- Articles in Press

- Current Issue

Journal Archive

Join our Community on:

Biofuel Research Journal`s Official Channel on WeChat (in Mandarin Chinese)

Latest News

Biofuel Research Journal

has been accepted to be indexed by Inspec!

"Inspec, produced by The

Institution of Engineering

and Technology , has been

the definitive engineering

and physics research database

for over 50 years"

Read more about Inspec on Clarivate TM

has been accepted to be indexed by Ei Compendex (Engineering Village)!

Read more here !

Read the Editor`s Pick: Biogas Collection here !

is now indexed by ProQuest!

We are delighted to announce .... Read more here !

Celebrating a year of growth

for Biofuel Research Journal !

This year marks a year of growth .... Read more here !

| Advances in biofuel technology are crucial as the world transitions from fossil fuels to sustainable energy sources. Central to this effort is the continuous improvement of catalysts, which enhance biofuel yield and minimize unwanted by-products that can impact sustainability. Researchers from the UAE have made significant progress by using advanced computational modeling to optimize beta zeolite (BEA) catalysts specifically for oleic acid upgrading—a critical process in biofuel production ( ). By fine-tuning the silica-to-aluminium ratios within BEA zeolites, they identified conditions that balance high fuel yields with reduced coke deposition. Additionally, Cu-dopped BEA catalysts have shown promise in lowering environmental impacts and costs, making them strong candidates for future biofuel innovations. This research pushes the boundaries of catalyst design and offers valuable insights for creating more efficient and sustainable biofuel processes. |

Biofuel Research Journal (BRJ) defines “biofuel” in both a specific and generalized context. In the specific sense, BRJ focuses on traditional biofuels and bioproducts derived from biomass. This includes biofuels such as biodiesel, bioethanol, biogas, and algal biofuels, as well as bioproducts like bio-based smart materials, biocomposites, and bio-based chemicals. In a generalized sense, BRJ extends the definition of “biofuel” to include any bio-based technologies, innovations, and strategies that contribute to reducing carbon emissions and fueling the transition toward a sustainable bioeconomy. Here, "biofuel" includes efforts that drive the shift from a carbon-intensive economy to a resilient, bio-based economy. Through this dual approach, BRJ aims to highlight the comprehensive role that both specific biofuels and generalized bio-based innovations play in fostering a sustainable future. The journal welcomes original articles, review papers, case studies, short communications, and hypotheses on the following topics:

- Biofuels and Bioproducts: Traditional biofuels such as biodiesel, bioethanol, biogas, algal biofuels, and emerging biofuel sources, as well as bioproducts like bio-based smart materials, biocomposites, and their applications in industries like food, pharmaceuticals, and others. These developments contribute to the traditional understanding of biofuels and bioproducts, and the broader bioeconomy.

- Innovative Bio-based Strategies: Exploring innovative technologies and strategies that contribute to carbon reduction and sustainability, supporting the journal’s broader definition of biofuel as a driver of the bioeconomy. These strategies are integral to BRJ’s generalized definition of biofuels as enablers of the bioeconomy.

- Biomass Valorization: Research into efficient biomass conversion methods, biorefineries, and bioprocesses aimed at maximizing energy output and value-added products, aligning with the shift toward a bio-based economy. This aligns with both specific biofuel production and broader efforts to transition to a bioeconomy.

- Biomass-Derived Materials for Energy and Storage Systems: Developing biomass-derived materials for use in energy systems, including fuel cells, batteries, supercapacitors, and photovoltaics, contributing to sustainable energy solutions.

- Biomass-Derived Materials for Environmental Sustainability: Investigating biomass-derived materials for carbon capture, pollution mitigation, and other environmental sustainability applications that mitigate climate change and promote circularity.

- Sustainable Applications in Food and Medicine: Utilizing biomass-derived materials in sustainable packaging, functional food ingredients, drug delivery systems, tissue engineering, and regenerative medicine to support a circular bioeconomy. These applications contribute both to the bio-based economy and a circular economy.

- Catalytic Applications of Biomass-Derived Materials: Advancing green manufacturing processes through biomass-derived catalysts and sustainable chemical transformations.

- Techno-Economic and Environmental Assessments: Evaluating the techno-economic feasibility and sustainability of biofuels, bioproducts, and biomass-derived material pathways (life cycle assessment, exergy, emergy, risk assessment), ensuring compliance with global sustainability standards. These analyses ensure the sustainability of bio-based innovations across different scales.

- Climate Change and Bioeconomy Integration: Examining the role of biofuels and bio-based innovations in mitigating climate change and promoting the transition to a low-carbon bioeconomy. These innovations not only reduce greenhouse gas emissions but also align with global sustainability goals.

- Integrated Biofuel and Bioproduct Processing Systems: Highlighting novel and integrated approaches to biofuel and bioproduct processing that optimize efficiency and resource use, key drivers for both specific biofuel production and the broader bioeconomy transition.

- Artificial Photosynthesis for Biofuel Production: Exploring research on artificial photosynthesis as an emerging, sustainable pathway for biofuel production, reinforcing the journal's focus on next-generation bio-based energy solutions.

- Biofuels and Bioproducts in Developing Economies: Encouraging the promotion and adoption of biofuels, bioproducts, and bio-based technologies in developing economies, contributing to local economic development, sustainability, and global climate mitigation.

- Circular Economy and Resource Efficiency: Investigating the role of biofuels and bioproducts in circular economy frameworks, with an emphasis on resource efficiency, waste valorization, and sustainable biomass utilization as part of broader efforts to build a resilient bioeconomy.

BRJ supports interdisciplinary collaboration and invites contributions from researchers, policymakers, and industry leaders to accelerate the transition to a sustainable bioeconomy through innovative bio-based solutions. The journal is committed to maintaining the highest standards of peer review and editorial integrity, ensuring that only high-quality and impactful research is published. As an open-access journal, BRJ is completely free-of-charge, allowing unrestricted access to cutting-edge research for researchers, policymakers, and industry leaders alike. Biofuel Research Journal is indexed in Scopus and Web of Science . BRJ currently has no fees. Learn More . Editor-in-Chief: Vijai Kumar Gupta > View Full Editorial Board

Editorial Board

10.18331/BRJ2024.11.3.1

- PDF 226.38 K

Research Paper

Cascading valorization of defatted rice bran for lactic acid fermentation and biogas production.

Pages 2146-2167

10.18331/BRJ2024.11.3.2

Christiane Herrmann; Raj Shekhar Bose; Anna-Katrin Neu; Roland Schneider; Maria Alexandri

- View Article

Sustainable catalytic pathways for biofuel precursors: quantitative conversion of glucose to gluconic acid using Pt-Zn biochar catalyst

Pages 2168-2180

10.18331/BRJ2024.11.3.3

Hengyu Hao; Haixin Guo; Bingkun Chen; Richard Lee Smith Jr; Shen Feng

Beyond tradition: charting a greener future for cassava starch industry using multi-criteria decision-making

Pages 2181-2193

10.18331/BRJ2024.11.3.4

Varshini Ravichandran; Deepak Kumar; Sivakumar Mani; Karthik Rajendran

Advanced computational modelling for biofuel catalyst optimization: enhancing beta zeolite acidity for oleic acid upgrading

Pages 2194-2210

10.18331/BRJ2024.11.3.5

Seba AlAreeqi; Daniel Bahamon; Ismail I.I. Alkhatib; Kyriaki Polychronopoulou; Lourdes F. Vega

Publication Information

Indexing and abstracting.

Advertisement

Biofuels: present and future

- S.I. : Biofuels

- Published: 08 May 2024

Cite this article

- Richard Vincent Asase ORCID: orcid.org/0009-0002-7712-5955 1 ,

- Queency N. Okechukwu 1 &

- Maria N. Ivantsova 1

516 Accesses

9 Altmetric

Explore all metrics

Biofuels represent a promising departure from conventional fossil fuels, presenting viable remedies for both energy security and environmental apprehensions. This review intricately examines the various realms of biofuels, encompassing their historical progression, present status, obstacles, and outlook. Commencing with an in-depth exploration of their historical antecedents and developmental milestones, this paper navigates through the spectrum of biofuel variants, encompassing first, second, and third-generation iterations. It meticulously scrutinizes the methodologies of production, advantages, limitations, and ecological implications associated with each variant, providing a nuanced comprehension seldom found in singular sources. A pivotal emphasis is placed on technological innovations propelling the biofuel industry’s advancement, shedding light on recent breakthroughs such as nanotechnologies and mathematical models in biofuel production. Moreover, the paper thoroughly assesses the current global landscape of biofuel production, dissecting the health, environmental, and socioeconomic ramifications of their utilization. The findings reveal that the field of biofuels is still developing and possesses a lot of opportunities toward environmental sustainability. Only a small part of the world is experiencing the production and utilization of biofuels, hence the need for its campaign to engulf the entire world. Also, most of the modern technologies identified in this work are on a laboratory basis and require the needed scalability skills for industrial production. Finally, this work of varied viewpoints seeks to serve as a significant scholarly resource for stakeholders, policymakers, academics, and professionals within the industry, offering insights to grasp and influence the trajectory of biofuels.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Global Conclusions and Future Perspectives

Biofuels: An Overview

Introduction

Explore related subjects.

- Environmental Chemistry

Data availability

Not applicable.

Adewale, P., Dumont, M. J., & Ngadi, M. (2015). Recent trends of biodiesel production from animal fat wastes and associated production techniques. Renewable and Sustainable Energy Reviews , 45 , 574–588. https://doi.org/10.1016/j.rser.2015.02.039 .

Article CAS Google Scholar

Ahmed, S. F., Debnath, J. C., Mehejabin, F., Islam, N., Tripura, R., Mofijur, M., Hoang, A. T., Rasul, M. G., & Vo, D. V. N (2023a). Utilization of nanomaterials in accelerating the production process of sustainable biofuels. Sustainable Energy Technologies and Assessments , 55 , 102894. https://doi.org/10.1016/j.seta.2022.102894 .

Article Google Scholar

Ahmed, S. F., Debnath, J. C., Mehejabin, F., Islam, N., Tripura, R., Mofijur, M., Hoang, A. T., Rasul, M. G., & Vo, D. V. N (2023b). Utilization of nanomaterials in accelerating the production process of sustainable biofuels. Sustainable Energy Technologies and Assessments , 55 , 102894. https://doi.org/10.1016/j.seta.2022.102894 .

Alam, F., Mobin, S., & Chowdhury, H. (2015). Third generation biofuel from algae. Procedia Engineering , 105 , 763–768. https://doi.org/10.1016/j.proeng.2015.05.068 .

Anderson, J. E., DiCicco, D. M., Ginder, J. M., Kramer, U., Leone, T. G., Raney-Pablo, H. E., & Wallington, T. J. (2012). High octane number ethanol–gasoline blends: Quantifying the potential benefits in the United States. Fuel , 97 , 585–594. https://doi.org/10.1016/j.fuel.2012.03.017 .

Araújo, K. (2018). Low Carbon Energy transitions . Oxford University Press. https://doi.org/10.1093/oso/9780199362554.001.0001 .

Arora, A., Nandal, P., Singh, J., & Verma, M. L. (2020). Nanobiotechnological advancements in lignocellulosic biomass pretreatment. Materials Science for Energy Technologies , 3 , 308–318. https://doi.org/10.1016/j.mset.2019.12.003 .

Asomaning, J., Omidghane, M., Chae, M., & Bressler, D. C. (2016). Thermal processing of algal biomass for biofuel production. Current Opinion in Green and Sustainable Chemistry , 2 , 1–5. https://doi.org/10.1016/j.cogsc.2016.08.005 .

Atabani, A. E., Silitonga, A. S., Badruddin, I. A., Mahlia, T. M. I., Masjuki, H. H., & Mekhilef, S. (2012). A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renewable and Sustainable Energy Reviews , 16 (4), 2070–2093. https://doi.org/10.1016/j.rser.2012.01.003 .

Balasubramanian, R., Abishek, A., Gobinath, S., & Jaivignesh, K. (2022). Alternative fuel: Hydrogen and its thermodynamic behaviour. Journal of Human Earth and Future , 3 (2), 195–203. https://doi.org/10.28991/HEF-2022-03-02-05 .

Bera, S., Banerjee, T., & Samanta, A. (2021). Evaluation of enzymatic delignification of rice straw residues for bioethanol production. International Journal of Renewable Energy Technology , 12 (2), 99. https://doi.org/10.1504/IJRET.2021.115276 .

Bhatia, S. K., Jagtap, S. S., Bedekar, A. A., Bhatia, R. K., Patel, A. K., Pant, D., Banu, R., Rao, J., Kim, C. V., Y.-G., & Yang, Y. H. (2020). Recent developments in pretreatment technologies on lignocellulosic biomass: Effect of key parameters, technological improvements, and challenges. Bioresource Technology , 300 , 122724. https://doi.org/10.1016/j.biortech.2019.122724 .

Bidir, M. G., Millerjothi, N. K., Adaramola, M. S., & Hagos, F. Y. (2021). The role of nanoparticles on biofuel production and as an additive in ternary blend fuelled diesel engine: A review. Energy Reports , 7 , 3614–3627. https://doi.org/10.1016/j.egyr.2021.05.084 .

Bogaerts, A., Neyts, E., Gijbels, R., & van der Mullen, J. (2002). Gas discharge plasmas and their applications. Spectrochimica Acta Part B: Atomic Spectroscopy , 57 (4), 609–658. https://doi.org/10.1016/S0584-8547(01)00406-2 .

Botella, L., Stankovikj, F., Sánchez, J. L., Gonzalo, A., Arauzo, J., & Garcia-Pérez, M. (2018). Bio-oil hydrotreatment for enhancing solubility in biodiesel and the oxydation stability of resulting blends. Frontiers in Chemistry , 6 . https://doi.org/10.3389/fchem.2018.00083 .

Brar, A., Kumar, M., Soni, T., Vivekanand, V., & Pareek, N. (2021). Insights into the genetic and metabolic engineering approaches to enhance the competence of microalgae as biofuel resource: A review. Bioresource Technology , 339 , 125597. https://doi.org/10.1016/j.biortech.2021.125597 .

Cameron, D. E., Bashor, C. J., & Collins, J. J. (2014). A brief history of synthetic biology. Nature Reviews Microbiology , 12 (5), 381–390. https://doi.org/10.1038/nrmicro3239 .

Carboué, Q., Claeys-Bruno, M., Bombarda, I., Sergent, M., Jolain, J., & Roussos, S. (2018). Experimental design and solid state fermentation: A holistic approach to improve cultural medium for the production of fungal secondary metabolites. Chemometrics and Intelligent Laboratory Systems , 176 , 101–107. https://doi.org/10.1016/j.chemolab.2018.03.011 .

Cheah, W. Y., Sankaran, R., Show, P. L., Tg. Ibrahim, T. N. B., Chew, K. W., Culaba, A., & Chang, J. S. (2020). Pretreatment methods for lignocellulosic biofuels production: Current advances, challenges and future prospects. Biofuel Research Journal , 7 (1), 1115–1127. https://doi.org/10.18331/BRJ2020.7.1.4 .

Chowdury, K. H., Nahar, N., & Deb, U. K. (2020). The growth factors involved in microalgae cultivation for biofuel production: A review. Computational Water Energy and Environmental Engineering , 09 (04), 185–215. https://doi.org/10.4236/cweee.2020.94012 .

Clauser, N. M., Felissia, F. E., Area, M. C., & Vallejos, M. E. (2021). A framework for the design and analysis of integrated multi-product biorefineries from agricultural and forestry wastes. Renewable and Sustainable Energy Reviews , 139 , 110687. https://doi.org/10.1016/j.rser.2020.110687 .

Dahman, Y., Syed, K., Begum, S., Roy, P., & Mohtasebi, B. (2019). Biofuels. In Biomass, Biopolymer-Based Materials, and Bioenergy (pp. 277–325). Elsevier. https://doi.org/10.1016/B978-0-08-102426-3.00014-X .

Dave, N., Varadavenkatesan, T., Selvaraj, R., & Vinayagam, R. (2021). Modelling of fermentative bioethanol production from indigenous ulva prolifera biomass by saccharomyces cerevisiae NFCCI1248 using an integrated ANN-GA approach. Science of the Total Environment , 791 , 148429. https://doi.org/10.1016/j.scitotenv.2021.148429 .

Demirbas, A., & Fatih Demirbas, M. (2011). Importance of algae oil as a source of biodiesel. Energy Conversion and Management , 52 (1), 163–170. https://doi.org/10.1016/j.enconman.2010.06.055 .

Devi, A., Singh, A., Bajar, S., & Owamah, H. I. (2021). Nanomaterial in liquid biofuel production: Applications and current status. Environmental Sustainability , 4 (2), 343–353. https://doi.org/10.1007/s42398-021-00193-7 .

Dutta, K., Daverey, A., & Lin, J. G. (2014). Evolution retrospective for alternative fuels: First to fourth generation. Renewable Energy , 69 , 114–122. https://doi.org/10.1016/j.renene.2014.02.044 .

Elgarahy, A. M., Hammad, A., El-Sherif, D. M., Abouzid, M., Gaballah, M. S., & Elwakeel, K. Z. (2021). Thermochemical conversion strategies of biomass to biofuels, techno-economic and bibliometric analysis: A conceptual review. Journal of Environmental Chemical Engineering , 9 (6), 106503. https://doi.org/10.1016/j.jece.2021.106503 .

Erdei, B., Frankó, B., Galbe, M., & Zacchi, G. (2012). Separate hydrolysis and co-fermentation for improved xylose utilization in integrated ethanol production from wheat meal and wheat straw. Biotechnology for Biofuels , 5 (1), 12. https://doi.org/10.1186/1754-6834-5-12 .

Ghag, S. B., Vavilala, S. L., & D’Souza, J. S. (2019). Metabolic engineering and genetic manipulation of novel biomass species for biofuel production. In Advanced Bioprocessing for Alternative Fuels, Biobased Chemicals, and Bioproducts (pp. 13–34). Elsevier. https://doi.org/10.1016/B978-0-12-817941-3.00002-4 .

Godbole, V., Pal, M. K., & Gautam, P. (2021). A critical perspective on the scope of interdisciplinary approaches used in fourth-generation biofuel production. Algal Research , 58 , 102436. https://doi.org/10.1016/j.algal.2021.102436 .

Gonzales, R. R., Sivagurunathan, P., & Kim, S. H. (2016). Effect of severity on dilute acid pretreatment of lignocellulosic biomass and the following hydrogen fermentation. International Journal of Hydrogen Energy , 41 (46), 21678–21684. https://doi.org/10.1016/j.ijhydene.2016.06.198 .

Graham-Rowe, D. (2011). Agriculture: Beyond food versus fuel. Nature , 474 (7352), S6–S8. https://doi.org/10.1038/474S06a .

Guo, M. (2020). The Global Scenario of Biofuel Production and Development (pp. 29–56). https://doi.org/10.1007/978-81-322-3965-9_3 .

Hellsmark, H., Mossberg, J., Söderholm, P., & Frishammar, J. (2016). Innovation system strengths and weaknesses in progressing sustainable technology: The case of Swedish biorefinery development. Journal of Cleaner Production , 131 , 702–715. https://doi.org/10.1016/j.jclepro.2016.04.109 .

Heredia-Olea, E., Pérez-Carrillo, E., Montoya-Chiw, M., & Serna-Saldívar, S. O. (2015). Effects of extrusion pretreatment parameters on sweet sorghum bagasse enzymatic hydrolysis and its subsequent conversion into bioethanol. BioMed Research International , 2015 , 1–10. https://doi.org/10.1155/2015/325905 .

Hossain, M. N., Bin, Basu, J. K., & Mamun, M. (2015). The production of ethanol from micro-algae spirulina. Procedia Engineering , 105 , 733–738. https://doi.org/10.1016/j.proeng.2015.05.064 .

Hosseinzadeh, G., Sajjadi, S. M., Mostafa, L., Yousefi, A., Vafaie, R. H., & Zinatloo-Ajabshir, S. (2023). Synthesis of novel direct Z-scheme heterojunction photocatalyst from WO3 nanoplates and SrTiO3 nanoparticles with abundant oxygen vacancies. Surfaces and Interfaces , 42 , 103349. https://doi.org/10.1016/j.surfin.2023.103349 .

Huang, H., & Tang, L. (2007). Treatment of organic waste using thermal plasma pyrolysis technology. Energy Conversion and Management , 48 (4), 1331–1337. https://doi.org/10.1016/j.enconman.2006.08.013 .

Ingle, A. P., Chandel, A. K., Antunes, F. A. F., Rai, M., & da Silva, S. S. (2019). New trends in application of nanotechnology for the pretreatment of lignocellulosic biomass. Biofuels Bioproducts and Biorefining , 13 (3), 776–788. https://doi.org/10.1002/bbb.1965 .

Ishizaki, H., & Hasumi, K. (2014). Ethanol production from biomass. In Research Approaches to Sustainable Biomass Systems (pp. 243–258). Elsevier. https://doi.org/10.1016/B978-0-12-404609-2.00010-6 .

Jambo, S. A., Abdulla, R., Mohd Azhar, S. H., Marbawi, H., Gansau, J. A., & Ravindra, P. (2016). A review on third generation bioethanol feedstock. Renewable and Sustainable Energy Reviews , 65 , 756–769. https://doi.org/10.1016/j.rser.2016.07.064 .

Jatoi, A. S., Abbasi, S. A., Hashmi, Z., Shah, A. K., Alam, M. S., Bhatti, Z. A., Maitlo, G., Hussain, S., Khandro, G. A., Usto, M. A., & Iqbal, A. (2023). Recent trends and future perspectives of lignocellulose biomass for biofuel production: A comprehensive review. Biomass Conversion and Biorefinery , 13 (8), 6457–6469. https://doi.org/10.1007/s13399-021-01853-8 .

Jeswani, H. K., Chilvers, A., & Azapagic, A. (2020). Environmental sustainability of biofuels: a review. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences , 476 (2243). https://doi.org/10.1098/rspa.2020.0351 .

Jiang, D., Ge, X., Zhang, T., Chen, Z., Zhang, Z., He, C., Zhang, Q., & Li, Y. (2020). Effect of alkaline pretreatment on photo-fermentative hydrogen production from giant reed: Comparison of NaOH and ca(OH)2. Bioresource Technology , 304 , 123001. https://doi.org/10.1016/j.biortech.2020.123001 .

Johansson, M. T., & Ilic, D. D. (2018). Review of sustainable development of the road transport sector – are there geographical differences? WEENTECH Proceedings in Energy , 4 (2), 67–87. https://doi.org/10.32438/WPE.8918 .

Keasling, J., Garcia Martin, H., Lee, T. S., Mukhopadhyay, A., Singer, S. W., & Sundstrom, E. (2021). Microbial production of advanced biofuels. Nature Reviews Microbiology , 19 (11), 701–715. https://doi.org/10.1038/s41579-021-00577-w .

Kong, H., Yang, X., Gu, Z., Li, Z., Cheng, L., Hong, Y., & Li, C. (2018). Heat pretreatment improves the enzymatic hydrolysis of granular corn starch at high concentration. Process Biochemistry , 64 , 193–199. https://doi.org/10.1016/j.procbio.2017.09.021 .

Kucharska, K., Hołowacz, I., Konopacka-Łyskawa, D., Rybarczyk, P., & Kamiński, M. (2018). Key issues in modeling and optimization of lignocellulosic biomass fermentative conversion to gaseous biofuels. Renewable Energy , 129 , 384–408. https://doi.org/10.1016/j.renene.2018.06.018 .

Kucharska, K., Słupek, E., Cieśliński, H., & Kamiński, M. (2020). Advantageous conditions of saccharification of lignocellulosic biomass for biofuels generation via fermentation processes. Chemical Papers , 74 (4), 1199–1209. https://doi.org/10.1007/s11696-019-00960-1 .

Li, Y., Zhang, R., Liu, G., Chen, C., He, Y., & Liu, X. (2013). Comparison of methane production potential, biodegradability, and kinetics of different organic substrates. Bioresource Technology , 149 , 565–569. https://doi.org/10.1016/j.biortech.2013.09.063 .

Li, C., Zhao, X., Wang, A., Huber, G. W., & Zhang, T. (2015). Catalytic transformation of lignin for the production of chemicals and fuels. Chemical Reviews , 115 (21), 11559–11624. https://doi.org/10.1021/acs.chemrev.5b00155 .

Li, J., Tao, J., Yan, B., Jiao, L., Chen, G., & Hu, J. (2021). Review of microwave-based treatments of biomass gasification tar. Renewable and Sustainable Energy Reviews , 150 , 111510. https://doi.org/10.1016/j.rser.2021.111510 .

Liu, Y., Cruz-Morales, P., Zargar, A., Belcher, M. S., Pang, B., Englund, E., Dan, Q., Yin, K., & Keasling, J. D. (2021). Biofuels for a sustainable future. Cell , 184 (6), 1636–1647. https://doi.org/10.1016/j.cell.2021.01.052 .

Liu, X., Chen, Z., Lu, S., Xu, B., Cheng, D., Wei, W., Shen, Y., & Ni, B. J. (2023). Heterogeneous photocatalytic conversion of biomass to biofuels: A review. Chemical Engineering Journal , 476 , 146794. https://doi.org/10.1016/j.cej.2023.146794 .

Lopes, M. L., Paulillo, S. C., de Godoy, L., Cherubin, A., Lorenzi, R. A., Giometti, M. S., Bernardino, F. H. C., Neto, C. D. A., H. B., & Amorim, H. V. (2016). de. Ethanol production in Brazil: a bridge between science and industry. Brazilian Journal of Microbiology , 47 , 64–76. https://doi.org/10.1016/j.bjm.2016.10.003 .

López-Linares, J. C., Lucas, S., García-Cubero, M. T., Jiménez, J. J., & Coca, M. (2020). A biorefinery based on brewer’s spent grains: Arabinoxylans recovery by microwave assisted pretreatment integrated with butanol production. Industrial Crops and Products , 158 , 113044. https://doi.org/10.1016/j.indcrop.2020.113044 .

Luque, R., Menéndez, J. A., Arenillas, A., & Cot, J. (2012). Microwave-assisted pyrolysis of biomass feedstocks: The way forward? Energy & Environmental Science , 5 (2), 5481–5488. https://doi.org/10.1039/C1EE02450G .

Malode, S. J., Gaddi, S. A. M., Kamble, P. J., Nalwad, A. A., Muddapur, U. M., & Shetti, N. P. (2022). Recent evolutionary trends in the production of biofuels. Materials Science for Energy Technologies , 5 , 262–277. https://doi.org/10.1016/j.mset.2022.04.001 .

Mohammadi, M., Shafiei, M., Abdolmaleki, A., Karimi, K., Mikkola, J. P., & Larsson, C. (2019). A morpholinium ionic liquid for rice straw pretreatment to enhance ethanol production. Industrial Crops and Products , 139 , 111494. https://doi.org/10.1016/j.indcrop.2019.111494 .

Monlau, F., Sambusiti, C., Barakat, A., Guo, X. M., Latrille, E., Trably, E., Steyer, J. P., & Carrere, H. (2012). Predictive models of biohydrogen and biomethane production based on the compositional and structural features of lignocellulosic materials. Environmental Science & Technology , 46 (21), 12217–12225. https://doi.org/10.1021/es303132t .

Mulyaningtyas, A., & Sediawan, W. B. (2019). Effect of combined pretreatment of lignocellulose and the kinetics of its subsequent bioconversion by aspergillus niger. Biocatalysis and Agricultural Biotechnology , 21 , 101292. https://doi.org/10.1016/j.bcab.2019.101292 .

Mushtaq, F., Mat, R., & Ani, F. N. (2014). A review on microwave assisted pyrolysis of coal and biomass for fuel production. Renewable and Sustainable Energy Reviews , 39 , 555–574. https://doi.org/10.1016/j.rser.2014.07.073 .

Mutsengerere, S., Chihobo, C. H., Musademba, D., & Nhapi, I. (2019). A review of operating parameters affecting bio-oil yield in microwave pyrolysis of lignocellulosic biomass. Renewable and Sustainable Energy Reviews , 104 , 328–336. https://doi.org/10.1016/j.rser.2019.01.030 .

Nagendranatha Reddy, C., Kondaveeti, S., Mohanakrishna, G., & Min, B. (2022). Application of bioelectrochemical systems to regulate and accelerate the anaerobic digestion processes. Chemosphere , 287 , 132299. https://doi.org/10.1016/j.chemosphere.2021.132299 .

Neag, E., Stupar, Z., Maicaneanu, S. A., & Roman, C. (2023). Advances in biodiesel production from microalgae. Energies , 16 (3), 1129. https://doi.org/10.3390/en16031129 .

Nizami, A. S., & Rehan, M. (2018). Towards nanotechnology-based biofuel industry. Biofuel Research Journal , 5 (2), 798–799. https://doi.org/10.18331/BRJ2018.5.2.2 .

Nizamuddin, S., Baloch, H. A., Griffin, G. J., Mubarak, N. M., Bhutto, A. W., Abro, R., Mazari, S. A., & Ali, B. S. (2017). An overview of effect of process parameters on hydrothermal carbonization of biomass. Renewable and Sustainable Energy Reviews , 73 , 1289–1299. https://doi.org/10.1016/j.rser.2016.12.122 .

OECD-FAO Agricultural (2023). Outlook 2023–2032 . OECD. https://doi.org/10.1787/08801ab7-en .

Orugba, H. O., Oghenejoboh, K. M., Oghenejoboh, U. M., & Ohimor, O. E. (2021). Production of biodiesel from a novel combination of Raphia Africana kernel oil and turtle shell (Centrochelys Sulcata) Heterogenous Catalyst. Journal of Human Earth and Future , 2 (3), 258–268. https://doi.org/10.28991/HEF-2021-02-03-07 .

Ou, L., Thilakaratne, R., Brown, R. C., & Wright, M. M. (2015). Techno-economic analysis of transportation fuels from defatted microalgae via hydrothermal liquefaction and hydroprocessing. Biomass and Bioenergy , 72 , 45–54. https://doi.org/10.1016/j.biombioe.2014.11.018 .

Pathak, C., Mandalia, H. C., & Rupala, Y. M. (2012). Biofuels: Indian energy scenario. Research Journal of Recent Sciences , 1 (4), 88–90.

Google Scholar

Phwan, C. K., Ong, H. C., Chen, W. H., Ling, T. C., Ng, E. P., & Show, P. L. (2018). Overview: Comparison of pretreatment technologies and fermentation processes of bioethanol from microalgae. Energy Conversion and Management , 173 , 81–94. https://doi.org/10.1016/j.enconman.2018.07.054 .

Puligundla, P., Oh, S. E., & Mok, C. (2016). Microwave-assisted pretreatment technologies for the conversion of lignocellulosic biomass to sugars and ethanol: A review. Carbon Letters , 17 (1), 1–10. https://doi.org/10.5714/CL.2016.17.1.001 .

Punnathanam, V., & Shastri, Y. (2020). Efficient optimization of a large-scale biorefinery system using a novel decomposition based approach. Chemical Engineering Research and Design , 160 , 175–189. https://doi.org/10.1016/j.cherd.2020.05.023 .

Rana, M. S., Bhushan, S., Sudhakar, D. R., & Prajapati, S. K. (2020). Effect of iron oxide nanoparticles on growth and biofuel potential of Chlorella spp. Algal Research , 49 , 101942. https://doi.org/10.1016/j.algal.2020.101942 .

Reilly, M., Dinsdale, R., & Guwy, A. (2015). Enhanced biomethane potential from wheat straw by low temperature alkaline calcium hydroxide pre-treatment. Bioresource Technology , 189 , 258–265. https://doi.org/10.1016/j.biortech.2015.03.150 .

Rezayeenik, M., Mousavi-Kamazani, M., & Zinatloo-Ajabshir, S. (2023). CeVO4/rGO nanocomposite: Facile hydrothermal synthesis, characterization, and electrochemical hydrogen storage. Applied Physics A , 129 (1), 47. https://doi.org/10.1007/s00339-022-06325-y .

Robles-Medina, A., González-Moreno, P. A., Esteban-Cerdán, L., & Molina-Grima, E. (2009). Biocatalysis: Towards ever greener biodiesel production. Biotechnology Advances , 27 (4), 398–408. https://doi.org/10.1016/j.biotechadv.2008.10.008 .

Rouleau, M., Egyed, M., Taylor, B., Chen, J., Samaali, M., Davignon, D., & Morneau, G. (2013). Human Health impacts of biodiesel use in on-road heavy duty diesel vehicles in Canada. Environmental Science & Technology , 47 (22), 13113–13121. https://doi.org/10.1021/es4023859 .

Roy, R., Rahman, M. S., & Raynie, D. E. (2020). Recent advances of greener pretreatment technologies of lignocellulose. Current Research in Green and Sustainable Chemistry , 3 , 100035. https://doi.org/10.1016/j.crgsc.2020.100035 .

Ruiz, H. A., Galbe, M., Garrote, G., Ramirez-Gutierrez, D. M., Ximenes, E., Sun, S. N., Lachos-Perez, D., Rodríguez-Jasso, R. M., Sun, R. C., Yang, B., & Ladisch, M. R. (2021). Severity factor kinetic model as a strategic parameter of hydrothermal processing (steam explosion and liquid hot water) for biomass fractionation under biorefinery concept. Bioresource Technology , 342 , 125961. https://doi.org/10.1016/j.biortech.2021.125961 .

Sandesh, K., & Ujwal, P. (2021). Trends and perspectives of liquid biofuel – process and industrial viability. Energy Conversion and Management: X , 10 , 100075. https://doi.org/10.1016/j.ecmx.2020.100075 .

Santos, L. C., dos, Adarme, O. F. H., Baêta, B. E. L., Gurgel, L. V. A., & de Aquino, S. F. (2018). Production of biogas (methane and hydrogen) from anaerobic digestion of hemicellulosic hydrolysate generated in the oxidative pretreatment of coffee husks. Bioresource Technology , 263 , 601–612. https://doi.org/10.1016/j.biortech.2018.05.037 .

Santos, F., Eichler, P., de Queiroz, J. H., & Gomes, F. (2020). Production of second-generation ethanol from sugarcane. In Sugarcane Biorefinery, Technology and Perspectives (pp. 195–228). Elsevier. https://doi.org/10.1016/B978-0-12-814236-3.00011-1 .

Saravanan, A., Senthil Kumar, P., Jeevanantham, S., Karishma, S., & Vo, D. V. N. (2022). Recent advances and sustainable development of biofuels production from lignocellulosic biomass. Bioresource Technology , 344 , 126203. https://doi.org/10.1016/j.biortech.2021.126203 .

Sarip, H., Hossain, M. S., N., M. A. M. N., & Allaf, K. (2016). A review of the thermal pretreatment of lignocellulosic biomass towards glucose production: Autohydrolysis with DIC technology. Bioresources , 11 (4), 10625–10653. https://doi.org/10.15376/biores.11.4.Sarip .

Savi, E. L., Herculano, L. S., Lukasievicz, G. V. B., Torquato, A. S., Baesso, M. L., Astrath, N. G. C., & Malacarne, L. C. (2017). Evaluation of thermo-oxidative stability of biodiesel. Energy & Fuels , 31 (7), 7132–7137. https://doi.org/10.1021/acs.energyfuels.7b00696 .

Scarlat, N., Dallemand, J. F., Monforti-Ferrario, F., & Nita, V. (2015). The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environmental Development , 15 , 3–34. https://doi.org/10.1016/j.envdev.2015.03.006 .

Scovronick, N., & Wilkinson, P. (2014). Health impacts of liquid biofuel production and use: A review. Global Environmental Change , 24 , 155–164. https://doi.org/10.1016/j.gloenvcha.2013.09.011 .

Shah, A., Darr, M., Khanal, S., & Lal, R. (2017). A techno-environmental overview of a corn stover biomass feedstock supply chain for cellulosic biorefineries. Biofuels , 8 (1), 59–69. https://doi.org/10.1080/17597269.2016.1200864 .

Shahbeik, H., Peng, W., Kazemi Shariat Panahi, H., Dehhaghi, M., Guillemin, G. J., Fallahi, A., Amiri, H., Rehan, M., Raikwar, D., Latine, H., Pandalone, B., Khoshnevisan, B., Sonne, C., Vaccaro, L., Nizami, A. S., Gupta, V. K., Lam, S. S., Pan, J., Luque, R., & Aghbashlo, M. (2022a). Synthesis of liquid biofuels from biomass by hydrothermal gasification: A critical review. Renewable and Sustainable Energy Reviews , 167 , 112833. https://doi.org/10.1016/j.rser.2022.112833 .

Shahbeik, H., Peng, W., Kazemi Shariat Panahi, H., Dehhaghi, M., Guillemin, G. J., Fallahi, A., Amiri, H., Rehan, M., Raikwar, D., Latine, H., Pandalone, B., Khoshnevisan, B., Sonne, C., Vaccaro, L., Nizami, A. S., Gupta, V. K., Lam, S. S., Pan, J., Luque, R., & Aghbashlo, M. (2022b). Synthesis of liquid biofuels from biomass by hydrothermal gasification: A critical review. Renewable and Sustainable Energy Reviews , 167 , 112833. https://doi.org/10.1016/j.rser.2022.112833 .

Shahid, M. K., Kim, J. Y., Shin, G., & Choi, Y. (2020). Effect of pyrolysis conditions on characteristics and fluoride adsorptive performance of bone char derived from bone residue. Journal of Water Process Engineering , 37 , 101499. https://doi.org/10.1016/j.jwpe.2020.101499 .

Shahid, M. K., Batool, A., Kashif, A., Nawaz, M. H., Aslam, M., Iqbal, N., & Choi, Y. (2021). Biofuels and biorefineries: Development, application and future perspectives emphasizing the environmental and economic aspects. Journal of Environmental Management , 297 , 113268. https://doi.org/10.1016/j.jenvman.2021.113268 .

Sheikh, M. M. I., Kim, C., Park, H., Kim, S., Kim, G., Lee, J., Sim, S., & Kim, J. W. (2013). Effect of torrefaction for the pretreatment of rice straw for ethanol production. Journal of the Science of Food and Agriculture , 93 (13), 3198–3204. https://doi.org/10.1002/jsfa.6155 .

Shokravi, Z., Shokravi, H., Aziz, M. A., & Shokravi, H. (2019). The fourth-generation biofuel: A systematic review on nearly two decades of research from 2008 to 2019. Fossil Free Fuels (pp. 213–251). CRC. https://doi.org/10.1201/9780429327773-12 .

Singh, J., & Gu, S. (2010). Commercialization potential of microalgae for biofuels production. Renewable and Sustainable Energy Reviews , 14 (9), 2596–2610. https://doi.org/10.1016/j.rser.2010.06.014 .

Srivastava, N., Singh, R., Srivastava, M., Mohammad, A., Harakeh, S., Singh, P., Pal, R., Haque, D. B., Tayeb, S., Moulay, H. H., M., & Gupta, K., V (2023). Impact of nanomaterials on sustainable pretreatment of lignocellulosic biomass for biofuels production: An advanced approach. Bioresource Technology , 369 , 128471. https://doi.org/10.1016/j.biortech.2022.128471 .

Suali, E., & Sarbatly, R. (2012). Conversion of microalgae to biofuel. Renewable and Sustainable Energy Reviews , 16 (6), 4316–4342. https://doi.org/10.1016/j.rser.2012.03.047 .

Tabatabaeinejad, S. M., Zinatloo-Ajabshir, S., Amiri, O., & Salavati-Niasari, M. (2021). Magnetic Lu 2 Cu 2 O 5 -based ceramic nanostructured materials fabricated by a simple and green approach for an effective photocatalytic degradation of organic contamination. RSC Advances , 11 (63), 40100–40111. https://doi.org/10.1039/D1RA06101A .

Talebnia, F., Karakashev, D., & Angelidaki, I. (2010). Production of bioethanol from wheat straw: An overview on pretreatment, hydrolysis and fermentation. Bioresource Technology , 101 (13), 4744–4753. https://doi.org/10.1016/j.biortech.2009.11.080 .

Tareen, W. U. K., Dilbar, M. T., Farhan, M., Ali Nawaz, M., Durrani, A. W., Memon, K. A., Mekhilef, S., Seyedmahmoudian, M., Horan, B., Amir, M., & Aamir, M. (2019). Present status and potential of biomass energy in Pakistan based on existing and future renewable resources. Sustainability , 12 (1), 249. https://doi.org/10.3390/su12010249 .

Usmani, R. A., Mohammad, A. S., & Ansari, S. S. (2023). Comprehensive biofuel policy analysis framework: A novel approach evaluating the policy influences. Renewable and Sustainable Energy Reviews , 183 , 113403. https://doi.org/10.1016/j.rser.2023.113403 .

Van Dyk, J. S., & Pletschke, B. I. (2012). A review of lignocellulose bioconversion using enzymatic hydrolysis and synergistic cooperation between enzymes—factors affecting enzymes, conversion and synergy. Biotechnology Advances , 30 (6), 1458–1480. https://doi.org/10.1016/j.biotechadv.2012.03.002 .

Velmurugan, R., & Incharoensakdi, A. (2016). Proper ultrasound treatment increases ethanol production from simultaneous saccharification and fermentation of sugarcane bagasse. RSC Advances , 6 (94), 91409–91419. https://doi.org/10.1039/C6RA17792A .

Velvizhi, G., Jacqueline, P. J., Shetti, N. P., Mohanakrishna, K. L., G., & Aminabhavi, T. M. (2023). Emerging trends and advances in valorization of lignocellulosic biomass to biofuels. Journal of Environmental Management , 345 , 118527. https://doi.org/10.1016/j.jenvman.2023.118527 .

Verardi, A., Lopresto, C. G., Blasi, A., Chakraborty, S., & Calabrò, V. (2020). Bioconversion of lignocellulosic biomass to bioethanol and biobutanol. In Lignocellulosic Biomass to Liquid Biofuels (pp. 67–125). Elsevier. https://doi.org/10.1016/B978-0-12-815936-1.00003-4 .

Voloshin, R. A., Rodionova, M. V., Zharmukhamedov, S. K., Veziroglu, T. N., & Allakhverdiev, S. I. (2019). Review: Biofuel production from plant and algal biomass. Alternative Energy and Ecology (ISJAEE) , 7-9 , 12–31. https://doi.org/10.15518/isjaee.2019.07-09.012-031 .

Yang, C., Wang, S., Yang, J., Xu, D., Li, Y., Li, J., & Zhang, Y. (2020). Hydrothermal liquefaction and gasification of biomass and model compounds: A review. Green Chemistry , 22 (23), 8210–8232. https://doi.org/10.1039/D0GC02802A .

Zhang, S., Yan, Y., Li, T., & Ren, Z. (2005). Upgrading of liquid fuel from the pyrolysis of biomass. Bioresource Technology , 96 (5), 545–550. https://doi.org/10.1016/j.biortech.2004.06.015 .

Zhang, S., Wang, J., Zhu, S., Liu, X., Xiong, Y., & Zhang, H. (2020). Effects of MgCl2 and mg(NO3)2 loading on catalytic pyrolysis of sawdust for bio-oil and MgO-impregnated biochar production. Journal of Analytical and Applied Pyrolysis , 152 , 104962. https://doi.org/10.1016/j.jaap.2020.104962 .

Zheng, T., Jiang, J., & Yao, J. (2021). Surfactant-promoted hydrolysis of lignocellulose for ethanol production. Fuel Processing Technology , 213 , 106660. https://doi.org/10.1016/j.fuproc.2020.106660 .

Zhou, Z., Liu, D., & Zhao, X. (2021). Conversion of lignocellulose to biofuels and chemicals via sugar platform: An updated review on chemistry and mechanisms of acid hydrolysis of lignocellulose. Renewable and Sustainable Energy Reviews , 146 , 111169. https://doi.org/10.1016/j.rser.2021.111169 .

Zhu, J. Q., Zong, Q. J., Li, W. C., Chai, M. Z., Xu, T., Liu, H., Fan, H., Li, B. Z., & Yuan, Y. J. (2020). Temperature profiled simultaneous saccharification and co-fermentation of corn stover increases ethanol production at high solid loading. Energy Conversion and Management , 205 , 112344. https://doi.org/10.1016/j.enconman.2019.112344 .

Zhuang, X., Liu, J., Wang, C., Zhang, Q., & Ma, L. (2022). A review on the stepwise processes of hydrothermal liquefaction (HTL): Recovery of nitrogen sources and upgrading of biocrude. Fuel , 313 , 122671. https://doi.org/10.1016/j.fuel.2021.122671 .

Zinatloo-Ajabshir, S., & Salavati-Niasari, M. (2016). Facile route to synthesize zirconium dioxide (ZrO2) nanostructures: Structural, optical and photocatalytic studies. Journal of Molecular Liquids , 216 , 545–551. https://doi.org/10.1016/j.molliq.2016.01.062 .

Zinatloo-Ajabshir, S., Morassaei, M. S., Amiri, O., & Salavati-Niasari, M. (2020). Green synthesis of dysprosium stannate nanoparticles using Ficus carica extract as photocatalyst for the degradation of organic pollutants under visible irradiation. Ceramics International , 46 (5), 6095–6107. https://doi.org/10.1016/j.ceramint.2019.11.072 .

Ziolkowska, J. R. (2018). Introduction to Biofuels and Potentials of Nanotechnology (pp. 1–15). https://doi.org/10.1007/978-3-319-75052-1_1 .

Download references

Acknowledgements

The research funding from the Ministry of Science and Higher Education of the Russian Federation (Ural Federal University Program of Development within the Priority-2030 Program) is gratefully acknowledged.

The study received no external funding.

Author information

Authors and affiliations.

Institute of Chemical Engineering, Ural Federal University Named after the First President of Russia B. N. Yeltsin, Yekaterinburg, Russia

Richard Vincent Asase, Queency N. Okechukwu & Maria N. Ivantsova

You can also search for this author in PubMed Google Scholar

Contributions

Writing-original draft RVA; Writing- reviewing and editing, QNO; Conceptualization and supervision, MNI.

Corresponding author

Correspondence to Richard Vincent Asase .

Ethics declarations

Competing interests.

No competing interest.

Ethical approval

Additional information, publisher’s note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Asase, R.V., Okechukwu, Q.N. & Ivantsova, M.N. Biofuels: present and future. Environ Dev Sustain (2024). https://doi.org/10.1007/s10668-024-04992-w

Download citation

Received : 10 October 2022

Accepted : 29 April 2024

Published : 08 May 2024

DOI : https://doi.org/10.1007/s10668-024-04992-w

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Renewable energy

- Technological innovations

- Socioeconomic impacts

- Environmental impacts

- Find a journal

- Publish with us

- Track your research

Loading metrics

Open Access

Essays articulate a specific perspective on a topic of broad interest to scientists.

See all article types »

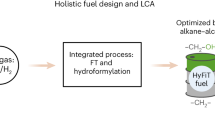

The potential of biofuels from first to fourth generation

Contributed equally to this work with: Philipp Cavelius, Selina Engelhart-Straub

Roles Conceptualization, Data curation, Investigation, Validation, Visualization, Writing – original draft, Writing – review & editing

Affiliation Werner Siemens-Chair of Synthetic Biotechnology, TUM School of Natural Sciences, Technical University of Munich (TUM), Garching, Germany

Roles Conceptualization, Data curation, Funding acquisition, Project administration, Supervision, Writing – original draft, Writing – review & editing

Roles Conceptualization, Data curation, Supervision, Writing – review & editing

Affiliation Chair of Technical Chemistry II, TUM School of Natural Sciences, Technical University of Munich (TUM), Garching, Germany

Roles Conceptualization, Data curation, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing

* E-mail: [email protected] (DA); [email protected] (TB)

- Philipp Cavelius,

- Selina Engelhart-Straub,

- Norbert Mehlmer,

- Johannes Lercher,

- Dania Awad,

- Thomas Brück

Published: March 30, 2023

- https://doi.org/10.1371/journal.pbio.3002063

- Reader Comments

The steady increase in human population and a rising standard of living heighten global demand for energy. Fossil fuels account for more than three-quarters of energy production, releasing enormous amounts of carbon dioxide (CO 2 ) that drive climate change effects as well as contributing to severe air pollution in many countries. Hence, drastic reduction of CO 2 emissions, especially from fossil fuels, is essential to tackle anthropogenic climate change. To reduce CO 2 emissions and to cope with the ever-growing demand for energy, it is essential to develop renewable energy sources, of which biofuels will form an important contribution. In this Essay, liquid biofuels from first to fourth generation are discussed in detail alongside their industrial development and policy implications, with a focus on the transport sector as a complementary solution to other environmentally friendly technologies, such as electric cars.

Citation: Cavelius P, Engelhart-Straub S, Mehlmer N, Lercher J, Awad D, Brück T (2023) The potential of biofuels from first to fourth generation. PLoS Biol 21(3): e3002063. https://doi.org/10.1371/journal.pbio.3002063

Copyright: © 2023 Cavelius et al. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Funding: This work was supported by the German Federal Ministry of Education and Research (BMBF) (031B0853A to NM). The funders had no role in study design, data collection and analysis, decision to publish, or preparation of the manuscript.

Competing interests: The authors have declared that no competing interests exist.

Abbreviations: EEA, European Environment Agency; EIC, European Innovation Council; GHG, greenhouse gas; GMO, genetically modified organism; ILUC, indirect land use change; IPCC, Intergovernmental Panel on Climate Change; IRENA, International Renewable Energy Agency; RED, Renewable Energy Directive

Introduction

For decades, global energy demand is on the rise due to economic growth and a rapidly growing world population. Additionally, the standard of living is increasing worldwide, in most cases correlating with increased energy consumption, as energy is needed in almost every aspect of our lives, including land, water, and air transport as well as in agriculture, commercial, industrial, and domestic sectors [ 1 ]. To date, fossil fuels account for around 80% of the world’s energy demand [ 2 ], despite being a major instigator for global warming, representing roughly 89% of total greenhouse gas (GHG) emissions in 2020 [ 3 ]. Additionally, fossil fuels are predicted to deplete with the steadily increasing energy demands. As petroleum demand is constantly on the rise, estimations predict a shortage by 2070 to 2080 [ 4 ]. To that end, distinct biofuel types such as liquid and biogas should be methodologically and strategically developed as a preventive measure against predicted energy shortages, all while reducing the anthropogenic climate impact and preserving the environment.

Currently, biofuels are categorized as first to fourth generation, depending on feedstock and/or biosynthetic platform (i.e., genetic engineering). In this Essay, we present comparative advantages and disadvantages among these categories, as well as fossil sources. Furthermore, the development of biofuel technologies hinges on the socioeconomic and political landscape, which can greatly benefit from policy recommendations by respective regulatory bodies. At present, the European Union has the most stringent biofuel legislation and the most ambitious climate impact goals. Hence, we focus on EU-centered development with respect to current biofuel technology platforms at various stages of industrial deployment, the legislative framework implemented in the EU, as well as policy recommendations that would accelerate academic breakthroughs toward industrial implementation. Although, our recommendations are EU-centric, many are also applicable on a global level.

The four generations of biofuels

One alternative to fossil fuels are biofuels, which originate from organic matter and therefore can be regrown and are termed renewable. Biofuels emit less GHGs and are in general more eco-friendly (non-toxic, sulfur-free, biodegradable) than their fossil fuel predecessors [ 5 ]. Biofuels contribute to the achievement of Sustainable Development Goals 7 (affordable and clean energy) and 13 (climate action) of the United Nations [ 6 ]. Global demand for biofuels is set to grow by 41 to 53 billion liters, or 28%, over 2021 to 2026 [ 7 ]. Typically, one can find four main types of biofuel discussed in the context of fermentation: biogas, bioethanol, biobutanol, and biodiesel. The physiochemical properties of these biofuels are compared to fossil-based fuels in Table 1 .

- PPT PowerPoint slide

- PNG larger image

- TIFF original image

https://doi.org/10.1371/journal.pbio.3002063.t001

Biogas formation is a fairly simple process that has been utilized for several decades. It includes four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Mixed microorganisms consortia and waste streams are combined in a sealed fermentation system in the absence of oxygen. During the biogas production process, microorganisms hydrolyze waste materials into sugars, peptides and amino acids, fatty acids, and to some part into acetate and hydrogen. Afterwards, acidogenic bacteria convert those intermediate products into organic acids, mainly constituting acetic acid. In addition, they produce carbon dioxide and hydrogen. In the third step, acetogenesis, acetate is formed from hydrogen and carbon dioxide produced in the previous stage. Lastly, methanogenesis follows, creating methane from the products of acetogenesis and acidogenesis [ 8 ]. These gases can then be transformed into hydrogen and/or electricity, or can be stored as biomethane in existing geological reservoirs [ 9 ]. Since the Ukraine crisis began, the resulting lack of fossil fuel availability in the EU has led to biogas being politically pushed as a substitute to natural gas [ 10 ].

Compared to gas (biogas/hydrogen), liquid fuels offer higher energy density and simplified transport and storage. This renders them more compatible with current engine and turbine technologies [ 11 ]. Most engines and turbines are designed and built for the use of liquid fuels, which makes liquid biofuels an easy drop-in solution without the need for modifying present engine technologies or infrastructure [ 5 , 12 ]. These gaseous fuels pose a significant safety hazard as they ignite at lower energies and are flammable over a range of concentrations, hydrogen to higher extent, requiring high level of safety procedures [ 13 ]. The low boiling point and high octane number of bioethanol allow blending with gasoline to a certain extent. The added benefits include a more complete combustion and reduced tailpipe emissions, boosting the engine performance and reducing CO 2 emissions. It is, however, inapt for blending with diesel. Diesel engines require hydrocarbons of higher chain length and low autoignition temperature. However, biodiesel, being of similar chemical constitution, can be blended with fossil-based diesel and hence constitutes a major energy-dense liquid biofuel. A third increasingly attractive biofuel is biobutanol, which holds high promise as it displays superior properties to bioethanol such as higher energy density (25% more energy than ethanol) and usually lower water content due to increased hydrophobicity. Biobutanol is less volatile and possesses less corrosive properties, making it easier and safer to use and store [ 11 , 14 – 19 ]. More importantly, it can be blended with both gasoline, fossil-based or biodiesel at any ratio without the need of new engine technologies and might even allow complete substitution of gasoline, while the use of ethanol is only possible as additive [ 11 , 18 ].

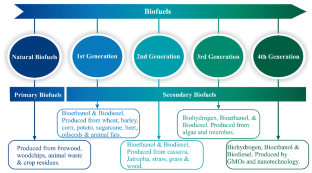

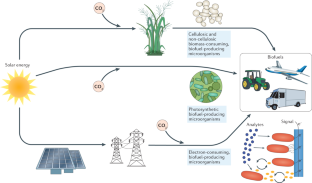

While the classification of biofuel technologies somewhat varies in the literature, products can generally be classed as first to fourth generation, depending on the type of feedstock and conversion process that was applied ( Fig 1 ) [ 5 ].

https://doi.org/10.1371/journal.pbio.3002063.g001

First-generation biofuels

Biofuels of the first generation are mainly divided into bioethanol and biodiesel. Bioethanol production of the first generation is based on microbial fermentation of edible feedstocks, rich in starch and sucrose, such as wheat, corn, and sugarcane in Europe, North America, and South America, respectively. Commercial strains include but are not limited to Saccharomyces cerevisiae , S . stipites , and S . pombe . Bioethanol production is not limited to first-generation biofuels; depending on the feedstock and production strain, bioethanol can also be categorized as second and third generation [ 32 – 35 ]. Biodiesel is mainly obtained from food-grade rapeseed, soy, or palm oil sourced from Europe, South America, and Asia, respectively. In contrast to bioethanol, it is only partially biosynthesized as its production includes chemically catalyzed steps such as transesterification of the lipids with alcohols. Enzymatic catalysis currently only exists on a lab scale [ 36 , 37 ]. Although biobutanol production is also possible by sugar fermentation from sugar cane, corn, wheat, and other food crops, it is limited by lower productivity and yields, product inhibition, and high costs [ 11 , 16 , 18 , 38 ].

During the global food demand crisis in 2007/2008, crops used for biofuel became more important to be used as food, giving rise to the “food versus fuel” debate that persists to date. Additionally, an increased demand for crops (e.g., corn) for fuel production yielded an increased market price for those foods [ 5 ]. Models predict that massive agricultural areas would be needed for fuel production and still could supply only limited amounts of fuel compared to the overall demand. It is estimated that more than two times the globally available area of arable land would needed to meet the global market demand for biodiesel when produced from rapeseed oil [ 39 ]. Furthermore, increased market values of palm oil and other biofuel cultures prompted extended deforestation of tropical rainforests for biofuel crop plantations, which releases more CO 2 than the emission saved by those biofuels. In 2008, Fargione and colleagues estimated that it would take 319 years to repay the biofuel carbon debt resulting from clearing of tropical rainforest in Brazil and subsequent conversion to soybean plantations [ 40 ].

Second-generation biofuels

As a result of the issues of the first generation, second-generation biofuels were developed, utilizing lignocellulosic biomass from agricultural and woodland residues as well as other waste streams (for example, from food industry like wheat bran, animal fats, or wastes of cooking and frying oil). Other non-food plants like the drought-resistant shrub or tree Jatropha curcas , which can also be grown in wastelands, might yet be a different promising source for second-generation biofuels [ 41 ]. Hence, second-generation biofuels circumvent the need for agricultural land use change and do not compete with food resources. However, often second-generation waste streams represent more complex feedstocks than sugarcane or palm oil, potentially containing compounds able to reduce fermentation efficiency, such as lignin. Therefore, application of additional pretreatment steps are common, increasing process time and costs [ 5 , 42 , 43 ].

For the most part, biofuels of the first and in the vast majority of the second generation are commercially produced, around 4% and 96% in 2019, respectively [ 44 ]. One example is the commercially available sunliquid from Clariant, which is a cellulosic ethanol from currently underutilized agricultural residues, such as straw. The first commercial ethanol plant in Romania started production in 2022, with plans to convert 250,000 tons of locally sourced agricultural residues to 50,000 tons of ethanol per year. After enzyme production, which hydrolyses cellulose and hemicellulose to sugar monomers, optimized microorganisms are used in fermentation to produce ethanol. These microorganisms can utilize various carbon sources like glucose and xylose, ensuring higher yields and enabling high efficiency and flexibility in waste valorization as more building blocks of waste streams can be converted to product [ 45 ]. Alongside ethanol producers, the production of second-generation biodiesel is possible from microbial lipids produced by organisms, such as Cutaneotrichosporon oleaginosus , a yeast capable of producing up to 90% (w/w) lipids per biomass in a fermentation process, which can be grown on residue streams (e.g., wheat bran hydrolysate medium) [ 46 – 49 ]. Second-generation biodiesel can also be sourced from waste oils via catalytic cracking and hydrogenation. Drawbacks of this process include incomplete conversion and coke formation, which leads to the deactivation of the catalyst. [ 50 , 51 ]. Biobutanol production on lignocellulose biomass and other waste streams is most commonly based on Clostridia fermentation, as it is one of the oldest and best-established fermentative processes for butanol production. Many Clostridia are natural butanol producers and possess the ability to metabolize a variety of different substrates. However, similar to its first-generation predecessor, the process is limited by low butanol titers and product inhibition [ 11 , 16 , 18 , 38 ]. Typically, butanol is produced via ABE fermentation, which results in solvents in ratio of 3 parts acetone, 6 parts butanol, and 1 part ethanol, and butanol refinement is not an energetically favorable solution. Other drawbacks also include cell toxicity at low concentration [ 52 , 53 ]. To that end, cell-free isobutanol biosynthesis using a designed artificial metabolic pathway has been developed [ 54 ]. At present, this approach remains costly for commercialization.

Various carbonaceous compounds can be transformed to syngas by gasification. Commonly, it is a gaseous waste stream from industrial processes such as steel manufacture, in which fossil fuels are burned in the process. Syngas is a mixture mainly consisting of carbon monoxide (CO), CO 2 , and hydrogen. It can be derived from biomass, including lignocellulosic compounds, coal, animal or municipal solid waste, and industrial CO-rich gases. This gas can be metabolized by strictly anaerobic, methanogenic archaea as well as by acetogenic bacterial genera such as Acetobacterium or Clostridium , often used in syntrophic fermentations. The process is mostly focused on biosynthesis of organic acids and alcohol compounds such as acetate, ethanol, and butanol [ 55 – 57 ]. Advantages of syngas fermentation compared to other second-generation approaches are high feedstock flexibility as well as high rates of energy and carbon capture. Complicated pretreatments of second-generation feedstocks can be replaced with gasification, using all components of the biomass, including lignin and other recalcitrant compounds [ 58 ]. LanzaTech developed a process converting feedstocks including industrial waste streams to fuel and chemicals utilizing bacteria. They estimate a total product capacity of 600,000 metric tons as well as 1,000,000 metric tons of captured carbon per year, for all their plants combined [ 59 ]. Since 2022, a demonstration plant in Japan has turned municipal solid waste to ethanol, with a production target of 20 tons of ethanol per day [ 60 ].

More than half of the biologically stored carbon is bound in marine biomass, especially macroalgae and seagrass. Detached seagrass material is seasonally washed on beaches and shore lines; due to low biological degradation and herbivore consumption, an excess of it accumulates as waste. Estimations of up to 40 million tons of dry seagrass biomass, which can be used for biofuel production, are given. Through enzymatic hydrolysis, the carbohydrate content of the seagrass can be used in a fermentation medium for microorganisms, additionally offering low nitrogen and phosphorus content, which is typically required for lipid production [ 61 ].

Despite the highly favorable ability to valorize waste streams, second-generation biofuels by themselves will not be sufficient to supply energy for the current worldwide demand. As is the case for food crops with first-generation biofuels, biomass used in these processes is available in limited amounts. Therefore, second-generation biofuels must be combined with other technologies to ensure sufficient provision of fuels. This prompted research on third-generation biofuels. However, scientific estimations predict second-generation biofuels could supply up to 30% of the world’s transportation energy [ 5 ].

Third-generation biofuels

Third-generation biofuels are mainly derived from microalgae and cyanobacteria biomass, which can be used to naturally generate alcohols and lipids to transform into biodiesel or any other high energy fuel product. Algae exhibit 2- to 4-fold higher photosynthesis rates than terrestrial plants, resulting in faster biomass formation [ 62 ]. Algae do not require arable land or fresh water for cultivation. Many cultures can be grown using waste water, brackish or salt water, which is cost efficient and circumvents competition with agricultural activity [ 63 , 64 ]. Most importantly, efficient algae cultivation requires a direct CO 2 supply, which can be derived from industrial emitters or by atmospheric carbon capture. In conventional cultivation systems, around 70% of supplied CO 2 is used for photosynthesis and therefore biomass production [ 65 ]. Hence, algae biofuels potentially could have a negative carbon footprint as they directly bind the GHG in their biomass. One of the most prominent third-generation processes is the production of biodiesel or other energy density biofuels, such as biokerosene, using oleaginous microalgae [ 66 , 67 ].

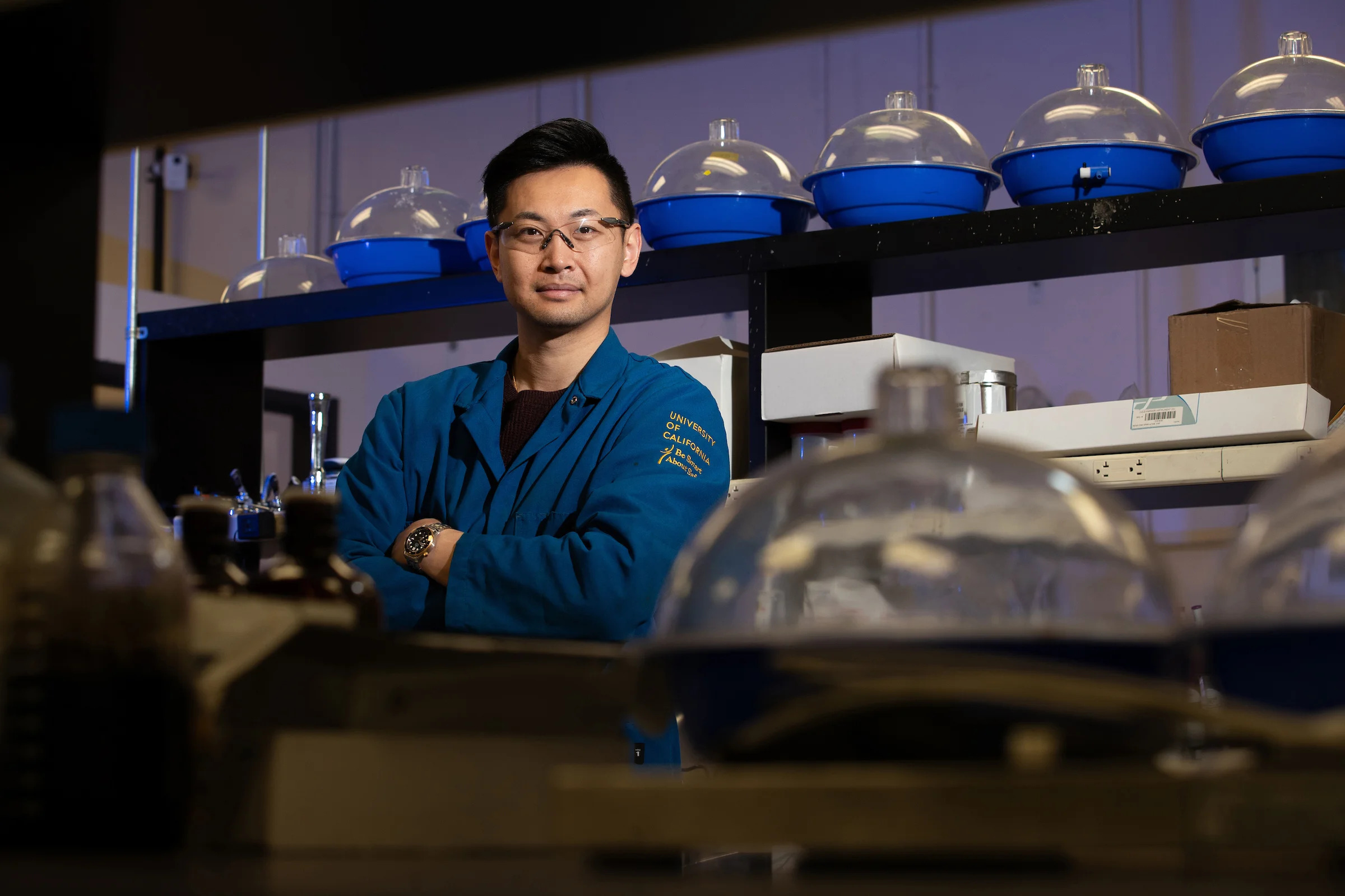

One of the most economically critical and versatile operations in algal biofuel production is algae cultivation. Algal bioreactors ( Fig 2 ) are independent of location and climate, therefore can be operated almost irrespective of these factors. For low price, high volume products, such as biofuels, algae are commonly cultivated in open ponds. Open pond reactors are significantly cheaper in their construction and operation but have drawbacks like high loss of water through evaporation and lack of temperature control, which lowers biomass productivity. The alternative, preferred for high price, low volume products, such as cosmetic ingredients, is a closed photobioreactor, where process parameters can be precisely controlled, which often leads to higher productivity [ 63 , 68 ]. These bioreactors also enable a three-dimensional mode of cultivation, significantly increasing the productivity per area. In contrast to second-generation biofuels, the third-generation processes completely decouple biofuel production from the need for agricultural land. Additionally, algal-based oil production is likely greater than that in higher plants, as lipids mainly accumulate in specific parts of the plant (e.g., in rape seeds), while in algae, each cell can contain high amount of lipids, making the process more mass efficient. One bottleneck in production is harvesting, as the low size and density of the microalgal cells combined with the sensitivity of the cells to changes in pH render it challenging. [ 66 ]. Furthermore, downstream processing for algal biofuels is commonly more energy intensive than other biofuel productions [ 63 , 69 ]. Araújo and colleagues mapped 447 algae and cyanobacteria Spirulina production units in 2021 in the EU [ 70 ]. Most of these companies directed their biomass to the production of food, feed, and related uses; commercial application of biofuels only had a very small share. Further technological developments in upscaling and reduction of production costs are necessary for commercialization.

This image showcases the open algae cultivation systems located at Technical University of Munich, Ottobrunn.

https://doi.org/10.1371/journal.pbio.3002063.g002

Fourth-generation biofuels

The latest biofuel generation, termed fourth-generation biofuels, encompasses the use of genetic engineering to increase desired traits of organisms used in biofuel production. This applies to a variety of traits from utilizing multiple types of sugars (e.g., pentoses and hexoses), to higher lipid synthesis or increased photosynthesis and carbon fixation. For model organisms, such as Escherichia coli and Saccharomyces cerevisiae , a wide variety of tools for genetically engineering the regulation of endogenous pathways or inserting new pathways are reported. Unfortunately, for most native producers of biofuels, the genetic engineering toolbox is far more limited.

Currently, two different approaches have been adopted: engineering of pathways in native producers (optimizing growth rates, utilization of different carbon sources, directing the metabolic flux toward biofuel production and increased production titers) and reconstruction of pathways identified in natural producers in more genetically accessible model organisms. A wide variety of microorganisms can be used as heterologous hosts for the production of biofuels, including bacteria, yeast, and algae. Their metabolic versatility enables the use of various substrates to produce a wide range of biofuels. For example, butanol pathway genes from Clostridia were introduced into E . coli , Pseudomonas putida , and Bacillus subtilis strains [ 14 , 16 , 19 ]. While the introduction of heterologous genes is well established, a major challenge is the disruption of competing metabolic fluxes. Another obstacle for high product titers can be toxicity of large amounts of product on the cell. To enable increased accumulation of biofuels, the cellular stress response can be modified through genetic engineering, for example, with cell membrane modifications. Through the overexpression of certain membrane transporters, biofuel molecules can be secreted into the medium thereby circumventing accumulation as well as toxicity while simultaneously simplifying product recovery. In E . coli , membrane transporters have been used successfully to excrete n-alkanes, such as n-octane [ 71 , 72 ]. However, the overexpression of transporters is challenging as it modifies the membrane composition, creating a metabolic burden as well as potentially overloading the cellular import and export, thereby disabling the cells ability to regulate its internal environment/homeostasis [ 71 ].

Genetically modified algae can offer higher product yields and a variety of other improvements compared to wild-type algae. In order to enhance photosynthetic efficiency, the antennae systems of algae capable of absorbing a broader range of the light spectrum could be transferred to more suitable production organisms [ 44 , 73 ]. With respect to genetic engineering, CRIPSR/Cas9 is a frequently used tool, as it offers a simple design with efficient transfection and targeted gene disruption [ 74 ].

In fourth-generation biofuel processes that focus on genetically optimized cyanobacteria, the production of ethanol, as well as other fuel products such as butanol, isobutanol, and modified fatty acids have been realized successfully [ 75 , 76 ]. While 1-butanol production reached titers of 300 mg/L, bioethanol titers of up to 5.5 g/L were reported [ 77 – 79 ].

For the efficient optimization of native producers, systems biology can offer many insights. The availability of whole-genome sequences is essential, as this information allows for the annotation of genes to their respective function and reconstruction of the innate metabolic pathways, which can subsequently be modified. Recent advances have been made in the field of genome sequencing allowing for a more rapid and cost-efficient collection of data [ 19 ], while the gene expression patterns in different growth environments can be analyzed by transcriptomics and protein products identified by proteomics.

With genetic engineering tools, the quantity and quality of biofuels can be controlled and increased but will need political acceptance and support to be widely adopted [ 5 ]. There is a controversial debate around genetic engineering in agriculture and medicine, especially in Europe; therefore, similar concerns can be anticipated surrounding the use in biofuel production. A European-based study came to the conclusion that genetically engineered algae for biofuel production would be accepted by the majority of consumers, when the safety of the systems can be guaranteed [ 80 ]. However, with proper containment methods and carefully selected locations, such risks could be drastically minimized. Therefore, closed production systems with high security standards are expected to be built [ 80 ]. Additional biocontainment methods can be directly based on genetic changes inside the production cells such as auxotrophies or kill switches, significantly decreasing the risk of genetically modified organism (GMO) escape [ 44 , 81 ].

One alternative to targeted genetic engineering is random mutagenesis, which can be described as accelerated evolution. Microorganisms and products generated by this approach are not subjected to GMO regulations. Furthermore, this technique can be performed with little knowledge about the production organism and production pathway. Random mutagenesis can be achieved by a variety of methods such as UV light, chemical agents, or fast neutron irradiation. For the first time, the latter was applied on C . oleaginosus , resulting in mutants with elevated lipid titers suitable for biodiesel applications. It is noteworthy that biodiesel from prominent oleaginous yeast platforms, such as Yarrowia lipolytica , C . oleaginosus , Rhodosporidium toruloides , and Lipomyces starkeyi , are compliant with international biodiesel standards, including US ASTM D6751 and EU standard EN 14214 [ 82 , 83 ].

A new, more experimental approach to fourth-generation biofuels is the production of electrobiofuels. These are based on the approach to establish new-to-nature hybrid systems, which are able to use renewable electricity and carbon sources directly for the production of commodity chemicals and biofuels, thereby enabling the conversion of solar energy into storable liquid fuel. Such a process could combine the higher photon efficiency of modern photovoltaic systems (compared to photosynthesis) with the sustainability of biofuel production, increasing overall process effectiveness [ 84 ].

Economics of biofuels in transportation

Apart from reducing GHG emissions and air pollution, biofuel industries can contribute to energy security on a local and national scale, as it is not reliant on local reservoirs of fossil oil. Additionally, the creation of new employment and economic growth, especially in rural locations, should positively impact the social environment as well. However, to fully exploit all the positive traits of biofuels, further research and investments are necessary, as the production of biofuels requires more processing steps compared with the conventional methods of drilling into the ground to obtain crude oil, followed by refining. Therefore, at present, biofuels commonly exceed fossil fuel production costs. Furthermore, raw materials for biofuel production do not compare to crude oil in energy density, requiring far greater amounts of biomass for the same energy output compared to fossil sources. The infrastructure required for the sector of biofuel production has to be extensively developed as well. One example is the primary energy needed to run the process, which should be obtained through sustainable operations. Candidates for that include solar and wind energy among others. Thus, by reducing the overall production cost and increasing process efficiency, biofuels could become more competitive to fossil fuels. Furthermore, by-products of biofuel production should be efficiently utilized in a circular economy, which could increase cost efficiency of such processes.

Transportation is one of the most socioeconomically sensitive sectors for the use of liquid biofuels ( Fig 3 ). It contributes about 17% of global CO 2 emissions [ 85 , 86 ], and so far, sustainable solutions are not fully developed. Due to their limitations, current technologies for biofuels are not likely to completely replace fossil fuels in their entirety but can offer new routes for waste stream valorization in a circular economy and contribute significantly to minimize our dependency on fossil fuels one step at a time. A complementary approach to this goal is electric cars, which have zero tailpipe emissions, although CO 2 emissions are associated with the production of the car and the source of the electricity. Essential in electric vehicle batteries are metals like lithium, cobalt, nickel, and manganese. The demand for these metals is surging, while at the same time toxic waste electronics are accumulating all over the world. Traditional recycling/extraction methods require high temperatures and strong acids. This is a high energy process involving toxic chemicals. One alternative is bioleaching or biomining, which employs microbes such as Acidithiobacillus ferrooxidans that can bind and recover metals, bypassing the need for high temperatures and toxic chemicals [ 87 – 90 ]. This emerging technology offers an eco-friendly approach to recycling but still requires extensive research and development. Additionally, a new infrastructure must be put into place, supporting millions of electric cars at the same time. To that point, a combination of synthetic and biofuels in synergy with electric cars might be an optimal solution for the years to come, partially substituting fossil fuels, thereby drastically reducing CO 2 output of transportation.

The transport sector, specifically, results in 17% of emissions. Adapted from Ritchie and colleagues (2020), Carbon Leadership Forum 2020 [ 85 , 86 ].

https://doi.org/10.1371/journal.pbio.3002063.g003

EU policy recommendations

In order to promote the use of clean and sustainable energy at the industrial, retail, and consumer level, a cohesive framework of policies is imperative. The European Commission and European Environment Agency (EEA) have cooperated with the International Renewable Energy Agency (IRENA) and the Intergovernmental Panel on Climate Change (IPCC) in leading the efforts for clean energy transition through a number of directives and legislations since the 1990s [ 91 – 94 ]. These efforts manifest as a commitment by EU countries to lower GHG emissions and increase the use of renewable energy. Most notable is the Renewable Energy Directive (RED), which came into force in 2009. Through this directive, EU countries set targets for renewable energy consumption, including a subtarget mandating 10% of energy used in transport to be produced from renewables. It is noteworthy that the deployment of renewable energy has continuously grown, exceeding 22% in 2020 [ 92 ]. The legislation also mandates GHG reduction targets for fuel suppliers, requiring a reduction in GHG intensity of the fuel mix by 6% in 2020 [ 92 ]. In 2018, the commission revised the legislative proposal and the European Parliament and the EU Council proposed amendments as RED II. Therewith, the EU aims to increase the share of renewable energy to 32% and in transport to at least 14%, including a minimum share of 3.5% of advanced biofuels (second- and third-generation biofuels). The latter streamlines waste residues, such as agricultural waste (e.g., straw), and also encompasses renewable electricity in road and rail transport [ 95 ].