Dezeen Magazine dezeen-logo dezeen-logo

Ten future materials that could change the way we build

Following news that hemp could be used as a low-cost, low-carbon way of reinforcing concrete , here are 10 promising new construction materials including plastic that's stronger than steel and 3D-printed mushroom columns .

Researchers are developing materials that perform better or that tread more lightly on the planet – and ideally do both.

In the near future, natural materials including hemp and mycelium as well as synthetic ones such as carbon fibre and high-performance plastics could play a much bigger part in the construction process.

Here are ten innovative new materials from our archive:

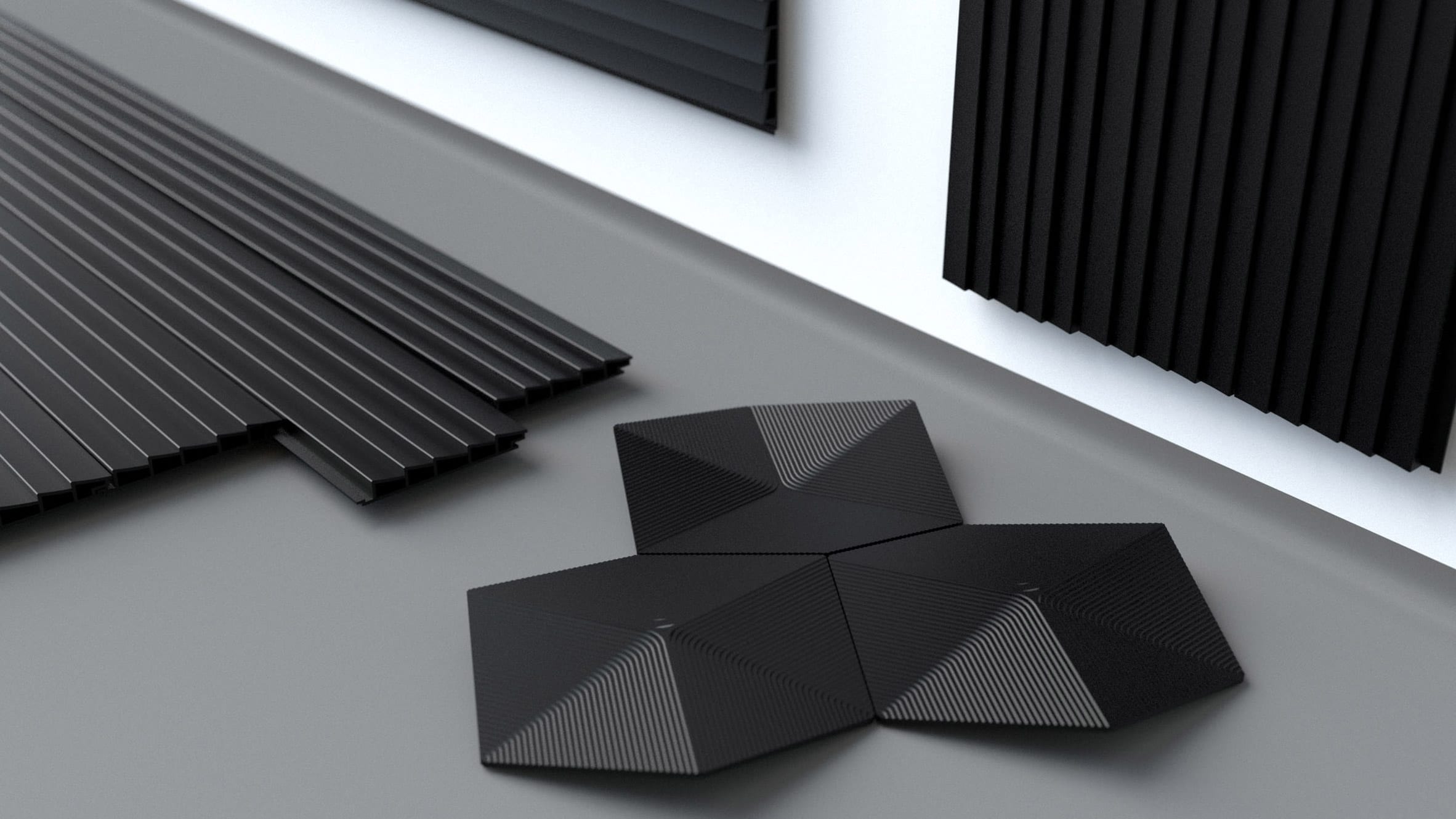

Biochar cladding

German start-up Made of Air produces bioplastic from forest and farm waste that sequesters carbon and can be used to make objects including cladding.

Hexagonal panels dubbed HexChar were installed on an Audi dealership in Munich last year, marking the first time the product had been used on a building.

Find out more about biochar cladding ›

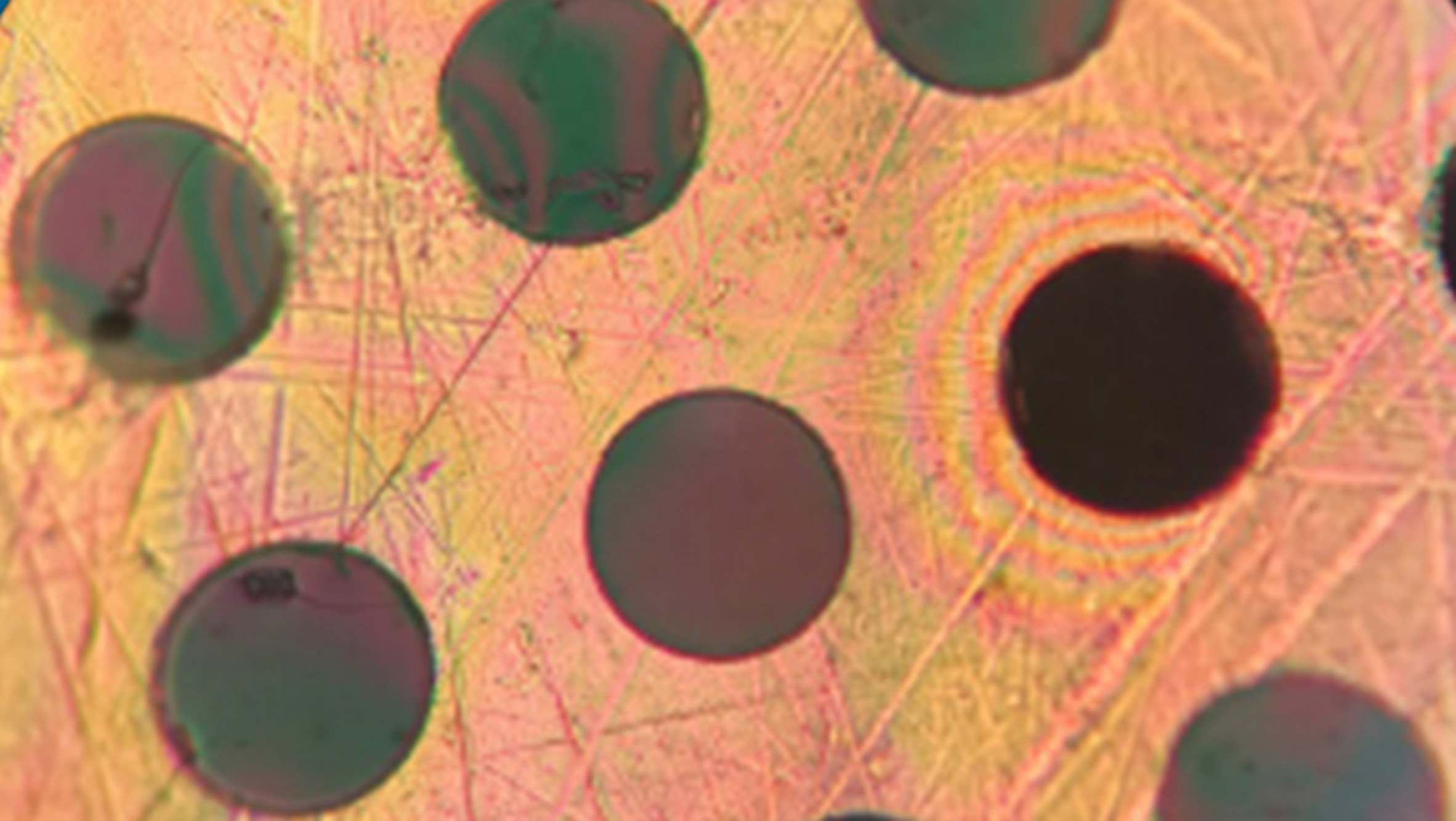

Carbon-fibre reinforced concrete

This newly developed type of concrete is strengthened with carbon-fibre yarn, so far less concrete is needed for a structure of the same strength.

Researchers at the Technical University of Dresden have been working with German architecture firm Henn to create the building made from this "carbon concrete", which will be named The Cube.

Find out more about carbon-fibre reinforced concrete ›

Super-strong plastic

Invented by Massachusetts Institute of Technology chemical engineers, 2DPA-1 is light and mouldable like all plastics, while being twice as strong as steel.

Synthesised using a new polymerisation process, it will first be used as an ultrathin coating to enhance the durability of objects, but could one day be developed into a structural reinforcement material for buildings.

Find out more about 2DPA-1 ›

3D-printed mycelium

There are many ways of using mycelium , which is the branching, vegetative part of a fungus, for construction.

One is Blast Studio's 3D-printing method, which the London practice used to make a two-metre-high column that can be used as a load-bearing architectural element. It also yields a mushroom crop.

Find out more about 3D-printed mycelium ›

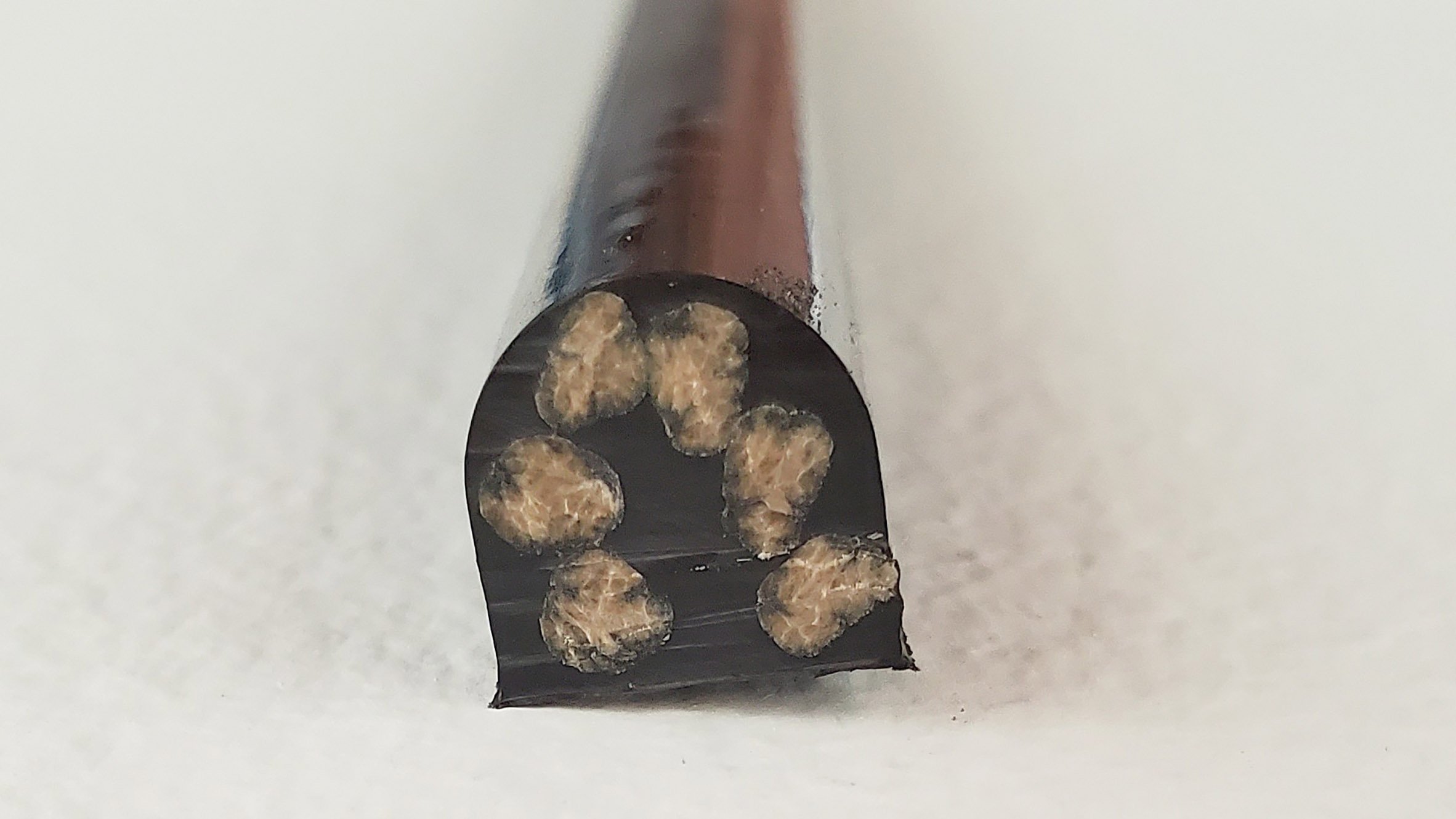

Made of one of the world's most carbon-sequestering plants, hemp rebar is currently in development at the USA's Rensselaer Polytechnic Institute.

It aims to be a low-cost, low-carbon alternative to standard steel rebar that also avoids the problem of corrosion, extending the lifespan of concrete structures.

Find out more about hemp rebar ›

Carbon-sequestering Carbicrete

Canadian company Carbicrete has developed a method for sequestering carbon in concrete, claiming its product captures more carbon than it emits.

Instead of calcium-based cement, which is highly CO2 emitting, Carbicrete relies on waste slag from the steel industry plus carbon captured from industrial plants. It has been used to make concrete masonry units and precast panels.

Find out more about carbon-sequestering Carbicrete ›

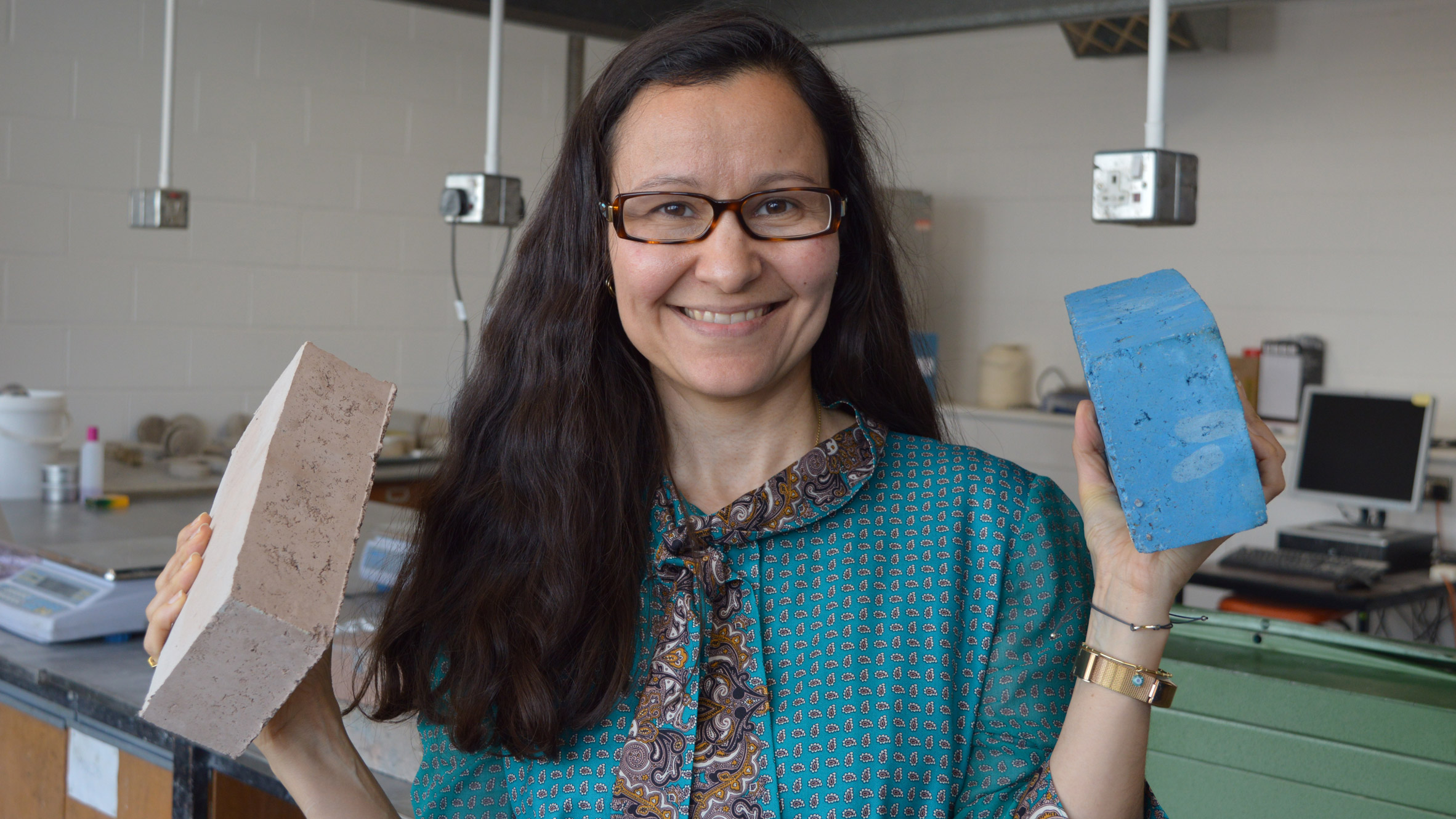

K-Briq construction waste bricks

Invented by engineering professor Gabriela Medero at Edinburgh's Heriot-Watt University and launched through her startup Kenoteq, the K-Briq is made of 90 per cent construction waste and is unfired.

The low-carbon alternative to regular bricks is already available to order in standard or bespoke colours.

Find out more about K-Briq ›

Chipboard from potato peelings

London-based designers Rowan Minkley and Robert Nicoll created this eco-friendly alternative to single-use materials like MDF and chipboard.

Called Chip[s] Board, it is created from potato peelings and made without formaldehyde or other toxic resins, and can be used as a building material.

Find out more about chipboard from potato peelings ›

Green Charcoal loofah bricks

Engineered by researchers at the Indian School of Design and Innovation in Mumbai, these bio-bricks are made of soil, cement, charcoal and organic luffa fibres – better known as loofah, the plant commonly used for bath sponges.

The natural gaps in the loofah's fibrous network enable the bricks to double as a home for animal and plant life, increasing the biodiversity of cities.

Find out more about Green Charcoal loofah bricks ›

Waste paper construction board

Honext's construction board is made of paper that has already gone through several reuse cycles, meaning that the remaining cellulose fibres are too short to be bound together in order for it to be made into paper again.

Honext mixes together the waste cellulose fibres with water and enzymes to make the boards, which can be used for interior partitioning or cladding.

Find out more about waste paper construction board ›

Dezeen is on WeChat!

Click here to read the Chinese version of this article on Dezeen's official WeChat account, where we publish daily architecture and design news and projects in Simplified Chinese.

- Architecture

Subscribe to our newsletters

A quarterly newsletter rounding up a selection of recently launched products by designers and studios, published on Dezeen Showroom.

Our most popular newsletter, formerly known as Dezeen Weekly, is sent every Tuesday and features a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

Sent every Thursday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and invitations to Dezeen events.

A daily newsletter containing the latest stories from Dezeen.

Daily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Weekly updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

News about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

News from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates and invitations to Dezeen events.

News about our Dezeen Awards China programme, including entry deadlines and announcements. Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected] .

For more details, please see our privacy notice .

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

- Discovery Platform

- Innovation Scouting

- Startup Scouting

- Technology Scouting

- Tech Supplier Scouting

- Venture Clienting

- Startup Program

- Trend Intelligence

- Business Intelligence

- All Industries

- Industry 4.0

- Manufacturing

- Case Studies

- Research & Development

- Corporate Strategy

- Corporate Innovation

- Open Innovation

- New Business Development

- Product Development

Share this:

- Click to share on Facebook (Opens in new window)

- Click to share on Twitter (Opens in new window)

- Click to share on LinkedIn (Opens in new window)

Explore the Top 10 Material Trends & Innovations in 2025

Delve into the world of novel materials & their role in enhancing productivity and sustainability across industries. Our extensive research covers the latest material trends, analyzing insights from 2453 companies. This includes key developments in green materials, nanotechnology, 3D printing, material informatics, and more!

The ongoing changes in the energy, automotive, logistics, manufacturing, and construction sectors, coupled with the advancements of Industry 4.0, are fueling the demand for novel materials. These material trends encompass a variety of solutions, including sustainability-focused materials, lightweighting, 3D printing applications, and surface engineering, as well as the creation of smart materials, nano-formulations, and advanced composites with superior properties.

Additionally, the widespread implementation of artificial intelligence (AI), machine learning (ML), and data management is empowering researchers to rapidly innovate and develop new materials. This significantly reduces the time it takes for emerging materials to reach the market, from several decades to just a few years.

This article was last updated in July 2024.

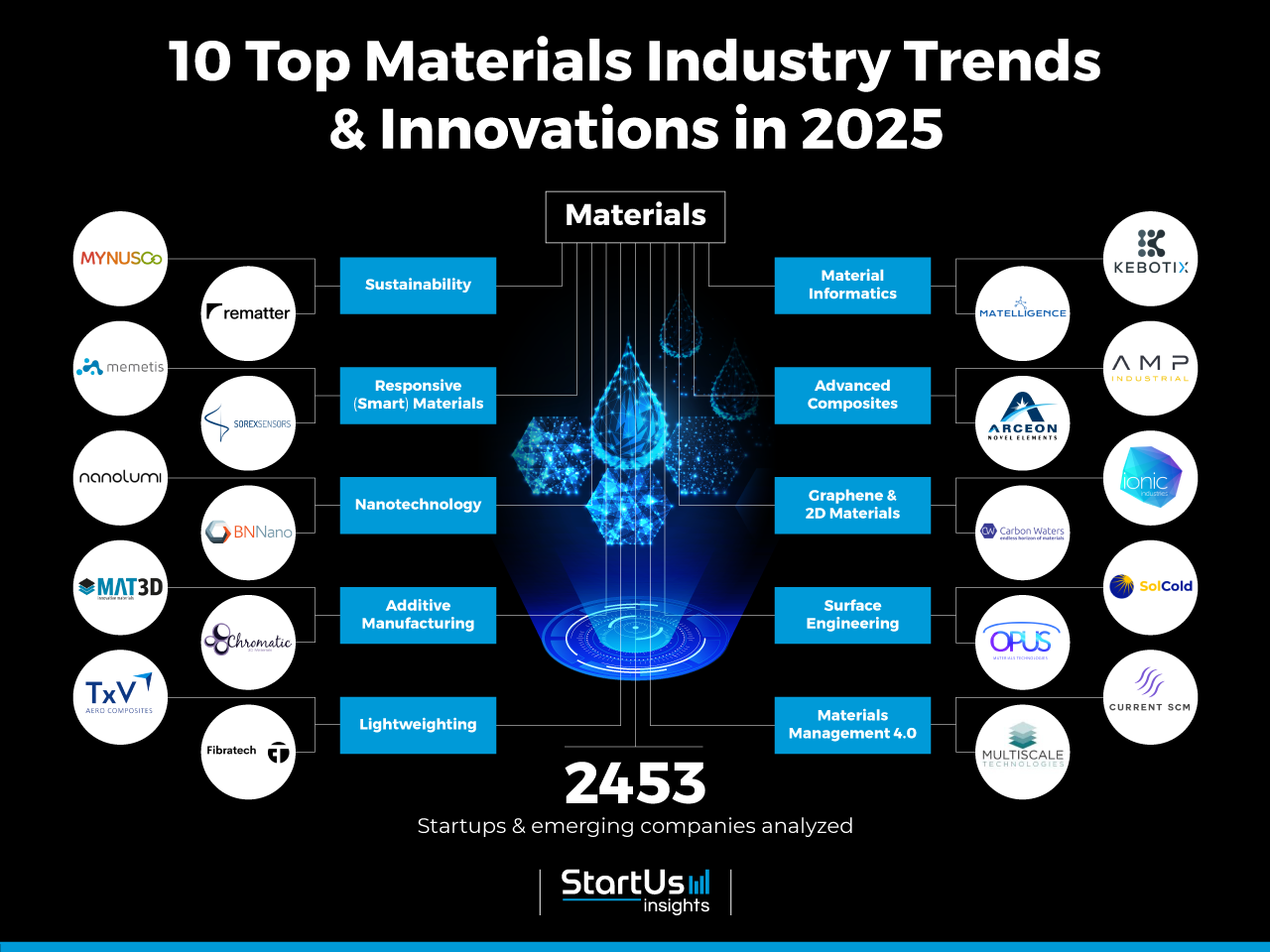

Innovation Map outlines the Top 10 Materials Trends & 20 Promising Startups

For this in-depth research on the Top Material Trends & Startups, we analyzed a sample of 2453 global startups & scaleups. This data-driven research provides innovation intelligence that helps you improve strategic decision-making by giving you an overview of emerging technologies in the materials industry. In the Material Industry Innovation Map, you get a comprehensive overview of the innovation trends & startups that impact your company.

What are the Trends in the Materials Industry (2025)?

- Sustainable Materials

- Smart & Responsive Materials

- Nanotechnology

- Additive Manufacturing

- Lightweighting

- Material Informatics

- Advanced Composites

- Graphene & 2D Materials

- Surface Engineering

- Materials Management 4.0

Want to explore all Materials innovations & trends?

Request Sample Database

These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform , covering 4.7M+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant technologies and industry trends quickly & exhaustively.

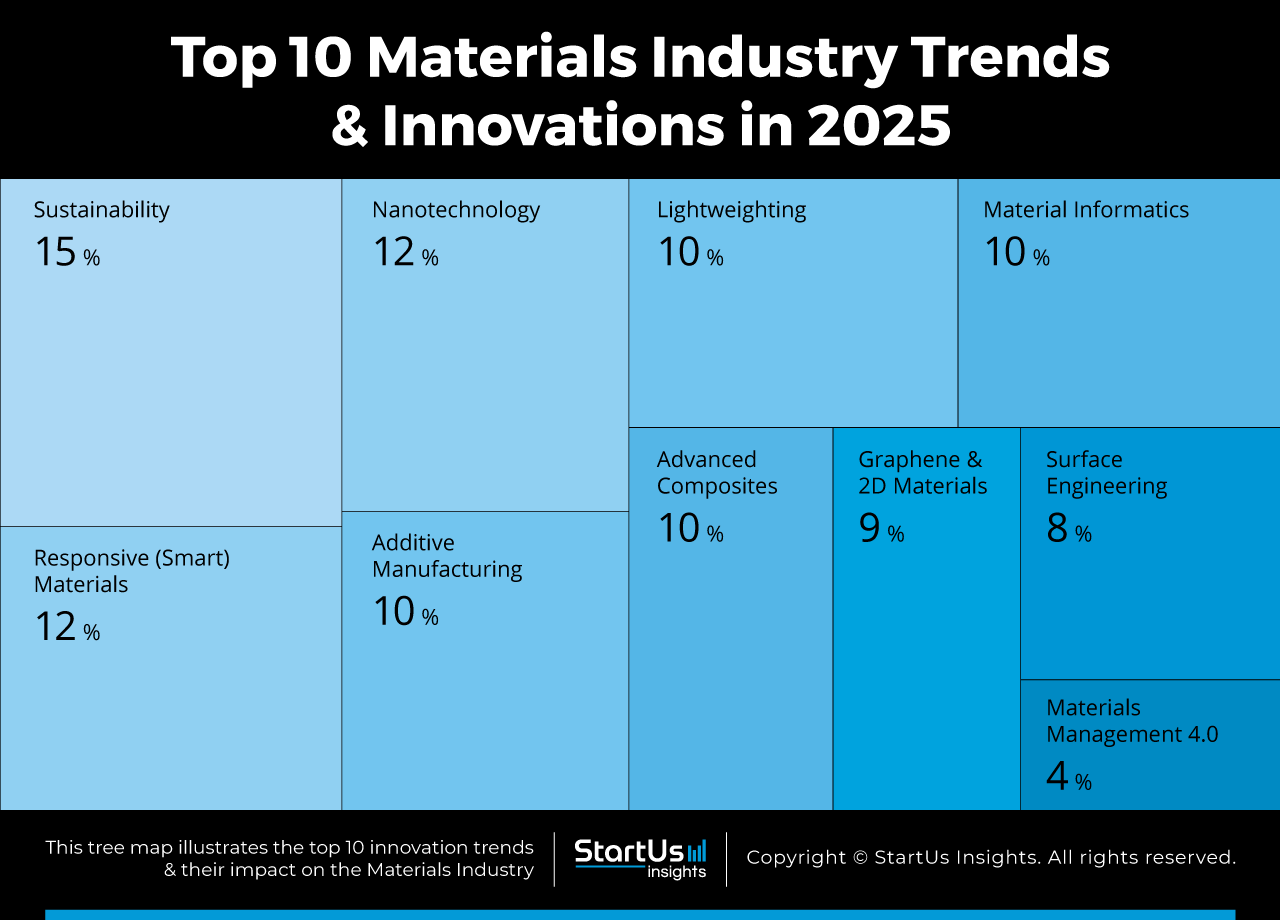

Tree Map reveals the Impact of the Top 10 Materials Industry Trends

Based on the Materials Innovation Map, the Tree Map below illustrates the impact of the Top 10 advanced materials technologies in 2025. Startups now develop sustainable, responsive, and smart materials that also offer improved physical properties. For example, biodegradable plastics, thermally adaptive fabric, and flexible displays. Novel formulations, including nanomaterials and biomaterials, impart new functionalities to existing materials while expanding the scope of innovation.

Additive manufacturing, advanced composites, and 2D materials also lead to the development of various lightweight materials. Along with materials informatics and management, surface engineering impacts several industries from energy, automotive, and construction, to biotechnology, healthcare, and textiles.

Click to download

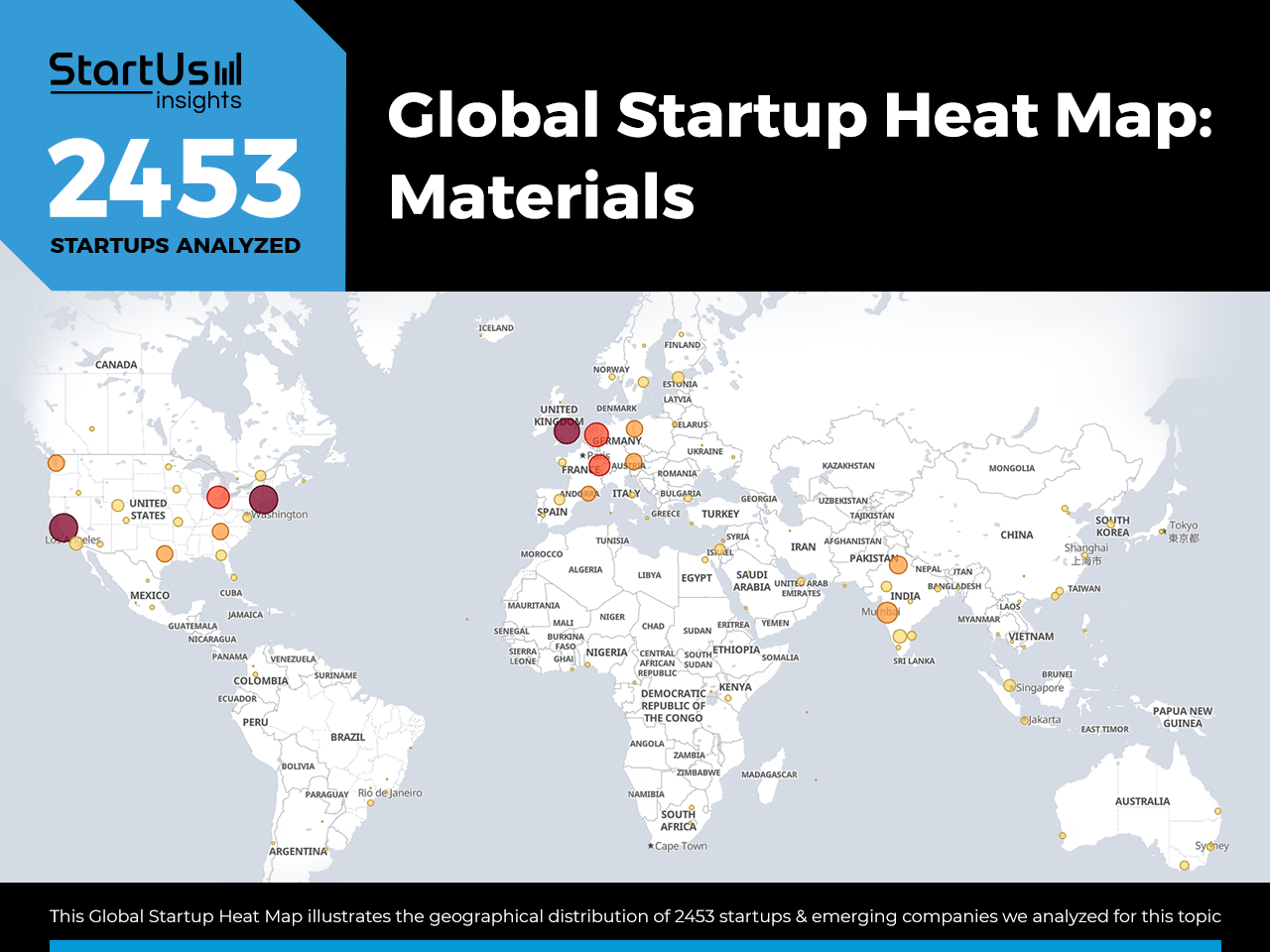

Global Startup Heat Map covers 2453 Materials Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 2453 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform , the Heat Map reveals that Europe & the US are home to most of these companies while we also observe increased activity in South-East Asia, Australia as well India.

Below, you get to meet 20 out of these 2453 promising startups & scaleups as well as the solutions they develop. These 20 startups were hand-picked based on criteria such as founding year, location, funding raised, and more. Depending on your specific needs, your top picks might look entirely different.

Top 10 Materials Industry Trends in 2025

1. sustainable materials.

The substantial waste generated during the use and production of materials has led governments to implement various environmental regulations. Industries across the board, including construction, automotive, packaging, and manufacturing, are reevaluating their processes in terms of material lifecycle.

To reduce their carbon footprint, these sectors are increasingly adopting sustainable materials, aiming to decrease the planet’s waste burden. Sustainable materials not only support circular systems but also facilitate the implementation of a circular economy .

MYNUSCo produces Biocompound Materials

Indian material technology startup MYNUSCo intends to assist the automotive, logistics, packaging, hospitality, and consumer goods industries with their sustainability objectives. The startup produces biodegradable and recyclable compounds based on agricultural waste and renewable resources.

Its products contribute to conserving natural deposits and forests while also ensuring scalability and adaptability for existing manufacturing processes.

Rematter makes Sustainable Floor Slabs

Rematter is a Swiss startup that manufactures sustainable floor slabs. They are constructed from a frame of solid timber beams with rammed earth infills and the connections are dry-joined or screwed. This allows for easy disassembly and re-use of components.

The slab material also features high mechanical characteristics like fire resistance and enhanced strength as well as has a lower carbon footprint. Rematter’s slabs enable builders to make sustainable buildings and ensure efficient material recovery at the end of life.

2. Responsive & Smart Materials

To meet specific industrial use case requirements, novel materials under development are being tailored with application-specific characteristics. Advances in materials science are enabling the creation of smart materials with programmable properties that react to external stimuli.

Startups are designing materials and products with diverse qualities, including thermo-, electro-, and photo-chromism, piezoelectricity, shape memory, self-healing , and phase-change attributes. The piezoelectric smart materials market, a segment of this field, is estimated to grow at a CAGR of 15.63% between 2024 and 2028, with the market size forecasted to increase by USD 39.49 billion, highlighting the rapid advancement and growing demand for smart materials.

Memetis offers High-Performace Actuators

German startup Memetis creates ultra-compact miniature actuators based on shape memory alloys. The startup enables a memory effect in its materials, which also sustain extreme deformations, and later revert to their original shape.

Its property supports the performance of the actuators even in small or dense installation spaces. Memetis offers solutions for consumer electronics, telecommunications, optical technology, mobility, and industry 4.0.

Sorex Sensors develops Film Bulk Acoustic Resonator (FBAR) Technology

Sorex Sensors is a UK-based startup developing high-sensitivity micro-electromechanical system (MEMS) sensors on silicon wafers using a thin-film piezoelectric material. The startup utilizes FBAR technology to create a piezoelectric effect.

The piezoelectric effect enables the startup to accurately detect temperature and mass changes on a femtogram scale. This allows small-scale devices with low-power requirements to respond to external stimuli. Some use cases of this solution include thin-film metrology as well as gas and particulate monitoring.

3. Nanotechnology

Nanotechnology advancements reveal that materials at the nanoscale exhibit different characteristics from their bulk counterparts. The emergence of nanofibers, nanotubes, allotropes, quantum dots, and other nanomaterials offers immense potential for value addition.

These nanomaterials enhance the performance of industrial products at an atomic level. Companies, especially in electronics, energy, mobility, and manufacturing, are leveraging nanomaterials to maintain a competitive edge.

Nanolumi makes Perovskite Nanocrystals

Singaporean material technology startup Nanolumi intends to overcome the weaknesses of QD technology for electronic displays with its reliable and safe perovskite nanocrystals. The startup combines cadmium-free origin, broad light spectrum coverage, purer color performance, and high-volume mass-production suitability. Nanolumi’s product also intends to supplant conventional perovskite nanocrystals and QDs for premium electronics.

BNNano provides Enhanced Boron Nitride Nanotubes

The US-based startup BNNano manufactures boron nitride nanotubes with superhydrophobic, high electrical insulation as well as high thermal and mechanical stability characteristics. The startup offers its nanomaterial as powders, master alloys, masterbatches, and custom mixes. It finds applications in the aerospace, automotive, defense, and textile industries as well as for radiation protection and thermal management.

4. Additive Manufacturing

Emerging additive manufacturing facilities are evolving beyond traditional thermoplastics, focusing on materials that offer greater flexibility, customization, functionality, and produce less waste. The advancement of 3D printing technologies is driving improvements in metals, alloys, ceramics, fibers, and their compounds. 3D printing is also fostering the development of new, durable polymer filaments with enhanced conductance, melting, and chemical resistance properties.

The 3D printing materials market is expected to reach USD 6.92 billion by 2029 . This growth reflects the increasing demand for innovative materials in additive manufacturing.

MAT3D offers Composite Polymeric Materials

Italian startup MAT3D is developing new polymeric materials for additive manufacturing that offer strengthened functional attributes. The startup’s materials replace high-performance plastics for metal 3D printing. Its solutions also include a variety of resins with increased electrical, magnetic, anti-bacterial, and thermo-mechanical properties for industrial markets.

Chromatic 3D Materials manufactures 3D Printed Polyurethanes

US-based startup Chromatic 3D Materials produces a set of durable high-performance polyurethane elastomers for 3D printing, which are simultaneously adaptable and resilient. The startup offers a great degree of customization and compatibility with additives while also ensuring the quality of the final products. Chromatic 3D Materials’ products cater to the automotive, manufacturing, and consumer goods markets, among others.

5. Lightweighting

Industries ranging from aerospace to mobility are seeking innovative ways to reduce excess weight, thereby enhancing fuel efficiency and handling. This has led to research into materials like aluminum, magnesium, titanium, high-strength plastics, and carbon fiber. These materials allow industries to lessen the environmental and operational impacts of heavier parts.

Additionally, lightweighting innovations in materials provide safety and reliability levels comparable to heavier alternatives. The global lightweight materials market size is expected to be valued at USD 276.4 Billion by 2030 at a CAGR of 8.3% during the forecast period (2023-2030).

TxV Aero advances Aerospace Composites Manufacturing

The US-based startup TxV Aero designs and engineers custom laminate materials and finished composite parts for applications in commercial aerospace. Using advanced technology, the startup fabricates lightweight thermoplastic assemblies with tailored features, including ply orientation, pad-ups, near-net shapes, and more. Further, TxV Aero works on retrofit aerospace applications to increase overall productivity.

Fibratech makes Composite Automotive Wheels

Polish startup Fibratech intends to overcome the lightweighting and performance limitations of aluminum in the mobility sector. It develops hybrid composite-metallic wheels for vehicles, augmented with carbon fiber. Fibratech’s material attains general mass reduction, stiffness increase, and design customization, compared to widely used forged aluminum wheels.

Learn How 10 Emerging Technologies Shape Your Industry!

6. Material Informatics

Large companies today are adopting a data-driven approach to materials, utilizing informatics, computational techniques, and machine learning (ML), and artificial intelligence (AI). This approach enables them to systematically organize and model materials data.

Material Informatics not only optimizes the extraction of scientific insights from complex materials data but also accelerates research and development (R&D) timelines, saving time and labor.

Kebotix provides a Self-Driving Material Discovery Lab

The US-based startup Kebotix develops a self-driving laboratory solution for materials research to accelerate new materials exploration. The startup leverages big data, AI-based decision-making, dedicated robotics, and a convenient interface to streamline cycles for scientists. Kebotix is particularly interested in tackling challenges in sustainability, public health, and hazardous industrial substances.

Matelligence enables AI-Based Materials Screening

Canadian startup Matelligence provides material science experts with data-driven tools for materials discovery. Its solution comprises computational techniques with patented AI algorithms to lower the number of required scientific experiments and expedite screening procedures. Matellligence’s platform primarily targets clean energy, electronics, and manufacturing, among other sectors.

7. Advanced Composites

Advanced composites, a significant trend in the materials industry, are engineered materials made from two or more constituent materials with significantly different physical or chemical properties. These composite solutions are known for their exceptional strength-to-weight ratio, corrosion resistance, and durability. Key benefits include enhanced performance, longevity, and lightweight properties, leading to energy efficiency and reduced environmental impact.

They find extensive applications across various industries, such as aerospace for aircraft components, automotive for lightweight and fuel-efficient vehicles, construction for robust and durable structures, and sports equipment for improved performance and durability. Their adaptability and superior properties make them a pivotal material choice in modern engineering and design. The global composites market is projected to reach USD 168.6 billion by 2027 , growing at a CAGR of 8.2% from 2022 to 2027.

AMP Industrial offers Continuous-Fiber Composites For Propellers

The US-based startup AMP Industrial fabricates advanced composites for unmanned aerial systems (UAS). The startup leverages unidirectional continuous fiber-reinforced thermoplastics (CFR-TP) to make its composites. They feature a high strength-to-weight ratio and material toughness, as well as support customizable materials design for high-performance applications.

ARCEON creates High-Temperature Resistant Composites (HTRC)

Dutch startup ARCEON creates innovative high-temperature resistant composites for satellites, rockets, and engine parts. Its products withstand temperatures exceeding 1000 degrees Celsius, retain a low coefficient of thermal expansion, contain lightweight materials, and also reinforce mechanical robustness and durability.

8. Graphene & 2D Materials

Advancements in nanotechnology have enabled materials science companies to develop pathways for two-dimensional (2D) materials. These materials, known for their excellent thermal conductivity and mechanical strength, enhance the capabilities of various industrial applications. While most 2D materials like germanene, silicene, stanene, and phosphorene are still in the research phase, graphene stands out as the first successfully commercialized 2D material.

Graphene offers improved tensile strength , intra-sheet bonding, surface durability, electron mobility, flexibility, and thermal resistance. It finds applications in several industries, including electronic displays, supercapacitors, automotive, construction paints, and plastics manufacturing.

Ionic Industries makes Graphene Materials

Australian startup Ionic Industries aspires to bridge the gap between graphene research and developing its commercial applications. The startup incorporates expertise and patented processes of graphene and graphene oxide manufacturing. Ionic Industries specializes in graphene additives for water treatment and nanofiltration, as well as for energy storage.

Carbon Waters offers Graphene Dispersions

French startup Carbon Waters focuses on liquid graphene applications for a diverse range of markets. The startup’s graphene dispersions provide barrier coatings, lubrication, and anti-corrosion properties for industrial surfaces and mechanisms. In addition, the solution improves thermal management for electronics and semiconductors as well as electrical conductivity for manufacturing and consumer devices.

9. Surface Engineering

Industrial surfaces, constantly subjected to wear and tear, corrosion, UV radiation, and other detrimental elements, necessitate coatings that provide enhanced durability. Such coatings are crucial for safeguarding assets in the automotive, industrial, agricultural, marine, and manufacturing sectors, and they play a key role in boosting productivity.

Additionally, advancements in engineering have enabled the development of surfaces with hydrophobic, omniphobic, self-cleaning, and smoothing properties. In the wake of the COVID-19 pandemic, surface engineers are intensifying their efforts to perfect antimicrobial coatings, aiming to provide more robust protection across both industrial and non-industrial environments.

SolCold develops Anti-Stokes Fluorescence Technology

Israeli startup SolCold develops a surface modification solution based on a nano filter and an active cooling paint. Using anti-stokes fluorescence technology, the startup transforms heat and radiation from the sun into a low-cost cooling system. The startup’s technology creates a reverse relationship between solar activity and heat transfer. This solution caters to the transportation, construction, agriculture, and textile industries.

OPUS Materials offers Bespoke Material Technology

UK-based startup OPUS Materials engineers innovative anti-soiling and self-cleaning coatings for the aerospace, mobility, marine, and renewable energy industries. The startup’s solution improves fuel consumption and airflow, reduces corrosion, and optimizes material efficiency. Additionally, OPUS Materials allows for creating coating materials by design and also supports the establishment of corresponding supply chains.

10. Materials Management 4.0

Industry 4.0 is driving the adoption of its methodologies in the management, handling, and processing of materials. This encompasses everything from autonomous mining and sophisticated automated fabrication to robotic handling and cloud computing, leading to swift digitization and interconnection within the materials sector. Consequently, the creation of new materials is occurring alongside their integration into the latest industrial technologies of the fourth industrial revolution.

Current SCM makes Material Management Software

Current SCM is a Canadian startup that develops material management software. It allows businesses to create virtual warehouses to easily store and track materials as well as leverage real-time inventory data. It also enables procurement teams to identify over and under scenarios and split orders based on current demand.

Further, the software provides a centralized spot for companies to track vendor information, validate order status, and material receiving. The startup’s software thus centralizes materials management by combining materials allocation, inventory tracking, material release and receiving, and grouping. This saves time and increases efficiency for industries like construction, energy, and agriculture.

Multiscale Technologies enables AI-powered Materials Innovation

Multiscale Technologies is a US-based startup that advances AI-powered materials innovation. The startup’s platform combines generative AI and a proprietary knowledge system for inverse materials design. This way, it enables high-throughput measurements with tiny samples.

The platform thus enables material manufacturers and researchers to reduce time to market, maximize cost savings, increase quality control, and enhance quality assurance. This way, it accelerates material design and optimizes manufacturing.

Discover all Materials Technologies & Startups

Swift progress in materials science is speeding up research and experimentation, improving the sustainability, lightweighting, nanomolecular, and programmable features of materials. Consequently, industries such as aerospace, automotive, manufacturing, energy, and packaging that quickly embrace these material trends are benefiting from these emerging innovations. Recognizing the advancements in materials innovations is crucial, given the extensive applications of new materials in industrial, commercial, and even household products.

The Materials Industry Trends & Startups outlined in this report only scratch the surface of trends that we identified during our in-depth research. Among others, sustainable and smart materials will transform the sector as we know it today. Identifying new opportunities and emerging technologies to implement into your business early on goes a long way in gaining a competitive advantage. Get in touch to easily and exhaustively scout relevant technologies & startups that matter to you.

Your Name Business Email Company

Get our free newsletter on technology and startups.

Protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Discover our Free Materials Report 22 pages

Get free updates on Global Startups, Technologies & Trends!

Join 25k subscribers.

Business Email

Materials 22 pages report

Additive manufacturing 22 pages report.

First & Last Name Business Email Company

Smart Packaging

Industry 4.0 22 pages report.

Leverage our unparalleled data advantage to quickly and easily find hidden gems among 4.7M+ startups, scaleups. Access the world's most comprehensive innovation intelligence and stay ahead with AI-powered precision.

Get in touch

Your Name Business Email Company How can we support you? (optional)

Stay Ahead with Our Monthly Newsletter

Join our community of 15K+ innovation leaders and get the latest insights on emerging startups, technologies, and industry trends delivered straight to your inbox. Subscribe now to stay on top of the latest advancements!

Protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Attention NAE Members

Starting June 30, 2023, login credentials have changed for improved security. For technical assistance, please contact us at 866-291-3932 or [email protected] . For all other inquiries, please contact our Membership Office at 202-334-2198 or [email protected] .

Click here to login if you're an NAE Member

Recover Your Account Information

- Publications

- Cutting Edge Research

The Future of Engineering Materials: Multifunction for Performance-Tailored Structures

Author: Leslie A. Momoda

MIT Engineers Create the “Impossible” – New Material That Is Stronger Than Steel and As Light as Plastic

The new substance is the result of a feat thought to be impossible: polymerizing a material in two dimensions.

Using a novel polymerization process, MIT chemical engineers have created a new material that is stronger than steel and as light as plastic, and can be easily manufactured in large quantities.

The new material is a two-dimensional polymer that self-assembles into sheets, unlike all other polymers, which form one-dimensional, spaghetti-like chains. Until now, scientists had believed it was impossible to induce polymers to form 2D sheets.

Such a material could be used as a lightweight, durable coating for car parts or cell phones, or as a building material for bridges or other structures, says Michael Strano, the Carbon P. Dubbs Professor of Chemical Engineering at MIT and the senior author of the new study.

“We don’t usually think of plastics as being something that you could use to support a building, but with this material, you can enable new things,” he says. “It has very unusual properties and we’re very excited about that.”

The researchers have filed for two patents on the process they used to generate the material, which they describe in a paper published in Nature on February 2, 2022. MIT postdoc Yuwen Zeng is the lead author of the study.

Two Dimensions

Polymers, which include all plastics, consist of chains of building blocks called monomers. These chains grow by adding new molecules onto their ends. Once formed, polymers can be shaped into three-dimensional objects, such as water bottles, using injection molding.

Polymer scientists have long hypothesized that if polymers could be induced to grow into a two-dimensional sheet, they should form extremely strong, lightweight materials. However, many decades of work in this field led to the conclusion that it was impossible to create such sheets. One reason for this was that if just one monomer rotates up or down, out of the plane of the growing sheet, the material will begin expanding in three dimensions and the sheet-like structure will be lost.

However, in the new study, Strano and his colleagues came up with a new polymerization process that allows them to generate a two-dimensional sheet called a polyaramide. For the monomer building blocks, they use a compound called melamine, which contains a ring of carbon and nitrogen atoms. Under the right conditions, these monomers can grow in two dimensions, forming disks. These disks stack on top of each other, held together by hydrogen bonds between the layers, which make the structure very stable and strong.

“Instead of making a spaghetti-like molecule, we can make a sheet-like molecular plane, where we get molecules to hook themselves together in two dimensions,” Strano says. “This mechanism happens spontaneously in solution, and after we synthesize the material, we can easily spin-coat thin films that are extraordinarily strong.”

Because the material self-assembles in solution, it can be made in large quantities by simply increasing the quantity of the starting materials. The researchers showed that they could coat surfaces with films of the material, which they call 2DPA-1.

“With this advance, we have planar molecules that are going to be much easier to fashion into a very strong, but extremely thin material,” Strano says.

Light but Strong

The researchers found that the new material’s elastic modulus — a measure of how much force it takes to deform a material — is between four and six times greater than that of bulletproof glass. They also found that its yield strength, or how much force it takes to break the material, is twice that of steel, even though the material has only about one-sixth the density of steel.

Matthew Tirrell, dean of the Pritzker School of Molecular Engineering at the University of Chicago , says that the new technique “embodies some very creative chemistry to make these bonded 2D polymers.”

“An important aspect of these new polymers is that they are readily processable in solution, which will facilitate numerous new applications where high strength-to-weight ratio is important, such as new composite or diffusion barrier materials,” says Tirrell, who was not involved in the study.

Another key feature of 2DPA-1 is that it is impermeable to gases. While other polymers are made from coiled chains with gaps that allow gases to seep through, the new material is made from monomers that lock together like LEGOs, and molecules cannot get between them.

“This could allow us to create ultrathin coatings that can completely prevent water or gases from getting through,” Strano says. “This kind of barrier coating could be used to protect metal in cars and other vehicles, or steel structures.”

Strano and his students are now studying in more detail how this particular polymer is able to form 2D sheets, and they are experimenting with changing its molecular makeup to create other types of novel materials.

Reference: “Irreversible synthesis of an ultrastrong two-dimensional polymeric material” by Yuwen Zeng, Pavlo Gordiichuk, Takeo Ichihara, Ge Zhang, Emil Sandoz-Rosado, Eric D. Wetzel, Jason Tresback, Jing Yang, Daichi Kozawa, Zhongyue Yang, Matthias Kuehne, Michelle Quien, Zhe Yuan, Xun Gong, Guangwei He, Daniel James Lundberg, Pingwei Liu, Albert Tianxiang Liu, Jing Fan Yang, Heather J. Kulik and Michael S. Strano, 2 February 2022, Nature . DOI: 10.1038/s41586-021-04296-3

The research was funded by the Center for Enhanced Nanofluidic Transport (CENT) an Energy Frontier Research Center sponsored by the U.S. Department of Energy Office of Science, and the Army Research Laboratory .

Related Articles

Turning diamond into metal – for improved solar cells, leds, and power electronics, new polymer material uses carbon dioxide to self‐repair, mit develops ultrafine high performance polyethylene fibers, new material provides an elastic “second skin”, new battery could overcome key drawbacks of lithium-air batteries, new hydrogel hybrid could be used to make artificial skin, mit researchers create perfect nanoscrolls from graphene oxide, niobium nanowire yarns make high-performance supercapacitors, mit develops membrane that can separate highly mixed oil-spill residues, 116 comments.

what is the melting point?

This is a highly crosslinked polymer, so it probably degrades before melting. Additionally, polyaramids like these tend to have higher phase transition points than most other polymers.

The fact that no one realizes they just created “vibraniun” 🤣

Super well written and easy to follow for armchair scientists like me. Thanks!

If the new material is truly stronger than steel I wonder how will manufacturers of various parts for cars, airplanes and cell phones for example be molded into specific shapes? What tools would be required to cut such material into the desired shapes for various consumer products? Or is the hardening polymer applied after the the material is already cut to its specific measurement?

Highly uninformed reporting to mislead general public who are not expected to know the mechanical properties of most materials. This is a shame on the part of the article’s author. Bad publicity. Ask the authors or read the Nature article. MIT should take steps against this kind of publication and the authors of such uninformed journalists.

Note that they reference A36’s value for the yield strength of structural steel for their comparison — this is a soft steel in comparison with some alloys and treatments of steel.

Oh, goody. More plastics.

My thoughts exactly. How do we * get rid of it* after it has served its intended use?

Well there is a term for that, Recycling. But western society needs to start using that term and implementing it and not trying to “recycle” our polymers back to China..

These plastics aren’t gonna be used for soda bottles or food containers. Did you even read the article?

So…plastics aren’t bad for the environment?

These plastics aren’t gonna be used for soda bottles or food containers. Did you even read the article?

The plot twist might be that for application as phone screens perhaps it might, on some of chance, be brittle as a plastic? Then, as with all amazing technologies such as every version of Corning’s gorilla glass, will break if you just accidentally drop your phone (assuming this material is used for the screen). Tee hee!

Plastic is not brittle its the far opposite of that, it’s too soft. Gorilla glass is glass, glass is very brittle but very hard, hence phone screens do not scratch easily. So if they want to use this as a screen, the issue will be in scratches and not shattering. Look up Motorola’s unbreakable screen.

Modulus of steel is 200 GPa compared to this material’s 12.8 GPa. High strength steels have yield strength in excess of 1400 MPa compared to this plastic’s 488 MPa. 2D materials like Graphene has modulus of >1 Terra Pa and strength of >100 GPa. How does the author of this article claim the superiority compared to existing materials? The authors of the Nature article does not claim what the article says.

nothing works when it -10 C

If nothing works at -10°C then why does the instrumentation on the Webb telescope work at -370°C? In fact they must be at that temperature because they are extremely sensitive in the infrared. There are some materials that are strong but not brittle at very low temperatures. Not sure but I think it’s called the ‘thermal tensile strength coefficient’. It’s one of the reasons barium was used for the construction of the primary mirror on the Webb. Barium has exceptionally stable properties at very low temperatures. I would expect, that if this material is what they claim, its properties are stable over a wide thermal range.

I agree, though I have one correction. The primary mirrors of the JWST are made of Beryllium, not Barium.

James Webb space telescope doesn’t use polymers…jeez!

Tired of stories that mean nothing. Use it or lose it.

Very Good. Exciting Development.

Isn’t Polymer Chemistry Fascinating! Polymers with cross linked Covalent Bonds (which are extremely Strong Bonds) will theoritically be stronger than the Ionic Bonding we are all highly familier with, like a mixture of Salt ( Sodium Chloride) and Potassium Bicarbonate and other Salts we mix with Water or Juice and give kids playing baseball in the sun, so they dont get dehydrated!!

This is very good at two dimensional level. Was wondering if such materials and polymers can be created at a one-dimensional level. I guess at a Zero Dimensionnal Level Matter would have been will have completely transformed into Energy. I wonder what are the phases in this One to Zero Dimensional Transformation and can we create completely indestructible Material as we approach the Zeroth Dimension. I was wondering if negative dimensions exist and what happens in these dimensions. Are Animatter Polymers Formed? Exendthe logic of Dimensional Matter to Antimatter!

Get a cross functional team together with Physics specialists, Quantum Chemistry & Phhysics Specialists, Nano Chemistry Experts, Biologists and other appropriate engineering and other talent together, to explore the implication, for Polymers like amino acid chains , protiens etc. The possibilities for Health and Medical ScienceProgress is endless.

After all except for the breath of Life, all the rest in a biological species is polymer chemistry at work.

Views expressed are personal and not binding on anyone.

Hemp forms a stronger bond than steel and a lighter weight than carbon fiber but here we are acting like Ford didn’t buy and bury those patents nearly 100 years ago..this is trash. Stop using toxic plastics and focus on organic materials.

If so those Patents are public knowledge and their protections would have expired decades ago.

Do not waste your time replying to someone saying Hemp is stronger than steel and then blaming a company that has nothing to do with steel production as the cause.

Perhaps he meant to say technologies were buried, rather than patents were buried. And I heard a version where Henry Ford was trying to use such a technology and others were responsible for crushing it. I’m not claiming to have evidence; just keep in mind that contradiction with your current worldview is also not negative evidence.

I’d be interested to see how it performs as an H2 tank liner coating.

I noticed you’re still working with polymers.

Dr. Nichols : “Still? What else would I be working with?”

Haha. I had the same thought. Could this be the “transparent aluminum” of Star Trek? Seriously, is this polymer transparent?

And what effect of a superstrong plastic have on our oceans, seafood, and air ? Considering the overall mass of nanoplastics on the environment, this must be studied, if not regulated.

If it super strong, as well as water and gas resistant, wouldn’t it be preferable to what we’re already throwing into the ocean?

Geez, I hope not.

Fungi are the cure for plastics in the environment. We the people just need to demand it from our fearless leaders…😁

Does this material mean we’ll soon have all plastic firearms?

Exactly! 3d printed guns at home that aren’t traceable oh my! 😜😜😜 The liberals are going to have a stroke..

I wonder whether this could be used to produce a new generation of spacesuits. Seems like it could be well suited to the task.

P.S. what’s with all the wackadoodle plastics-are-bad regressives in the comments section? Why do they even read articles about science and engineering if they’re so opposed to it? Just to make themselves angry? 🤦♂️

This is not new. They created JB Weld a long time ago.

Why don’t the entities that funded the research (US taxpayers) own the patents?

Same reason the Pharmaceutical industry makes billions and billions and leaves the public in the dark ages. Uber Capitalist propaganda and greed. The future is Smarter democracies and social-anarchist public owned and operated industry.

Because MIT received donations from big tech companies that want to use their research to make billions. Why do you think they want you to take the shot(we paid billions for) and not use ivermectin, valacyclovir, zinc and vitamin D?

So, MIT created storm trooper armor aka plastisteel? Excellent. Now find other applications for it. Will this stuff resist GCRs? Maybe it could be used by Nasa and space x for cheaper rockets, space suits, death stars? Or on ships? Imagine boats that don’t rust or submersibles that could withstand crush depths over 900 meters. Or maybe it could replace automotive sheet metal by a large percentage. Think Tesla plaid but faster. Or maybe prosthetic body parts. Or Darpa Petmen with skeletons made from this stuff? Get in touch with Dr. Rabenei at ncsu and collaborate on composite metal foam. Maybe the two technologies can be merged. Now get cracking I’m still waiting on evolved miracle materials. I needed poly mimetic alloy yesterday!

What company gets to work with the new material. ,Is it a new oddity that’s forming, Who has the right to patterns. Hoping since is taxpayer funding, we need little clarification.. thank you..

Dupont probably “donated” a couple million fed notes to MIT so they can use the technology and make billions. Same song and dance the pharmaceutical industry performs for things like COVID-19 immune system booster shots..

No mention of fatigue properties.

Even if they compare strength with A36 (1018) which is around 30-40K PSI in a not heat treated state, this translates to ~60K PSI… For plastic, that’s an incredible number! Teflone, for example, has 2K PSI strength. Polyurethane – up to 5K PSI only.

Can this material be used to produce energy? I would think material could be used to coat public roads to capture solar and produce energy and eliminate giant solar fields.

“MIT postdoc Yuwen Zeng is the lead author of the study.” Which means the CCP already has all of the research and data.

Good God, can you be more racist!

Chinese is a nationality. Not a race. Humans are a race.

Attacking whole cultural identity and grouping individuals into non-thinking non-feeling labels makes you a fascist Nazi. If you disagree you are just an ignorant mini tyrant. Who’d take you seriously? Only a Mother could pretend to accept such faults. Please 🙏 leave the comments section to better evolved persons.

Apparently you think the Chinese Communist Party is an Ally of the US and that they haven’t been sending students to gain education in the west for decades so they can steal our technologies..I’m not woke or have ill feelings against the Chinese, I just read about how they are stealing our technology from educational institutions.

Chinese is a nationality, Asian is a race, Human is a species, woke is a neuroses.

There isn’t a “race” section in taxonomy..

Further, he said CCP not “people of Chinese heritage”.

I swear these days you couldn’t throw a white guy far enough to avoid hitting someone looking for any possible angle to point and shout “racist” at you without even thinking it through.

It’s time they just declare “woke” a religion of neurotic white people at this point.

Pull your head out of woke behind. You are a fool if you believe that the Chinese Communist Party does not already know about, and have access to, the information and research discussed in this article.

Be sure there is no security to protect this so that China, Russia, and a other adversaries can steal this intellectual property and use it against us.

This may be the most important advancement a century. It literally changes everything.

I said that after every science/tech article I read for about five years before reality smacked me in the face and informed me that breathlessly exuberant articles about a breakthrough are essentially 1 in a 1000. Almost none of those thousands of articles have been a breakthrough for one piece of context or another.

Let’s just say it looks promising and has a lot of potential. 😉

Why so many Chinese involved in this polymer thing? Just asking for a friend.

Have your friend Google :”Thousand Talents Plan”

Aliens already did this..

Hope this isn’t made from Petroleum, the green fascists want to eliminate that.

Them ornamentals sure are clever.

Already stolen IPR by China,,,next.

I recall in Star Trek there is a scene where Scotty divulges the secret to making transparent aluminium. Science imitates art it would seem. Transparent steel is amazing.

MIT postdoc Yuwen Zeng……………

So the Chinese have already stolen it then, got it.

Is it going to be proprietary or is it going to be shared with the Chinese?

They already know..

Leftist will at first live it. Then a realization will set in. You can’t make this or any other plastic without oil. The cognitive dissonance will make their heads explode.

Can we just once please assure that this technology won’t be stolen by the Chinese?

Transparent aluminum, as was predicted in Star Trek III with the whales.

Star Trek referred to this as “transparent aluminum “

It’s an article celebrating a scientific breakthrough. This is not the place to post negative comments. Make your own website or blog if you insist on sharing your negative opinions. The bigotry is totally unacceptable. I am having difficulty understanding how the assumption that just because the main author of the research and some of the other researchers have Chinese names they are automatically sharing the research with China. That’s totally absurd. So based off of that logic nobody with a Chinese name has ever been born somewhere else other than China, and every person with a Chinese name has direct connection with the Chinese government and scientists in China just in case they are ever part of any ground breaking research, any scientific breakthrough, or any major scientific discovery that’s not made in China they can quickly share the information with China? And so what if the research is shared with China. God forbid that a Chinese scientist uses this research to develop some type of medical device that ends up saving the life of a parent, a child, or even your own.

Simmer down, Senor Chang.

The Chinese Communist Parties military is pretty excited about the many military uses this will have.

A 2D polymer?

Here’s hoping we get scaled up plastic-toy-car-strength in a full sized automobile.

Can it pass California regulation? How long before cancer develops?

OMG! “Everything” is probably cancerous in California…

‘ñuff said!

That’s what ET has been making their UFOs out of. They’re not going to be happy that we figured out how to make it.

Nice! Make one of these, please:

https://en.wikipedia.org/wiki/Vacuum_airship

This could help with getting weapons through metal detectors. Love it!!!

Fantastic invention. Could be used for dental applications? Is there any future downside to 2DPA-1? Is it fileable? How would the appropriate people dispose of pieces of it? What could cause it to decompose to “go back to nature?” Just wondering about this new invention’s parameters.

Hmmmm, sounds like graphene oxide/graphene hydroxide. Nano size, can be added to a solution, self assemble and strong enough to withstand passing through a needle and the human body. Oh, and it’s indestructible. Good luck detoxing that shot!

If it is stronger than steel and does not degrade quickly, this could change a lot. Mostly if it can be molded. Possibly make cars lighter and yet safer, a better gas mileage. The lighter weight may allow the ability to make flying vehicles too.

“Yuwen Zeng is the lead author of the study.” I guess the Chinese will have this to market before us.

So, sounds like someone actually invented the plasteel from “Dune”…

Transparent aluminum

After the Democrats eliminate oil and gas production, where will they get the stuff to make this?

Can you make a large coil of the material and form and stamp parts in a press like steel? Or would it have to be like injection molding?

– TRANSPARENT ALUMINUM –

So, if the football team jumps through it after half time, how does that go?

Have the Chinese stole it yet?

if you read the article carefully, the lead scientist for this is a Chinese

I can’t help but suspect that none of the conspiracy touting xenophobic wackjobs have ever, in their whole life, made a productive contribution to society. But congratulations on being a white (European) immigrant, you have so much to be proud of. I didn’t realize being white gave me the authority to dismiss the rest of humanity.

Well…now you know.

Well then, make Masks for Politicians…Air Can’t penetrate, Good Job…

But does it cause cancer in California?

Just what we need. Xing ping to write home about it and Biden will willingly hand it over to the people’s republic

Confused about the hydrogen bonds that are mentioned since hydrogen only has one electron to bond with and if it’s part of a polymer it’s bonded to the carbon backbone. So you might be talking about van der Waals or weaker bonds I guess right? Many polymers use cross-linking for copolymers can be formed into a semi-crystalline material which is going to be much stronger than such bonds I think what you’re trying to say is this is if in film that has great strength and potential for impermeability but I don’t see how this could be a building block for a three-dimensional material without additional cross-linking or crystal entity from some other molecule. It’s all very interesting but I’m not sure if it’s contextualized accurately here.

The title of this article makes it sound like they invented Vibranium.

I like to know how resistant it is to UV (sunlight). Plastics, like my patio furniture, degrades over time in the sun.

Is this stuff recyclable?

Reverse engineering of uap technology this has been around since the 70s and just coming to surface 😂😂😂

Plastics can be made from hemp and / or bamboo, no petrochemicals needed. We need to start making tiny houses that can better withstand: floods, tornados, hurricanes, lightning, UV rays, etc. Making buildings out of plywood and 2×4’s coated in this stuff might make them as strong as concrete and steel.

I like how you avoid calling it was it is, plastic. Stop infoscamming people!

Great! Now how about a grease based”Graffiti” DISSOLVING paint for public buildings. Also, why cannot we learn from civilizations from the past and just stick to brick and mortar? I appreciate the strength of newly discovered materials for bridges etc. But the new materials being used to for new offices, living spaces look to weather and age horribly. I love brick and mortar. All shades.

Interesting that noones commented on the sponsoring. Namely the US military one. From which I find it highly unlikely that any participants weren’t rigorously classified before inclusion. So anyone saying that it’s Chinese by default of it’s scientists is ignorant. What should be concerning if not alarming is the military s desire for this technology’s creation

Calling dibs on “Poly-Impossibli-AshardasSteel-plastic”

read about this a few months ago its not even plastic….try more like graphite, but reduced to its simplest form then is able to connect for structure plus formed into shape by placing it into a polymer. so think about the new age of 3D printing just now since the world is going paperless now we have a use for all those pencils.

How do I delete this website!

Save my name, email, and website in this browser for the next time I comment.

Type above and press Enter to search. Press Esc to cancel.

- MSE Strategic Plan 2023

- Undergraduate Programs

- Graduate Programs

Research Topics

- Research Groups

- Research Videos

- Research Professionals

- Graduate Students

- MSE Advisory Council

- Awards and Honors

- Position Openings in MSE

- Collaborative Facilities Across Campus

- Alumni Spotlights

- Distinguished Alumni Award

- Class Photos

- Giving Opportunities

- Recruit Students

- MSE Newsletters

- Experience and Employment

- Graduate Services and Activities

- Forms & Checklists

- Identity, Health, Wellness

The field of Materials Science & Engineering is evolving dramatically as we enter the 21st Century. What began as the study of metals and ceramics in the 1960s has broadened in recent years to include semiconductors and soft materials. With this evolution and broadening of the discipline, current research projects span multiple materials classes and build on expertise in many different fields. As a result, current research in Materials Science and Engineering is increasingly defined by materials systems rather than materials classes.

At Cornell, the Department of Materials Science & Engineering (MS&E) has adopted this new systems-based vision of the field by defining four strategic areas which are considered to be critical for today’s emerging research. The four strategic research areas are Energy Production and Storage, Electronics and Photonics, Bioinspired Materials and Systems, and Green Technologies.

Materials Science & Engineering is an exciting and vibrant interdisciplinary research field. Cornell MS&E draws upon its world-class faculty, innovative researchers, state-of-the-art facilities and highly collaborative research environment to respond to challenging technological and societal demands both in the present and the future.

Energy Production and Storage

Energy research will prove to be the most prosperous growth area for the department, the College and the University. The inevitability of an energy crisis and global climate change has intensified efforts in alternative energy research around the world. The excitement building around this sector is reminiscent of the early years of the information technology revolution. Among the many possible sources of alternative energy, the following areas are particularly aligned with the current materials research at Cornell as they play to our existing strengths: photocatalysis, photovoltaics, thermoelectrics, phononics, batteries and supercapacitors .

Relevant Research Areas:

- Energy Systems

- Advanced Materials Processing

- Materials Synthesis and Processing

- Nanotechnology

- Nonlinear Dynamics

- Polymers and Soft Matter

- Semiconductor Physics and Devices

Electronics & Photonics

The use of semiconductor devices and circuits will continue to play a major role in modern life. Therefore electronics and photonics are considered premier growth areas. As feature sizes decrease, incremental research based on current methods and materials is unlikely to enable Moore's Law to continue. New materials and processing techniques are needed. Advances in nanoscale fabrication have led to recent advances in this field. We have targeted the following areas: oxide semiconductors, 3D integration, materials beyond silicon, high K and low K dielectrics, plasmonics, spintronics, and multiferroics.

- Computational Mechanics

- Computational Solid Mechanics

- Condensed Matter and Material Science

- Surface Science

Bioinspired Materials and Systems

Scientists and engineers are increasingly turning to nature for inspiration. The solutions arrived at by natural selection are often a good starting point in the search for answers to scientific and technical problems. Designing and building bioinspired devices or systems can tell us more about the original animal or plant model. The following areas are particularly aligned with the current materials research at Cornell: bioinspired composites, engineered protein films for adhesion, lubrication and sensing applications , molecular tools for in-vitro and in-vivo imaging (C-Dots, FRET), as well as biomaterials for tissue engineering and drug delivery.

- Biomedical Engineering

- Biomechanics and Mechanobiology

- Biomedical Imaging and Instrumentation

- Biotechnology

- Drug Delivery and Nanomedicine

- Mechanics of Biological Materials

- Nanobio Applications

Green Technologies

The 21st century has been called the "century of the environment." Neither governments nor individual citizens can any longer assume that social challenges such as pollution, dwindling natural resources and climate change can be set aside for future generations. Strategies for clean and sustainable communities need to be established now, community by community. A dawning era of creativity and innovation in "green technology" (also known as "clean technology") is bringing the promise of a healthier planet (as well as the prospect of growing businesses) that can sustain its health. We have targeted green composites and new systems for CO2 capture and conversion as areas of future growth .

Millions of new materials discovered with deep learning

Amil Merchant and Ekin Dogus Cubuk

- Copy link ×

AI tool GNoME finds 2.2 million new crystals, including 380,000 stable materials that could power future technologies

Modern technologies from computer chips and batteries to solar panels rely on inorganic crystals. To enable new technologies, crystals must be stable otherwise they can decompose, and behind each new, stable crystal can be months of painstaking experimentation.

Today, in a paper published in Nature , we share the discovery of 2.2 million new crystals – equivalent to nearly 800 years’ worth of knowledge. We introduce Graph Networks for Materials Exploration (GNoME), our new deep learning tool that dramatically increases the speed and efficiency of discovery by predicting the stability of new materials.

With GNoME, we’ve multiplied the number of technologically viable materials known to humanity. Of its 2.2 million predictions, 380,000 are the most stable, making them promising candidates for experimental synthesis. Among these candidates are materials that have the potential to develop future transformative technologies ranging from superconductors, powering supercomputers, and next-generation batteries to boost the efficiency of electric vehicles.

GNoME shows the potential of using AI to discover and develop new materials at scale. External researchers in labs around the world have independently created 736 of these new structures experimentally in concurrent work. In partnership with Google DeepMind, a team of researchers at the Lawrence Berkeley National Laboratory has also published a second paper in Nature that shows how our AI predictions can be leveraged for autonomous material synthesis.

We’ve made GNoME’s predictions available to the research community. We will be contributing 380,000 materials that we predict to be stable to the Materials Project, which is now processing the compounds and adding them into its online database . We hope these resources will drive forward research into inorganic crystals, and unlock the promise of machine learning tools as guides for experimentation

Accelerating materials discovery with AI

About 20,000 of the crystals experimentally identified in the ICSD database are computationally stable. Computational approaches drawing from the Materials Project, Open Quantum Materials Database and WBM database boosted this number to 48,000 stable crystals. GNoME expands the number of stable materials known to humanity to 421,000.

In the past, scientists searched for novel crystal structures by tweaking known crystals or experimenting with new combinations of elements - an expensive, trial-and-error process that could take months to deliver even limited results. Over the last decade, computational approaches led by the Materials Project and other groups have helped discover 28,000 new materials. But up until now, new AI-guided approaches hit a fundamental limit in their ability to accurately predict materials that could be experimentally viable. GNoME’s discovery of 2.2 million materials would be equivalent to about 800 years’ worth of knowledge and demonstrates an unprecedented scale and level of accuracy in predictions.

For example, 52,000 new layered compounds similar to graphene that have the potential to revolutionize electronics with the development of superconductors. Previously, about 1,000 such materials had been identified . We also found 528 potential lithium ion conductors, 25 times more than a previous study , which could be used to improve the performance of rechargeable batteries.

We are releasing the predicted structures for 380,000 materials that have the highest chance of successfully being made in the lab and being used in viable applications. For a material to be considered stable, it must not decompose into similar compositions with lower energy. For example, carbon in a graphene-like structure is stable compared to carbon in diamonds. Mathematically, these materials lie on the convex hull. This project discovered 2.2 million new crystals that are stable by current scientific standards and lie below the convex hull of previous discoveries. Of these, 380,000 are considered the most stable, and lie on the “final” convex hull – the new standard we have set for materials stability.

GNoME: Harnessing graph networks for materials exploration

GNoME uses two pipelines to discover low-energy (stable) materials. The structural pipeline creates candidates with structures similar to known crystals, while the compositional pipeline follows a more randomized approach based on chemical formulas. The outputs of both pipelines are evaluated using established Density Functional Theory calculations and those results are added to the GNoME database, informing the next round of active learning.

GNoME is a state-of-the-art graph neural network (GNN) model. The input data for GNNs take the form of a graph that can be likened to connections between atoms, which makes GNNs particularly suited to discovering new crystalline materials.

GNoME was originally trained with data on crystal structures and their stability, openly available through the Materials Project . We used GNoME to generate novel candidate crystals, and also to predict their stability. To assess our model’s predictive power during progressive training cycles, we repeatedly checked its performance using established computational techniques known as Density Functional Theory (DFT), used in physics, chemistry and materials science to understand structures of atoms, which is important to assess the stability of crystals.

We used a training process called ‘active learning’ that dramatically boosted GNoME’s performance. GNoME would generate predictions for the structures of novel, stable crystals, which were then tested using DFT. The resulting high-quality training data was then fed back into our model training.

Our research boosted the discovery rate of materials stability prediction from around 50%, to 80% - based on MatBench Discovery , an external benchmark set by previous state-of-the-art models. We also managed to scale up the efficiency of our model by improving the discovery rate from under 10% to over 80% - such efficiency increases could have significant impact on how much compute is required per discovery.

AI ‘recipes’ for new materials

The GNoME project aims to drive down the cost of discovering new materials. External researchers have independently created 736 of GNoME’s new materials in the lab, demonstrating that our model’s predictions of stable crystals accurately reflect reality. We’ve released our database of newly discovered crystals to the research community. By giving scientists the full catalog of the promising ‘recipes’ for new candidate materials, we hope this helps them to test and potentially make the best ones.

Upon completion of our latest discovery efforts, we searched the scientific literature and found 736 of our computational discoveries were independently realized by external teams across the globe. Above are six examples ranging from a first-of-its-kind Alkaline-Earth Diamond-Like optical material (Li4MgGe2S7) to a potential superconductor (Mo5GeB2).

Rapidly developing new technologies based on these crystals will depend on the ability to manufacture them. In a paper led by our collaborators at Berkeley Lab, researchers showed a robotic lab could rapidly make new materials with automated synthesis techniques. Using materials from the Materials Project and insights on stability from GNoME, the autonomous lab created new recipes for crystal structures and successfully synthesized more than 41 new materials, opening up new possibilities for AI-driven materials synthesis.

A-Lab, a facility at Berkeley Lab where artificial intelligence guides robots in making new materials. Photo credit: Marilyn Sargent/Berkeley Lab

New materials for new technologies

To build a more sustainable future, we need new materials. GNoME has discovered 380,000 stable crystals that hold the potential to develop greener technologies – from better batteries for electric cars, to superconductors for more efficient computing.

Our research – and that of collaborators at the Berkeley Lab, Google Research, and teams around the world — shows the potential to use AI to guide materials discovery, experimentation, and synthesis. We hope that GNoME together with other AI tools can help revolutionize materials discovery today and shape the future of the field.

- My presentations

Auth with social network:

Download presentation

We think you have liked this presentation. If you wish to download it, please recommend it to your friends in any social system. Share buttons are a little bit lower. Thank you!

Presentation is loading. Please wait.

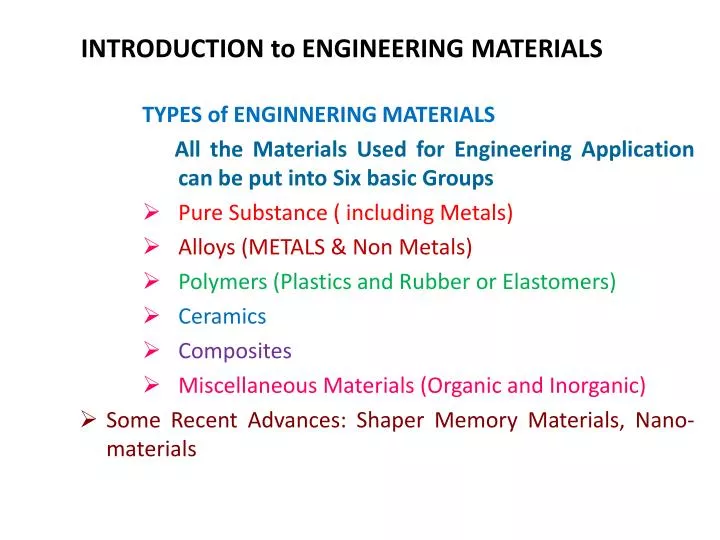

Introduction to Engineering Materials

Published by Marsha Francis Modified over 6 years ago

Similar presentations

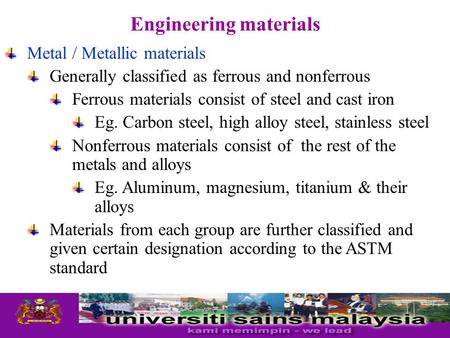

Presentation on theme: "Introduction to Engineering Materials"— Presentation transcript:

Ken YoussefiSJSU, ME dept. 1 Material Selection Function MaterialShape Process Material selection and process cannot be separated from the shape and the.

Engineering materials

Manufacturing with Composite

Polymers and Composites

Romina Javadianfard Period: 3. Alloys Alloy is a solid combination of atoms of two or more metals. Alloy is a solid combination of atoms of two or more.

Material Science and Materials Processing (Day 1) Class

Selection Criteria Properties Availability Cost Manufacturability

Ceramics Mixture of metallic and non-metallic elements (clay products). Traditional: whiteware, tiles, brick, sewer pipe, pottery, and abrasive wheels.

Design For Engineering Materials Science 2006 Greg Heitkamp This material is based upon work supported by the National Science Foundation under Grant No.

Types of Material IE 351 Lecture 3.

Materials - Metals Ken Youssefi PDM I, SJSU.

Forging new generations of engineers. Organics Metals and Alloys Polymers Ceramics Composites.

Fundamentals of Material Science and Engineering - Introduction Engr. Lina D. dela Cruz Chemical Engineering Department Technological Institute of the.

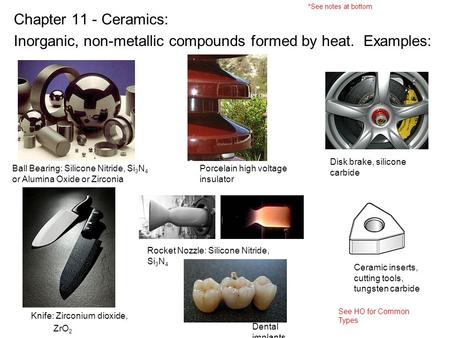

Inorganic, non-metallic compounds formed by heat. Examples:

Engineering Materials Dr. Berlanty Iskander. Types of Materials.

CE 241 MATERIALS SCIENCE Introduction

Categories of Materials Metals and Alloys Polymers Ceramics Composites.

Engineering Materials

About project

© 2024 SlidePlayer.com Inc. All rights reserved.

FREE K-12 standards-aligned STEM

curriculum for educators everywhere!

Find more at TeachEngineering.org .

- TeachEngineering

- Fun Look at Material Science

Lesson Fun Look at Material Science

Grade Level: 11 (9-12)

(three class periods)

Lesson Dependency: None

Subject Areas: Chemistry, Physics

NGSS Performance Expectations:

- Print lesson and its associated curriculum

Activities Associated with this Lesson Units serve as guides to a particular content or subject area. Nested under units are lessons (in purple) and hands-on activities (in blue). Note that not all lessons and activities will exist under a unit, and instead may exist as "standalone" curriculum.

- Battle of the Beams

| Lesson | Activity |

TE Newsletter

Engineering connection, learning objectives, worksheets and attachments, more curriculum like this, pre-req knowledge, introduction/motivation, associated activities, vocabulary/definitions, additional multimedia support, user comments & tips.

Creative engineering materials are continuously being developed, selected and used in all facets of industries, from consumer products to space exploration. Chemistry and physics are the backbone sciences in this field. Purposefully designed materials provide the means for modern products and tools to be built. Humanity has had a firm grasp of engineering materials and how to manipulate performance for centuries. However, until recently, we have not had the tools to fully understand the underlying mechanisms to such enhancements and provide optimized material solutions. Scientists and engineers develop and use basic principles to design new materials for different and ever-demanding applications. Materials design and behavior assessment is a function of mathematics, experimentation and a firm understanding of metallurgy and material science principles. Collaboratively, we are able to produce optimized materials that serve multiple functions within a given application and environment.

After this lesson, students should be able to:

- Describe basic structures of materials.

- Relate basic structures to four classes of materials.

- Identify modes of failure, mechanical behavior and relate to classes of materials.

- Explain materials development for engineering design requirements.

- Discuss various applications of materials and role in society.

Educational Standards Each TeachEngineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards. All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN) , a project of D2L (www.achievementstandards.org). In the ASN, standards are hierarchically structured: first by source; e.g. , by state; within source by type; e.g. , science or mathematics; within type by subtype, then by grade, etc .

Ngss: next generation science standards - science.

| NGSS Performance Expectation | ||

|---|---|---|

| HS-PS2-6. Communicate scientific and technical information about why the molecular-level structure is important in the functioning of designed materials. (Grades 9 - 12) Do you agree with this alignment? Thanks for your feedback! | ||

| This lesson focuses on the following aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Communicate scientific and technical information (e.g. about the process of development and the design and performance of a proposed process or system) in multiple formats (including orally, graphically, textually, and mathematically). Alignment agreement: Thanks for your feedback! | Attraction and repulsion between electric charges at the atomic scale explain the structure, properties, and transformations of matter, as well as the contact forces between material objects. Alignment agreement: Thanks for your feedback! | Investigating or designing new systems or structures requires a detailed examination of the properties of different materials, the structures of different components, and connections of components to reveal its function and/or solve a problem. Alignment agreement: Thanks for your feedback! |

International Technology and Engineering Educators Association - Technology

View aligned curriculum

Do you agree with this alignment? Thanks for your feedback!

State Standards

Texas - science.

Basic chemistry or physics concepts, such as the effects of temperature on solubility, force concept and safe laboratory concepts.

(In advance, prepare to show students the 28-slide Introduction to Material Science and Engineering Presentation , a PowerPoint file, and gather materials to conduct a class demonstration. See materials and instructions, below. The presentation includes basic information regarding material classes, material applications, and material behavior and serves as a foundation for acquiring basic knowledge for the remainder of the lesson. Allow 20-30 minutes for the presentation. The class demo illustrates the different classes of materials and material behavior, and engages the students in a review of presentation content.)

What is material science? (Listen to student ideas.) If it weren't for material scientists and engineers, we would have never made it to the moon, nor would your laptop work!