- Corpus ID: 169555558

Technology Transfer from a Technical University: A Case Study of IIT Delhi

- P. Bhattacharya

- Published 1 September 2005

- Engineering, Business

11 Citations

Foundation for innovation and technology transfer (fitt): a case study on industry–academia interface in india, the roadmap for enhancing university–industry research collaboration in india, science, technology, innovation and ip in india: new directions and prospects, towards an integrated model for academia- industry interface in india, university-industry technology transfer: issues and probable remedies, melbourne institute working paper series working.

- Highly Influenced

Indian Universities and their Involvement in Patenting Activity

Recognize the role of academia and industry to match between demand and supply of quality manpower, structural equation modeling ( sem ) approach to identify critical success factors of technology transfer : an empirical analysis from indian context, determining design patent similarity based on the ordinary observer test, one reference, technology transfer and the intellectual property issues emerging from it – an analysis from a developing country perspective, related papers.

Showing 1 through 3 of 0 Related Papers

Tata Electronics and Powerchip Semiconductor Manufacturing Corporation (PSMC) Complete Landmark Agreement for Technology Transfer to Build India's First Semiconductor Fab

News provided by

26 Sep, 2024, 18:41 IST

Share this article

NEW DELHI , Sept. 26, 2024 /PRNewswire/ -- Tata Electronics, a wholly owned subsidiary of Tata Sons Pvt. Ltd, a pioneer in India's electronics manufacturing sector, has announced a significant step forward in its journey to establish India's first semiconductor Fab in Dholera, Gujarat. In a landmark move towards establishing semiconductor manufacturing in India , Tata Electronics has completed the Definitive Agreement with Powerchip Semiconductor Manufacturing Corporation (PSMC) of Taiwan . This pivotal agreement is a cornerstone of Tata Electronics' strategy to bring sophisticated semiconductor manufacturing technology and best practices to the shores of India and serve global customers with a robust and resilient supply chain.

As per the agreement, PSMC will provide design and construction support to build India's first AI-enabled state-of-the-art greenfield Fab in Gujarat, license a broad portfolio of technologies and provide engineering support to successfully transfer licensed technologies to the Gujarat Fab. This Fab will have manufacturing capacity of up to 50,000 wafers per month and will include next-generation factory automation capabilities deploying data analytics and machine learning to achieve industry-best factory efficiency. The new semiconductor Fab will manufacture chips for applications such as power management IC, display drivers, microcontrollers (MCU) and high-performance computing logic, addressing the growing demand in markets such as AI, automotive, computing and data storage, and wireless communication.

This pioneering agreement between Tata Electronics and PSMC will bring to India a portfolio of cutting-edge semiconductor technologies, advanced skill set and talent, and a network of semiconductor manufacturing suppliers and ecosystem partners, setting the foundation for an indigenous semiconductor ecosystem in India . The agreement marks a seminal moment in positioning India as a trusted partner in the global semiconductor supply chain and accelerates the country's journey towards 'Make in India , For the World' as it transforms into a global semiconductor manufacturing hub.

With a total investment of up to INR 91,000 crores ( ~US$11bn ), the Fab will create over 20,000 direct and indirect skilled jobs. With this Fab, India for the first time will be able to address the growing chip demand of domestic and global customers. Tata Group's multi-fab vision for Dholera is projected to create over 1,00,000 skilled jobs.

N Chandrasekaran, Chairman, Tata Sons , said, "We are pleased to partner with PSMC, whose technology and expertise will significantly accelerate our roadmap to pioneer semiconductor manufacturing in India . This collaboration is a key milestone, and I am confident that our comprehensive technology partnership with PSMC will pave the way for innovation, drive growth, and strengthen the global semiconductor supply chain. It will position us to play a key role in the growing semiconductor market to serve global customers."

Dr Frank Huang , Chairman of Powerchip Group and CEO of PSMC, said, "We are excited to collaborate with Tata Electronics on this pioneering initiative to establish India's first semiconductor Fab in Gujarat. It reflects our commitment to providing cutting-edge technology and expertise, helping Tata Electronics create a state-of-the-art facility that will catalyze India's semiconductor landscape. This partnership represents a win-win situation, as it positions PSMC and the Taiwanese ecosystem to gain a significant first-mover advantage in the rapidly expanding Indian market , while helping India achieve self-reliance in semiconductor manufacturing. I strongly believe that our partnership will be foundational to the India - Taiwan collaboration in semiconductors and will inspire more commercial and strategic tie-ups between the two sides."

Notably, Tata Electronics has already engaged two esteemed design firms from Taiwan to create a top-tier Fab that adheres to global standards of quality, safety, and sustainability. The collaboration between Tata Electronics, PSMC and the Taiwanese ecosystem is poised to strengthen the resilience of the global supply chain and effectively cater to the needs of global customers.

About the Tata Group

Founded by Jamsetji Tata in 1868, the Tata Group is a global enterprise headquartered in India , comprising 30 companies across ten verticals. The group operates in more than 100 countries across six continents, with a mission 'To improve the quality of life of the communities we serve globally, through long-term stakeholder value creation based on Leadership with Trust.'

Tata Sons is the principal investment holding company and promoter of Tata companies. Sixty-six percent of the equity share capital of Tata Sons is held by philanthropic trusts, which support education, health, livelihood generation and art and culture.

In 2023-24, the revenue of Tata companies, taken together, was $165 billion . These companies collectively employ over 1 million people.

Each Tata company or enterprise operates independently under the guidance and supervision of its own board of directors. There are 26 publicly listed Tata enterprises with a combined market capitalisation of $365 billion as of March 31, 2024 .

About Powerchip Semiconductor Manufacturing Corporation

Powerchip Semiconductor Manufacturing Corporation (PSMC) is the world's seventh-largest pure-play foundry, with four 12-inch and two 8-inch fabs in Taiwan , capable of producing over 2.1 million 12-inch equivalent wafers annually. Since its establishment in 1994, the company transitioned successfully from DRAM manufacturing to advanced foundry services for memory and logic chips. Ranked seventh in global semiconductor ESG evaluations, PSMC demonstrates strong governance and environmental commitment. In May 2024 , PSMC's new 12-inch fab in Taiwan's Tongluo Science Park began operations with a planned capacity of 1.2 million wafers annually, using advanced 28nm and wafer stacking technologies.

About Tata Electronics Private Limited.

Tata Electronics Pvt. Ltd. is a prominent global player in the electronics manufacturing industry, boasting growing capabilities in Electronics Manufacturing Services, Semiconductor Assembly & Test, Semiconductor Foundry, and Design Services. Established in 2020 as a new initiative of the Tata Group, the company aims to enhance its global customer service through integrated offerings across a trusted electronics and semiconductor value chain. With a rapidly expanding workforce, the company currently employs over 45,000 individuals and has significant operations in Gujarat, Assam, Tamil Nadu, and Karnataka, India. Tata Electronics is committed to creating a socio-economic footprint by employing a large number of women in its workforce and actively supporting local communities through initiatives in healthcare, hygiene, and education.

Contact:

Pooja Rajput [email protected] +91 99102 78452

Modal title

Also from this source, tata group to build the nation's first fab in dholera.

In a significant step towards creating an indigenous ('Make in India, For the World') semiconductor ecosystem in India, Government of India has...

Semiconductors

Computer & Electronics

Electronic Components

The Economic Times daily newspaper is available online now.

Tata electronics and psmc complete agreement for tech transfer to build india’s first semiconductor fab.

The company said the new semiconductor fab will manufacture chips for applications such as power management IC, display drivers, microcontrollers (MCU) and high-performance computing logic, addressing the growing demand in markets such as AI, automotive, computing and data storage, and wireless communication.

Artificial Intelligence(AI)

Java Programming with ChatGPT: Learn using Generative AI

By - Metla Sudha Sekhar, Developer and Lead Instructor

Basics of Generative AI : Unveiling Tomorrow's Innovations

Generative AI for Dynamic Java Web Applications with ChatGPT

Mastering C++ Fundamentals with Generative AI: A Hands-On

Master in Python Language Quickly Using the ChatGPT Open AI

Office Productivity

Zero to Hero in Microsoft Excel: Complete Excel guide 2024

Vastu Shastra Course

By - Sachenkumar Rai, Vastu Shashtri

Data Science

SQL for Data Science along with Data Analytics and Data Visualization

Web Development

A Comprehensive ASP.NET Core MVC 6 Project Guide for 2024

Mastering Microsoft Office: Word, Excel, PowerPoint, and 365

Digital marketing - Wordpress Website Development

By - Shraddha Somani, Digital Marketing Trainer, Consultant, Strategiest and Subject Matter expert

Mastering Full Stack Development: From Frontend to Backend Excellence

Financial Literacy i.e Lets Crack the Billionaire Code

By - CA Rahul Gupta, CA with 10+ years of domain experience, trainer

Business Storytelling Masterclass

By - Ameen Haque, Founder of Storywallahs

Future of Marketing & Branding Masterclass

By - Dr. David Aaker, Professor at Haas School of Business

Human Potential and the Future of Employment

By - Lynda Gratton, Co-chair of the World Economic Forum Council on Work, Wages and Job Creation, Professor of Management Practice

ESG and Business Sustainability Strategy

By - Vipul Arora, Partner, ESG & Climate Solutions at Sattva Consulting Author I Speaker I Thought Leader

Financial Reporting and Analytics

By - Dr. C.P. Gupta, Professor: Department of Finance and Business Economics, University of Delhi

Read More News on

Silver prices are trending higher. Here’s what it means for the long-term investors

How a little-known Delhi-based company bought Nasdaq-listed Ebix out of bankruptcy

Why your SIP investment may work, until one day, it won’t.

The importance of tackling money laundering and terror financing through offshore gaming platforms

Taken to duck Houthi attacks, Cape of Good Hope now gives shipping firms a sinking feeling

5 problems SpiceJet needs to fix to be competitive again

Find this comment offensive?

Choose your reason below and click on the Report button. This will alert our moderators to take action

Reason for reporting:

Your Reason has been Reported to the admin.

To post this comment you must

Log In/Connect with:

Fill in your details:

Will be displayed

Will not be displayed

Share this Comment:

Uh-oh this is an exclusive story available for selected readers only..

Worry not. You’re just a step away.

Prime Account Detected!

It seems like you're already an ETPrime member with

Login using your ET Prime credentials to enjoy all member benefits

Log out of your current logged-in account and log in again using your ET Prime credentials to enjoy all member benefits.

To read full story, subscribe to ET Prime

₹34 per week

Billed annually at ₹2499 ₹1749

Super Saver Sale - Flat 30% Off

On ET Prime Membership

Unlock this story and enjoy all members-only benefits.

Offer Exclusively For You

Save up to Rs. 700/-

ON ET PRIME MEMBERSHIP

Get 1 Year Free

With 1 and 2-Year ET prime membership

Get Flat 40% Off

Then ₹ 1749 for 1 year

ET Prime at ₹ 49 for 1 month

Market Savvy Offer

Get flat 20% off on ETPrime

90 Days Prime access worth Rs999 unlocked for you

Exclusive Economic Times Stories, Editorials & Expert opinion across 20+ sectors

Stock analysis. Market Research. Industry Trends on 4000+ Stocks

Get 1 Year Complimentary Subscription of TOI+ worth Rs.799/-

Stories you might be interested in

- Help & FAQ

Academia-industry technology transfer – a detailed study on indian scenario at global platform

- Department of Pharmaceutical Quality Assurance, Manipal College of Pharmaceutical Sciences, Manipal

- Department of Pharmacy Management, Manipal College of Pharmaceutical Sciences, Manipal

- Technology Transfer Office

Research output : Contribution to journal › Review article › peer-review

Translation of research and innovation from universities or academic institutions to market for societal benefits demand substantial and persistent efforts. This could be achieved through various means and one of the most preferred method of translating university research into commercially viable product is through technology transfer or technology licensing. This urges on establishing technology transfer offices in universities/academia comprising a group of experts from various fields focusing on protecting and commercializing inventions disclosed by faculty members, students or other stakeholders of the organization. This paper discusses various successful strategies and technology transfer models between industry and academia in developed nations as well as a few important success factors. It also provides an insight on evolution of technology transfer practices (governing Acts and legislation) and current status of technology transfer in India.

| Original language | English |

|---|---|

| Pages (from-to) | 4981-4989 |

| Number of pages | 9 |

| Journal | |

| Volume | 13 |

| Issue number | 10 |

| DOIs | |

| Publication status | Published - 12-10-2020 |

All Science Journal Classification (ASJC) codes

- Pharmacology, Toxicology and Pharmaceutics (miscellaneous)

- Pharmacology (medical)

Access to Document

- 10.5958/0974-360X.2020.00873.2

Other files and links

- Link to publication in Scopus

- Link to the citations in Scopus

Fingerprint

- india INIS 100%

- industry INIS 100%

- technology transfer INIS 100%

- Indians Social Sciences 100%

- Technology Transfer Social Sciences 100%

- Specific Industry Economics, Econometrics and Finance 100%

- universities INIS 50%

- Success Factor Economics, Econometrics and Finance 50%

T1 - Academia-industry technology transfer – a detailed study on indian scenario at global platform

AU - Ravi, Ramya

AU - Janodia, Manthan D.

N1 - Funding Information: Collaborate for opportunities for funding to work on their research ideas, entrepreneurship and utilization of resources. Funding Information: (a) Contract research sponsored by industry: Publisher Copyright: © RJPT All right reserved.

PY - 2020/10/12

Y1 - 2020/10/12

N2 - Translation of research and innovation from universities or academic institutions to market for societal benefits demand substantial and persistent efforts. This could be achieved through various means and one of the most preferred method of translating university research into commercially viable product is through technology transfer or technology licensing. This urges on establishing technology transfer offices in universities/academia comprising a group of experts from various fields focusing on protecting and commercializing inventions disclosed by faculty members, students or other stakeholders of the organization. This paper discusses various successful strategies and technology transfer models between industry and academia in developed nations as well as a few important success factors. It also provides an insight on evolution of technology transfer practices (governing Acts and legislation) and current status of technology transfer in India.

AB - Translation of research and innovation from universities or academic institutions to market for societal benefits demand substantial and persistent efforts. This could be achieved through various means and one of the most preferred method of translating university research into commercially viable product is through technology transfer or technology licensing. This urges on establishing technology transfer offices in universities/academia comprising a group of experts from various fields focusing on protecting and commercializing inventions disclosed by faculty members, students or other stakeholders of the organization. This paper discusses various successful strategies and technology transfer models between industry and academia in developed nations as well as a few important success factors. It also provides an insight on evolution of technology transfer practices (governing Acts and legislation) and current status of technology transfer in India.

UR - http://www.scopus.com/inward/record.url?scp=85109259252&partnerID=8YFLogxK

UR - http://www.scopus.com/inward/citedby.url?scp=85109259252&partnerID=8YFLogxK

U2 - 10.5958/0974-360X.2020.00873.2

DO - 10.5958/0974-360X.2020.00873.2

M3 - Review article

AN - SCOPUS:85109259252

SN - 0974-3618

JO - Research Journal of Pharmacy and Technology

JF - Research Journal of Pharmacy and Technology

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Download Free PDF

Exploring University-Industry Technology Transfer in India: Two Models

2016, Journal of Research Innovation and Management Science

The purpose of this paper is to understand the influence of policy environment on development of technology transfer in university industry linkage in India. This study reviews literature on design perspectives of university spin offs including large scale survey of Indian universities, cross national comparisons and analysis of documents from professional bodies. There is evidence that policy environment is composed of structures that influence the implementation of a design. There is a policy shift that favoured indigenous state led technology transfer to private partnership in technology transfer in India. The opening of the Indian economy introduced policy environment favouring entrepreneurship. Two models of technology transfer in university-industry are proposed. The type I model is a technology push process that results in an IPR based regime where as the type II is a business pull model that favours university spin offs. Unlike the linear model of growth of technology transfer in the West, there has been a persistent divide between the sub systems of intellectual property and entrepreneurship in India. Research into the environment that designs a policy outcome in academic entrepreneurship may offer a template for a system that co-opts both IPR and entrepreneurship. Indian universities have been analysed for performance based on their traditional role in academics. The non traditional roles like technology transfer have been evaluated only through comparative case studies. This research fills the gap by giving an overview of the Indian scene and proposes theoretical models to understand them.

Related papers

Journal of the Knowledge Economy, 2021

In recent years, there is a great emphasis on transferring inventions and technologies originating from academia to industry through technology transfer/licensing or commercialization. The efforts of the Government of India (GOI) aim to create socially useful innovation through university-industry technology transfer. The objective of the study is to examine and understand enabling factors and barriers for technology transfer among Indian universities. The study covers three key aspects: (1) the awareness and practice of patents and research commercialization among Indian academia, (2) comprehending strategies adapted to commercialize research activities, and (3) barriers in university-industry technology transfer (TT). This paper is an attempt to answer the research question whether current dynamics within Indian universities create an environment for enabling knowledge transfer/commercialization and propose plausible suggestions to enable academia-industry technology transfer. A s...

The Journal of Technology Transfer, 2000

Journal of Entrepreneurship and Management, 2017

Universities acting as catalyst for entrepreneurial activities are central to the phenomenon of academic entrepreneurship. Lack of appropriate academic entrepreneurship models has hindered the smooth transfer of knowledge/technology from university to industry in India. The study explores the synergy between the academia and industry through academic entrepreneurship which is crucial to develop a world class higher education system. This paper attempts to understand the processes and stages of academic entrepreneurship activities besides focussing on education and entrepreneurship in India. Further, it discusses a few models and frameworks which integrate academic entrepreneurship, economic development and education in developing countries. The paper concludes with the argument that it is essential to restructure education/research to enable its integration within the economy which nurtures entrepreneurship.

Asian Journal of Innovation and Policy

Seoul Journal of Economics, 2009

Journal of Entrepreneurship, Management and Innovation (JEMI), Volume 8, Issue 1, 2012: p. 68-83, 2012

In developed countries, the academic entrepreneurship makes up a very important element of academic environment activities. For some time, the increase in the role of technology transfer and knowledge commercialisation has been also promoted in Poland. Strong connections between the scholarship and the economy (in the future, within the university of the third generation) have a chance to build an economy based on knowledge in our country. The flow of knowledge and the introduction of new solutions (results of scholarly research) in enterprises take place through the intermediary of various methods of transfer and commercialisation paths. Independent of the manner, each fulfils an important role in the public life and economy. This is confirmed by the experience of the States that are recognised as innovation leaders, and presented in the paper as examples of Polish scholars’ academic entrepreneurship.

Journal of technology management & innovation, 2012

IAEME PUBLICATION, 2020

The objective of this paper is to study the various Technology Transfers and its commercialization followed by various public funded Research and Development institutions in India. More specifically, this paper also examined and highlighted the challenges faced by the Research and Development institutions and industries. Technology Transfer is the complete process which enables the disclosure of advancement in Science and Technology. Research institutions and their industry partnership in the field of science and technology is complex and needs to be developed through customized model and mechanisms. The protection and the licensing mechanism of intellectual property rights at such institutions are the focus of attention of the policy makers at all levels. Over the last 50 years, Government Research institutions (GRES) have played a major role in developing science and technology in the country. They have supported a variety of government initiatives and functions by proving basic and applied research, technological development and engineering solutions. Successful technological development requires a deep understanding of the technical context of applications and relies on the organizations culture and environment in which scientists, engineers and technicians often coming from different disciplines work and interact. Therefore, an organization’s learning base is not only the sum of its individual employees, there is also addition by the “organizational knowhow’’. In view of the above, a detailed commercialization process followed by Indian Research and Development institutions has been studied and the success of such technology transfer analysis and commercialization has been reviewed with reference to controlling parameters. The effort of technology development is complete only when it is adopted or adapted by the end user as a product suitable for commercial applications. It is most important that the research organization needs to understand industry or work in close collaboration with the industry. To enhance linkages between research institutions and industry, one should augment market driven research and assign value to innovative research. Universities and Research and Development institutions should have initiated technology transfer and commercialization efforts. Public Sector Research and Development institutions should take special initiative to bring forth a multitude of benefits to society and generate a model that needs to be promulgated in emerging economies especially utilizing our indigenous resources. This paper presents major five Indian public funded Research and Development institutions, their Technology Transfer models involving their unique approaches for commercialization of products that assured overall benefit to the society while simultaneously promoting the Indian economy

Referred Chapter in Academic Entrepreneurship and Technological Innovation: A Business Management Perspective

arXiv (Cornell University), 2023

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

CURRENT SCIENCE, 2014

GALAXY INTERNATIONAL INTERDISCIPLINARY RESEARCH JOURNAL (GIIRJ), 2021

Advances in Management and Applied Economics

SSRN Electronic Journal, 2000

Review of International …, 2011

Management and Economics Research Journal, 2019

The Journal of Technology Transfer, 2011

Space and Culture, India

Environmental Economics, 2017

Small Business Economics

Technology Innovation Management Review

Related topics

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Faculty & Research

NEC - India: The Opportunity in the Indian Growth Story (Abridged Version)

V. (Paddy) Padmanabhan

Professor of Marketing

Professor of Strategy

Our website has a lot of features which will not display correctly without Javascript.

Please enable Javascript in your browser

Here how you can do it: http://enable-javascript.com

- Technology Transfer

FDI, Technology Transfer and Spillover —A Case Study of India

- January 2010

- Jawaharlal Nehru University

- This person is not on ResearchGate, or hasn't claimed this research yet.

Discover the world's research

- 25+ million members

- 160+ million publication pages

- 2.3+ billion citations

- Biniam Zemene

- C.H. Sahyaja

- G. Rajeshkumar

- K.S. Sekhararao

- N K Taneja Arjun

- Chi-Mei Lin

- Fredrik Sjoholm

- Ruben Tansini

- Mario Zejan

- Håkan Persson

- Xiaoying Li

- Recruit researchers

- Join for free

- Login Email Tip: Most researchers use their institutional email address as their ResearchGate login Password Forgot password? Keep me logged in Log in or Continue with Google Welcome back! Please log in. Email · Hint Tip: Most researchers use their institutional email address as their ResearchGate login Password Forgot password? Keep me logged in Log in or Continue with Google No account? Sign up

- General publications

Technology Transfer in India

Description.

EU SMEs interested in venturing the Indian market by way of technology transfer arrangement must ensure drawing up a clear and unambiguous contract.

- 21 OCTOBER 2022

Share this page

Browse Econ Literature

- Working papers

- Software components

- Book chapters

- JEL classification

More features

- Subscribe to new research

RePEc Biblio

Author registration.

- Economics Virtual Seminar Calendar NEW!

FDI, Technology Transfer and Spillover —A Case Study of India

- Author & abstract

- 19 References

- 2 Citations

- Most related

- Related works & more

Corrections

(Centre for International Trade and development)

Suggested Citation

Download full text from publisher, references listed on ideas.

Follow serials, authors, keywords & more

Public profiles for Economics researchers

Various research rankings in Economics

RePEc Genealogy

Who was a student of whom, using RePEc

Curated articles & papers on economics topics

Upload your paper to be listed on RePEc and IDEAS

New papers by email

Subscribe to new additions to RePEc

EconAcademics

Blog aggregator for economics research

Cases of plagiarism in Economics

About RePEc

Initiative for open bibliographies in Economics

News about RePEc

Questions about IDEAS and RePEc

RePEc volunteers

Participating archives

Publishers indexing in RePEc

Privacy statement

Found an error or omission?

Opportunities to help RePEc

Get papers listed

Have your research listed on RePEc

Open a RePEc archive

Have your institution's/publisher's output listed on RePEc

Get RePEc data

Use data assembled by RePEc

Advertisement

Factors Affecting Technology Transfer and Commercialization of University Research in India: a Cross-sectional Study

- Open access

- Published: 24 February 2021

- Volume 13 , pages 787–803, ( 2022 )

Cite this article

You have full access to this open access article

- Ramya Ravi 1 &

- Manthan D. Janodia ORCID: orcid.org/0000-0003-0000-9673 2

9745 Accesses

20 Citations

25 Altmetric

Explore all metrics

In recent years, there is a great emphasis on transferring inventions and technologies originating from academia to industry through technology transfer/licensing or commercialization. The efforts of the Government of India (GOI) aim to create socially useful innovation through university-industry technology transfer. The objective of the study is to examine and understand enabling factors and barriers for technology transfer among Indian universities. The study covers three key aspects: (1) the awareness and practice of patents and research commercialization among Indian academia, (2) comprehending strategies adapted to commercialize research activities, and (3) barriers in university-industry technology transfer (TT). This paper is an attempt to answer the research question whether current dynamics within Indian universities create an environment for enabling knowledge transfer/commercialization and propose plausible suggestions to enable academia-industry technology transfer. A self- assessed structured methodology is contemplated and applied. Convenience sampling methods were adopted. Administrators of 25 universities overseeing research and development activities/patent cell/incubation cell or industrial collaboration of universities were approached to participate in the study. Indian universities are categorized as (i) public funded universities and (ii) private institutes for the purpose of the study. It is interesting to understand that public funded universities have an advantage in terms of receiving funds and licensing the research to potential industrial partners. The authors further conclude that research undertaken in academia is far from the demands of the industry. Even though the relevant supporting system for enhancing university-industry collaboration is in place, such as establishing technology transfer office (TTO) in the university, they hardly channelize the resources for socially useful innovation. It is important for Indian academia to undertake commercially viable research for the benefit of society.

Similar content being viewed by others

University-Industry Technology Transfer in India: a Plausible Model Based on Success Stories from the USA, Japan, and Israel

Identifying the key barriers and their interrelationships impeding the university technology transfer in taiwan: a multi-stakeholder perspective.

University technology transfer efficiency in a factor driven economy: the need for a coherent policy in Egypt

Explore related subjects.

- Artificial Intelligence

Avoid common mistakes on your manuscript.

Introduction

Innovation is the direct outcome of structured and planned scheme of work, referred to as research. The competition among the industry is exceedingly independent of the research undertaken by public funded or private research organizations and universities. The main advantage of universities are the faculty members and students who constantly enter the system, bringing fresh concepts, ideas that eventually leads to research and innovation. Accessibility to results obtained from research is the core challenge to rebuild the ideas to innovation and further convert to commercially viable product (European commission, 2009 ). Thus, dissemination of innovation from universities and research institutions to parties capable of commercialization is defined as technology transfer (TT). The main objectives of technology commercializing include leveraging R&D outcome and intellectual assets, raise the accessibility of scientific outcome to broad range of consumers, development of new services and products ready for commercialization, and last but not the least, to intensify industrial competition. The transfer can originate either due to technology push (through research) or market pull (through industry). The international scope of technology commercialization may encompass developed nations, developing nations and other countries with economy transition (Thompson, 2015 ). In the current trend, universities must position themselves as authentic players to raise the chance of success in R&D probably by two aspects: increase in knowledge transfer by using scientific knowledge and raise the business value of knowledge transfer by introducing cutting edge breakthrough technologies (Baron, 2020 ). Though there is enough literature discussing cases of technology transfer from research institutions in developed nations, there are very few instances of knowledge transfer between universities and industries in India. Very few articles discuss technology transfer in Indian academia. Hyndman et al. studied and compared knowledge commercialization practices of Massachusetts Institute of Technology (MIT) with Indian academia. The author emphasized the lack of policy to support commercializing technology in India (Hyndman et al., 2005 ). Comprehending knowledge transfer models, practiced in the USA and Germany, Rath et al. proposed a model suited to Indian scenario that supports fiscal incentives to encourage large-scale industry-academia partnerships. Further, the proposed model emphasized on channelizing the profit, obtained from commercialization of technology originating from university, to R&D (Rath et al., 2014 ). A study by Srivastava et al. stressed upon the importance of creation of companies around academic technologies and job creation to promote the economic growth. Further, the study suggests that one commercialization model may not be successful in all universities, as there are differences in culture, resources, environment, and priorities among universities (Srivastava & Chandra, 2012 ). A review by Pagar et al. explained the significance of continuous exchange of information between industry and academia to maintain the quality of the product transferred (Pagar et al., 2014 ). In the past decade there has been an emphasis on Indian academia to generate revenue from research outcomes, and hence, knowledge transfer/technology transfer becomes an integral part of discussion about Indian academia.

As the availability of literature on the commercialization of technology in Indian academia is limited, this paper explores the state of knowledge exchange by presenting data on Indian universities regarding intellectual property and technology transfer practices in both public and private universities. The NIRF data for the year 2018 has also been used for the purpose of this study. The study covers three key aspects: (1) the awareness and practice of patents and research commercialization among Indian academia, (2) comprehending strategies adapted to commercialize research activities, and (3) barriers in university-industry technology transfer . The paper is an attempt to answer the research question whether the current dynamics within Indian universities create an environment for enabling knowledge transfer/commercialization and proposes plausible suggestions to enable academia-industry technology transfer. The study further aims to comprehend the scenario and recommend strategies to support technology transfer in Indian academia. The method used for the study proposes and implies a self-assessment concerning the activities of innovation and research commercialization capacity. Relevant results obtained from the respondents were cross verified with the publically available data for a few universities through their organization webpage. This allows a qualitative and semi- quantitative approach to the study.

Literature Review

Evolution of technology innovation in india.

The past five decades looks progressive in terms of technology evolution in India, including innovation and research. The first scientific policy, enacted in 1958, emphasized on importance of technology in India. India has a history of success stories among a few research and development organizations. One such initiative is from National Chemical Laboratory (NCL innovations)—a chief laboratory of The Council of Scientific and Industrial Research (CSIR) under the central government of India. In its 80 years of existence, NCL has an impressive history of commercializing technology both within India and abroad in collaboration with industry. In 1950s, NCL was successful in launching organic chemicals and manufacturers of dye for the first time. In Green Revolution during 1960s, NCL played a significant role in establishing various agro- chemical based companies. In 1970s after the launch of Patent Act in India, NCL has worked with various pharma companies and developed manufacturing processes for drugs (Nandagopal et al., 2011 ). In 1988, the Technology Information Forecasting and Assessment Council (TIFAC), an autonomous body owned by Government of India under Department of Science and Technology, was established to provide financial support for infrastructure and to develop and commercialize technologies under “Home Grown Technology” Scheme (Kumar & Jain, 2002 ).

Emphasizing the importance of promoting local goods, “Make in India” initiative launched in 2014 by Government of India includes the salient features to facilitate inventions, protect Intellectual Property, foster innovation, and build best manufacturing infrastructure in the country. In May 2016, first national IPR policy was released. Through this policy, GOI aimed to promote, create awareness, and enforce intellectual property. Moreover, the government prioritized to bring the administration of IP laws under Department of Industrial Promotion and Policy (DIPP) (Joseph, 2016 ).

The objectives of the policy were as follows:

Emphasize the significance of intellectual property among all sectors in the society

Stimulate creation of intellectual property by undertaking appropriate measures

Have stringent IP laws, consistent with international obligations

Modernize and strength IP administration and catalyze the commercialization of IP rights

Strengthen the enforcement on combating IP violations

Capacity development by strengthening and expanding human resources, institutions for training, research and skill building in IP (Joseph, 2016 )

Adding to the initiatives promoting IP, “Cell for IPR Promotion and Management” (CIPAM) under the aegis of DIPP for promotion, creation and commercialization of IP assets were constituted. CIPAM enforced a nationwide promotion scheme titled “Creative India; Innovative India” to create awareness on the benefits of the new IPR policy. The duration for the scheme was for 3 years (April 2017 to March 2020). The primary objective of the scheme was to conduct IP awareness workshops/seminars in collaboration with industry organizations, academic institutions, and other stakeholders across the country (Department of Industrial Policy and Promotion, Ministry of Commerce and Industry and Government of India, 2016 ).

Positioning of Indian Universities in Terms of IP Generation and Technology Commercialization

The inception of formal technical education in India dates back to the mid-nineteenth century. In 1945, an All India Council for Technical Education (AICTE) was set at a national advisory body to facilitate the infrastructure for technical education in India.

Universities in India are governed by Department of Higher Education under the Ministry of Human Resources Development (now Ministry of Education), Government of India. Indian universities are categorized as public funded and private (state private or deemed to be) universities based on the University Grants Commission (UGC) Act 1956. Later in 1987, All India Council for Technical Education Act was constituted to regulate and sustain the standards in technical education system in India. In the past decade, there have been several amendments in legislative framework for the public universities under various states governance in India.

In 2008, The Protection and Utilization of Public Funded Intellectual Property Bill (PUPFIP) was proposed to address the challenges in the university-industry technology transfer. The provisions of the Bill were to provide incentives to the universities through public funded research wherein:

Ownership of patents remains with the academic institute on inventions from government funded projects.

Institute creating an invention must inform the funding agency within 60 days of the creation.

Research institute must inform the government agency about the intention to patent the invention within 90 days; if they fail to inform, under defined prior Acts, the agency will acquire the title of patent.

Bill had the provision of 30% of royalties given to the inventor.

On receiving the government aided funds, the research institute must frame an intellectual management committee to process the innovation in terms of assignment of rights, potential for marketing the invention in concern, licensing agreements.

There were a few concerns expressed with implementation of PUPFIP. The major mission of the bill was to commercialize the invention, which lead to fear of ignoring public concerns and priorities. Other major concern of the bill was non-disclosure requirement insisted by the government on the research institutes, thus increasing bureaucracy and suppressing innovations and academic exchanges. The Ministry of Science and Technology had created a board of authorities to support the entrepreneur generation and support through National Science and Technology Entrepreneurship Development Board (NSTEDB) in 2009. The NSTEDB had supported the creation of Technology Business Incubators (TBI) and Technology Parks. TBIs were created at IIT-Delhi, Chennai, Mumbai, Kanpur, Delhi University and Banaras Hindu University (BHU), Varanasi. Despite the initiatives, the research commercializing at Indian Universities are sub-par compared with developed nations (Srivastava & Chandra, 2012 ).

In 2018, AICTE had initiated a program to empower faculty members by organizing a cell in all technical institutions, universities, deemed to be universities, and other institutions for training, known as AICTE Training and Learning (ATAL) academy. The main objective of ATAL academy is to impart quality technical education in India, support institutions in fostering research, innovation, and entrepreneurship through training. The training sessions are conducted through online portal in the form of workshops, orientations, learning communities, or faculty development programs. Government of India has announced to establish more than eleven such academies throughout the country (AICTE Training And Learning ( ATAL) Academy & Govt. of India, 2020 ). Ministry of Human Resource Development (MHRD), Government of India, established MHRD’s Innovation Cell (MIC) in 2019 to systematically foster the culture of innovation among all Higher Education Institutions (HEIs) in the country. The primary focus of MIC is to encourage, inspire, and nurture young students by exposing them to new ideas. Major programs under MIC include the following:

Smart India Hackathon (SIH) 2019, a nationwide initiative, to inculcate a culture of product innovation and a mindset of problem solving (AICTE-India, 2019 )

Institution Innovation Councils (IIC) to create local innovation ecosystem and support scouting ideas and pre-incubation of ideas

Atal Ranking of Institutions on Innovation Achievements (ARIIA) is an initiative in India to rank all major higher educational institutions and universities in India on indicators related to “Innovation and Entrepreneurship Development” amongst students and faculty members. ARIIA is set to channelize the institutions towards becoming competent in global platform and be forefront in innovations. The major indications for consideration of the HEIs to be ranked under ARIIA are as follows: Budget and Funding Support, Infrastructure and Facilities, Awareness, Promotions and support for Idea Generation and Innovation, Promotion and Support for Entrepreneurship Development, Innovative Learning Methods and Courses, Intellectual Property Generation, Technology Transfer and Commercialization, and Innovation in Governance of the Institution.(MHRD’s innovation council & Govt. of India. ( 2019 ).

National Innovation and Start-up Policy for Students and Faculty provides the framework on intellectual property ownership, revenue sharing mechanisms and norms for technology transfer, and commercialization (MHRD’s innovation council, Ministry of Human Resource Development & AICTE, 2019 ).

Earlier in India, the focus was on research and development, whereas now emphasis is also on creation of intellectual property and technology commercialization. Several universities have created facilities, infrastructure, and human resources to foster innovation, generate intellectual property, and commercialize academic research. This paper is an attempt to understand the barriers in commercializing academic research in India.

Research Methodology

The two main parameters underlying the study framework of research technology commercialization of the Indian universities includes the following:

Details on patent activities carried out in the universities in the past 5 years (2013–2018)

Revenue generated during the past 5 years (2013–2018)

The study framework for this research include qualitative and semi-quantitative analysis. The variables addressed in the study are represented in Table 1 . Convenient sampling was adopted.

Type of study: Cross-sectional study

Duration of study: 2 years (June 2018 to June 2020)

Sampling method: Convenience sampling

Sampling unit: Administrators of universities responsible for research/intellectual property/ technology commercialization/incubation cell

Sample size: 40 universities/institutes

Type of questionnaire: structured questionnaire

Data collection: in person where feasible, or through Google Form.

Data analysis

The questionnaire was designed by adapting the concept proposed by Association of University Technology Managers (AUTM) and Brazilian Survey of Technology transfer (Livesey, 2014 ). The questions in the questionnaire include descriptive, multiple choice, dichotomous, and scaled responses.

Results and Discussion

A total of 40 universities were approached for study of which only 25 responded with a response rate of 62.5%. Among other 25 universities/institutes (one respondent did not have technology transfer/IP office and hence excluded from analysis), four organizations were central government institutions, seven organizations were state private universities/institutions, five organizations were deemed to be universities, while eight others were private research organizations. IP policy was implemented in 17 universities, whereas six of them mentioned that the policy was under preparation and would be implemented within 6 months. The responses help to understand that IP policy has become an integral part of the research system in Indian universities.

As shown in Fig. 1 , 41% respondents had 2–5 years of experience in IP/TT, whereas 17% have more than 10 years of experience and 21% had less than a year or more than 6–10 years of experience.

Number of years of experience in IP/TT

The university/institute practiced customized strategies to transfer technology as shown in Fig. 2 . As there was no specific model practiced for TT, personal contacts in industry were the most preferred approach to license the invention, whereas the other approach was to organize innovation exhibitions. All the organizations adapted a combination of strategies as needed.

Strategies adapted by universities to attract potential licensee

Invention disclosure could be one of the important metric to assess innovation potential. In our study, it was observed that 33% of the universities had less than ten invention disclosures, whereas, 29% had more than 30 invention disclosures by the researchers in the past 5 years. Public universities correspond to higher number of invention disclosure due to higher quantum of funding received from the government. About 71% of the universities had entrepreneurship policy applicable to foster entrepreneurship among faculty members.

The number of patents granted to universities in past 5 years is shown in Fig. 3 . As is visible, the number of patents granted to the universities improved from 2016 to 2017. The data obtained through questionnaire was cross-verified for a few universities with the details publically available on their website. On analyzing the results, the universities governed under state or central government are consistently performing well in terms of patent applications filed and number of patents granted.

Number of patents granted to universities in the past 5 years

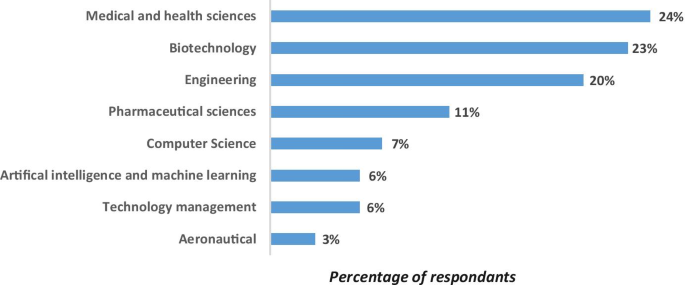

We tried to understand the scientific fields that are considered having maximum potential for technology commercialization. Though many universities have expertise in various fields, medical sciences and biotechnology domains are considered having maximum potential for technology commercialization as shown in Fig. 4

Domains deriving maximum inventions potential for commercialization

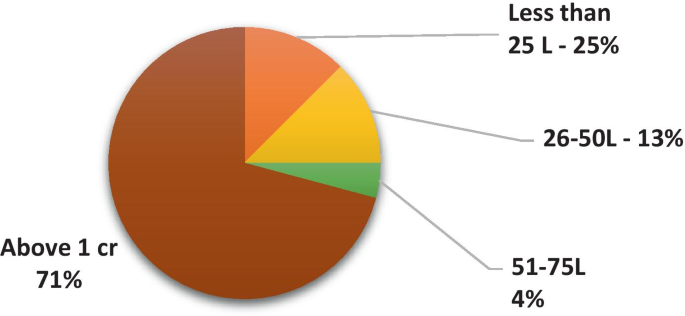

The budget allocation of the universities for IP/TT activities in the past 5 years is shown in Fig. 5 . The respondents stated that there was no separate budget allocated for IP/TT activities, but was included under research budget. The budget allocated in the last 5 years remains mostly unchanged.

Budget allocation for research /IP/TT activities in the past 5 years

We also tried to correlate budget allocated and expenditure on TT activities. The data on budget and expenditure is shown in Fig. 6 . In case of a few universities, the expenditure exceeded the budget allocated. The anomaly could be due to the fact that a few universities received funds for research from government funding agencies, which was not considered as a part of intramural research budget. The researchers of the universities/institutes were aware of patenting, but the concept of commercializing the invention is not well entrenched in their minds. The initiatives of establishing an IP/TT cell among universities is yet to strategize regarding use of resources for technology commercialization. The primary focus of TT/IP cell in the organization was related to technology evaluation (49%), licensing the invention (42%), business management (6%), and marketing (3%). Most of the universities focus on all the above listed activities based on the requirements.

Expenditure on university R&D activities in past 5 years

The number of active industrial collaboration was high (more than 30) among public universities. As shown in Fig. 7 , the concept of technology commercialization is far behind among Indian universities compared with their counterparts in the developed countries.

Number of technologies transferred, licensed, sold in past 5 years

As shown in Fig. 8 , 13% of the universities generated a revenue of more than INR 1 Crore through technology transfer activities, whereas other universities/organization/institutes claim to have initiated discussion with industrial partners.

Approximate revenue generated from transfer/sale from IP/TT in pipeline of IP/TT

There is paucity of data and studies about university-industry technology transfer in Indian context. As a reference it would be interesting to compare it with other regions.

The Malaysian government under the 10th Malaysian Plan (2011–2015) had increased their R&D budget to RM 741 million among the universities as a part of research grants. The 2011 report states that among the total number of 313 inventions identified with potential of commercialization, only 58 research products were commercialized from 16 public funded universities. The critical factor identified as a barrier to commercialize R&D results was lack of absorptive capacity and entrepreneurial skills among the researchers (Latif et al., 2016 ). According to a study on commercializing research findings at schools of agriculture in Iran, it was found that research activities carried out at universities are independent from the research priorities that are in demand. The study noted that the mechanism of delivering a technology are not adequately tested or have been ineffective (Mostoufi & Highway, 2016 ).

The survey conducted in government research organizations in Sri Lanka reveals that there were 239 technological innovations, 11 new processes, and 11 new products, derived from the research organizations between the 2001 and 2008. Technology transfer was 80–90% successful, whereas technology commercialization rate was 40%. The study concluded that the policies were not adequate to support technology commercialization and the attempts of transfer were a self-activated endeavor that lacked coordination (Perera et al., 2015 ). Further, the quantitative findings about universities with University Technology Transfer Office (UTTO) focus on commercializing technology, some strategies that were employed include: (a) agenda of research commercialization to be included in the mission statement, (b) allocated funding for internal research commercialization as a part of UTTO’s budget, and (c) the funding for multi-purpose commercialization activities including prototype and business development. The qualitative study suggested the Australian UTTO is governed by panel of experts, with strong management support and most of all access to resources and staff with potential knowledge on commercialization (Alhomayden, 2017 ).

In the Republic of Serbia, research system is regulated under Law on Scientific and Research Activity and the innovation system is under Law of Innovation activity. As research organizations and institutes are not an integral part of innovation system, academia do not possess a strategic approach in research management creating innovation with a focus on commercialization (Belgrade, 2016 ). A survey conducted in three countries of Africa (Ghana, Kenya, and Zambia) suggested that dedicated Research and Development centers in Africa are limited and has shown a decline in past decades, as nearly 80% of budget allocated to top research centers goes toward salary for the staff. Moreover, the awareness of technology transfer at institutional level is negligible. Some of the research centers have expressed concerns on lack of multidisciplinary approach. It was recommended that relevant policies are framed and attempts made to recruit personnel trained in technology transfer (Africa U. N. E. C., 2013 ).

Our study focuses on three key aspects taking into account the challenges in university-industry technology transfer across regions: (1) the awareness and practice of patents and research commercialization among Indian academia, (2) comprehending strategies adapted to commercialize research activities, and (3) barriers in university-industry technology transfer. In terms of patents and technology transfer, Indian universities can be broadly classified into four categories: central government aided universities, state government funded universities, deemed to be universities, and state private universities/institutes. The most important findings are focused around the issues of patenting and technology transfer, not their strategic approach. The general outcome emerging from the study is discussed below.

Key aspect 1. The awareness and practice of patents and research commercialization among Indian academia

Compilation of the activities on patenting (inventions disclosed, patents filed and granted) and research commercialization was undertaken based on self- assessment. The word “declared” is associated with the realistic data provided by the university authorities which is emphasized in the study. The self-assessment of the analysis is shown in Table 2 . Considering the number of patents filed in the past 5 years, there has been consistency in the filing pattern among the public funded universities/institutes, whereas there has been increased awareness in the pattern of filing among private and deemed to be universities. This could be due to the central government funds received by central and state universities. A general trend observed gives a positive correlation between financial support received by the public funded universities from the funding agencies such as Department of Science and Technology (DST) or Department of Biotechnology (DBT) and other government funding agencies under GOI. Similarly, active industrial collaboration among the government aided universities/institutes are relatively high compared with other universities/institutions. On the contrary, less than five technologies are transferred/licensed/sold by the public funded universities that corresponds to a large proportion (75–86%) of public funded universities. The private organizations have higher number of active industrial collaborations yet minimal research commercialization activities. The revenue generated from the knowledge commercialization is comparatively high among the centrally funded universities with limited industrial partnership.

It is evident that with minimal industrial collaborations, high value is generated by the government universities/ institutes through knowledge transfer. Among private organizations despite high number of collaborations with the industrial partners, the value generated from the knowledge transfer is observed to be low. The results could lead to further studies exploring this inverse correlation.

Key aspect 2. Comprehending strategies adapted to commercialize research activities

Unlike in developed nations, there is no specific model proposed or practiced to commercialize research by Indian academia. As shown in Fig. 4 , inventions in the field of medical and health sciences, biotechnology, and engineering derive maximum potential for commercialization. The common strategy adopted to attract potential licensee is based on individual contacts of faculty with industry partners. The study emphasizes that the research undertaken in many universities/institutes are far from meeting the industrial needs. The probable solutions could be to create centralized repositories of technologies available at universities on a platform maintained by Government of India to provide the required assistance, something similar to government e- Marketplace (GEM) (Vihar, 2019 ).

Key aspect 3. Barriers in university-industry technology transfer encountered by the faculty members are (1) lack of adequate resources and infrastructure; (2) lack of creativity and critical thinking in curricula; (3) over emphasis on publications due to lack of awareness on patenting, publishing, and commercializing the research; (4) IP cell or similar offices are established merely to meet statutory requirements; (5) lack of qualified people to manage IP/TT activities; and (6) conflict between commercially viable and academic research.

The survey results reveal that the practice of IP generation and technology transfer is underdeveloped in the country. In order to make technology transfer more relevant:

Universities/institutes should leverage the expertise either in specific domains or pursue interdisciplinary research to attain high value through knowledge commercialization.

Universities should have people with the required skill sets manning the IP and tech transfer offices. Currently, in many universities, the responsibility is given to an individual who does not have required experience, expertise, and skills. This leads to a halo and the required outcomes expected by universities are not fulfilled. Additionally, the institutes should also promote interdisciplinary research to leverage domain strengths.

(2) Focus on commercially viable research

Universities should focus on outside-in approach where researchers are sensitized to work on commercially viable research. At present, in academia researchers follow an inside-out approach which leads to a knowledge gap. The inside-out approach is where researchers work on a problem that may address their inquisitiveness but does not lead to a research outcome that does not have commercial potential.

identify mechanisms to reach out to and collaborate with industry through exhibitions, conference and research partnerships

Universities/institutions should develop a mechanism wherein they showcase their research outcomes to industry with an intention to collaborate or license their invention. Current mechanisms to reach out to industry by academic institutions are inefficient and there exist no structure to strengthen industry-academia collaborations. These solutions though are not a guarantee to successful technology transfer but can help shape strategies to improve chances of stronger industry academia collaboration/technology commercialization among Indian universities.

Our current research has a few limitations. The data is collected from a small sample size. The respondent bias also cannot be ruled out while providing responses to the questionnaire.

In order to extract more meaningful data for analysis, it is required that a large-scale study involving a larger sample size with varying size and structure of universities, geographical spread, management systems be carried out.

Africa, U. N. E. C. for. (2013). National experiences in the transfer of publicly funded technologies in Africa: Ghana, Kenya and Zambia.

AICTE Training And Learning ( ATAL ) Academy. (2020). Government of India. 410917. https://www.aicte-india.org/sites/default/files/ATAL/atal%20vision%20mission.pdf

AICTE - India. (2019). Smart - India Hackaton. https://www.aicte-india.org/Initiatives/smart-india-hackathon

Alhomayden, R. S. R. (2017). University Technology Transfer Performance in Australia. Tez .

Baron, M. (2020). Open innovation capacity of the polish universities. Journal of the Knowledge Economy , (October 2015). https://doi.org/10.1007/s13132-017-0515-8

Belgrade. (2016). Research for innovation: strategy on scientific and technological development of The Republic of Serbia for the period 2016–2020. Ssrn . https://doi.org/10.2139/ssrn.2478304

Department of industrial policy and promotion, Ministry of Commerce & Industry; Govt. of India. (2016). CIPAM: Cell for IPR Promotion and Management, 1–7. http://cipam.gov.in/wp-content/uploads/2017/07/Scheme-IPR-Awareness.pdf

European commission. (2009). Expert GroupK nowledge Transfer. (2009), (November). http://www.desca-agreement.eu/fileadmin/content/New_DESCA_Website/2009Expertgroup_on_knowledge_transfer_final_report.pdf

Hyndman, K. G., Gruskin, S. M., & Iyer, C. S. (2005). Technology transfer: what India can learn from the United States. Journal of Intellectual Property Rights, 10 (September), 399–405.

Google Scholar

Joseph, R. K. (2016). Who will Gain from the National IPRs policy, Research gate (July2016). http://www.desca-agreement.eu/fileadmin/content/New_DESCA_Website/2009Expertgroup_on_knowledge_transfer_final_report.pdf

Kumar, V., & Jain, P. K. (2002). Commercializing new technologies in India: a perspective on policy initiatives. Technology in Society, 24 (3), 285–298. https://doi.org/10.1016/S0160-791X(02)00009-X

Latif, N. S. A., Abdullah, A., & Jan, N. M. (2016). A pilot study of entrepreneurial orientation towards commercialization of university research products. Procedia Economics and Finance, 37 (16), 93–99. https://doi.org/10.1016/s2212-5671(16)30098-3

Livesey, F. (2014). Report on survey of Brazilian Technology Transfer Offices (TTOs), (June). https://www.inova.unicamp.br/sites/default/files/images/FCO_BrazilTTOsurveyReport_0.pdf

MHRD’s innovation council & Govt. of India. (2019). Institution innovation council. https://www.mic.gov.in/iic.php#

MHRD’s innovation council, Ministry of Human Resource Development, AICTE. (2019). National innovation and startup policy 2019 for students and faculty. https://mic.gov.in/assets/doc/startup_policy_2019.pdf

Mostoufi, A., & Highway, A. (2016). Findings in Schools of Agriculture in Iran : a Qualitative, 5–14.

Nandagopal, M., Gala, K., & Premnath, V. (2011). Improving technology commercialization at research institutes: Practical insights from NCL Innovations. Innovation Educators’ Conference (IEC), Indian School of Business, Hyderabad, 1–12. https://www.venturecenter.co.in/pdfs/ISB-Conf-Paper-ver04.pdf

Pagar, S., Khivansara, A., Pagar, P., Gandhi, M., & Jondhale, S. (2014). Review pilot study of entrepreneurial orientation towards commercialization of university research products . International Journal of Pure & Applied Bioscience, 2 (3), 145–153.

Perera, H., Mudalige, D., & Liyanage, C. (2015). A case study of technology transfer process in a government research organization in Sri Lanka. Researchgate.Net , (March). Retrieved from. http://www.researchgate.net/profile/Darshana_Mudalige/publication/273629620_A_Case_Study_of_Technology_Transfer_Process_in_a_Government_Research_Organization_in_Sri_Lanka/links/5506d3250cf2d60c0e6db0d1.pdf

Rath, S., Nathani, A., Patel, D., Kulkarni, P., & Gota, V. (2014). Status of technology transfer in India—the much needed Magic Remedy. Current Science, 106 (8), 1058–1060.

Srivastava, P., & Chandra, S. (2012). Technology commercialization: Indian university perspective. Journal of Technology Management and Innovation, 7 (4), 121–131. https://doi.org/10.4067/S0718-27242012000400010

Thompson, D. (2015). Tech transfer and commercialisation, (May). https://scienceportal.org.by/upload/2015/June/Inconet%20EaP%20-%20Presentation/8%20Thompson_Tech%20Transfer%20and%20Commercialisation.pdf

Vihar, J. (2019). guideline on government e- MARKETPLACE ( GeM ). https://www.suniv.ac.in/docs/Guide-line-on-GeM-SU.pdf

Download references

Open access funding provided by Manipal Academy of Higher Education, Manipal

Author information

Authors and affiliations.

Department of Pharmaceutical Quality Assurance, Manipal College of Pharmaceutical Sciences, Manipal Academy of Higher Education, Manipal, 576104, Karnataka, Manipal, India

Department of Pharmacy Management, Manipal College of Pharmaceutical Sciences, Manipal Academy of Higher Education, Manipal, 576104, Karnataka, Manipal, India

Manthan D. Janodia

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Manthan D. Janodia .

Additional information

Publisher’s note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Ravi, R., Janodia, M.D. Factors Affecting Technology Transfer and Commercialization of University Research in India: a Cross-sectional Study. J Knowl Econ 13 , 787–803 (2022). https://doi.org/10.1007/s13132-021-00747-4

Download citation

Received : 21 February 2020

Accepted : 19 January 2021

Published : 24 February 2021

Issue Date : March 2022

DOI : https://doi.org/10.1007/s13132-021-00747-4

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Technology transfer

- Commercialization

- Industry-academia partnership

- Find a journal

- Publish with us

- Track your research

Loading metrics

Open Access

Peer-reviewed

Research Article

‘Our project, your problem?’ A case study of the WHO’s mRNA technology transfer programme in South Africa

Roles Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Supervision, Writing – original draft, Writing – review & editing

* E-mail: [email protected]

Affiliations Faculty of Medicine, Department of Pharmacology, Dalhousie University, Halifax, Canada, Health Justice Institute, Schulich School of Law, Dalhousie University, Halifax, Canada

Roles Conceptualization, Data curation, Formal analysis, Writing – original draft, Writing – review & editing

Affiliations Program of Ethics, Politics and Economics, Yale University, New Haven, Connecticut, United States of America, Information Society Project, Yale Law School, New Haven, Connecticut, United States of America

- Matthew Herder,

- Ximena Benavides

- Published: September 23, 2024

- https://doi.org/10.1371/journal.pgph.0003173

- Peer Review

- Reader Comments

In June 2021 the World Health Organization (WHO) and the Medicines Patent Pool (MPP) launched an mRNA technology transfer programme. With a South African consortium serving as the hub, the programme aimed to increase vaccine manufacturing capacity in low- and middle-income countries (LMICs) in view of the “vaccine apartheid” that was observed during COVID-19. Following Clarke’s “situational analysis,” the present study assessed whether the mRNA programme differs from the approach and practices that comprise current biopharmaceutical production. Numerous documentary sources, including legal agreements underpinning the programme, funding agreements, and patent filings, were reviewed. Semi-structured interviews with 35 individuals, ranging from the programme’s architects and university scientists to representatives from LMIC vaccine manufacturers taking part in the programme were also conducted. While the mRNA programme may improve the sharing of knowledge, other design features, in particular, weak conditionalities around product affordability, participants’ freedom to contract with third parties, and acceptance of market-based competition, are in line with the status quo. Further, WHO and MPP’s tight control over the programme evokes the dynamics that are often in play in global health, to the detriment of empowering LMIC-based manufacturers to generate mRNA products in response to local health needs.

Citation: Herder M, Benavides X (2024) ‘Our project, your problem?’ A case study of the WHO’s mRNA technology transfer programme in South Africa. PLOS Glob Public Health 4(9): e0003173. https://doi.org/10.1371/journal.pgph.0003173

Editor: Roojin Habibi, University of Ottawa Faculty of Law - Common Law, CANADA

Received: February 7, 2024; Accepted: August 22, 2024; Published: September 23, 2024

Copyright: © 2024 Herder, Benavides. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Data Availability: In order to preserve the confidentiality of people who participated in this research, but do not wish their identities to be disclosed we are unable to share interview transcripts in their entirety. The research ethics board at Dalhousie University approved this research provided that participants' identities would remain confidential. Inquiries about data availability related to this project can be sent to [email protected] .

Funding: One author (MH) holds a Chair in Applied Public Health, funded by the Canadian Institutes of Health Research (CIHR) and Public Health Agency of Canada (PHAC). This Chair carries a salary award as well as funding for research activities. However, neither CIHR nor PHAC played any role whatsoever in the design of the present study, data collection, analysis or writing process.

Competing interests: We have read the journal’s policy and the authors of this manuscript have the following competing interests: Matthew Herder was a member of the Patented Medicine Prices Review Board (PMPRB), Canada’s national drug pricing regulator, and received honoraria for his public service, June 2018 – February 2023. The PMPRB had no role whatsoever in the design or conduct of this research. Ximena Benavides worked for GAVI - The Vaccine Alliance, COVAX Facility, from May to October of 2021, as a Yale Institute for Global Health fellow.

Introduction

In June 2021 Afrigen Biologics, a for-profit company based in Cape Town, South Africa set out to change the global landscape of biopharmaceutical production. Chosen by the World Health Organization (WHO) to serve as the hub of an mRNA technology transfer programme, Afrigen’s initial task was to make an mRNA COVID-19 vaccine against SARS-CoV-2 and distribute the technology to manufacturers located in other low- and middle-income countries (LMICs). The motivation was plain: established makers of COVID-19 vaccines, especially mRNA vaccines, had largely neglected populations in LMICs [ 1 , 2 ]. In view of that “vaccine apartheid,”[ 3 ] building capacity to make vaccines locally for local populations became imperative. The WHO turned to a model of knowledge-sharing that was previously deployed in response to concerns that the global influenza virus sharing network was under-serving people in LMICS [ 4 – 6 ]. Another Geneva-based organization, the Medicines Patent Pool (MPP), was charged with managing the mRNA programme’s fundraising and legal needs.

Within six months Afrigen succeeded in producing its own mRNA COVID-19 candidate, “AfriVac 2121 [ 7 ].”. The programme has the potential to be transformative as a model of vaccine production [ 8 ], encompassing both upstream research and development (R&D) and ‘end-to-end’ vaccine manufacturing. Still, the initiative faces several risks, including precarious levels of funding, the looming threat of patent litigation by established mRNA vaccine manufacturers, and a range of governance issues that have complicated the work of an organization created out of dire need—all the while trying to develop the technical capacity to produce high-quality mRNA-based technologies that protect against not only COVID-19 but also tuberculosis (TB), malaria, human immunodeficiency virus (HIV), and other diseases that disproportionately afflict people in LMICs.