- News and Events

- Worldwide Installations

- Company Brochure

Call Now +91 99157 43183

Write to us [email protected]

- Company Profile

- About Founder

- About Chairman

- Chairman’s Message

- Production Head

- Executive Director

- Vision & Mission

- CSR & Child Labour

- Our Presence

- Certifications & Memberships

- Awards & Achievements

- Testimonials

- Fabrication Shop

- Machine Shop

- Assembly Shop

- Packaging and despatch

- Oil Expeller / Oil Press – G 10

- Oil Expeller / Oil Press – G 20

- Oil Expeller / Oil Press – G VC-I

- Oil Expeller / Oil Press – G 60

- Oil Expeller / Oil Press – G MK-III

- Oil Expeller / Oil Press – G 150

- Oil Expeller / Oil Press – G MK-IV

- Oil Expeller / Oil Press – G MK-V-C

- Oil Expeller / Oil Press – G 240

- Oil Expeller / Oil Press – G 600

- Oil Expeller / Oil Press – G 1500

- Oil Expeller / Oil Press – G 2400

- Oil Expeller / Oil Press – Palm Kernel

- Soybean Extruder

- Seed Decorticator

- Seed Cleaner

- Hammer Mill

- Copra Cutter

- Seed / Nut Cracker

- Copra Dryer

- Filter Press with Pump

- Pressure Leaf Filter

- Polishing Filters

- Vibro Separator

- Boiler – Horizontal (IBR)

- Boiler – Vertical (Non IBR)

- Thermic Fluid Heater

- Water Softening Plant

- Solvent Extraction Plant

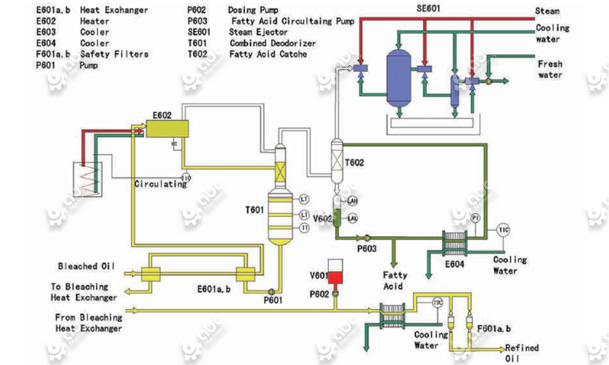

- Edible Oil Refinery Plant

- Fish, Poultry & Animal Feed Mill Plant

- EFB, MSW, Plastic & Industrial Shredder

- Material Handling Equipments

- Palm Kernel & other Oil Expeller / Oil Press Spare Parts

- Enquire Now

- News & Events

8 Steps To Start a Small Edible Oil Manufacturing Business

- Oil Extraction Machine / Oil Press

- Oil Mill Plants

- Solvent Extraction Plants

- Cooking Oil Refinery Plants

- Baobab Seed Oil Mill Plant

- Sunflower Oil : Everything we need to know

- Shea Butter: Origins, Production, Uses and Benefits

- Canola Oil Extraction Machines

- Coconut Oil Machine

- Oil Expeller – Goyum 10

- Oil Expeller – Goyum 20

- Oil Expeller – Goyum VC-I

- Oil Expeller – Goyum 60

- Oil Expeller – Goyum MK-III

- Oil Expeller – Goyum 150

- Oil Expeller – Goyum MK-IV

- Oil Expeller – Goyum MK-V-C

- Oil Expeller – Goyum 240

- Oil Expeller – Goyum 600

- Oil Expeller – Goyum 1500

- Oil Expeller – Goyum 2400

- Oil Expeller – Palm Kernel

- Decorticator

- Seed Cracker

- Filterpress with Pump

- Boiler – Vertical (Non IBR)

- Palm Kernel & Other Oil Expeller Spare Parts

Vegetable edible oil refers to oil obtained from oilseeds and nuts through an extraction process. Since their is an improvement in people’s living standards, the consumption of edible oils is also increasing day by day. Therefore, the extraction of vegetable oil is a profitable venture that in most cases rewards manufacturers with good profitable returns.

Vegetable oil is extracted from various oil seeds & nuts such as mustard / canola / rapeseed, copra / coconut, soya bean / soybean, peanut / groundnut, sunflower, cottonseed, sesame, neem, palm fruit & palm kernel, niger, sheanuts, flaxseed / linseed, etc through a mechanical pressing process. Non-edible oil is extracted from jatrpoha seed, castor seed, etc. People use cooking oils for various purposes including Cooking / Household, Animal feed, Furniture polish and conditioner, Leather preservative / Soap making, Hair moisturizer, etc. Nowadays, vegetable oil is also used as biodiesel fuel.

So if you want to start a small business or self-employment business, a cooking oil production business may be the best option to consider.

The following steps you need to set up an edible oil manufacturing business:

Step 1. learn more about the business.

Learn more about the business is the first step to start an oil mill company. Study the requirements of cooking oil manufacturing business in terms of technology, capital, market and competition. Please visit the website page https://www.oilexpeller.com/various-activity-of-oil-mill/ to gain more knowledge of the edible oil manufacturing industry.

Step 2. Craft your business plan

Either you should have an oil mill project report or adequate knowledge to start an edible oil production plant which includes the proposed land for oil production plant, sources of funds / capital, right oil mill machinery & equipment provider , return on investment (ROI), etc.

Before choosing a place for your edible oil processing plant, you have to consider the availability of raw materials, workforce, transport & road infrastructure, electricity availability, target market, etc. Oil Manufacturing plant location should be close to the target market and raw material sources which will reduce supply and transportation costs.

Having a good business plan is like to have a compass before going on an ocean trip. This gives you insights into everything you will need to establish and run a business successfully.

Step 3. Select your source of raw materials

You have two options to obtain the raw materials needed for the vegetable oil extraction plant. You can buy oil seeds from the supplier or have your own farm for the cultivation of oil seeds & nuts.

Step 4. Find a good plant location

The location of your business is another very important factor that can make your business more successful. It’s best to find the location which is close to your source of raw materials. For example, if you will be going into mustard oil production, you should locate your extraction plant nearby mustard oil plantation or suppliers. This will reduce transportation costs which will add to your profits.

Step 5. Get the funds

You will need money for buying land, machinery, plant construction, raw materials, working capital, etc. You will easily attract investors or get loans from banks or other lending institutions if you have a detailed oil mill project report which reflects that your business is profitable, sustainable and you have good knowledge about it.

Step 6. Choose suitable manufacturer and machines

We – GOYUM are leading manufacturer and exporter of cooking oil processing line and already have experience and expertise of more than 50 years in edible oil industry. We have exported to more than 63 Countries worldwide.

We provide a complete oil extraction plant on turnkey basis with excellent after sales support. Our advanced technology plants are reliable, robust, excellent in quality, reasonably priced, works continuously with efficiency.

Step 7. Hire employees

By using different hiring mediums, you can hire employees as per your requirements for your oil production plant.

You can also use your personal contacts to hire employees / workforce for effective running of your edible oil processing plant.

Step 8. Plan the packaging and distribution

The oil is collected in the filtered oil storage tank and then it is tested, if it’s found up to the mark and has passed all the parameters set by your country government, the oil is taken to the packing stage for packing and distribution.

When the oilseeds are pressed, we get oil & oilcake. Oil Cakes have some quantity of oil in them and they are used to make animal feeds which are normally packed in bags.

Goyum Screw Press is engaged in designing, manufacturing, exporting, installation & commissioning and after-sales support for edible & non-edible oil mill industry.

We offer oil mill machinery for various oilseeds & nuts such as oil expeller / screw oil press machines , seed cleaner, decorticator, flaker, cracker, extruder, meal cooler, hammer mill, copra dryer, palm nutcrackers, boiler, oil filtration equipment, elevator, conveyor, control panel and many more.

Need guidance to start a vegetable oil manufacturing business?

Please contact us so that our sales team will communicate with you to provide you professional guidance and quotation as per your requirements. They will also share some videos, pictures, layouts, etc. for you better understanding.

Related Posts

No related posts.

Enquiry Now

(Please fill the below form)

- Troubleshooting

What are The Key Benefits of Setting Up an Edible Oil Plant

Verified by

Are you making plans to start an edible oil refinery? Or do you want to evaluate the potential risks and challenges associated with setting up an edible oil plant? If yes, then you have landed in the right place.

In this blog, we will discuss the benefits of setting up edible oil refinery plants, which will help you make informed decisions on your plant establishment and unlock limitless opportunities to thrive.

According to Statista , the Edible oil market is projected to reach a revenue of US$117.1 billion in 2023, with an anticipated annual growth rate of 6.72% (CAGR 2023-2028). Hence, the future opportunities in an edible oil refinery are bright, but to make the most of these opportunities, you need to plan and strategize your edible oil refinery production.

And the first step to maximizing your oil refinery's production is to set up a plant that delivers sustainable oil production. The purpose of sustainable oil production is to address the challenges that the current edible oil market industry faces. There is always a threat and high risk of disruption in the supply chain in the edible oil market due to disruptions like War, climate change, and uneven demand.

Hence, to mitigate such high risk challenges, edible oil refineries or entrepreneurs need a sustainable oil production strategy, and that is possible by setting up an organized edible oil plant.

So, to make you understand the importance of sustainable vegetable oil production, we are going to discuss the benefits of setting up an edible oil plant further in the next section. Hence, let’s begin our journey.

What are the Benefits of Setting Up an Edible Oil Plant?

Setting up an edible oil refinery plant can offer a multitude of advantages, contributing to both personal and economic growth. Vegetable oils are essential ingredients in cooking and food preparation, making them a staple in every household and restaurant.

However, edible oils are not only used in preparing food or consumed in food associated industries; the uses of cooking oils are diverse. These cooking oils are used in making medicines, research and development, cosmetics, and health supplements, which makes the demand for edible oils remain steady due to the indispensable role they play in various industries globally.

Hence, in order to ensure a constant and sustainable supply of edible oils and to thrive in a disruptive market environment, it is necessary to set up an edible oil processing plant. And here are the key benefits of Edible Oil refinery plant establishment:

Elevates Oil Quality and Sustainability

An edible oil refinery plant plays a crucial role in enhancing the quality and sustainability of cooking oils. Raw or crude oils obtained from sources like seeds, nuts, and fruits often contain impurities, undesirable flavors, and volatile compounds.

The refinery process involves various stages of purification and refinement to remove these impurities, which results in conversion of oils that are safe for consumption and have improved taste, aroma, and stability.

Additionally, the impact of refined edible oil impacts many aspects, such as

- Refining removes harmful substances and potential contaminants from the oils, making them healthier for consumption. This is especially important as cooking oils are a fundamental ingredient in daily diets.

- The removal of impurities leads to oils with a cleaner taste and aroma. This enhances the flavor of cooked dishes and preserves the natural essence of the ingredients.

- Refined oils are more stable and have a longer shelf life due to the removal of components that can cause spoilage or fouling.

- Refined oils have consistent quality, ensuring that they perform reliably during cooking processes such as frying, sautéing, and baking.

- Refining processes can include steps to minimize the environmental impact of production, such as proper waste management and energy-efficient practices.

Foster Employments

Establishing an edible oil refinery plant creates a significant number of job opportunities in various sectors of the economy. From skilled labor to managerial positions, the refinery plant requires a diverse workforce to manage and operate different aspects of the production process.

The diverse employment opportunities not only support the operations of the refinery plant but also contribute to the holistic growth and development of the community and broader society.

However, fostering employment through setting up of a cooking oil refinery plant impacts many other aspects, such as

- The setup and operation of the refinery plant generate direct employment opportunities within the local community. People can find jobs as machine operators, quality control technicians, maintenance staff, administrative personnel, and more.

- The refinery plant provides a platform for individuals to acquire specialized skills related to oil processing, quality control, equipment maintenance, and industrial management.

- With an increased workforce, there is a boost in economic activity as employees spend their earnings in the local economy. This stimulates demand for goods and services, supports other businesses, and contributes to the overall growth of the community.

- Job opportunities improve the socio-economic well-being of individuals by providing a means of earning a livelihood and supporting their families. This can lead to higher living standards and an improved quality of life.

- The refinery plant contributes to reducing unemployment rates in the area, which in turn enhances the stability and harmony of the local society.

- Employees gain valuable skills and knowledge through their work in the refinery. This skill acquisition can have long-term benefits, as these skills can be transferred to other industries or future career opportunities.

Offers Tailored Products

An edible oil refinery plant has the capability to produce a variety of edible oil products by customizing the refining process to meet specific consumer demands. Different types of oils, blends, and formulations can be created to align with varying industry needs, taste preferences, and health considerations.

By crafting oils that align with different preferences and requirements, the plant enhances customer satisfaction, strengthens brand loyalty, and positions itself as a dynamic player in the edible oil market.

The impact of customized cooking oil production is

- People have different preferences when it comes to cooking oils. Some prefer neutral oils for versatile cooking, while others seek oils with distinct flavors like olive oil or coconut oil. A refinery plant can craft oils that match these preferences.

- Consumers increasingly prioritize health and nutrition. The refinery plant can produce oils with specific health benefits, such as high-oleic oils or oils with omega-3 fatty acids, addressing the needs of health-conscious individuals.

- Different culinary practices require specific oils. A refinery plant can create oils suitable for high-heat cooking, deep frying, salad dressings, or baking, catering to the specific requirements of various cooking methods.

- The refinery plant can stay attuned to food trends and innovations. For example, if there is a growing demand for plant-based diets, the plant can produce oils that align with these dietary choices.

- Offering tailored products allows the plant to establish a distinct brand identity. Consumers are more likely to choose a brand that offers products tailored to their needs and preferences.

Enhance Food Security and Stability

One of the significant advantages of establishing an edible oil refinery plant is the enhancement of food security and stability. This benefit encompasses the plant's role in ensuring a consistent and reliable supply of edible oils, even in the face of external disruptions.

This reduces dependency on imported oils and mitigates the risks associated with supply chain disruptions due to factors such as global trade fluctuations, transportation challenges, or geopolitical tensions.

Such independent cooking oil production has a diverse impact on multiple factors such as

- Global events such as trade disputes, geopolitical tensions, or natural disasters can affect the availability of imported goods. A local refinery plant reduces the impact of such events on the availability of essential cooking oils.

- Regardless of external challenges, a local refinery plant can continue its operations, guaranteeing that cooking oils remain available to consumers without interruptions.

- In times of crisis or emergencies, having a local source of essential food items like cooking oils is crucial. The refinery plant enhances a community's ability to respond effectively to unforeseen situations.

- The establishment of a refinery plant encourages the cultivation of oilseed crops locally. This not only supports local farmers but also contributes to the diversification of agricultural activities.

- Reliance on imported oils can expose communities to price fluctuations and market uncertainties. A local refinery plant helps stabilize prices and reduces price shocks caused by global market changes.

- Food sovereignty entails a community's ability to control its food production. The refinery plant empowers communities to exercise greater control over a crucial aspect of their diet.

- Local production offers greater control and transparency over the supply chain. This leads to efficient distribution, reduced transportation costs, and minimized waste.

Meets Quality Standards and Compliance

An edible oil refinery plant operates under the framework of quality control measures, ensuring that the production processes align with industry standards and governmental regulations.

Setting up an edible oil refinery plant offers the significant benefit of meeting quality standards and compliance. This advantage pertains to the plant's adherence to stringent regulations and industry standards that ensure the production of safe, high-quality edible oils.

Here’s how quality standards and compliance impact various factors

- Compliance quality standards guarantee that the cooking oils produced by the refinery plant are safe for consumption. This is essential for public health and consumer confidence.

- Adherence to industry standards ensures that the quality of the cooking oils remains consistent across batches. Consumers can trust that they are receiving oils of the same high quality each time they make a purchase.

- Rigorous quality control minimizes the presence of contaminants, toxins, and harmful substances in the oils, safeguarding consumers from potential health risks.

- Consistently meeting quality standards enhances the credibility and trustworthiness of the plant. Consumers are more likely to choose oils from a plant known for its commitment to quality.

- A refinery plant that consistently produces oils that meet quality standards contributes to the positive reputation of the entire edible oil industry. This fosters consumer confidence and regulatory trust.

Enhance Profitability and Efficiency

An edible oil refinery plant streamlines the production process, implements cost-effective measures, and improves operational efficiency. This results in higher profitability and a stronger financial outlook for the business.

This advantage highlights the plant's ability to optimize operations, reduce costs, and improve overall financial performance.

Such an advantage impacts several factors, such as

- Through efficient production processes, resource allocation, and waste reduction, the refinery plant can lower production costs. This directly contributes to improved profit margins.

- Operational efficiency can lead to increased production capacity. The plant can process larger quantities of raw materials within the same timeframe, catering to growing market demands.

- Effective management of resources and processes minimizes the wastage of raw materials and energy. This reduction in waste directly translates into cost savings.

- Streamlined processes and efficient workflows result in quicker turnaround times for production. This responsiveness enables the plant to fulfill orders promptly.

- Efficiency-driven processes ensure consistency in the quality of cooking oils. This consistency contributes to customer satisfaction and repeat business.

Reduces Supply Chain Complexity

The establishment of an edible oil refinery plant offers a valuable benefit by reducing supply chain complexities. This advantage highlights the plant's role in streamlining the production process, minimizing dependencies on external sources, and simplifying the overall supply chain.

This reduces the need to source oils from distant locations, leading to streamlined operations and enhanced supply chain management.

The factors that impact supply chain management by setting up edible oil refinery plant are

- By producing oils locally, the plant reduces reliance on external suppliers for finished goods. This autonomy contributes to greater operational control.

- Local production allows for better inventory forecasting and management. The plant can respond to fluctuations in demand more effectively.

- The shorter distance between production and distribution points leads to faster lead times. This agility enables the plant to meet consumer demand promptly.

- Shorter transportation routes enable more efficient distribution, reducing the risk of product spoilage and ensuring fresher products for consumers.

- External disruptions, such as geopolitical tensions or transportation challenges, have minimal impact on the plant's ability to produce and supply cooking oils.

- Local production ensures a steady and consistent supply of cooking oils to consumers, promoting customer satisfaction and loyalty.

- The simplified supply chain allows the plant to focus on producing tailored products that cater to specific consumer preferences.

Now, as we discuss the benefits of setting up a refined oil manufacturing plant, we will move on to the next section, where we will discuss the challenges and their solutions to setting up an edible oil plant.

Hence, let’s move on to the next section and explore it.

What are the Challenges and Solutions to Setting up an Edible Oil Plant?

As every coin has two sides, setting up an edible oil production plant also has a few drawbacks along with its benefits. However, such drawbacks have solutions, so let’s discuss them briefly in this section.

Lack of Skilled Labor

One of the significant hurdles in establishing an edible oil plant is the scarcity of skilled workers familiar with the specialized processes involved. Operating an oil plant requires individuals who understand the intricacies of machinery, quality control, and safety protocols.

Solution: To address this challenge, it is essential to invest in training programs. Collaborate with local technical institutions or vocational schools to design courses that teach the necessary skills.

By imparting knowledge and hands-on training, you can nurture a pool of capable workers who are equipped to manage the plant's operations efficiently.

Infrastructure and Location Shortage

Determining the optimal location for the edible oil plant and ensuring the availability of suitable infrastructure is a complex task. The plant's efficiency relies on factors such as transportation access, proximity to raw materials, and a well-designed layout.

Solution: Overcoming this challenge involves meticulous planning. Choose a location strategically, taking into account transportation networks that facilitate the movement of raw materials and finished products.

Constant Technological Advancement

The landscape of industrial technology is continuously evolving, and edible oil plants must adapt to remain competitive. Failing to stay updated with the latest advancements can hinder operational efficiency and product quality.

Solution: Allocate resources for ongoing technological upgrades. Employ experts who can monitor industry trends and assess the applicability of new technologies to the plant's processes.

Regularly invest in advanced technologies or get in touch with edible oil refinery plant manufacturers to get innovative solutions for your edible oil process. The edible oil refinery plant manufacturers provide a comprehensive solution and utilize cutting-edge technologies for sustainable oil production.

Ready to Set up an Edible Oil Plant?

By going through this blog, if you are ready to set up an edible oil plant, you can get in touch with seasoned oilseeds, oils, and fats technology company . They will help you establish an edible oil refinery plant embedded with the latest technologies. They possess the expertise to assist you at every step of the way, from conceptualization to implementation, ensuring that your venture is equipped with the latest industry innovations and best practices.

Get in touch with them today and lay the foundation for a successful and modern edible oil plant that meets the demands of today's dynamic market.

N & T Engitech

This blog was created by NandT Engitech using automation technology and was carefully reviewed and verified by our editorial team and an industry expert.

Build Something People Want

Let's talk about your engineering needs to find the best solutions.

Related Post

How Can You Find the Best Oil Extraction Machine Manufacturers for Your Small Edible Oil Plant?

How Does Biodiesel Production Influence the Future of Energy?

Understanding the Importance of Industrial Spares in Edible Oil Plants

Submit your business inquiry.

Are you interested in learning more about our technologies? Feel free to contact us right away to discuss your project.

- Food & Beverages

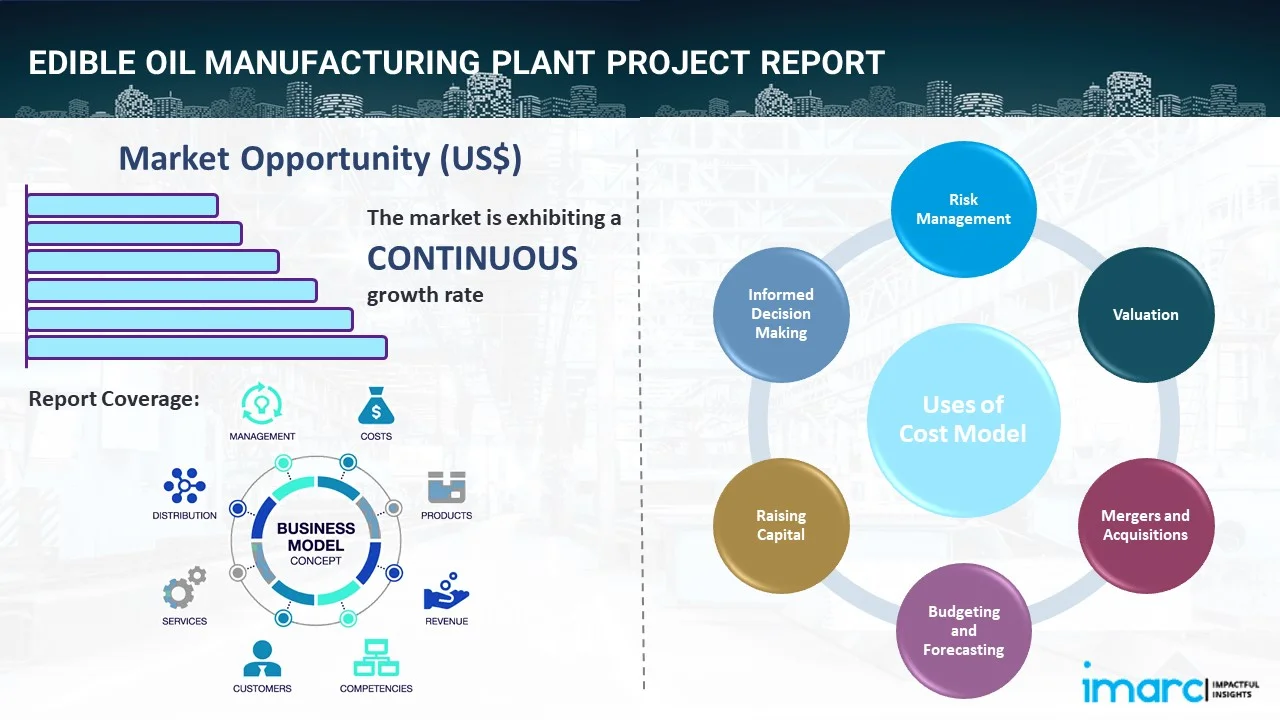

Edible Oil Manufacturing Plant Project Report

Edible oil manufacturing plant project report 2024: industry trends, plant setup, machinery, raw materials, investment opportunities, cost and revenue.

- Report Description

- Table of Contents

- Methodology

- Request Sample

Report Overview:

IMARC Group’s report, titled “Edible Oil Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up an edible oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The report also provides detailed insights into project economics influencing the edible oil manufacturing plant cost, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

Edible oil, a fundamental ingredient in culinary traditions worldwide, plays a pivotal role in cooking, flavoring, and nutrition. Derived from various plant and seed sources, such as olive, soybean, sunflower, and coconut, edible oils serve as cooking mediums, add richness to dishes, and provide essential fatty acids necessary for a balanced diet. Beyond its culinary significance, edible oil has a significant impact on global agriculture, trade, and health, as consumers increasingly seek healthier options and sustainable production methods. The versatile nature of edible oil makes it an indispensable component of daily cooking routines and a vital element in the food industry, reflecting its enduring relevance in modern kitchens and diets.

This ingredient offers a multitude of advantages and applications in culinary and industrial settings. Firstly, it serves as a versatile cooking medium, enabling frying, sautéing, and baking while enhancing the flavors of dishes. Edible oils also contain essential fatty acids that promote overall health, including heart health. They are a source of energy and aid in nutrient absorption. In addition to cooking, edible oils find applications in the food industry, serving as ingredients in salad dressings, sauces, and baked goods. Moreover, they are used in non-food sectors like cosmetics, pharmaceuticals, and biofuels. Their lubricating properties make them essential in machinery and industrial processes.

The edible oil market is shaped by a combination of market drivers and evolving trends that reflect changing consumer preferences, health consciousness, and global economic dynamics. The ever-increasing global population drives consistent demand for edible oils as they are a dietary staple in most cuisines. As urbanization rises, more people rely on convenient, pre-packaged foods and dine out frequently, leading to a higher demand for edible oils in the foodservice industry. Growing health awareness has led consumers to seek oils with healthier profiles, such as those low in saturated fats and high in unsaturated fats like olive and avocado oils. Economic development and rising incomes in emerging economies contribute to increased consumption of edible oils, as consumers have greater purchasing power. There is a growing trend towards healthier oil options, including cold-pressed, organic, and oil blends with health-promoting additives like omega-3 fatty acids. Consumers are increasingly interested in the transparency of the oil production process and product labeling, prompting companies to provide detailed information on sourcing and processing methods.

The following aspects have been covered in the edible oil manufacturing plant report:

- Market Trends

- Market Breakup by Segment

- Market Breakup by Region

- Price Analysis

- Impact of COVID-19

- Market Forecast

The report provides insights into the landscape of the edible oil industry at the global level. The report also provides a segment-wise and region-wise breakup of the global edible oil industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of edible oil, along with the industry profit margins.

- Product Overview

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

The report also provides detailed information related to the edible oil manufacturing process flow and various unit operations involved in a manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

- Land, Location and Site Development

- Plant Layout

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, expenditure, and other edible oil manufacturing plant setup. Additionally, the report provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

manufacturing-plant-raw-materials.webp)

- Capital Investments

- Operating Costs

- Expenditure Projections

- Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

The report also covers a detailed analysis of the project economics for setting up an edible oil manufacturing plant. This includes the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the edible oil manufacturing plant report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up an edible oil manufacturing plant.

Profitability Analysis:

| Particulars | Unit | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 |

|---|---|---|---|---|---|---|

| US$ | XX | XX | XX | XX | XX | |

| US$ | XX | XX | XX | XX | XX | |

| US$ | XX | XX | XX | XX | XX | |

| % | XX | XX | XX | XX | XX | |

| US$ | XX | XX | XX | XX | XX | |

| % | XX | XX | XX | XX | XX |

Report Coverage:

| Report Features | Details |

|---|---|

| Edible Oil | |

| Unit Operations Involved, Quality Assurance Criteria, Technical Tests, Mass Balance, and Raw Material Requirements Selection Criteria and Significance, Location Analysis, Project Planning and Phasing of Development, Environmental Impact, Land Requirement and Costs Importance and Essentials, Layout, Factors Influencing Layout Machinery Requirements, Machinery Costs, Machinery Suppliers (Provided on Request) Raw Material Requirements, Raw Material Details and Procurement, Raw Material Costs, Raw Material Suppliers (Provided on Request) Packaging Requirements, Packaging Material Details and Procurement, Packaging Costs, Packaging Material Suppliers (Provided on Request) Transportation Requirements and Costs, Utility Requirements and Costs, Energy Requirements and Costs, Water Requirements and Costs, Human Resource Requirements and Costs Capital Costs, Techno-Economic Parameters, Income Projections, Expenditure Projections, Product Pricing and Margins, Taxation, Depreciation Liquidity Analysis, Profitability Analysis, Payback Period, Net Present Value, Internal Rate of Return, Profit and Loss Account, Uncertainty Analysis, Sensitivity Analysis, Economic Analysis Market Trends and Analysis, Market Segmentation, Market Breakup by Region, Price Trends, Competitive Landscape, Regulatory Landscape, Strategic Recommendations, Case Study of a Successful Venture | |

| US$ (Data can also be provided in the local currency) | |

| US$ 3450 US$ 4450 US$ 5450 | |

| The report can also be customized based on the requirement of the customer | |

| 10-12 Weeks | |

| PDF and Excel through email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the edible oil market performed so far and how will it perform in the coming years?

- What is the market segmentation of the global edible oil market?

- What is the regional breakup of the global edible oil market?

- What are the price trends of various feedstocks in the edible oil industry?

- What is the structure of the edible oil industry and who are the key players?

- What are the various unit operations involved in an edible oil manufacturing plant?

- What is the total size of land required for setting up an edible oil manufacturing plant?

- What is the layout of an edible oil manufacturing plant?

- What are the machinery requirements for setting up an edible oil manufacturing plant?

- What are the raw material requirements for setting up an edible oil manufacturing plant?

- What are the packaging requirements for setting up an edible oil manufacturing plant?

- What are the transportation requirements for setting up an edible oil manufacturing plant?

- What are the utility requirements for setting up an edible oil manufacturing plant?

- What are the human resource requirements for setting up an edible oil manufacturing plant?

- What are the infrastructure costs for setting up an edible oil manufacturing plant?

- What are the capital costs for setting up an edible oil manufacturing plant?

- What are the operating costs for setting up an edible oil manufacturing plant?

- What should be the pricing mechanism of the final product?

- What will be the income and expenditures for an edible oil manufacturing plant?

- What is the time required to break even?

- What are the profit projections for setting up an edible oil manufacturing plant?

- What are the key success and risk factors in the edible oil industry?

- What are the key regulatory procedures and requirements for setting up an edible oil manufacturing plant?

- What are the key certifications required for setting up an edible oil manufacturing plant?

Report Customization

While we have aimed to create an all-encompassing edible oil plant project report , we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include:

- The report can be customized based on the location (country/region) of your plant.

- The plant’s capacity can be customized based on your requirements.

- Plant machinery and costs can be customized based on your requirements.

- Any additions to the current scope can also be provided based on your requirements.

Why Buy IMARC Reports?

- The insights provided in our reports enable stakeholders to make informed business decisions by assessing the feasibility of a business venture.

- Our extensive network of consultants, raw material suppliers, machinery suppliers and subject matter experts spans over 100+ countries across North America, Europe, Asia Pacific, South America, Africa, and the Middle East.

- Our cost modeling team can assist you in understanding the most complex materials. With domain experts across numerous categories, we can assist you in determining how sensitive each component of the cost model is and how it can affect the final cost and prices.

- We keep a constant track of land costs, construction costs, utility costs, and labor costs across 100+ countries and update them regularly.

- Our client base consists of over 3000 organizations, including prominent corporations, governments, and institutions, who rely on us as their trusted business partners. Our clientele varies from small and start-up businesses to Fortune 500 companies.

- Our strong in-house team of engineers, statisticians, modeling experts, chartered accountants, architects, etc. has played a crucial role in constructing, expanding, and optimizing sustainable manufacturing plants worldwide.

India Dairy Market Report Snapshots Source:

Statistics for the 2022 India Dairy market share, size and revenue growth rate, created by Mordor Intelligence™ Industry Reports.

- India Dairy Market Size Source

- --> India Dairy Market Share Source

- India Dairy Market Trends Source

- India Dairy Companies Source

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Purchase options

Benefits of Customization

Personalize this research

Triangulate with your data

Get data as per your format and definition

Gain a deeper dive into a specific application, geography, customer, or competitor

Any level of personalization

Get in Touch With Us

UNITED STATES

Phone: +1-631-791-1145

Phone: +91-120-433-0800

UNITED KINGDOM

Phone: +44-753-714-6104

Email: [email protected]

Client Testimonials

IMARC made the whole process easy. Everyone I spoke with via email was polite, easy to deal with, kept their promises regarding delivery timelines and were solutions focused. From my first contact, I was grateful for the professionalism shown by the whole IMARC team. I recommend IMARC to all that need timely, affordable information and advice. My experience with IMARC was excellent and I can not fault it.

The IMARC team was very reactive and flexible with regard to our requests. A very good overall experience. We are happy with the work that IMARC has provided, very complete and detailed. It has contributed to our business needs and provided the market visibility that we required

We were very happy with the collaboration between IMARC and Colruyt. Not only were your prices competitive, IMARC was also pretty fast in understanding the scope and our needs for this project. Even though it was not an easy task, performing a market research during the COVID-19 pandemic, you were able to get us the necessary information we needed. The IMARC team was very easy to work with and they showed us that it would go the extra mile if we needed anything extra

Last project executed by your team was as per our expectations. We also would like to associate for more assignments this year. Kudos to your team.

.webp)

We would be happy to reach out to IMARC again, if we need Market Research/Consulting/Consumer Research or any associated service. Overall experience was good, and the data points were quite helpful.

The figures of market study were very close to our assumed figures. The presentation of the study was neat and easy to analyse. The requested details of the study were fulfilled. My overall experience with the IMARC Team was satisfactory.

The overall cost of the services were within our expectations. I was happy to have good communications in a timely manner. It was a great and quick way to have the information I needed.

My questions and concerns were answered in a satisfied way. The costs of the services were within our expectations. My overall experience with the IMARC Team was very good.

I agree the report was timely delivered, meeting the key objectives of the engagement. We had some discussion on the contents, adjustments were made fast and accurate. The response time was minimum in each case. Very good. You have a satisfied customer.

.webp)

We would be happy to reach out to IMARC for more market reports in the future. The response from the account sales manager was very good. I appreciate the timely follow ups and post purchase support from the team. My overall experience with IMARC was good.

IMARC was a good solution for the data points that we really needed and couldn't find elsewhere. The team was easy to work, quick to respond, and flexible to our customization requests.

- Competitive Intelligence and Benchmarking

- Consumer Surveys and Feedback Reports

- Market Entry and Opportunity Assessment

- Pricing and Cost Research

- Procurement Research

- Report Store

- Aerospace and Defense

- Agriculture

- Chemicals and Materials

- Construction and Manufacturing

- Electronics and Semiconductors

- Energy and Mining

- Food and Beverages

- Technology and Media

- Transportation and Logistics

Quick Links

- Press Releases

- Case Studies

- Our Customers

- Become a Publisher

United States

134 N 4th St. Brooklyn, NY 11249, USA

+1-631-791-1145

Level II & III, B-70, Sector 2, Noida, Uttar Pradesh 201301, India

+91-120-433-0800

United Kingdom

30 Churchill Place London E14 5EU, UK

+44-753-714-6104

Level II & III, B-70 , Sector 2, Noida, Uttar Pradesh 201301, India

+44-20-8040-3201

We use cookies, including third-party, for better services. See our Privacy Policy for more. I ACCEPT X

Chat With Us

Schedule A Call Back

Our Experts are ready to assist you, Let's Connect with Us By submit your enquiry.

Welcome to Corpseed. Please type your query, and we shall provide immediate assistance.

Didn't receive code? Resend OTP

Your Enquiry has been received !!

Our legal advisor will contact you shortly.., how to start an edible oil manufacturing business.

Have you ever thought about starting your own edible oil manufacturing business?

The journey from seed to shelf can be exciting and fulfilling, but it also requires careful planning and execution to ensure success.

In this article, I will share a step-by-step guide on how to start your own edible oil manufacturing business, covering everything from choosing the appropriate set of equipment to manufacturing your business. Whether you're just starting or looking to improve your existing business, this guide will provide practical tips and strategies to help you achieve your goals and thrive in the competitive edible oil industry.

So, let's get started and help you know more about it.

Table of Contents

What is Edible Oil?

Different types of cooking oil , what is the cooking oil manufacturing process, required machinery for oil manufacturing business , a step-by-step guide to starting your own edible oil manufacturing business, top companies in edible oil industry , what is the edible oil manufacturing plant cost, what is the market size of edible oil manufacturing, get your edible manufacturing business on the right track: the importance of fssai license, trade license, and pollution certificate.

--------------Blog Contact Form-------------

Edible Oil or cooking oil Refers to a liquid fat derived from plants or animals used in baking and other cooking methods. With oil, you can cook at higher temperatures for long periods, making it quicker and more appealing to taste buds; while distributing heat evenly and reducing the possibility of burning. In addition, Edible Oil consists of various types, including edible peanut oil, edible vegetable oil, soyabean oil, etc.

There are several types of cooking oil, and quite a few are of the following importance-

- Olive Oil is one of the most beneficial cooking oils to include in a healthy diet. It is rich in antioxidants, beneficial compounds that can reduce chronic diseases. It also contains Vitamin E, a powerful antioxidant that can reduce inflammation and protect against oxidative damage.

- Peanut Oil:- Peanut oil is a great choice for frying due to its ability to withstand high temperatures before breaking down. It has a neutral flavour making it a great addition to many dishes. Additionally, peanut oil is a good source of vitamin E, antioxidants, and healthy monounsaturated fats, though it needs to be consumed in moderation. All-in-all, peanut oil is suitable cooking oil and can add a unique flavour to your dishes.

- Soybean & other Vegetable oils:- Vegetable oil comprises Soyabean & corn oil which mainly includes; soybean, canola, and sunflower oils. Moreover, it has a high smoke point and is involved in the processes like stir-frying & baking.

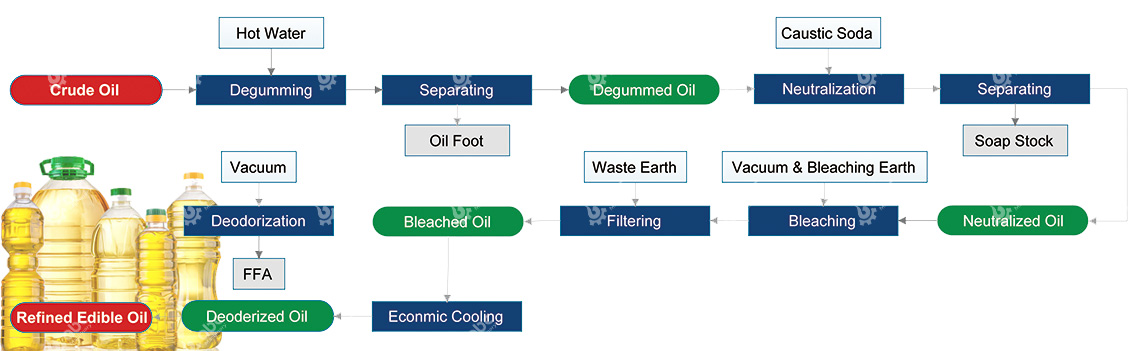

The Cooking Oil Manufacturing process can be broken down into several steps,

Let us have a look at it-

- Step 1:- Initially, it involves Processing and extracting oils from derived fats and vegetable sources. The extraction oils and fats are utilized for human consumption but are used in animal feed or for medicinal properties.

- Step 2:- Then we come to the preparation of raw material with the process of cleaning, husking, rushing, and conditioning. Most of the time, the extraction process is mechanical by using the involvement of solvents like hexane.

- Step 3:- The Next process includes boiling, skimming, pressing, or filtering involving solvent extraction, where solvent & crude oil are separated. These residues, in turn, are processed again to gain by-products like Animal feed. The crude oil even includes processes involving bleaching, refining, Deodorization & Neutralization.

Edible oil manufacturing covers a range of machinery used in the edible oil refinery, which might vary, depending on the kind of plant, such as:

- Thermic Fluid Boiler

- Box Stamping

- Barometric Condenser

- Weighing Scale

- Screw Expeller

- Steam Generator

- Oil Presser

- Storage Tank

- Sealing & Packing Machine

- Oil Filters

The guide to starting your own edible manufacturing business is as follows-

- Step 1 - What is your business: Before making business plans, one needs to discover more about it. Such a thing will help you gauge various components and requirements related to capital, competition & market in the edible oil business.

- Step 2 - Identify your business plan: After discovering your business intent via research, you need to mend a business plan. To do this, you require comprehensive knowledge of initiating edible oil production with adequate land, machinery, capital, etc. Check for raw materials, hire skilled staff, and know your target audience. Look at the big picture & how your edible manufacturing business can prosper.

- Step 3 - Decide the source of raw materials: As a firm that aspires to set up an edible oil plant, you need to track down the Main sources of raw materials required for extracting vegetable oil. You may even contact a supplier or grow the same on your farm.

- Step 4 - Hunt for plant location: Choosing the Location of your cooking oil plant seems crucial & can impact your business to a large extent. However, it is strategic to look for the area that carries the potential to generate maximum raw material. For instance, if you choose edible oil for your manufacturing business, then; you should find an extraction plant close to the plantation or mainly the suppliers. Being the best part, it carries the potential to minimize transportation costs.

- Step 5 - Seek funds: While Commencing a manufacturing business, one looks at raw materials, machinery & financial considerations. In the case of the latter, you can propose your proposal to investors or take loans from Banks.

- Step 6 - Look for machinery & manufacturers: You should focus on manufacturers; who carry experience and expertise of many years. Look for plants that are robust, high-quality, and priced adequately.

- Step 7 - Hire staff: People prefer skilled & experienced labour when it comes to; hiring staff. It is because they carry extensive knowledge and expertise in the required subject. For example; For an edible oil manufacturing business, you will recruit members with experience in a similar background as edible oil production. Isn't it?

- All those who know the Needs & Requirements of your edible oil plant in a much better way.

- Step 8 - Packaging: The extracted Oil is stored in the storage tanks, and if it passes all the standards set by the required authority, it is taken to the packaging & distribution stage.

If you are keen on knowing the top companies in the field of the Edible Oil Industry, the following are quite a few-

- Adani Wilmer Limited:- Adani is Responsible for manufacturing various products, such as cooking oils with ready-to-cook snacks, pulses, sugar, and salt. It has even joined hands with companies in expanding its venture & inviting new leads in edible oil manufacturing.

- Agro Tech Food Ltd:- It is a food trading & processing public company that takes care of the Processing, manufacturing and look the same trading of food products. They mainly produce edible oils, animal feeds & much more. It aims for the expansion & production of sustainable products. The firm concentrates on solidifying partnerships to work on newer projects while expanding its customer base.

- Emami Agrotech Limited:- Emami Agrotech Limited is an agritech company that manufactures edible oils, fats, and other ingredients. In addition, it is trying to maintain product quality and sustainability by attracting newer audiences to establish its global presence.

The capacity of an edible oil manufacturing plant, type of machinery, way of processing oil, etc., are all factors to consider when setting up a plant. The Edible Oil Manufacturing Plant is estimated to cost between 20 and 30 lakhs based on the investment.

The Edible Oils market is expected to generate US$28.23bn in revenue in 2023, and the market is expected to grow at a compound annual growth rate (CAGR) of 7.41% from 2023 to 2028. India is the largest market in terms of revenue, with US$28,230.00m in 2023. This is a testament that Edible Oils are an important part of the Indian diet. This trend is expected to continue over the next few years, with the market continuing to expand. With the growing demand for Edible Oils, the market is expected to continue to grow in the coming years.

As a business owner, you want to ensure that your company operates legally and ethically. Obtaining the necessary Licenses and certificates for the edible manufacturing business is a crucial step in achieving this goal. The Food Safety and Standards Authority of India (FSSAI) license, trade license, and Fire NOC are three essential documents that every business in India requires.

These Licenses and Certificates ensure that your business is adhering to the laws and regulations set by the government. They also demonstrate to your customers and stakeholders that you are committed to providing safe and responsible products and services.

- FSSAI (Food Safety and Standards Authority of India):- It is in charge of ensuring and safeguarding the welfare of the populace through appropriate regulation and oversight. The Ministry of Health and Family Welfare oversees this license. Anyone who deals with food goods must obtain a License and register. Any organization that works with products connected to Food must use the FSSAI. To verify whether Food satisfies the necessary quality requirements, the packaged Food comes with the FSSAI registration number . Therefore, You must submit an application based on your annual turnover to be certified by the FSSAI. If you must register, check the FSSAI checklist. You shall adhere to all procedures and requirements while registering. It is necessary to adhere to these requirements.

- Trade License:- This license is a must-have for all manufacturing businesses. A License includes a document/certificate that permits the applicant (person seeking to open a business) to establish a particular trade or business in any area/location.

- Fire NOCs:- To Mention, Fire NOCs state fire service to ensure that a building is not susceptible to fire-related accidents. Ensure and meet the criteria by the fire department. For this, An applicant requires NOC for his residential/ commercial building.

- Import-Export License:- An Import & Export Code is one of the requirements for businesses such as the edible oil manufacturing business on exporting or importing products from India. In addition, it comes under the Foreign Trade (Development & Regulation) Act of 1992 and India's Export Import (EXIM) Policy. It consists of a 10-digit code issued by the Director General of Foreign Trade with lifelong validity.

Starting an Edible oil manufacturing business can be lucrative, especially in areas where the demand for cooking oil is skyrocketing. However, like any other business, there are several points that you should consider before venturing into this industry. In addition, an edible oil manufacturing business can be a profitable venture if done in the correct ways. By conducting detailed research, developing a comprehensive business plan, and abiding by legal and regulatory requirements, you can set yourself up for a successful business venture in this industry. Remember to invest in high-quality equipment and machinery with a strong marketing strategy that will monitor and improve your production process.

This portion of the site is for informational purposes only. The content is not legal advice. The statements and opinions are the expression of author, not corpseed, and have not been evaluated by corpseed for accuracy, completeness, or changes in the law.

BOOK A FREE CONSULTATION

Get help from an experienced legal adviser. Schedule your consultation at a time that works for you and it's absolutely FREE.

Shamshad Alam

Latest articles.

Thank you for your vote! Would you have any suggestions for improvements?

Thanks so much for sharing your experience with us , we hope to see you again soon. .

Tailored Business Plans for Various Oilseeds

Are you considering the establishment of an edible oil business? Do you require a sample business plan for edible oil? In that case, let's delve into a comprehensive plan for initiating an edible oil business.

ABC Machinery engages in the design, manufacture, and export of edible oil extraction projects and assists in setting up various oil production plants. We also offer professional customized edible oil mill plants and various oilseed processing services.

- How to Setup Soya Oil Pressing Mill?

- How to Start a Sunflower Oil Refining Business?

- Business Plan for Operating A Olive Oil Pressing Plant

- Complete Cotton Seed Oil Processing Plant

- Business Plan for Setting Up a Palm Oil Processing Mill

- How to Invest in Establishing a Coconut Oil Manufacturing Factory?

- How to Extract Protein from Soybean

- Time to Setup Mustard Oil Press Machine Factory

Unleashing the Power: Exploring the Potential of the Oil Mill Business

The global demand for vegetable oils is on the rise, making the oil mill business a lucrative venture for entrepreneurs. According to market research, the global vegetable oil market is expected to reach USD 298.5 billion by 2027, driven by the rising health consciousness and increasing use of vegetable oil in various industries, including food, pharmaceuticals, and personal care.

By venturing into the oil mill business, you have the potential to tap into this growing market and generate significant profits. With the right business plan and marketing strategies, you can build a successful oil mill business that meets the demands of consumers worldwide.

3 Steps to Start an Oil Mill Plant Business

Step one: formulate a strategy for oil extraction.

Developing a sound strategy for your oil extraction business is the initial step in launching your company or oil mill.

Familiarize yourself with the technological, financial, market, and competitive aspects of the edible oil extraction industry.

Consult websites to acquire knowledge on the economic scope and industry statistics specific to your region.

Create a strategy encompassing the proposed location, target market, startup capital, operational expenses, and other financial considerations.

| Expense Category | Cost (USD) |

|---|---|

| Land Acquisition | $100,000 |

| Building Construction | $500,000 |

| Machinery and Equipment | $1,000,000 |

| Raw Material Supply | $200,000 |

| Utilities | $100,000 |

| Labor Costs | $300,000 |

| Permits and Licenses | $50,000 |

| Marketing and Promotion | $100,000 |

| Miscellaneous Expenses | $50,000 |

| Contingency Funds | $200,000 |

| Total | $2,600,000 |

Please note that these figures are just for illustration purposes, and the actual costs may vary depending on various factors such as location, size of the plant, quality of machinery, market conditions, and other considerations. It's crucial to conduct a detailed feasibility study and consult with industry experts to determine the accurate budget for your specific project.

Step Two: Complete Your Edible Oil Extraction Equipment

ABC Machinery stands as a leading exporter of machines for making edible oil. Our extraction machines are capable of processing a wide range of oilseeds, such as corn, soybean, peanut, cottonseed, rapeseed, sunflower seeds, rice bran, palm fruit, palm kernel, and more.

Our oil processing apparatus comprises sturdy and durable machines with excellent properties and adaptability. The plant is characterized by its safety, reasonable cost, superior quality, high automation levels, continuous operation, and advanced technology.

Step Three: Understanding the extraction process of edible oil

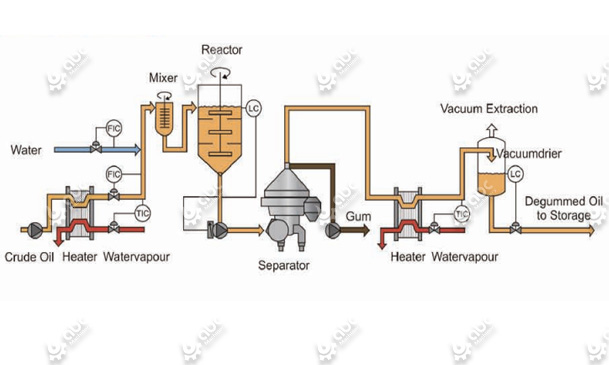

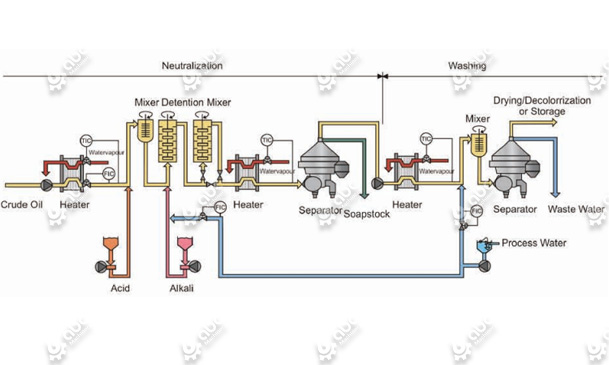

The extraction process of edible oil involves the following steps:

Raw material preparation: Select suitable edible oil raw materials such as peanuts, soybeans, cottonseeds, rapeseeds, etc. The raw materials are cleaned and screened to remove impurities and defective products.

Crushing and grinding: The raw materials are crushed into appropriate-sized particles to facilitate the release of oil. Crushers and grinders are commonly used for this step.

Steaming and heating: The crushed raw materials are subjected to steaming or heating in a steaming pot or heater. This process helps to break down the cell walls and facilitate the release of oil.

Oil pressing: The heated raw materials are fed into an oil press for the pressing process. Oil presses can employ different principles, such as physical pressing, solvent extraction, or a combination of both. Different methods yield different qualities and quantities of edible oil.

Oil settling and separation: The extracted mixture undergoes settling and separation processes to separate the oil from other components such as solids and water. Various techniques such as centrifugation or filtration may be employed for this purpose.

Refining: The extracted oil may undergo refining processes such as degumming, neutralization, bleaching, and deodorization to improve its quality, taste, and stability.

Packaging and storage: The refined edible oil is packaged in suitable containers and stored under appropriate conditions to maintain its quality and freshness.

It's important to note that the extraction process may vary depending on the type of edible oil and the specific requirements of the manufacturer.

Since these processes require the use of machines, it is crucial to invest in high-quality edible oil extraction machines for each stage.

Employing a good quality edible oil extraction machine will result in long-term time and cost savings. Therefore, it is imperative to carefully select your machines. To ensure smooth operation of your edible oil extraction machine, it is essential to hire competent employees. Advertise job openings for candidates experienced in the edible oil processing industry. Your team should include a technician, an assistant, a storekeeper, and approximately 5 to 10 other staff members, along with quality control, sales, administrative, and security personnel.

If you are interested in a personalized edible oil extraction machine, feel free to contact us! Simply provide details about your situation, such as location, factory size, planned budget, capacity requirements, and more. Based on this information, we can offer you the best tailored solution for your business.

Vegetable Oil Production Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business Plans » Agriculture Sector » Agro Processing

Are you about starting a vegetable oil production plant? If YES, here is a complete sample vegetable oil production business plan template & feasibility report you can use for FREE .

Okay, so we have considered all the requirements for starting a vegetable oil production business. We also took it further by analyzing and drafting a sample vegetable oil production business marketing plan template backed up by actionable guerrilla marketing ideas for vegetable oil production businesses. So let’s proceed to the business planning section.

Vegetable oil is the clear oil extract derived from components such as coconut, groundnut and palm kernel through a pressing and production process. Billions of gallons of vegetable oil are produced by farmers every year all over the globe.

Just in the united states alone, farmers produce as much as 16 billion pounds of vegetable oil every year. We humans use vegetable oil for a vast range of purposes, which include cooking, production of plastics and soaps. Also the waste products of vegetable oil production are now used to fuel diesel engines.

Vegetable oil production presents huge opportunities for career focused individuals, as this industry can boast of a large consumer base and various sectors to serve.

It also offers the option of working in collaboration with large vegetable oil extraction companies. This business might seem easy, but do not be deceived as starting a vegetable oil production business might be very hard but still remains the best option for you.

A Sample Vegetable Oil Production Business Plan Template

1. industry overview.

The World vegetable oil market is expected to grow pass 200 million metric tons by 2022, driven by the surging popularity of healthy, organic and unprocessed/unrefined vegetable oils. Low-fat, low-cholesterol and low-calorie vegetable oils are especially poised to benefit against the backdrop of growing consumer focus on health and fitness.

We are meant to understand that rising markets offer opportunities in the form of greater potential for higher market penetration and growth in per capita consumption, while in the developed markets, innovation in new flavours and healthy ingredients will spruce up consumption.

It is important to note that the Asia-Pacific represents the largest and the fastest growing market worldwide with a CAGR of 5.2% over the analysis period of 2010-2015.

It has been analysed that the main factors moving growth in the region include growing population and the corresponding growth in demand for food commodities; improved retailing network; changing dietary habits; rapid urbanization; improving living standards; increasing crop yields and oil production; changes in composition of vegetable oil consumption; and expanding non-edible applications.

2. Executive Summary

Hygienic Oil’s main goal is to provide a synthetic palm oil for our consumers in a way that is more sustainable and more cost effective than what our competitors are offering in the wide industry.

We at Hygienic Oil will be able to supply our consumers with synthetic Palm oil which is much cheaper than those of our competitors through our use of a vat-based fermentation process instead of making use of the traditional production process of purchasing expensive forested land. Our focus at Hygienic Oil will predominantly be on business to business selling whereby we will work as a manufacturer.

Hygienic Oil will do business from one major site in Kansas which will be made up of multiple large vats and outlying buildings for admin and research purposes. We believe that this facility will serve as a centre for distributing our synthetic Palm oil to shipping ports where it can be shipped around the world to companies such as Unilever.

Our management believe that our unique selling point of producing a more environmentally friendly alternative to naturally grown synthetic Palm oil will be the driving force behind generating interest and sales from consumers in the industry, and also gaining government and world approval.

We believe that our policies to use more environmentally friendly synthetic Palm oil will make sure that we retain customers, which our business will rely upon.

We at Hygienic Oil will also expect that, as arable land continues to dwindle in synthetic Palm oil producing countries and the price of synthetic Palm oil continues to soar, we will be able to capture more and more of our prospective customers’ sense of convenience and value generally. Cost in our business will be reduced by maintaining only a short supply chain.

Hygienic Oil will be owned by the six group members and the Emporia State University, each holding equal shares in the company. Also with the world currently becoming dependent on cultivation and production of agricultural products, including synthetic Palm oil, our unique business is very dedicated to reduce the impact this business would have on the world.

For this reason, the licenses to use this mode of production would be offered to the United States government at a negotiated price that would show the current value of synthetic Palm oil in the world. The US government would then be allowed or permitted to use the processes we devised at Hygienic Oil to continue to profit from trade in synthetic Palm oil components.

We strongly believe that replacing traditional methods of synthetic Palm oil production with Hygienic Oil would support the economy of the United States.

3. Our Products and Services

We at Hygienic Oil plan to offer the supply of lab-produced synthetic Palm oil to companies around the world. We have planned that Production will be based on-site in Kansas in a major complex located near to Kansas city shipping port to reduce the transport costs that comes with getting the synthetic Palm oil from the production factory to a position where it can be transported to our customers.

We believe that our one in a kind selling point of providing an environmentally less destructive alternative to current methods of synthetic Palm oil production will be very much enough to secure a leading role in the industry.

4. Our Mission and Vision Statement

- Our vision at Hygienic Oil is to create an oil production process that will reduce the effect and threat we pose to our environment due to all our industrial activities.

- Our mission at Hygienic Oil is to build a standard and world class synthetic Palm oil production business that in our own capacity will favourably compete with leaders in the industry. We want to build a synthetic Palm oil production business that will be seen as a vital alternative to the traditional synthetic Palm oil production process.

Our Business Structure

Our vision and picture of the kind of synthetic Palm oil production business we intend building and the business goals we want to achieve is what informed the amount we are ready to spend to make sure that we build a business with dedicated workforce and robust distribution network.

In view of that, we have decided to hire qualified and competent hands to occupy the following positions at Hygienic Oil;

- Chief Executive Officer (Owner)

Synthetic Palm oil Production Company Manager

Human Resources and Admin Manager

- Sales and Marketing Officer

- Accountants/Cashiers

Synthetic Palm oil Production Company Casual Workers

- Truck Drivers /Synthetic Palm oil Wholesale Distributors

- Customer Service Executives

5. Job Roles and Responsibilities

Chief Executive Officer

- Increases management’s effectiveness by recruiting, selecting, orienting, training, coaching, counseling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results; developing incentives; developing a climate for offering information and opinions; providing educational opportunities.

- Creates, communicates, and implements the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- Tasked with fixing prices and signing business deals.

- Tasked with providing direction for the business.

- Tasked with signing checks and documents on behalf of the company.

- Evaluates the success of the organization.

- Tasked with overseeing the smooth running of the synthetic Palm oil production company.

- Makes sure that quality is maintained at all times.

- Maps out strategy that will lead to efficiency amongst workers in the synthetic Palm oil production company.

- Tasked with training, evaluation and assessment of the workforce.

- Make sure operation of equipment by completing preventive maintenance requirements; calling for repairs.

- Make sure that the synthetic Palm oil production company meets the expected safety and health standard at all times.

- Tasked with overseeing the smooth running of HR and administrative tasks for the organization.

- Updates job knowledge by participating in educational opportunities; reading professional publications; maintaining personal networks; participating in professional organizations.

- Enhances department and organization reputation by accepting ownership for accomplishing new and different requests; exploring opportunities to add value to job accomplishments.

- Defines job positions for recruitment and managing interviewing process.

- Carries out staff induction for new team members.

- Tasked with training, evaluation and assessment of employees.

- Oversees the smooth running of the daily business activities.

Merchandize Manager

- Manages vendor relations, market/farm visits, and the ongoing education and development of the organization’s buying teams.

- Helps to maintain consistent quality and quantity of the synthetic Palm oil.

- Tasked with the purchase of palm kernels and measuring materials (drums, bottles, and plastics et al).

- Tasked with planning sales, monitoring inventory, selecting the merchandise, and writing pricing orders to vendors.

- Make sure that the organization operates within stipulated budget.

Sales and Marketing Manager

- Manages external research and coordinates all the internal sources of information to retain the organizations’ best customers and attract new ones.

- Models demographic information and analyses the volumes of transactional data generated by customer purchases.

- Identifies, prioritize, and reach out to new partners, and business opportunities et al.

- Tasked with supervising implementation, advocate for the customer’s needs, and communicate with customers.

- Develops, executes and evaluates new plans for expanding sales.

- Documents all customer contact and information.

- Represents the company in strategic meetings.

- Helps to increase sales and growth for the company.

- Tasked with operating synthetic Palm oil production equipment.

- Tasked with measuring and filling synthetic Palm oil into various containers as demanded by clients.

- Tasked with carrying out all casual or unskilled jobs in the synthetic Palm oil production company.

- Assists in loading and unloading of palm kernels and processed synthetic Palm oil.

- Handles any other duty as assigned by the synthetic Palm oil production company manager.

Accountant/Cashier

- Tasked with preparing financial reports, budgets and financial statements for the organization.

- Provides managements with financial analyses, development budgets and accounting reports; analyses financial feasibility for the most complex proposed projects; conducts market research to forecast trends and business conditions.

- Tasked with financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting.

- Tasked with developing and managing financial systems and policies.

- Tasked with administering payrolls.

- Makes sure of compliance with taxation legislation.

- Handles all financial transactions for the organization.

- Serves as internal auditor for the organization.

Distribution Truck Drivers

- Assist in loading and offloading palm kernels and processed synthetic Palm oil.

- Maintain a logbook of their driving activities to make sure of compliance with federal regulations governing the rest and work periods for operators.

- Keep a record of vehicle inspections and make sure the truck is equipped with safety equipment.

- Assist the transport and logistics manager in planning their route according to a delivery schedule.

- Local-delivery drivers may be required to sell products or services to stores and businesses on their route, obtain signatures from recipients and collect cash.

- Transport finished goods and raw materials over land to and from manufacturing company’s or retail and distribution centres.

- Inspect vehicles for mechanical and safety issues and perform preventative maintenance.

- Comply with truck driving rules and regulations (size, weight, route designations, parking, break periods etc.) as well as with company policies and procedures.

- Collect and verify delivery instructions.

- Report defects, accidents or violations.

Client Service Executive

- Makes sure that all contacts with customer (e-mail, walk-In centre, SMS or phone) provides the client with a personalized customer service experience of the highest level.

- Through interaction with customers on the phone, uses every opportunity to build client’s interest in the company’s products and services.

- Manages administrative duties assigned by the store manager in an effective and timely manner.

- Consistently stays abreast of any new information on Hygienic Oil products promotional campaigns to make sure accurate and helpful information is supplied to customers when they make inquiries.

6. SWOT Analysis

We at Hygienic Oil because of our zeal for excellence when it comes to running a standard synthetic Palm oil production business, have been able to contact some of the finest business consultants in Kansas to look through our business concept and together we were able to go through the prospect of the business and to be sure we have what it takes to run a standard synthetic Palm oil production business that can compete favourably in the synthetic Palm oil production sector.