating future earnings and can even be critical to the firm’s survival. Organizations must take in more than what they spend on operating costs over the long term if they want to grow and remain profitable. Increasing revenues, decreasing costs, or a mixture of both can accomplish this key goal. Procurement plays an important role in helping accomplish both objectives.

Through effective procurement strategies, organizations can be competitive in the quality and prices of their products and services. For example, reducing the costs of materials and services is an area in which procurement plays a vital role and thus helps to improve corporate profit margins. In many cases, procured goods and services provide a major area of opportunity for reducing costs and improving return on assets. Procurement departments must develop sourcing strategies to support the overall organizational strategy; they aim to ensure the survival and competitiveness of the whole organization. A sourcing strategy is the expression of the goals and objectives for selecting the best sources of supply and optimizing the procurement spend for an organization, which are tied to the overall corporate strategy. For example, a commodity sourcing strategy might develop a specific approach for a category or group of raw materials that maximize quality and minimize cost.

Procurement Roles and Activities

The procurement function seeks to obtain the highest quality of goods and services at the lowest possible costs at the right time and place. To achieve this goal, various roles and activities are performed at different levels of management within the procurement function. Procurement provides an ongoing analysis of price and cost trends. The cost of purchased goods often represents the most significant component of companies’ costs, so procurement functions must analyze the cost of sourcing products and services to ensure they are obtained at the lowest possible cost. Procurement roles and activities consist of the following functions:

- Procurement assists internal departments in defining and documenting material specifications to communicate to suppliers.

- Procurement estimates the future supply needs of organizations, which are then communicated to suppliers.

- Procurement ensures that sourced goods and services meet minimum quality standards in order to meet buyers’ expectations at an acceptable cost.

- Procurement regularly reports on material lead times and supplier performance.

- Procurement draws up contracts and negotiates mutually acceptable terms with suppliers. Procurement conducts market research to identify new suppliers to meet customers’ needs. Procurement expedites and authorized premiums for the delivery of shipments, where necessary, to ensure that production needs are met and deliver appropriate customer order fulfillment.

- Procurement finds and develops best-in-class suppliers. The success of procurement depends on its ability to align supply-based decisions with organizations’ strategic priorities and to identify or develop suppliers, analyze their capabilities, select the most appropriate options, and work with those suppliers to deliver continuous improvement.

- Procurement ensures the uninterrupted flow of materials, supplies, and services required to operate organizations. This prevents stock-outs or late deliveries of materials, components, and services (which can be extremely costly in terms of lost production), reduced revenue or profit, and a decline in customer goodwill.

Types of Buying Organizations

Organizations procure goods and services for different purposes. According to Fill and Fill (2005), here are the primary forms of organization that procure goods and services:

- Commercial organizations : Commercial organizations consist of industrial distributors, original equipment manufacturers (OEMs), users, and retailers. They procure goods as raw materials, components, and finished products for resale. Additionally, the miscellaneous materials and services needed to support running an organization need to be procured. Support items may range from office supplies and real estate to lawn services and health insurance policies.

- Governments : Governments are the biggest procurement customers. They often use procurement to meet small business (e.g., women-owned, veteran-owned, Native American-owned, etc.) objectives, spending many billions annually as a result. Governments’ procurement budget is spent on a wide range of activities, from public hospitals and schools to the organization of the departments themselves.

- Institutions : These include private universities, hospitals, and schools. Institutions buy, for example, textbooks, classroom furniture, medical equipment, audiovisual equipment, and computers.

- Public organizations : Public organizations include railways and nuclear power plants that make purchases for operational and production purposes.

Types of Products and Services Purchased

Procurement personnel are responsible for purchasing many different products and services, depending on the nature of their industry and the nature of their organization. These are examples of different goods and services procurement is responsible for procuring:

- Raw materials : These include products that have not been processed or have undergone only a small degree of processing. They are the basic materials in the production process and become part of final manufactured products. Examples include mined minerals, coal, and cotton.

- Semi-finished goods : They are also known as manufactured products because they have been partially assembled; however, they need further assembly and processing before they can be sold. These products are visible in final products and include elements such as steel and rolled wire.

- Capital equipment : Capital items are usually the most expensive purchases; they include large pieces of equipment used in production processes, such as power generating equipment and buildings.

- Original Equipment Manufacture (OEMs’) component parts : OEMs are products that are purchased for resale or assembled into final products with no further processing. An example of an OEM is the alternator in a motor engine.

- Maintenance, repair, operating materials : Maintenance, repair, and operating materials (MROs) are not directly required for the production process but are important for the continued operation of organizations, such as office and cleaning supplies and other consumables.

- Finished goods : Finished goods require no further processing. They are bought for resale or for use within organizations, such as stock bought for resale by retail organizations.

- Accessory equipment : Accessory equipment includes products used to facilitate production, such as personal computers, hand tools, desktop printers, and toolboxes.

- Services : According to Dwyer and Tanner (2009), services include transportation, advertising, banking, and labour services.

- Major subcontracted items : These include high-cost items used in finished products, such as automobile engines and aircraft engines.

Procurement Process Overview

The procurement process contains steps ranging from working to understanding firms’ needs through ongoing evaluations of supplier performances. These steps are:

- Identifying the Need : A need or requirement may arise from any function but is most often developed through the demand planning process. A need may be raw materials for production purposes or office furniture for administrative departments. User functions sometimes fail to identify needs promptly, which can result in urgent requirements and create challenges for procurement personnel; these challenges can include the need to expedite the supply of goods and the additional costs associated with paying a premium to expedite orders.

- Describing the Product or Service Needed : Requirements are communicated to the procurement function along with the appropriate documents, such as a purchasing requisition. The information contained in the requisition includes the date, originating department, account to be charged, complete descriptions and quantities of materials or services required, date when materials or services are needed, special instructions for shipping or service delivery, and the name of the authorized person initiating the request. As part of the procurement process, procurement professionals work with the person initiating the request to confirm that material and service specifications have been captured correctly. In many cases, engineering drawings and other documents accompany the requisition to describe complex and non-standard items accurately.

- Searching for Potential Suppliers : When appropriate suppliers are not available from a pre-approved list, procurement personnel assume the responsibility for finding other potential suppliers. This search can take place using catalogues, websites, professional organizations, and personal contacts.

- Evaluating and Selecting Suppliers : The critical task of evaluating potential suppliers is accomplished by a multi-function team that conducts a site visit to evaluate a wide range of capabilities, including management, manufacturing planning, process control, quality, and overall workload assessments. While procurement takes the lead, other functions support the evaluation process to ensure a supplier can actually meet the anticipated requirements with smaller standard-item and procurement and catalogue items bought through a published price list, the procurement professional may be able to perform an effective evaluation without assistance.

- Request for Price and Request for Quote Processes : This stage occurs when purchase requisitions are received by purchasing personnel and they initiate a request for price or request for quote (RFQ). Requests for price are initiated and sent to suppliers to obtain pricing for simple, lower-cost items while RFQs involve more complex and expensive items and are sent to suppliers to solicit specifications, pricing, delivery, and other requested information.

- Order Placement : After the request for price and RFQ responses are received, purchasing can place a PO. However, the purchasing buyer and supplier may have completed a negotiating process that included a final agreement on price, delivery arrangements, product requirements, and quality requirements before the buyer actually issues a PO.

- Evaluating Performance : After a supplier has been awarded a PO, it is continually evaluated to determine if its products satisfy the order details stipulated in the PO. Suppliers that provide acceptable products may receive additional orders in the future, but poor supplier performance may lead to removal from the approval database and a lack of future POs. Some procurement departments use supplier scorecards to evaluate supplier performances on quality, delivery timeliness, cost containment, and responsiveness.

Key Takeaways

Procurement is the management of all processes involved in obtaining the goods and services necessary for manufacturing products and providing customer services. Procurement focuses on sourcing activities, negotiations with suppliers, and the strategic selection of goods and services that enable an organization to achieve the best value from a select group of key supplier partners. Procurement functions must have close working relationships with other functions, including production, engineering, and sales and marketing functions because those areas use the products and services that procurement obtains. Organizations of different types are involved in procuring goods and services for different purposes, including commercial and public organizations, governments, and institutions. Stages in the procurement process include receiving requirements for purchase, describing the materials needed, defining and approving suppliers, soliciting suppliers using requests for price and RFQs, placing POs, and evaluating supplier performance.

Review Questions

References .

Dwyer, F. R., & Tanner, F. T. (2009). Business marketing: Connecting strategy, relationships, and learning (4th ed.). New York, NY: McGraw-Hill.

Fill, C., & Fill, K. E. (2005). Business-to-business marketing: Relationships, systems and communications. Harlow, UK: Pearson Education Limited.

Fottrell, Q., & Scheck, J. (2009, January 8). Dell moving Irish operations to Poland. The Wall Street Journal . http://www.wsj.com/articles/SB123141025524864021

Kale, P., & Singh, H. (2009). Managing strategic alliances: What do we know now, and where do we go from here? Academy of Management Perspectives.

Monczka, D., Trent, R., & Handfield, R. (2005). Purchasing and supply chain management (3rd ed.). New York, NY: McGraw-Hill.

ProPhotoStock. (2014, January 5). World technology and business [Image]. Deviantart. https://www.deviantart.com/prophotostock/art/World-Technology-and-Business-424996906 . Licensed for reuse under CC BY 3.0 .

Creative Commons Attribution

This chapter contains material adapted from Supply Management and Procurement Certification Track . LINCS in Supply Chain Management Consortium. March 2017. Version: v2.26. www.LINCSeducation.org .

Procurement in the Supply Chain World Copyright © 2022 by Angela Reid-Regier and Bryan Snage is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License , except where otherwise noted.

Share This Book

Purchasing and Sourcing Strategy in Companies Essay

- To find inspiration for your paper and overcome writer’s block

- As a source of information (ensure proper referencing)

- As a template for you assignment

Introduction

The role of finance function (q1), quality management (q2), supplier development (q3), risks associated with contracts (q4), avoidance of litigation and purchasing performance (q5), forecasting sales (q6), case of ben gibson (q7), calculation of economic order quantity (q8).

This report covers different aspects of procurement by companies. It focuses on the role of the finance function, quality management, supplier development and its challenges, risks associated with different types of contracts, avoidance of litigation, purchasing performance, and acceptance of a discounted price. Furthermore, this report includes calculations of ordering costs and forecasting methods.

The purchase function and finance function work together to furnish purchase orders and fulfill the requirements of the business. The finance department determines the available sources of funds and informs the purchasing department about the possibility of completing their purchases. The purchasing department is related to the operations of a business, which regularly monitors the requirements of the production process to ensure that it does not halt at any time due to the shortage of supplies. It is not concerned with the availability of finance; instead, it is responsible for the continuation of the production process.

Therefore, it places purchase orders to suppliers or sends them to the finance department for approval. This department decides to assess whether the purchase order can be completed or not. The cost of maintaining a certain level of inventory and reordering of supplies also need to be monitored and decided by the finance function. The finance management draws limits to the purchasing that the company can make. It knows the level of funds available and plays a leading role in negotiating the terms of payment with the seller. It is in a better position to negotiate a price discount or a more extended payment period, for example, if the company has cash shortage, then the finance management can negotiate credit terms with suppliers and make payments when the firm’s cash position improves.

In the same way, the finance department is responsible for large accounts receivable and related losses (Lasher, 2017). Therefore, it can be stated that the finance department plays a crucial role in sustaining the financial viability of the business. The purchasing and sale departments cannot operate efficiently without effective management of the finance function.

It is crucial for manufacturing companies to ensure that they have an uninterrupted supply of materials for production. It is argued that quality is an important factor throughout the firm’s supply chain. Moreover, it is essential for the purchasing department to make sure that the desired level of quality is maintained throughout the production cycle, starting from the acquisition of supplies to the development of the final product. The purchasing department works with suppliers so that they comply with its quality requirements. This has a direct impact on the production process and the costs associated with it. If the quality of supplies is unsatisfactory, then the company will incur high costs due to production losses. It implies that the purchasing department needs to perform quality checks at all stages of the supply chain (Musau, 2015). It performs inspections during the manufacturing process and receives quality reports from the production function.

The production department provides its requirements for supplies to the purchasing department, which then works with suppliers to fulfill its requirements, including physical description, dimensional requirements, chemical composition, industry standards, and performance specifications. It ensures that the production process continues without problems and the final product to be delivered to customers meets their demands or specifications. If the process is examined backward, then it could be stated that the purchasing department is responsible for attaining the desired level of quality that the company wants to offer to its customers. It is the responsibility of the purchasing department to find suitable suppliers who can meet the increasing demand for production and, at the same time, do not compromise the quality of supplies (Monczka, Handfield, & Giunipero, 2016).

Supplier development refers to the process through which companies establish and maintain close working relationships with certain suppliers to achieve a high-level of organizational efficiency. In this arrangement, firms work with specific suppliers on a one-to-one basis to assist them and improve their capabilities, performance, and quality that would ensure timely delivery of products and services. Therefore, it is essential for companies to create a network of suppliers who can confirm that their products will meet business requirements (Monczka et al., 2016). Moreover, it helps in lowering the cost of inputs by effectively managing relationships with suppliers. However, it is argued that this is not an easy task, and the outcomes of the firm-supplier relationship are not always fruitful. It often leads to a significant loss to both entities in terms of time and higher costs.

I agree with the statement of Chrysler’s executive as it is not possible to maintain 100% successful relationships between companies and suppliers. It also means that companies must develop relationships with multiple suppliers to avoid any disruption. There are various reasons for the failure of supplier development efforts. The primary reason is the differences in the organizational framework, approach, culture, values, and financial objectives between firms and suppliers. The problems between firms and suppliers intensify in the absence of effective leadership or ownership as most of the vendors are reluctant to commit their resources to innovation or improvement. Although such relationships initiate with common goals, they become difficult to manage as the deal or project expands in scope, and the lack of trust between entities worsens (Genovese, Koh, Kumar, & Tripathi, 2014).

Moreover, expectations on both sides may change, and supplier relationship managers need to address them beyond contractual terms. It is also common that companies and suppliers operate in different markets, which makes it challenging to monitor suppliers’ activities. Furthermore, interventions by the government or regulatory bodies can make it challenging to continue a business arrangement, for example, a Chinese firm is recently banned in the US, which is likely to affect the telecom industry that depends on its products and services. Thus, it could be stated that many uncontrollable factors affect supplier development.

Various risks associated with the three types of contracts, including fixed-price, incentive, and cost-based contracts are discussed in the following.

Fixed-price Contracts

These contracts have a fixed-price term, which means that the price of goods or services cannot be altered based on the contractors’ cost experience. Buyers face the risk of incurring a high cost of procurement (Eckerd & Girth, 2017). It means that the buyer has to pay a higher price despite a reduction in the cost of goods or services. However, fixed-price contracts have the least risk for the buyer. In this case, the Sharpe ratio is 0/100, which implies that the entire burden is on the contractor to make sure that goods or services are rendered within the set time at a price decided in the contract (Nyambuu & Tapiero, 2018).

Incentive Contracts

These contracts combine fixed price and incentive terms, which implies that the buyer pays additional compensation to the contractor if it fulfills all requirements of the contract. In this case, there is a higher risk to buyers in the case of inappropriate incentive measures for assessing the performance of the contractor (Eckerd & Girth, 2017).

Cost-based Contracts

There are three variations of cost-based contracts, namely Cost-Plus-Fee (CPF), Cost-Plus-Fixed-FEE (CPFF), and Cost-Plus-Incentive (CPIF). In all of these contracts, the buyer bears a high risk of paying the cost plus additional compensation (Eckerd & Girth, 2017). If the contractor overruns the procurement cost, the buyer is still responsible for paying this amount.

Litigation is one of the seven different methods of dispute resolution in which the case is submitted to the court and facts are presented to the independent jury that decides the dispute which has to be accepted by all involved parties. However, this method is avoided by many firms in settling contractual disputes due to the high cost of litigation. Moreover, companies prefer alternative methods of resolution that are less time intensive and helpful to avoid a procedure from which it may be difficult for them to recover. It is also noted that there are emotional effects of litigation on the management and employees of companies, which distracts them from their responsibilities. Litigation can also affect the firm’s relationships with other businesses, investors, employees, and customers as the negative outcome of the case can adversely affect its reputation and standing (Malm, Adhikari, Krolikowski, & Sah, 2017).

Effectiveness measures refer to the course of action that the management could follow to achieve the corporate objectives. When assessing purchasing effectiveness, the price paid for supplies is not an appropriate measure. For this purpose, inventory turnover, which determines that the number of times that the company converts its inventory into sales is a more useful measure. The company should focus on purchasing effectiveness measure when there is greater stability in the market or fluctuations in economic conditions are as expected. On the other hand, efficiency measures refer to the difference between planned and actual sacrifices that the management has to make to achieve the corporate objectives. Purchasing efficiency measure is not related to the number of units procured. It relates to the performance of the department responsible for this process. If the department manages its purchases within the budget, then it is considered efficient. The company should focus on purchasing efficiency measure when assessing the internal performance of the firm. Measuring purchasing performance is crucial as it is a crucial part of the firm’s supply chain. In this regard, effectiveness and efficiency measures are useful as they both assist in determining the overall purchasing performance.

The three-month moving average and exponential smoothing forecast are given in Table 1.

Table 1. Forecasting.

| 1 | 58 | ||

| 2 | 79 | ||

| 3 | 52 | 61 | |

| 4 | 68 | 63 | 53 |

| 5 | 81 | 66 | 51 |

| 6 | 79 | 67 | 52 |

| 7 | 76 | 52 |

MAD and MSE are calculated for each forecast in Table 2.

Table 2. MAD and MSE.

| 1 | 58 | |||||

| 2 | 79 | |||||

| 3 | 52 | 0% | ||||

| 4 | 68 | 63 | 5 | 5 | 30 | 7% |

| 5 | 81 | 66 | 15 | 15 | 230 | 18% |

| 6 | 79 | 67 | 12 | 12 | 156 | 15% |

| 7 | 76 | |||||

| MAD | 11 | |||||

| MSE | 139 |

Exponential Smoothing:

| 1 | 58 | |||||

| 2 | 79 | |||||

| 3 | 52 | 61 | (9) | 9 | 90 | 17% |

| 4 | 68 | 53 | 15 | 15 | 237 | 22% |

| 5 | 81 | 51 | 30 | 30 | 944 | 37% |

| 6 | 79 | 52 | 27 | 27 | 770 | 35% |

| 7 | 52 | |||||

| MAD | 20 | |||||

| MSE | 510 |

Based on the results given in Table 2, it is noted that 3-month moving average provides a better forecast as its MAD and MSE is lower. Moreover, error (%) of this method is lower than the exponential forecasting method.

It could be argued that Ben Gibson legally acted as he has the right to seek new suppliers of corrugated boxes, who can sell them at a lower price. The company has the legal right to rebid the corrugated contract and find latest offers. However, it can be stated that Gibson did not act ethically. His decision to initiate the bidding process to put pressure on the present supplier to lower its price of corrugated boxes can be regarded as sharp practices. Such practices fall short of actual fraud as Gibson was involved in misrepresentation of the issue faced by his company. It can be stated that he was willfully creating a competition between suppliers to take advantage of the situation by deceiving its current vendor.

My decision as the marketing manager for Southeastern Corrugated would be not to submit a bid by lowering the price of corrugated boxes. It may be possible to discuss the situation with Coastal Products and negotiate an acceptable price of corrugated boxes. However, if the discussion is unsuccessful, then it is logical for Coastal Products to seek a new supplier.

The assumptions of Economic Order Quantity (EOQ) are given below:

- There is a uniform demand rate throughout the period.

- There is a fixed item cost.

- The ordering and holding cost does not change over the period.

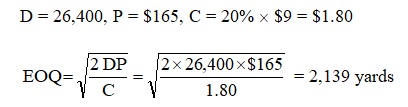

The economic order quantity is calculated in the following.

The number of orders per year is calculated as follows.

26,400 / 2,139 = 12 orders

The order level is determined by determining demand for denim cloth per working day and per week is calculated as follows.

26,400 / 250 = 105.6 yards per day

105.6 x 5 = 528 yards per week

Purchasing lead time = 2 weeks

Order level = 1,056 yards.

The total annual cost for the item is calculated as follows.

Total cost per yard ($9 + $1.80) = $10.80

Total annual cost = $10.80 x 26,400 = $285,120

Acceptance of Discounted Price (Q9)

Vendors often offer a price discount to encourage buyers to buy large quantities. However, the decision to avail this offer depends on the assessment of the business requirements by the purchasing manager. There are various factors which can affect the choice to buy a large quantity of a product at a discounted price. First, the purchasing manager needs to estimate production requirements. Since the company uses this product regularly, it may be feasible for the company to buy it and store it for the full year’s production. However, the storage life of the product and the company’s warehousing capacity should also be evaluated to make sure that it does not incur an inventory loss (Li, 2014). Second, the purchasing manager must consult with the finance department and determine if the benefit of a low price exceeds inventory management and reordering costs to be incurred by the company.

In case if the financial benefit of buying a large quantity of the product is greater than its related costs and expenses, then the purchasing manager should go ahead with it. Third, the finance department will assist by determining the availability of finance as the decision to purchase a large quantity of the product will incur a significant expenditure. Therefore, the purchasing manager should seek approval from the finance department, which will evaluate the use of funds between different alternate investments that the company may be considering. If there are no issues of liquidity, then it will be an appropriate decision to buy the product. Fourth, the purchasing manager should ensure that there are no quality issues with the product. In some cases, vendors try to get rid of their huge stocks by offering a large-quantity discount. Therefore, the manager must conduct an in-depth evaluation of the available product’s quality before accepting this offer.

Calculation of Relevant Cost (Q10)

The calculation of the relevant cost is given in Table 3.

Table 3. Relevant Cost.

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |||

| 2×3 | 5×6 | ||||||||

| Purchasing costs | $14.02 | per unit | 13,000 | $182,260 | $13.80 | per unit | 13,000 | $179,400.00 | |

| Ordering costs | 2.00 | per order | 130 | 260 | 2.00 | per order | 130 | 260 | |

| Inspection costs | 0.05 | per unit | – | 0 | 0.05 | per unit | 13,000 | 650 | |

| Opportunity carrying costs | 2.10 | per unit of average inventory per year | 50 | 105 | 2.07 | per unit of average inventory per year | 50 | 103.5 | |

| Other carrying costs (insurance, materials handling, and so on) | 3.10 | per unit of average inventory per year | 50 | 155 | 3.00 | per unit of average inventory per year | 50 | 150 | |

| Customer return costs | 10.00 | per unit returned | – | 0 | 10.00 | per unit returned | 325 | 3250 | |

| Stockout costs | 4.00 | per unit | 150 | 600 | 4.00 | per unit | 360 | 1440 | |

| Total annual relevant costs | $183,380 | $185,254 | |||||||

| Annual difference in favor of Sontkek | $1,874 | ||||||||

Table 3 shows that the total annual relevant cost when choosing Sontek is $183,380, and that of Denton is $185,254. John should buy from Sontek as there is an annual difference in favor of this supplier.

Calculation of Safety Stock (Q11)

The calculation of the safety stock is given in Table 4.

| 0 | 700 | 100 | 0.09 | $500 | 15 | $675 | ||

| 800 | 200 | 0.06 | $1,000 | 15 | $900 | |||

| 15 | ||||||||

| $1,575 | $0 | $1,575 | ||||||

| 100 | 800 | 100 | 0.06 | $500 | 15 | $450 | ||

| 15 | – | |||||||

| $450 | $500 | $950 | ||||||

| 200 | – | – | – | – | 15 | $0 | ||

| 15 | $500 | $500 |

The most likely demand is 600 units for two weeks as it has the highest probability, as shown in Table 4. Since the carrying cost is not identified, it is assumed to be $5. Stockouts can occur if demand is 700 and 800. If the demand is less than 600, there will be no stockout costs, but it will have carrying costs.

Eckerd, A., & Girth, A. M. (2017). Designing the buyer–supplier contract for risk management: Assessing complexity and mission criticality. Journal of Supply Chain Management, 53 (3), 60-75.

Genovese, A., Koh, S. L., Kumar, N., & Tripathi, P. K. (2014). Exploring the challenges in implementing supplier environmental performance measurement models: A case study. Journal Production Planning & Control – The Management of Operations, 25 (13-14), 1198-1211.

Lasher, W. R. (2017). Practical financial management. Boston, MA: Cengage Learning.

Li, X. (2014). Operations management of logistics and supply chain: Issues and directions. Discrete Dynamics in Nature and Society, 2014 , Web.

Malm, J., Adhikari, H. P., Krolikowski, M., & Sah, N. (2017). Litigation risk and investment policy. Journal of Economics and Finance, 41 (4), 829–840.

Monczka, R. M., Handfield, R. B., & Giunipero, L. C. (2016). Purchasing and supply chain management (6th ed.). Boston, MA: Cengage Learning.

Musau, E. G. (2015). Determinants of procurement function and its role in organizational effectiveness. IOSR Journal of Business and Management, 17 (2), 12-25.

Nyambuu, U., & Tapiero, C. S. (2018). Globalization, gating, and risk finance. Hoboken, NJ: John Wiley & Sons.

- Abu Dhabi National Oil Company: Supply Chain Management

- Supply Chain Management and Trading System Definition

- A Proper Pattern of Supply Chain Management

- Consolidated Electric Company's Inventory Control System

- Sustainable Sourcing and Procurement at Tesla

- Agile Supply Chain in the Fashion Industry

- Zara, H&M, United Colors of Benetton: Supplying Fast Fashion

- Walmart China's Transportation and Warehousing

- Outsourcing the Cleaning Services of Abu Dhabi National Oil Company

- Apple Incorporation: Supply Chain Management

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2021, July 17). Purchasing and Sourcing Strategy in Companies. https://ivypanda.com/essays/purchasing-and-sourcing-strategy-in-companies/

"Purchasing and Sourcing Strategy in Companies." IvyPanda , 17 July 2021, ivypanda.com/essays/purchasing-and-sourcing-strategy-in-companies/.

IvyPanda . (2021) 'Purchasing and Sourcing Strategy in Companies'. 17 July.

IvyPanda . 2021. "Purchasing and Sourcing Strategy in Companies." July 17, 2021. https://ivypanda.com/essays/purchasing-and-sourcing-strategy-in-companies/.

1. IvyPanda . "Purchasing and Sourcing Strategy in Companies." July 17, 2021. https://ivypanda.com/essays/purchasing-and-sourcing-strategy-in-companies/.

Bibliography

IvyPanda . "Purchasing and Sourcing Strategy in Companies." July 17, 2021. https://ivypanda.com/essays/purchasing-and-sourcing-strategy-in-companies/.

The Role of The Purchasing and Supply Functions

Cite this chapter.

832 Accesses

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Compact, lightweight edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

- Durable hardcover edition

Tax calculation will be finalised at checkout

Purchases are for personal use only

Institutional subscriptions

Unable to display preview. Download preview PDF.

Rights and permissions

Reprints and permissions

Copyright information

© 2004 Kluwer Academic Publishers

About this chapter

(2004). The Role of The Purchasing and Supply Functions. In: Global Purchasing and Supply Management. Springer, Boston, MA. https://doi.org/10.1007/1-4020-7817-X_1

Download citation

DOI : https://doi.org/10.1007/1-4020-7817-X_1

Publisher Name : Springer, Boston, MA

Print ISBN : 978-1-4020-7816-3

Online ISBN : 978-1-4020-7817-0

eBook Packages : Springer Book Archive

Share this chapter

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Publish with us

Policies and ethics

- Find a journal

- Track your research

Sample details

- Words: 2195

- Views: 1,174

Related Topics

- Business Process

- British Airways

- Minimum Wage

- Mission Statement

- Business Model

- Swot Analysis

- Corporation

- Procurement

- Foreign Policy

- Economic Development

- Benchmarking

The Purchasing Function Business

The buying map is described by Lysons and Gillingham ( 2003 ) as a map with resource to secure supplies. It is normally argued that the buying map is non strategically of import to enable administrations to derive competitory advantage. Carr and Pearson ( 2002 ) described nonstrategic buying as a map that is clerical in nature, reactive to other maps and concentrating on short-run issues. Ramsay and Croom ( 2008 ) on the other manus saw buying as a strategic map that contributes to the overall organizational competitory advantage. But Reck and Long in Carr and Pearson ( 2002 ) argues that buying map of a house can run between strategic and nonstrategic degrees within an administration. There is now a inquiry as to whether buying should still be sing the nonstrategic function of the buying map. This paper will be looking the function of buying that brand makes it strategic and how purchasing map is strategically of import in deriving competitory advantage for the administration with the assistance of theoretical account and tools/techniques for buying.

Buying is normally defined as obtaining the right quality stuff, at the right clip, in the right measure, from the right beginning, at the right topographic point ( Lysons and Gillingham 2003 ; Baily et al. 1998 ) . Van Weele ( 2005 ) besides defined buying as the direction of the company ‘s external supply of goods, services, capablenesss necessary for running, keeping and pull offing the company ‘s primary and support activities is secured at the most favorable conditions. Although, there is no in agreement definition of buying from literature, these definitions indicate that there is demand for supply necessitating to finding of specifications, supply continuity by taking a suited provider, efficient purchasing ( worth the value ) , and relationship to guarantee supply at the right clip to pull off stock list and proctor efficiency of providers thereby specifying the buying map.

ready to help you now

Without paying upfront

Many writers in the literature have identified the developments in buying. Reck and Long in Lysons and Gillingham 2003 identified that buying base on ballss through phases from passive ( no strategic way and supplier choice based on monetary value and handiness ) , independent ( buying holding functional efficiency with no respects to tauten ‘s competitory scheme ) , supportive ( supports the corporate scheme with respects to the competitory aim ) to integrative ( full integrating of buying scheme into the house ‘s corporate scheme ) stages to go a competitory arm for an administration. Van Weele ( 2005 ) besides identified that demand for decreased costs, merchandise standardization, invention, stock decrease, addition flexibleness, and buying synergisms can better an administration ‘s competitory place. In add-on, alterations in trade form, client demands, engineering, rival activity in the have wider concern context has affected the development of buying. An indicant of this is that an addition the importance of buying gives the administration the capableness to fulfill its clients ‘ demands by concentrating on activities that ensures quality merchandises of good values are produced in line with the administration ‘s competitory scheme.

Carr and Smeltzer ( 1997 ) were able to do a differentiation between buying scheme and strategic buying. Specifying buying scheme as the specific actions the buying map may take to accomplish its aims. While strategic buying was defined as the procedure of planning, measuring, implementing, and commanding schemes the buying follows. It is gathered from these definitions that the actions of the scheme of the buying map must be in line with the overall corporate scheme of the administration be it cost or distinction as identified by Porter ( 1985 ) and that the strategic buying must be able to direct the buying maps to guarantee that the long-run ends are achieved and the administration remains competitory. Although, there may be nonstrategic buying maps due to the low position and spend of the administration ( Carr and Pearson 2002 ) , strategic buying maps must be given top direction consideration as it is proactively involved accomplishing the house ‘s ends and adding value to the administration. However, this may merely go on when the buying map is integrated into the house ‘s strategic planning procedure and is thought of every bit of import to accomplish and keep a sustainable competitory advantage as concluded by Goh, Lau and Neo ( 1999 ) .

Strategic buying has been seen by many writers as impacting house public presentation, particularly in relation to supplier engagement. It was argued by Chen, Paulraj and Lado ( 2004 ) that strategic buying gives a competitory advantage by furthering closer working relationships with a limited figure of providers ; advance unfastened communicating among supply-chain spouses ; develop long-run strategic relationship orientation to accomplish common additions. Carr and Pearson ( 2002 ) besides argued importance of buying to new merchandise development as respects to choosing qualified providers every bit good as the engagement for merchandise development while McGinnis and Vallopra ( 1999 ) argued that buying and provider engagement contributes to higher merchandise quality, accomplishment of cost aims, and cut down new merchandise time-to-market. Besides Brookshaw and Terziovski ( 1997 ) ; Krause, Pagell and Curkovic ( 2001 ) were able to reason that strategic buying is capable of retaining a steadfast competitory precedences of quality, cost, bringing, dependability through the relationship with providers In other words, strategic buying with respects providers engagement can better an administration ‘s public presentation and client reactivity if involved in the planning procedure thereby increasing the house ‘s net incomes while deriving competitory advantage.

Addition in administration ‘s costs spent on buying activities from external beginnings as identified by Ramsay and Croom ( 2008 ) ; Baily et Al. ( 1998 ) indicates the demand for decrease in direct stuffs cost and net capital employed by administrations. Purchasing is able to accomplish these decreases with the usage of buying policies like competitory command and coaction with providers to do determinations that guarantee quality and logistics arrangement thereby salvaging cost and adding to the administration ‘s bottom line. Strategically puting buying in administrations ‘ determination devising procedure gives it command on buying costs and ability to take a provider base that is competitory and better than competition.

The demand for strategic cost direction and collaborative invention and designs, which may necessitate working with external provider has made administrations rethink their place in the value system and has resulted in the concern determination of automatizing or outsourcing non-critical maps go forthing more strategic buying undertakings. Outsourcing comes from a determination of an administration to concentrate on its nucleus activities ( Van Weele 2005 ) . This determination is reached when the administration discovered that executing a map in-house can no longer be carried out competitively, so outsourcing the map to a more proactive administration allows the advantage to be gained ( Baily et al. 1998 ) .

In add-on, it is non merely plenty to do outsourcing determinations, the choice of providers that will lend to the organizational ends is critical. Before choosing providers, Gadde and H & A ; aring ; kansson ( 1994 ) argued that the buying scheme must be decided, be it individual, parallel, multiple sourcing. But Svahn and Westerlund ( 2009 ) emphasised that the features of the buying scheme, efficiency ( cost-driven ) or effectivity ( invention and value-adding ) , affects supplier choice and manner buying manages the relationship with providers in line with the administrations competitory scheme. Buying must be able to measure the capablenesss of the providers through a series tools like e-procurement, buying portfolio direction, collaborative tools to place providers that can enable the house addition competitory advantage.

Drake and Lee ( 2008 ) , through the usage of Analytic Hierarchy Process ( AHP ) were able to underscore the importance of alining buying scheme with concern scheme. They argued that buying through AHP is able to prioritize the importance of constituents for fabrication or impact on the strategic precedences and that buying is able to guarantee the uninterrupted flow of stuffs through choice of providers in such a manner to run into the corporate scheme and competitory precedences ( quality, cost, velocity, flexibleness ) of the house.

Buying portfolio analysis suggested by Kraljic ( 1983 ) is an of import theoretical account for strategic buying. Kraljic was able to reason that a house ‘s supply scheme depends on two factors: net income impact and supply hazard and with that identified 4 portfolio quarter-circles: strategic, purchase, constriction and modus operandi. This theoretical account proposes that buying schemes must be chosen for each provider. Van Weele ( 2005 ) besides emphasised that a company ‘s spend can be categorised utilizing the 20:80 regulation ; which says 20 per centum of providers provide 80 per centum of supplies and evaluate providers harmonizing to precedence. From these two positions, buying must be able to place the providers of critical to non-critical merchandises and develop schemes that guarantee minimum supply hazard and increase purchasing power. Besides, Baily et. Al ( 2005 ) suggested that tiering of providers can assist place of import providers and better partnership with them. Wagner and Johnson ( 2004 ) argued that carefully configured, developed, and managed supplier portfolio can lend to the house ‘s value creative activity and competitory advantage. At this point, buying must hold a proactive attack to doing certain that it identifies supplier that contributes to the administration the competitory advantage needed.

Another importance of buying particularly when purchasing capital goods is that it focuses on entire cost direction. Most purchasing procedures are normally based on the monetary value as indicated by Baily et at. ( 1998 ) ; Van Weele ( 2005 ) . Baily et at. ( 1998 ) sees buying as of strategic importance as it able to concentrate on the entire acquisition cost than monetary value and bears in head the entire cost of ownership of capital goods like cost of care, trim parts in the long term. Purchasing is able to lend to the specifications by informing to other maps of bringing dependability, guaranting timely supply of necessary inputs to guarantee that the initial purchase monetary value entirely is considered but instead the entire life-time cost of equipments are considered to do certain buying is adding value to the administration by cut downing cost over clip. Again common relationship with providers can convey approximately cost, monetary value decrease and finally cost transparence as supported by Scating ( 1993 ) .

E-procurement is another strategic tool for buying that can lend to competitory advantage due to its immense cost nest eggs. William ( 2003 ) argued that E-procurement cuts across the whole buying procedure and helps ease early provider engagement every bit good as minimise complexnesss and unneeded costs as real-time information is shared between purchaser and marketer, it besides gives top direction visibleness as they are concerned with the increased operational spend. E-procurement has contributed to the success of many administrations, for case, Volvo ‘s provider choice ( Van Weele 2010 ) and Gap Inc. to cut down lead-time and overall operations of its retail channels ( Demery 2006 ) . Despite the benefits of e-procurement, if top direction do non strategically originate the demand for e-procurement, the benefits of it giving an administration competitory advantage are lost.

Conversely, after much consideration of the importance of strategic buying to derive competitory advantage, it is necessary to concentrate on non-strategic buying and why it is seen as non of import to derive competitory advantage. A nonstrategic buying map is task-oriented, while a strategic map makes concern determinations as argued by Carr and Smeltzer ( 2000 ) . Carr and Pearson ( 2002 ) besides argue that non-strategic buying has no part to the long-run ends of the house, are undistinguished and of low position. Indeed, if top direction of an administration does non see the importance in the buying function in lending to competitory advantage, it will go on to be seen as non-value adding and merely focussing of activities that are non-critical to the successful operation of the administration.

Wholly, the development in buying over clip has shown that there is a demand by administrations to integrate into their corporate policies buying scheme. Strategic engagement of buying for the overall purpose of commanding monetary values, cut downing costs, pull offing supply proactively, and bettering quality to successfully present goods and services that will fulfill the end-customers and enable the administration addition sustainable competitory advantage is indispensable.

At the bosom of conventional wisdom lies the statement that buying is non strategically of import for the administration to derive competitory advantage. This statement is seen as ungrounded due to the fact that buying is deriving importance within the academe and the concern environment. The demand for decrease of costs, betterment of value-added into the concern, better underside line has led to the improved relevancy of buying to the public presentation of an administration. Buying has over the old ages developed from non-strategic, transactional phase of securing supplies to a strategic, incorporate phase that focuses proactively on the entire satisfaction of both internal and external clients of an administration. Again, the alteration of buying to strategic buying, integrating buying scheme into the corporate scheme, for accomplishing competitory advantage has changed the position of administrations and has led to a reconsideration of the administration ‘s operation to make up one’s mind the nucleus competencies and non-core competencies and instead concentrate on the nucleus 1s and beginnings others from external beginnings. However, sourcing externally requires effectual provider relationship direction. Buying in this facet is able to choose providers that with collaborate in run intoing the administration ‘s competitory scheme. Buying is besides able to utilize tools and techniques like e-procurement and entire cost of ownership attack along with their accomplishments to pull off buying costs and balance power and dependance between the company and provider every bit good as work out schemes to utilize with different providers. Without giving a strategic importance of buying, an administration ‘s chances of addition competitory advantage may be missed.

Cite this page

https://graduateway.com/the-purchasing-function-business-essay-essay/

You can get a custom paper by one of our expert writers

- Board of directors

- Enterprise Resource Planning

- Collaboration

Check more samples on your topics

A study on green purchasing behavior.

Abstract Period of study – the study was conducted from September 2011 to January 2012 Purpose – the purpose of this paper are to identify the influence factors of green purchasing behavior of university students in Jakarta and to find out whether there is any gender differences Methodology – using convenience sampling, there was 200 university

Consumer Behaviour: Purchasing Sports Cars

Executive summary Consumer behaviour entails studying when, why, where, what and how consumers buy or do not buy a product or use a service. It mixes aspects from sociology, psychology, anthropology as well as economics. As Schiffman and Kanuk (2007) explain, consumer behaviour tries to comprehend the consumer decision making processes, as an individual and also

Factors Affecting Eco-Car Purchasing Decision for Thai Consumers

Title: Factors affecting Eco-Car purchasing decision for Thai consumers Introduction On the 13 September, 2011 Thai government have pass the policy to return the tax to first car buyers who purchase eco-car which have the engine size not larger than 1500 C. C. and price not more than 1,000,000THB. As we know Thailand is a net energy-importing

Purchasing Power Parity

1. The relationship between exchange rates and inflation levels of two countries can impact Blades' Thai revenue and costs, as the baht is freely floating. This connection's effect on Blades can be understood through the purchasing power parity (PPP) theory, which states that if one country has a higher inflation rate than another, there will

Marketing: Consumer Purchasing Decision Process

Marketing: Consumer Purchasing Decision Process Introduction In popular usage, the promotion of the products is known as the Marketing, where the advertising and branding of various products plays the vital role in this process. However, in broader and professional terms, a process that focuses the customer as its center and most important object for the selling of

Drink Market – Consumers Purchasing Behavior

Soft drinks are non-alcoholic water-based flavoured drinks that are optionally sweetened. acidulated and carbonated. Some carbonated soft drinks besides contain caffeine ; chiefly the brown-coloured Cola drinks. PROBLEM STATEMENT To happen out consumers purchasing behavior and to place spreads in the industry if any. RESEARCH OBJECTIVE To happen out the factors impacting soft drinks purchasing

Future Trends in Purchasing

Future Trends in Purchasing Purchasing has become an important function of the organization. The purchasing team must understand the goals and business strategy of the organization. Purchasing and inventory management will have a huge impact on the company’s bottom line. Part of the purchasing process is dealing with foreign suppliers and e-procurement. The purchasing personal

Expanding Capacity Without Purchasing New Equipment

Knowing this, I then take my output per hour and divide it by 16-hour days to find the actual production rate. B. Analyze where the focus of the company's efforts should be if Beck wants to expand capacity. Determine how much extra capacity he can get without causing another operation to become the bottleneck. From

Situational Influences On Purchasing Behavior

There was an investigation in an attempt to understand what situational influences affect purchasing behaviors of consumers. Fifty subjects were asked to complete a survey in determining what attributes affect the decision to purchase a product. The effect of purchase was based on three different times of day: morning, afternoon, and evening. The effect of

Hi, my name is Amy 👋

In case you can't find a relevant example, our professional writers are ready to help you write a unique paper. Just talk to our smart assistant Amy and she'll connect you with the best match.

IMAGES

VIDEO

COMMENTS

The purchasing function is described by Lysons and Gillingham (2003) as a function with resource to procure supplies. It is usually argued that the purchasing function is not strategically important to enable organisations to gain competitive advantage. Carr and Pearson (2002) described nonstrategic purchasing as a function that is clerical in ...

Purchasing is the function in a firm responsible for the professional management of a firm's interface with the supply market, to ensure its supply with the necessary goods and services provided ...

Strategic purchasing entails planning, implementation, evaluation, and controlling of strategic and operating purchasing decisions for directing all activities of the purchasing function toward opportunities consistent with the firm's ability to achieve its long-term goals. Three properties together form strategic purchasing as a holistic and ...

The purchasing function is described by Lysons and Gillingham (2003) as a function with resource to procure supplies. It is usually argued that the purchasing function is not strategically important to enable organisations to gain competitive advantage. Carr and Pearson (2002) described nonstrategic purchasing as a function that is clerical in ...

The purpose of this paper is to identify the major changes that have taken place in the role of the purchasing function in organizations over the last two decades. These are as follows: The purchasing function is taking on a more strategic role in many organizations. An emerging view is that the purchasing function should be on an equal level ...

An organisations purchasing or procurement department supports the strategic and operational goals of that firm by managing the purchases of input goods/services needed (Baily et al., 2015). The role includes the purchase of the right goods and services, at the right price/quality, delivered to the right place and being on time (Booth, 2010).

3. Explore the basic historical development of the purchasing function. 4. Understand the evolution of the basic supply management concept. 5. Differentiate between purchasing, supply management, and supply chain management. 6. Understand the relationship between the purchasing function and inventory, ordering, and transportation costs. 7.

The corporate purchasing function is an emerging concept no more than thirty years old. This means that academic knowledge is still relatively young compared to other internal departments. For a long time, and still today, it has not been given the importance it deserves. However, the context is increasingly reversing, and purchasing is rising to its rightful status as a strategic function.

Abstract. Purchasing is indeed an unusual and multifaceted job. It operates at the vital intersection between buyer and seller, where supply and demand forces meet. As such, its scope is broad, encompassing both internal and external elements of supply interaction. Download to read the full chapter text.