Supply Chain Management 101: Principles, Examples, and Templates

By Andy Marker | June 25, 2017 (updated February 22, 2022)

- Share on Facebook

- Share on LinkedIn

Link copied

Globalization has become an undeniable part of commerce over the last few decades, as large companies have grown first to source labor and parts from developing regions, and then to start selling in those same areas as they grew in wealth and buying power. Supply chains have had to keep in step, passing through numerous countries to obtain goods most efficiently and cost effectively, and growing more complex as a result. And on the other end, the supply chain grows more frayed in order to deliver to countless countries for consumption. For the largest companies, managing a supply chain can require dedicated teams in every area the chain touches. It’s safe to say that supply chain management is both an art and a science. This article will cover what a supply chain is, with examples; discuss how supply chain management works and its principles; and vital concepts in the field. Then we’ll move on to current issues and where the field is going. Finally, you’ll find useful resources, templates, and education programs. Ready? Let’s get started.

What Is a Supply Chain?

A supply chain is a collection of suppliers required to create one specific product for a company. The chain is made up of nodes or “links,” which can include multiple manufacturers for parts, then the completed product, then the warehouse where it is stored, then its distribution centers, and finally, the store where a consumer can purchase it. The concept of the chain is important, because each link is connected in a specific direction and order, and the next link cannot be reached without going through the previous one. Each link adds time and costs, and can involve labor, parts, and transportation. Every product a company carries may have its own supply chain, though they may use certain suppliers for multiple products. You can see why this gets so complicated, especially for international supply chains.

The process described above was that of a typical retail supply chain. However, there are many different types in practice. Here are three examples from well-known masters of supply chains: Example: Walmart and “Big Box” Retailers The “Big Box” store, which represents one of the major disruptions of the retail model from the last century, thrives on size, ubiquity, and well-planned supply chains to drive out the competition. How else would a company like Walmart make a profit on a t-shirt made overseas that retails for $5.00? Walmart succeeds by having fewer links in its supply chain, and buying more generic goods directly from manufacturers, rather than from suppliers with brand names and markup. It uses “Vendor Managed Inventory” to mandate that manufacturers are responsible for managing products in warehouses owned by Walmart. The company is also is particularly choosy with suppliers, partnering only with those who can meet the quantity and frequency it demands with low prices, and with locations that limit transportation needs. They manage their supply chain like one firm, with all partners operating on the same communication network. By buying at large enough quantities to take advantage of economies of scale, moving products directly from manufacturers to warehouses, and then delivering to stores which are large enough to be distribution centers, it reduces links in the supply chain and cost per item, translating to low prices for consumers.

Example: Amazon and “Ecommerce Platforms” Having overtaken Walmart as the world’s largest retailer in the last decade, Amazon’s “online big box” concept is a perfect example of unique supply chains. As an e-commerce shop, obviously they cut the retail store out and ship from distribution center to consumer’s homes directly. Where Amazon innovates is both in its supplier-side and its final supply chain link - delivery. Just about anyone can sell things on Amazon because it’s a platform, not just a shop. As a result, Amazon has more things than any other online store, so when people shop online, they think of Amazon. Then, it produces everyday goods cheaply, and underbids suppliers. Next, their warehouses make serious use of automation to store items going to like destinations together, ready for immediate transport. Finally, its investments in delivery staff and technology make 2-day shipping a basic expectation, and even same-day delivery a possibility. Amazon ditches third-party logistics (3PL) and fulfills orders itself.

Example: Tesla and Specialized, Owned Chains Automotive manufacturing has come a long way since Henry Ford used assembly line manufacturing to speed up the production of a single car model in a single color. Now, in a time when even American carmakers are opening factories abroad, Tesla is making innovative, incredibly popular, and luxurious cars right in California, a location with incredibly costly real estate. Rather than having a long supply chain of cheap part makers, they have a vertically integrated supply chain, with a full-service auto plant near its corporate headquarters and plans for a supplier park and a massive battery factory, and Tesla owns it all. Even more interesting is the digital supply chain the company promotes - new firmware and algorithm updates are pushed out to existing car owners over the cloud.

What Is Supply Chain Management?

As the name implies, supply chain management (SCM) is handling and optimizing all the many complicated facets of a supply chain, involving goods and services. Even ensuring timely handoff from manufacturer to shipper to supplier to shipper to buyer is a massive task, but to do it cost effectively and build net value is truly a challenge. Supply chain management is so important because modern commerce exists in a networked global economy. Most businesses are specialized - even department and big box stores are only really equipped to sell to customers, despite their wide variety of products. The value of vertical integration is hard to justify when communication costs and SCM tools are so inexpensive - it almost always makes more sense to outsource for price efficiency.

The concept of supply chain management was in effect long before the term was created in 1982. In the colonial era, international trade by ship was already making for complicated transportation issues and the need for efficiency. During the Industrial Revolution, the ability to quickly produce goods with machine assistance led to the need to manage significant inventory and constant consumption. By the time history arrives at Henry Ford’s famous assembly line for the world’s first car production in 1913, supply chain management had become an art. As the century wore on, more companies were producing more goods and looking for ways to reduce costs. They vertically integrated into owned supply chains to try reducing costs at each stage. In the 1980s and on, globalization became a realistic dream for many companies, because of computer systems, easier communication, and commerce-friendly trade laws. Around the 1990s, it became a common practice for firms to specialize, and focus on core competencies and outsourcing the rest, abandoning the vertical integration of the previous era. At this point, supply chains became truly complex, in order to coordinate hundreds of otherwise unrelated and geographically-distant manufacturers, suppliers, shippers, warehousers, and retailers. Now, in the “SCM 2.0” era, the Internet and new methodologies have led to collaborative platforms and democratized processes. This is allowing smaller competitors to use some of the same manufacturers as major players, and reducing inefficiencies for those manufacturers as a result. Better communication and planning tools are providing a way for small and large companies alike to manage even more complex supply chains.

Variants of SCM

Global SCM: The combination of global manufacturing with supply chain management, which must account for tariffs and local taxes as goods and services travel internationally to ultimately provide greater value at the end of the chain. SAP SCM: Systems, Applications, and Products (SAP) is a software company that revolutionized logistics and enterprise resource planning. It provides an automated way to manage supply chain networking, supply chain planning, and supply chain execution, along with production planning, business forecasting, and demand planning. Logistics and SCM: The art of coordinating efforts between every member of the supply chain to get products from their source to the consumer. Purchasing and SCM: The focus on the monetary aspect of SCM, from costs to value added at each link in the supply chain.

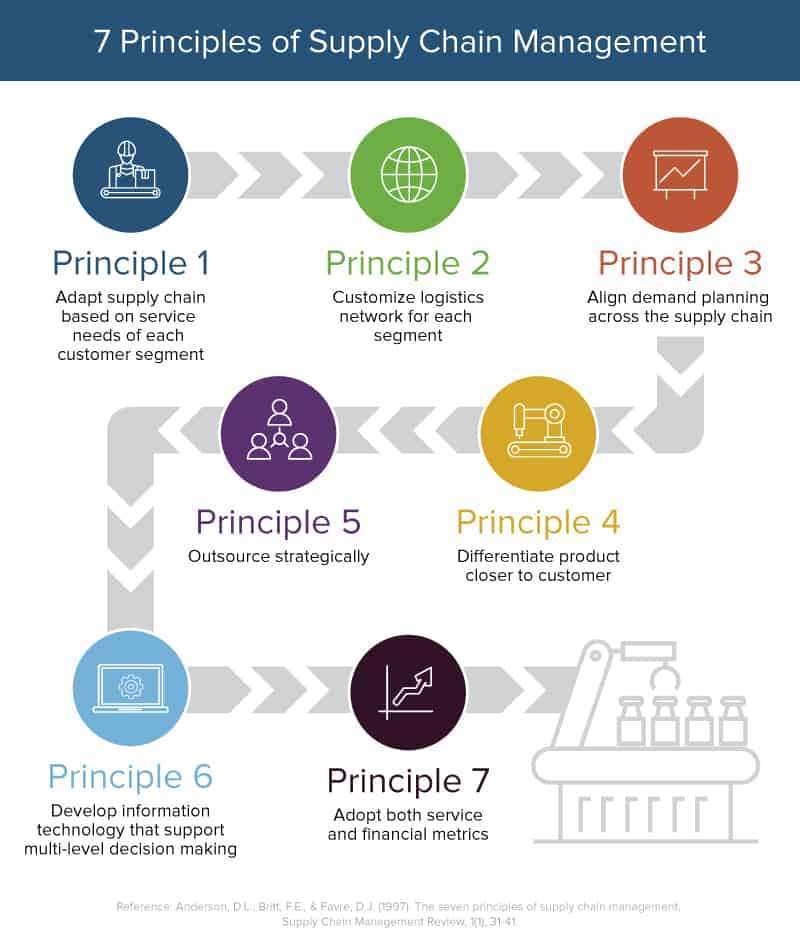

Principles of Good Supply Chain Strategy

Download Supply Chain Management Checklist

The Basics of Supply Chain Management Processes

There are key supply chain processes that you must take into consideration to effectively understand and manage them. These processes are all at play regardless of the type of supply chain you’re using. Customer relationship management (CRM) comes first, because as the principles of SCM state, you must adapt everything in the supply chain to the customer. If no one is buying, there’s no need to produce anything. At the front of your supply chain, where a store’s staff interacts with its consumers, they must have plans in place for ongoing relationships. They need CRM tools to gather customer information for marketing and market research, all to determine the products and services to offer in the future. Customer service management is another process that ties in, as it is where you gather negative and positive feedback to determine future needs. Demand management is closely linked with the previous two, as it takes customer interactions and orders into account to determine the workload all the way up the supply chain. At its core, customers buying more means make more, and customers buying less means make less. Customer forecasting is an important task that analysts must perform well to determine the current demand and what it will be in the future, to prevent waste in the supply chain. Product development is an important part of the supply chain that is informed by consumer demand. You must work with CRM and customer service data to determine what they want, which influences new products, product line extensions, and also what to stop making. You must integrate suppliers in this process because it affects cost, quality, and delivery time. Supplier relationship management goes without saying - if you want to produce your products on time and on budget, you need a solid rapport with everyone you’re outsourcing to in the chain. This impacts manufacturing flow management , which ensures everything gets where it needs to go without delay, and at the correct spec. Order fulfilment involves coordinating with distribution centers and either retail locations or 3PL to get the product direct to consumers. You’ve now made it all the way back to the beginning of the cycle, and need to pay attention to new CRM and customer service data. Returns management , also known as the “reverse supply chain,” is a vital part of the flow of products that doesn’t fit perfectly into the clean supply chain cycle. It involves picking up online orders from 3PL locations or from consumers’ addresses and accepting returns at retail locations. Once these items are put back into inventory, they must be ready to get to a different customer while the product run is still live.

What Supply Chain Managers Look for When Managing Supplier Relationships

One of the most complex parts of SCM is handling all the other people in the supply chain. They have their own needs and motivations, and to keep them all happy and working together with partners they are only loosely affiliated with is a challenge - especially when trying to meet deadlines and turn a profit. The following are what managers should focus on most in such relationships: Org Chart and Leadership Style: How is the supplier’s organization set up? Is it a vertical or horizontal structure? Is the leadership strong and long lasting, or fickle and prone to change? You need to know who you’ll be interfacing with, and who will be the next one in line should some shakeup occur. Business relationships are always between people, and don’t always survive a reorg. Management Style: How do the leaders at this supplier run their shop? Make sure it works with your crew. A micromanager at a relatively replaceable link in your supply chain will waste inordinate time, just as a hands-off manager at a vital link could result in sloppy delivery or substandard product quality. Company Culture: Always important for working with suppliers, determine what kinds of people rise to the top, and how everyone acts when nobody's watching. If, for example, middle managers are constantly in fear for their jobs because of ruthless quarterly performance reviews, they may over-promise, make excuses, or otherwise be unstable work partners. Product Flows: Once you know that you can work with the people, make sure their facilities are in order. Are they equipped for orders of the size and frequency you plan to make? How do they handle emergency, fast-turn around orders? What about other customers - are they only able to use their facilities for your product flows at certain portions of the month due to full inventory? Leave no stone unturned. Information Flows: Just as vital is the ability to control information about the day-to-day flow of materials, and to communicate and coordinate long-term plans. Is the supplier up on their product details, inventory, and SKU organization? Is their security and encryption up to the standards of your company, and your industry? Big data is useless if the right people don’t see it in time. Rewards and Risks: Take into account opportunities and threats of working with this supplier. Maybe they’re well-equipped to handle your exact product because they also work with your competitors. Perhaps they are new and establishing themselves, so offer a substantial discount, but may not be able to deliver on time? Do what’s best for the company, and use risk assessment to keep your whole supply chain operable.

Vital Supply Chain Management Concepts to Know

Having a passing familiarity with the following terms will help you see just what kind of skillset and abilities will be required when working in supply chain management: Border Adjustment Tax: Also known as a destination-based cash flow tax (DBCFT), it is a tax levied on imported goods which is important to know in global supply chains. Customer Relationship Management: Also known as CRM, this concept refers to providing ongoing service to customers and collecting data about their likes and purchases. There are also CRM tools that help automate and record interactions with customers. Cumulative Mean: A figure for knowing how much or how little to produce in advance, involving mean orders with all previous data treated as equally useful. Demand Management: Understanding customer behavior and patterns to control how much is ordered and produced at each link in the supply chain, with the goal of eliminating wasted production. Financial Flows: Credit terms, payment schedules, accounts payable and receivable, and other factors that you must monitor to determine if a supply chain is profitable or not. Information Flows: Transmission of orders, delivery status, and other data that influence the supply chain’s responsiveness to demand. Integrated SCM: This is a method of SCM wherein all of the links are tightly integrated, operating almost as one company rather than a loose association of buyers and sellers. Inventory Management: Monitoring and controlling orders, storage, and use of owned components to create the products your company sells. Lean Six Sigma: A data-backed philosophy of continuous improvement that focuses on preventing defects and mistakes rather than discovering them later, which reduces waste and production time via standardization. Read Everything You Need to Know About Lean Six Sigma to learn more about this methodology. Logistics: The physical movement of products from one link in the supply chain to the next, and the practice of improving their efficiency. Make vs. Buy: A simple evaluation of whether it is more cost-effective and time-efficient to produce a required product with your company’s existing resources, or to outsource the need. New Product Development: The creation of new products both in response to and in anticipation of customer demand, using data gleaned from CRM and the whole supply chain. Read Innovation for Everyone: Everything You Need to Know About New Product Development to learn more about this process. Operational Accounting: Accounting for a company that focuses on planning, directing, and controlling of daily activities by their costs and eliminating waste. Physical Flows: The actual movement of parts and products throughout the supply chain, which the Logistics team must manage and analyze to keep going without pause. Project Management: The process and tools involved in ensuring that a codified piece of work (project or product) gets done on time while keeping all contributors aware of their next step. Reverse Supply Chain: Aftermarket customer service, which may involve accepting returns, refurbishing and discounting, or otherwise finding use for the reacquired inventory. Risk Management: Identifying, evaluating, and then choosing which risks to address first, with the goal of reducing overall risk in a supply chain. S&OP: Sales and Operations Planning is a management process that aligns its constituent parts to ensure that the organization is only focused on operations that improve sales. Learn more about S&OP here . Strategic Sourcing: Formalizing a company’s information gathering in order to use its purchasing power to take advantage of the best values in the marketplace of suppliers. Theory of Constraints: A methodology that identifies the largest limiting factor in production, then finding a way to remove it to improve the efficiency of the entire production.

Current Issues in SCM

In addition to the major terms, it’s important to keep aware of legal, political, and social events which affect supply chain management when seeking a career in the field. Here are some of the bigger issues of the day: Dodd-Frank Decision: This was a 2010 law which included a clause on “Conflict Minerals.” It requires companies to audit their supply chains in order to determine whether gold, tungsten, tantalum, and tin came from the Democratic Republic of the Congo, and report on their due diligence. It adds an extra layer of complexity and costs to SCM for those involved in chains with those minerals. NGO Actions: Activist groups of all kinds work to end common practices within major companies’ supply chains, such as sweatshop labor, or push consumers towards less complicated supply chains by encouraging them to support local businesses and farms. SEC Regulations: Whereas NGO actions can force a company’s hand for PR reasons or changing the marketplace of ideas, the Securities and Exchange Commission can slap that same company with fines, making company’s quick to comply. Third-party audits of supply chains are an important part of keeping in step with these regulations. SECH Ratings: This is a rating that involves economic, social, and environmental judgements to gauge a company’s overall sustainability. Transparency: Though protecting data is important, certain measures of transparency can improve company performance. Among consumer products, many younger, disruptive brands make their supply chain a selling point in marketing by being upfront about how and where they get their components, and where they make their products. The reasoning goes, if a company is hiding something, there must be an unethical component to it. Sustainability Measures: As major companies and countries around the globe move towards sustainable production, all supply chains become impacted. Whether due to changing regulations or seeking good PR, many companies are working to reduce pollution and other issues in their chain.

The Future of Supply Chain Management

Aside from the issues of the day, it’s also vital to see where the field is going. The future of SCM is bright, but certainly evolving. We asked a group of experts and innovators in supply chain management to discuss what they believe the future of SCM holds:

Jake Rheude , Director of Business Development and Marketing for Red Stag Fulfilment

Over the next decade, we will see massive and disruptive forms of innovation both in terms of technology that expedites the speed at which customers receive their products ( drone delivery ) as well as technologies that drastically enhances the online shopping experience for customers, ( virtual reality ).

While these and other technologies no doubt have the opportunity to significantly change the landscape of online shopping and the supply chain, I expect we will see firms diverge on two different strategies. Some will rush to implement these costly new technologies in order to drive down the total time between an order being placed and last mile delivery, while other firms will stand by the current landscape (for most B2C online sellers) of product delivery in approximately two-days, acting cautiously, particularly in regards to the cost of these new technologies versus their impact on the overall value chain for consumers.

Certainly, there are niche industries where significant investments in drone delivery technology will provide a distinct competitive advantage, but I predict that for many B2C online sellers, the impact on the overall value chain of these new technologies will be misaligned with a consumer's perception of value, and therefore make the initial cost of these new technologies unjustified.

Lauren Stafford , Digital Publishing Specialist for Explore WMS

Embracing big data is an essential principle of modern SCM, specifically real-time data which has the potential to improve the efficiency of a supply chain and negate potential risks to strategy. We know that logistics optimization through technological innovations and data integration can make supply chains more efficient and more financially sound.

The future of the multi-modal SCM depends on successful integration with data and systems to achieve synchromodality. To achieve this, there needs to be a connection to all available transport modalities in the form of a real-time data flow. Once any issues with connectivity are addressed, a ranking system is required to consider a variety of variables such as dock schedules and material restrictions. Pricing data is another integral component.

The great advantage of a synchromodal platform is that it’s informed by every available option and makes a selection based on key factors like speed requirements. There is still significant work to be done in terms of how best to access and integrate a supply chain partner’s real-time data but, as these platforms are developed, we’re likely to see faster order processing times for large shipments and systems which can help generate a better ROI. The way we understand it, SCM is changing because now an efficient supply chain can be a competitive asset as opposed to a cost center.

John Boyd , founder of The Boyd Company, Inc

Probably the most dynamic link in the supply chain in recent years has been the "last mile": that movement of goods from a DC to a final destination in the home. E-commerce king Amazon has done much to challenge and ultimately rewrite the rules of last mile delivery. Last mile delivery has also produced a new warehousing subsector: the locker. Studies show that online shoppers not only want their packages now, they also want their packages delivered to places other than their homes. These lockers can be viewed as "micro warehouses" and will come with additional costs. We expect many to be operated by an emerging sector of third-party logistics (3PL) providers specializing in this particular segment of the supply chain.

Lockers are now common in Europe, where densely populated and congested urban centers make them a natural fit. We anticipate that lockers will also become the next boom sector within logistics/distribution site selection in the United States. Amazon already has automated lockers in six states, while the U.S. Postal Service has lockers located within post offices in the Washington, D.C., area.

Upstart third-party logistics providers will be looking for sites where they can locate lockers, such as in transit centers, apartment buildings, convenience stores, or any establishment that provides off-hours access for picking up packages. Also, the growing online meals industry is expected to fuel the need for temperature-controlled lockers for the delivery of perishables.

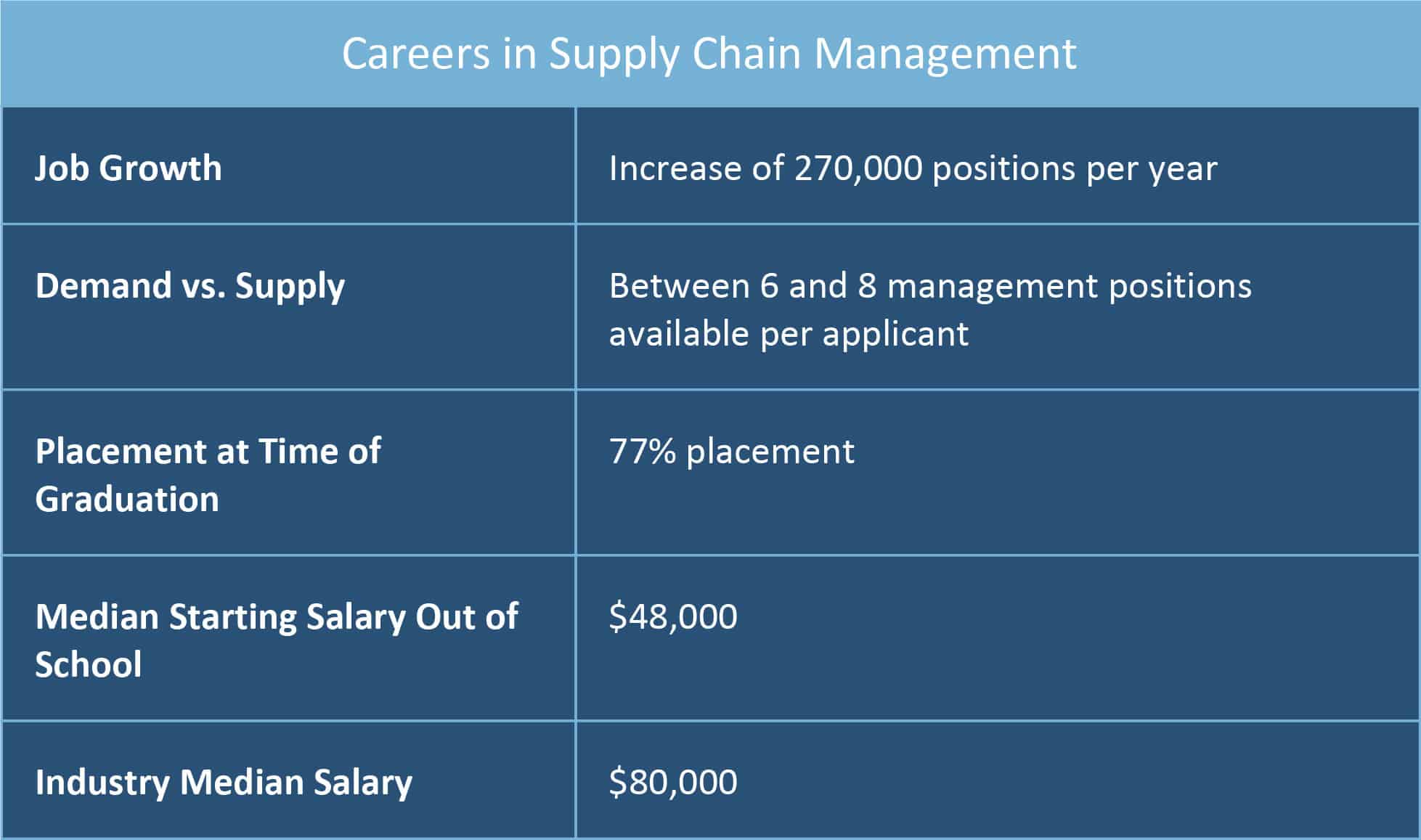

Careers in Supply Chain Management

With a bright future filled with unique challenges, a career in SCM is a strong choice. It might be surprising to hear about an industry that’s all about outsourcing and automation, but new experts are more vital than ever for global organizations and even local ones to grow. Look at these industry stats:

Career Paths

What kind of positions can you take on in supply chain management? Supply Chain Business Analyst: Examine your company’s workflow and come up with creative ways to streamline its business processes. Live and breathe efficiency. Inventory Control Administrator: Ensure that inventory systems’ data is accurate with physical inventory, troubleshoot discrepancies, discover root causes and interact with everyone related to this inventory. Purchasing Specialist: Work out deals with suppliers and compare bids to minimize cost across the supply chain. Procurement Manager: Research, evaluate, and purchase large quantities of products for companies to resell or use in operations. Determine what is in your company’s store, ecommerce shops, and more. Operations Analyst: Evaluate, report on, and improve the management of activities that generate recurring revenue for your organization, i.e. its core competencies. Material Planning Manager: Plan, monitor, and manage products and the materials required to make them in your organization’s manufacturing operations. You ensure the constant flow of materials so the factory never runs out.

Logistics Analyst: Evaluate and report on transportation of goods and services up and down your organization’s supply chain, ensuring that everything gets where it needs to go and when it needs to get there.

Top Higher Education Programs

Supply chain management is a game with global stakes, as such major universities and academies around the world offer Bachelor’s and Master’s degrees in the subject. If you want to secure a job in the sector with a Fortune 500, becoming accredited in SCM is vital. Look at some of the top schools on this list for more details on breaking into the industry:

- Cambridge University

- Copenhagen Business School

- Cranfield School of Management

- Eindhoven University of Technology

- London Business School

- Vlerick Business School

Certifications in Supply Chain Management

If a full Master’s program seems like too big a commitment, explore some of the short-term certifications available below. They give you a shot at entry level jobs if you’re inexperienced, and are a nice brush-up on current SCM standards for seasoned professionals.

- Chartered Institute of Supply Chain Management (CISCM) Chartered Supply Chain Management Professionals (CSCMP)

- Institute for Supply Management (ISM) Certified Professional in Supply Management (CPSM)

- Institute of Supply Chain Management (IOSCM)

- International Institute for Procurement and Market Research (IIPMR) Certified Supply Chain Specialist (CSCS) , Certified Procurement Professional (CPP) and Certified Supply Chain Associate (CSCA)

- International Supply Chain Education Alliance (ISCEA) Certified Demand Driven Planner (CDDP) and Certified Supply Chain Manager (CSCM)

- Association (SCMA) Supply Chain Management Professional (SCMP)

- The Association for Operations Management (APICS) Certified Supply Chain Professional (CSCP) and Certified Production and Inventory Management (CPIM)

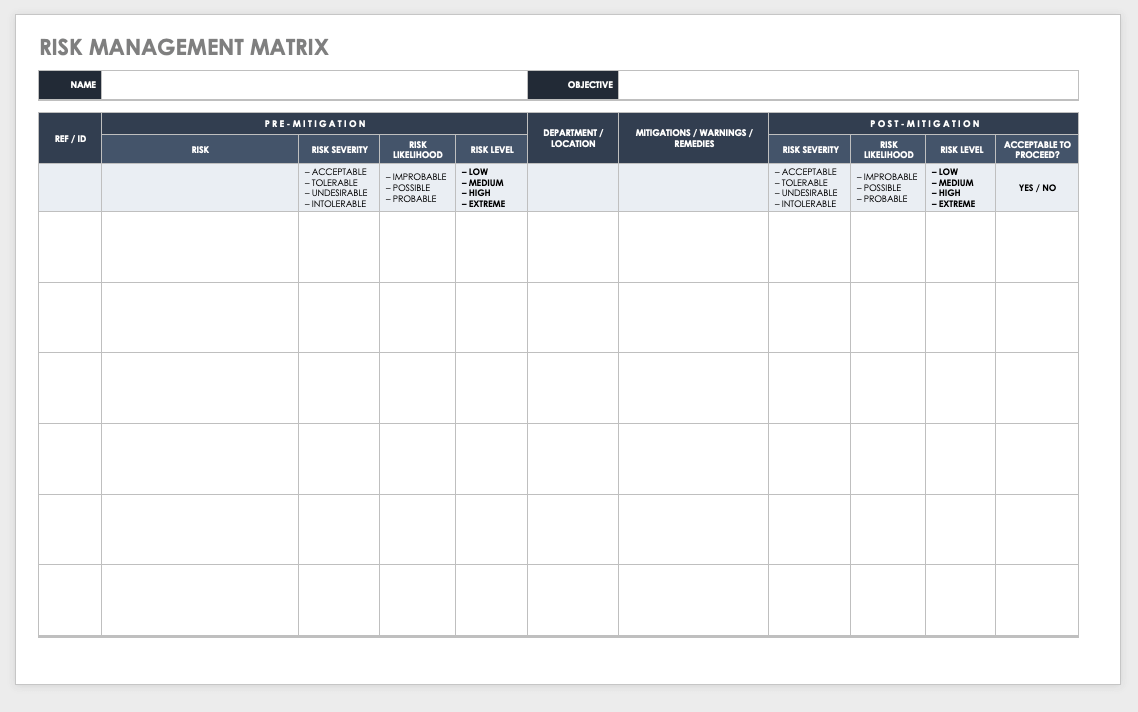

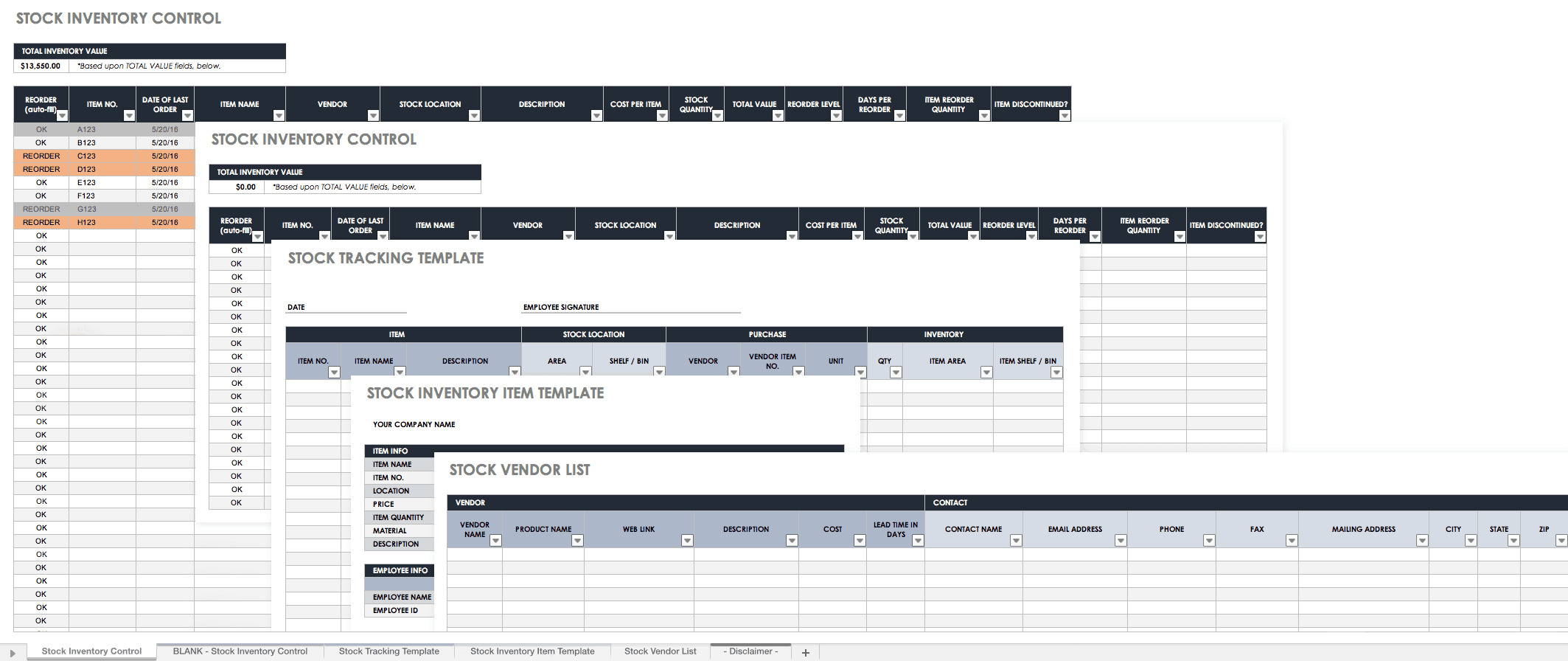

Supply Chain Management Templates

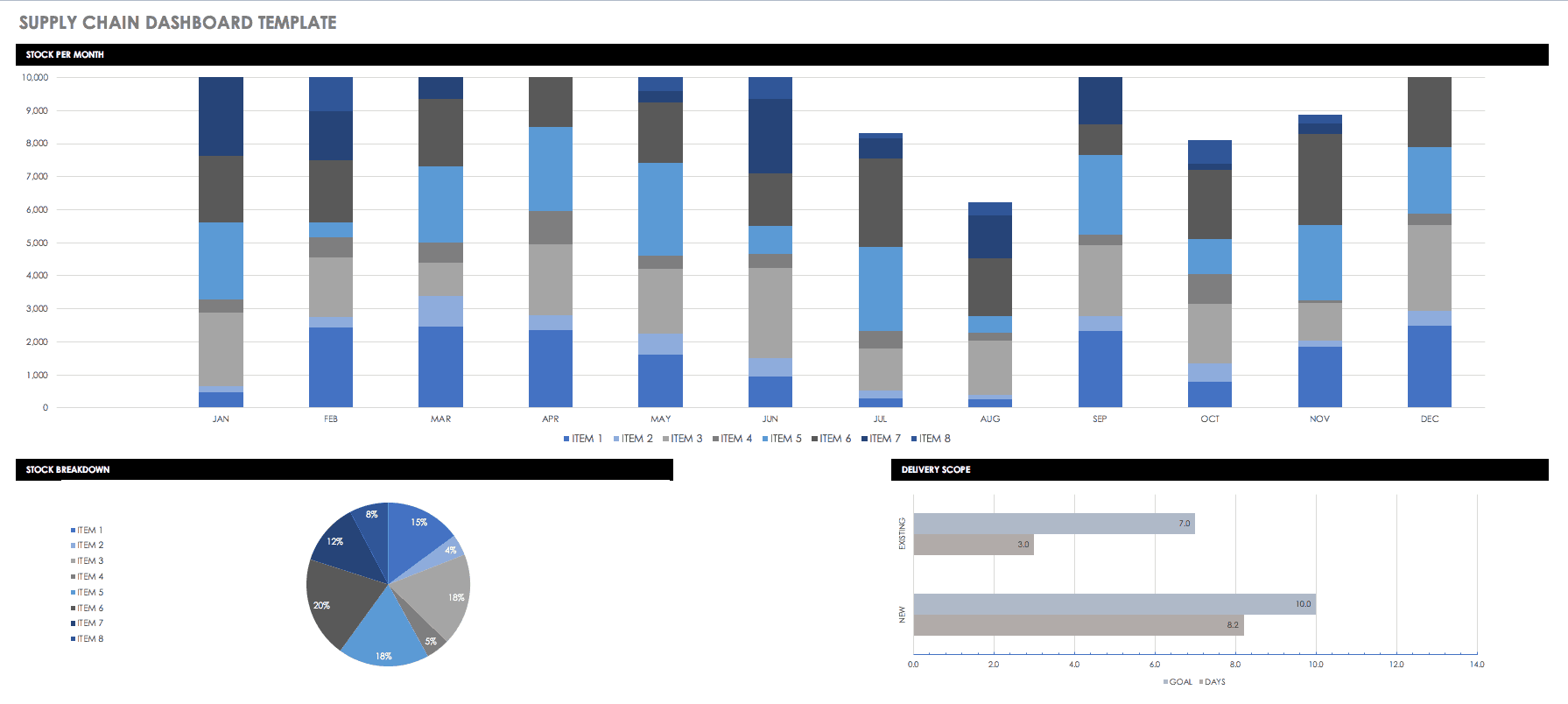

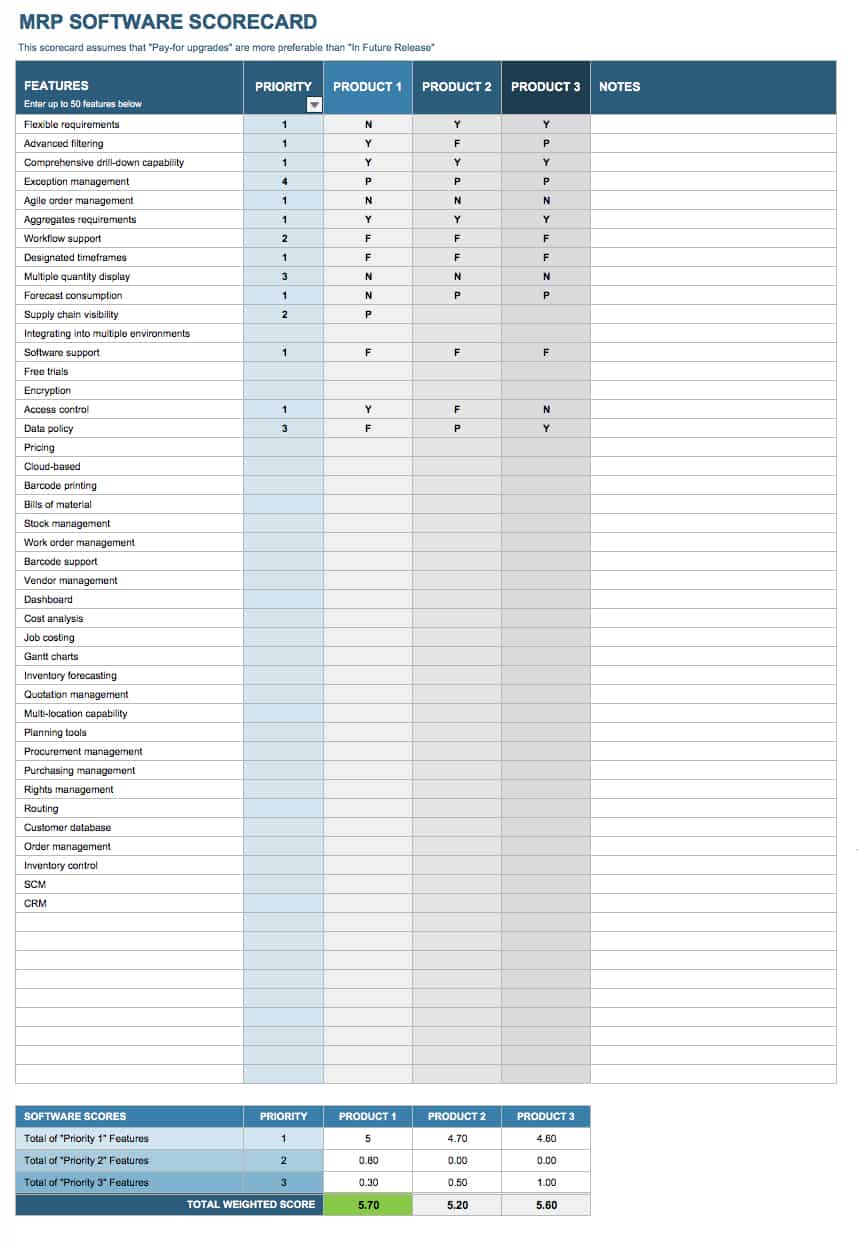

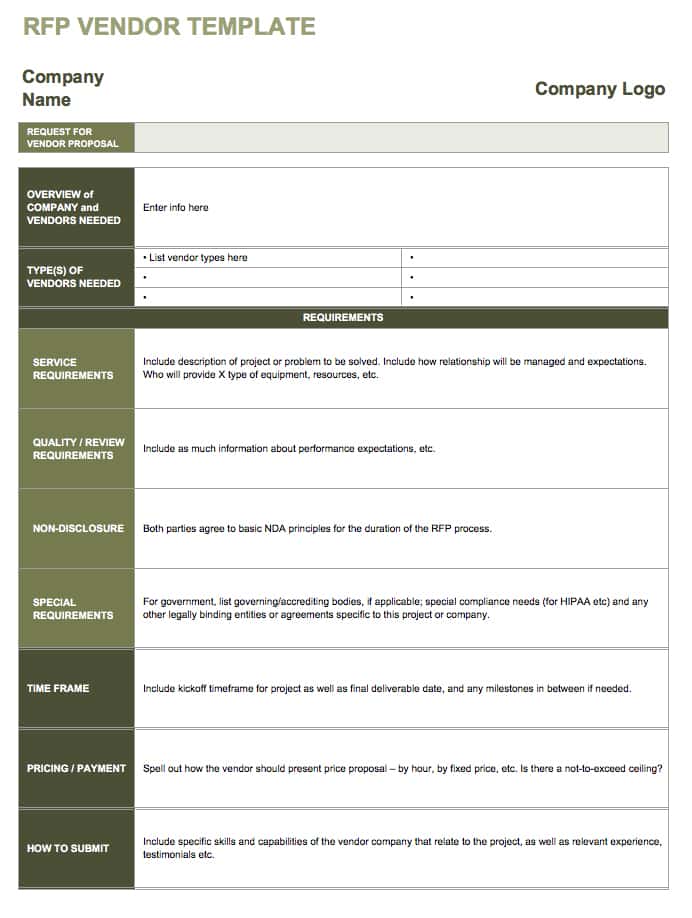

Outside of the physical work of checking inventory, or the personal work of communicating with different members of the supply chain’s links, much of your work as a supply chain manager is using systems and dashboards to get an understanding of logistics, operations, and flows. What follows are some templates that can help manage and streamline workflow, while understanding and sharing inventory reports and more.

Download Risk Management Matrix Template

Excel | Word | PDF | Smartsheet

Download Stock Inventory Control Template

Excel | Smartsheet

Download Supply Chain Dashboard Template

Download Microsoft Excel Template for Choosing MRP Software

Download RFP Vendor Template

A Better Way to Manage Supply Chain & Manufacturing Operations

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.

Discover why over 90% of Fortune 100 companies trust Smartsheet to get work done.

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Download Free PDF

Supply Chain Management Assignment

Related papers

This paper focuses on supply chain management network distribution and risk management and remedies. Supply chain management is a vital issue for the global competitiveness win situation and stay in the market. Here in the case of Anbessa shoes Share company (ASSC), raw materials are procured and ladies, child and men shoes are produced at its factory, shipped to warehouses for intermediate storage, and then shipped to retailers or customers. The supply chain, which is also referred to as the logistics network, consists of suppliers, manufacturing centers, warehouses, distribution centers, and retail outlets, as well as raw materials, work-in-process inventory, and finished products that flow between the facilities in the Abessa shoe factory. The company has experienced problems of market assessment, market research and development center and product distribution methods faced as big challenge leading to produce supply chain risk source at different point which leads them out of glo...

India is becoming a global manufacturing hub. Increasing demand in domestic and international markets is opening a new world of opportunities for the Indian Industry. Increasing competition, due to globalization is making inevitable for the Indian industries to provide cost effective quality output with stringent delivery schedules. Issues in supply of inferior quality, delayed supply, unwarranted cost escalation, etc. would adversely impact the credibility and business potential of the Indian industry. Amongst many difficulties faced by Indian manufacturers, supply chain disruption management is a major issue, which can result in large tangible and non-tangible losses. In current study lot of research has been done to understand what the Supply Chain Management is and how it is affecting organizations, what are different challenges and it can be proved as a tool for improving overall performance in today's global competitive environment.

Journal of Risk Research, 2012

Contemporary …

The paper develops a framework for supporting risk management according to the Enable process ‘Manage Supply Chain Risk’ defined by SCOR-Model. To this end, process mapping, project risk management, and performance measurement are integrated in order to provide an approach based on information and data currently recorded by the majority of companies. The methodology is illustrated by applying it to an ideal manufacturing supply chain. Future research efforts will focus on a comprehensive test of the framework in real settings in order to validate and refine it.

Computers & Industrial Engineering, 2002

Over the years, most of the firms have focused their attention to the effectiveness and efficiency of separate business functions. As a new way of doing business, however, a growing number of firms have begun to realize the strategic importance of planning, controlling, and designing a supply chain as a whole. In an effort to help firms capture the synergy of inter-functional and inter-organizational integration and coordination across the supply chain and to subsequently make better supply chain decisions, this paper synthesizes past supply chain modeling efforts and identifies key challenges and opportunities associated with supply chain modeling. We also provide various guidelines for the successful development and implementation of supply chain models.

Operations Management Research, 2010

Suppliers are expected to reduce manufacturing firm supply risks by minimizing supply failures and by resolving supply problems, even those ones resulting from firm’s actions. Integration mechanisms may enhance interaction and collaboration in the firm supply chain, especially in the buyer-supplier interface, to reach these goals. Based on case studies in four North-American manufacturing companies in the electronic and aerospace industries, we analyzed the importance of integration mechanisms for manufacturing firms to address supply problems. We also explored some drivers supporting those mechanisms. Supplier commitment was found to be a key integration factor to address supply problems. This may be accomplished by trust and power mechanisms. Internal integration between purchasing and manufacturing groups also played a significant role in supplier collaboration at the problem solving process. Customer integration seemed more important to address supply problems for contract manufacturers than for Original Equipment Manufacturing (OEM) firms. Although supply problems might originate several stages upstream in the supply chain, surprisingly there was no integration beyond direct suppliers in the manufacturing firm supply chain.

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

Related topics

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Already on SCMDOJO? Log in

I accept SCMDOJO'S Terms of Use and Privacy Notice .

Supply Chain Management Thesis Topics- Top 40 Ideas

- Career Advice

One of the most frequently asked questions from SCMDOJO followers is, I am doing a Supply Chain Management Master from Europe, the UK or the USA, and I need some Master Thesis ideas in Supply Chain.

Key academic research areas in SCM are offering robust and implementable supply chain management thesis that are transforming worldwide trends. The increasing strength of global Supply Chain Management (SCM) is one functional area that shows several students are seeking a good start, especially in solving significant problems in the form of Masters and PhD thesis .

Nevertheless, with the changing trends in the industry, some students are likely to struggle with the early stages of academic writing. A significant reason for this problem is usually down to a lack of ideas or facing new topics with low research activity.

Old Industries and New Industries

The recent pattern shifts in academia, from the traditional research approach to other conventional methods, is taking a more student-centred view. Most of the supply chain management thesis is crafted by students, including dissertation, topic creation, research, and more with help of their supervisors.

With new industries, like Amazon and Apple, transforming old concepts with technological disruption, there are new trends to look out for to help narrow your supply chain management thesis.

The 7 Powerful Supply Chain Trends (I also dubbed “Supply Chain 7.0”) have the potential to become a powerful influence over time. These trends include Augmented reality (AR), Big Data, Gamification of the supply chain, moving the supply chain to the “Cloud,” and the Internet of Things (IoT) – Industry 4.0. Also, Artificial Intelligence (AI) and machine learning in the supply chain, alongside 3D Printing, are now needed to support the product life cycle.

Forbes also highlights the key 2020 Supply Chain Technology Trends that are receiving lots of buzz in Supply Chain Management. In this regard, students seeking top-notch research areas for supply chain management thesis can consider new trends to help create adequate research content.

40 Supply Chain Management Thesis Topics for 2024

On these premises, any supply chain management thesis should be comprehensive. There several topics and areas to consider, and below are 40 Supply Chain Management Thesis Topics for 2020 that students can do research on towards an excellent postgraduate study in SCM.

Digital Transformation

- Digital Transformation Key Attributes; Challenges; enablers & Success Factors.

- Smart Government Initiatives: How Governments are Driving Digital Change.

- Digital Leadership is linking to Virtual Teams or Self Organised Teams (Agile PM).

- Did COVID 19 impact the implementation of digital transformation?

- Cross-functional collaboration in the decision-making process.

- The value of data and interdependencies in decision-making.

- Machine learning techniques in supply chain management.

- Blockchain Technology in Supply Chain Transparency: Evaluating the Impact on Traceability and Trust.

- The Role of Artificial Intelligence in Predictive Analytics for Inventory Management.

- Sustainability in Digital Supply Chain Management: A Comparative Analysis of Environmental Impact.

- Digital Transformation in Warehouse Management: Enhancing Efficiency and Customer Satisfaction

Sustainable Project Management (SPM)

- Can apply the SPM model or any of its dimensions to any type of project

- Can Blockchain help with Sustainable Project Management?

- Factors affecting the application of an efficient supply management system.

IoT- Industry 4.0 and Big Data

- Application of IoT in Logistics – Challenges; enablers & Success Factors

- The practicability of intertwined supply networks with IoT.

- Implementation of IoT in 3PL/4PL Industry – Challenges; enablers & Success Factors

- Big data and impact in DDMRP

- Evaluation of technology use in modern supply chain management.

- The extension of supply chain resilience through Industry 4.0

- The Impact of Industry 4.0 on Supply Chain Management.

- Implementation of E-logistics in Supply Chain Operations.

- Predictive Maintenance Strategies in Industry 4.0-enabled Supply Chains: A Case Study Approach

- Optimizing Supply Chain Decision-Making through Real-time Big Data Analytics

- Cybersecurity Challenges in IoT-Enabled Supply Chains: A Comprehensive Analysis.

Operations and Supply Chain Management

- Risk Evaluation and Management involved in a supply chain

- Partnerships Perspective in Supply Chain Management

- Assessing Supply Chain Risk Management Capabilities

- Implementation of Green Supply Chain Management Practices

- Supply Chain Management Practices and Supply Chain Performance Effectiveness

- The Impact of Supply Chain Management Practices on the Overall Performance of the org

- The Influence of Environmental Management Practices and Supply Chain Integration on Technological Innovation Performance

- The Relationship between Total Quality Management Practices and their Effects on Firm Performance

- Level of Commitment to Top Management regarding the TQM Implementation

- Impact of Mobility Solutions (transportation / latest technologies) on logistics.

- Study on the roles of supply chain management in corporate outsourcing.

- Evaluating strategies for cost reduction in SCM relating to exports and imports.

- Circular Economy Practices in Supply Chain Management: A Case Study Approach

- Demand Forecasting in Omnichannel Retail: A Comparative Analysis of Forecasting Models.

- Ethical and Sustainable Procurement Practices: An Examination of Implementation Challenges and Benefits.

Watch my YouTube vlog explaining more on Top 10 HOT TOPICS for Supply Chain Research for Master Thesis or Ph.D. Thesis.

Get My PhD Thesis- Supplier Development Framework

The supply chain systems of today are more likely to see massive changes technologically in the coming years. Some selected supply chain management thesis topics may face limited data or access to real-time data in making proper research and forecast, including seasonality and trends. So, due diligence is necessary to ensure you not only pick an exciting supply chain management thesis, but you also have sufficient access to data, studies, and materials useful in such an area. The impact of these trends alongside technological advancement in the selected areas would certainly help your thesis stand out and unique.

If are looking for more articles in the education category, you can visit this page

Frequently Asked Questions (FAQ)

What are the emergent research topics in the field of supply chain management.

Blockchain Integration : Exploring the application of blockchain technology to enhance transparency, traceability, and security in supply chains.

Sustainable Supply Chains : Investigating strategies for integrating environmentally friendly practices, ethical sourcing, and social responsibility into supply chain management.

Digital Transformation : Studying the impact of emerging technologies like artificial intelligence, machine learning, and the Internet of Things on optimizing supply chain processes.

Resilience and Risk Managemen t: Analyzing approaches to build resilient supply chains capable of adapting to disruptions, such as pandemics, natural disasters, and geopolitical events.

Circular Economy : Examining supply chain models that minimize waste and promote the reuse, recycling, and repurposing of materials.

Supply Chain Visibility : Researching ways to improve real-time visibility into supply chain activities to enhance decision-making and responsiveness.

Last-Mile Delivery Optimization : Investigating innovative approaches to streamline and optimize the final stages of product delivery to consumers.

Supply Chain Finance : Exploring financial strategies and tools to optimize cash flow and working capital within supply chains.

Collaborative Supply Chains : Studying methods to enhance collaboration and information-sharing among supply chain partners to achieve mutual benefits.

E-commerce Integration : Examining the challenges and opportunities associated with integrating e-commerce platforms into traditional supply chain models.

What are the 4 areas of supply chain management?

What is the primary goal of the supply chain.

The main goal of a supply chain is to efficiently and effectively manage the flow of products or services from the point of origin to the point of consumption. This involves optimizing processes from procurement and production to distribution and delivery. The overarching objective is to meet customer demands with the right products, in the right quantity, at the right time, while minimizing costs and maximizing overall supply chain performance.

What is the difference between supply chain and supply chain management?

The term “supply chain” refers to the entire network of entities and activities involved in the creation and delivery of a product or service, encompassing suppliers, manufacturers, distributors, retailers, and customers. “Supply chain management,” on the other hand, is the strategic coordination and oversight of these interconnected processes to optimize efficiency, reduce costs, and enhance overall performance. While the supply chain is the broader concept, supply chain management specifically involves the planning, execution, and control of various elements within that network to achieve business objectives.

Recommended Books

How to get a phd: a handbook for students and their supervisors.

How to Get a PhD: How to Set Yourself Up for Success in the First 12 Months (Getting My PhD)

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker , vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn , Facebook , Twitter or Instagram

- Research & Improvement

Free Supply Chain Digitalization Assessment

- Measure your organization's current digitalization readiness - 63 survey questions across six categories to achieve the objective

- Contact sales

Start free trial

An Introduction to Supply Chain Management (SCM)

Table of Contents

What is supply chain management, what is a supply chain, supply chain management process, parts of a supply chain model, benefits of supply chain management, supply chain management faq.

Supply chain management (SCM) is the discipline that manages the flow of supplies through all of the stages of a production cycle. SCM applies to any organization that executes projects, produces goods or provides services, as those activities require a supply chain to maintain a steady flow of resources. That’s where supply chain management comes in.

Supply chain management is very important in the business administration field because it affects other key business areas such as operations management, inventory control and quality management. But what really makes SCM so important is that it can also become an important competitive advantage for businesses.

The main goal of supply chain management is to make the most of the resources involved in a supply chain and be as productive as possible. People are managed and supplies require management as well . Whether those supplies are goods or services, they must be accounted for and carried through from start to finish with deliberate control. To better understand SCM, let’s define what a supply chain is.

A supply chain is a network that connects a company to suppliers of raw materials. It is also used to deliver a product to customers. The better the supply chain management, the more of a competitive advantage the company has.

Supply chains are steps that are required to get raw materials, products or services from the original state to the customer and improve customer relations. Large companies and projects usually have more than one supply chain, which is known as a supply network. Having supply chain managers and supply chain management is key to delivering customer value and maximizing the efficiency of your supply network.

Project management software can help you manage your supply chain and supply network. ProjectManager is a cloud-based work and project management software that has visual workflow features, such as kanban boards, that help keep your teams working at capacity without excess raw materials that need storage space. Get started with ProjectManager today for free!

The supply chain process is fundamental to good supply chain management. It is used by companies to make their supply chain as efficient and cost-effective as possible and deliver customer value and give them a competitive advantage. There are five steps to the supply chain process. They are as follows.

1. Planning

In order to control inventory and the manufacturing process companies must plan to match demand with supply, which is known as supply chain planning . This prevents overspending on warehouse space or not having raw materials needed for your manufacturing and slowing down delivery of product.

2. Sourcing

This step involves finding those vendors who can get the goods and services you need when you need them. Sourcing is how you get supplies when you need them and meet the demand of your customers .

Here is where those raw materials you procured are made into the products that meet your customers’ demand. This is where assembling, testing and packing occurs. Getting customer feedback is key to delivering customer value.

4. Delivering

Getting your finished product to the customer is the next crucial step in the SCM process. If you’re not able to get what you make to your customers all the previous steps are for naught. This makes delivering key to supply chain performance.

5. Returning

Returning or reverse logistics is part of what’s called post-delivery customer support process. It is important to have a clear channel for returns or risk tarnishing your brand. The company can then take these low quality, defective or expired materials and return them to their suppliers.

Related: 10 Free Manufacturing Excel Templates

To get the most out of SCM requires looking at the big picture in terms of an organization’s management. No longer is managing an individual company function enough. The integration of all activities involved in the supply chain is necessary: that means integration between different departments, such as purchasing and marketing.

Supply chain management also needs integration and collaboration between buyers and suppliers, joint product development, common systems and shared information. Here are the most important parts of any SCM system or model.

- Customer-Relations Management: There must be a managed approach to interacting with the company’s current and potential customers in order to understand what they want and expect.

- Customer-Service Management: This differs from customer-relations management in that it focuses on the interactions between the customer and the company instead of a more strategic management process. It helps facilitate a mutually satisfying goal for both customer and the company, as well as eliciting customer feedback and maintaining communications between the two parties, so there are positive feelings from both parties.

- Demand-Management Style: A methodology to forecast, plan for and manage the demand for products and services. This can address both macro-levels, as in global economics, but also micro-levels within the company.

- Order Fulfillment: The order fulfillment process that encompasses everything from point-of-sale interest to delivery of that product or service to the customer. It is the way a company responds to customer orders.

- Manufacturing-Flow Management: Manufacturing is a process, and supplies feed that process based on historic data surrounding how it has been done and what was needed historically. But that process needs flexibility as quantities change. Therefore, one must manage all activities related to planning, scheduling and managing the manufacturing process.

- Supplier Relationship Management (SRM): Supplies likely are coming from a third party, and those interactions must be strategically planned for. SRM is key to a healthy supply chain.

- Product Development and Commercialization: To reduce time to market, customers and suppliers are integrated into product vision and the product development process. Shortening the product life cycle keeps the company competitive. This process includes coordinating with customer relationship management to know customer needs, selecting materials and suppliers with procurement and developing a production technology in the flow of manufacturing to integrate the best supply chain flow for the product and market. When successful, this has a positive impact on cost, quality, delivery and market share.

- Returns Management: There will always be returns and the better they’re managed, the more productive and competitive the SCM process. Management of this aspect of the SCM means fast and easy returns management, automation and deciding how to process returned materials. Make sure information is visible to capture early in the process. Then control the flow of product, including receipts and reconciliation, noting if there are any quality issues.

Supply chain management is a hefty task with hefty rewards. Here are a few ways that well-executed SCM can benefit your business or project.

Keeps Businesses Competitive & Paces with Technology

The simple answer to why SCM is important to any business is that it helps them remain competitive. Markets change, and as the marketplace becomes increasingly global, the need for better efficiency is crucial. As management goals change, too, there is a move away from the past traditional relationships to incorporate and organize all business processes throughout a value chain of multiple companies.

Advances in information technology and the increasing use of outsourcing has also added to the expansion of the supply chain. This has created a need for a more collaborative network, so different enterprises can work harmoniously together.

Creates Productive Environments

These changes in how businesses are managed have led to the development of supply chain environments. Multinational companies, joint ventures, strategic alliances and other partnerships, as well as technological advancements, have contributed to more cooperation among those in the supply chain network. As supply chains become more holistic and cooperative, companies must adapt.

Proactive Strategy

But supply chain management is not merely reactive, it also helps to stimulate innovation and productivity by assisting companies with organizational learning. The more extended a company is in terms of its supply chain, the more adaptive it has to be. That leads to creative thinking, which results in innovation and increased productivity.

Satisfies Customers While Reducing Operating Costs

Customer service also benefits. Customers demand quality and they expect products to be available where and when they want them or delivered when on time. Supply chain management will also help with sale support after they’ve made the purchase.

But it’s not just the customer who benefits. As noted, SCM is instrumental in cutting operation costs. When smartly applied it can decrease purchasing, production and total supply change costs. This improves a company’s financial position by adding to profit leverage, reducing fixed assets and increasing cash flow.

SCM is a complex topic and you might have even more questions about it. Here are some quick answers about supply chain management topics.

What are the Components of Supply Chain Management (SCM)?

The 5 components of the supply chain management process are planning, sourcing, making, delivering and returning.

What Is Supply Chain Analysis?

Supply chain analysis is the process of auditing all the different steps of the supply chain to identify any possible areas of improvement.

What Is a Supply Chain Strategy?

A supply chain strategy is a roadmap that a company uses to source information, materials and equipment from its suppliers to create products and deliver them to its customers.

Supply chain management is just one more screw that can be tightened on the ship of business to help it sail better through the turbulent waters of industry. But it’s a complicated process, one that benefits from having robust project management tools to plan, monitor and report on the many aspects of the supply chain that need control. ProjectManager is a cloud-based software that has the tools to make you manage more efficiently and effectively. See what it can do by taking this free 30-day trial.

Deliver your projects on time and on budget

Start planning your projects.

Want to create or adapt books like this? Learn more about how Pressbooks supports open publishing practices.

13.6 Conclusion

As we conclude our exploration of Lean Supply Chains, it’s evident that the principles and practices of lean are not confined to the realm of manufacturing alone but extend into every sector and process where value is created and delivered. The journey through lean philosophy, techniques, and tools illuminates a path toward operational excellence, sustainability, and customer satisfaction. The transformative potential of lean lies not just in its ability to streamline operations and reduce waste but also in its capacity to foster a culture of continuous improvement and respect for people at every level of an organization.

For students across all majors, understanding and applying lean principles can provide a competitive edge in today’s dynamic and complex marketplace. Whether you’re pursuing a career in manufacturing, healthcare, finance, or any other sector, the lean approach offers valuable insights into optimizing processes, enhancing quality, and driving innovation. The versatility and adaptability of lean make it an invaluable framework for addressing the challenges and opportunities of the 21st century.

Moreover, the journey of lean is a continuous one, with no final destination. It is a cycle of constant learning, improvement, and adaptation. This book has laid the foundation, but the true depth and impact of lean can only be fully realized through application, experimentation, and ongoing exploration. I encourage you to delve deeper into the subjects that have intrigued you, seek out real-world examples of lean in action, and consider how you might apply these principles in your future career or endeavors.

Above all, remember that lean is more than a set of tools or methodologies; it is a mindset, a way of thinking that prioritizes value, respect for people, and continuous improvement. Embracing this mindset can lead to not only professional success but also personal growth and fulfillment. As you move forward, let the principles of lean guide you in creating value, solving problems, and making a positive impact in whatever field you choose to pursue.

Supply Chain Management - An Integrated Approach Copyright © by Piyush Shah is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License , except where otherwise noted.

Share This Book

- Search Search Please fill out this field.

- What Is Supply Chain Management?

- How SCM Works

5 Phases of Supply Chain Management (SCM)

Types of supply chain models, example of supply chain management (scm), the bottom line.

- Supply Chain

Supply Chain Management (SCM): How It Works & Why It's Important

:max_bytes(150000):strip_icc():format(webp)/jason_mugshot__jason_fernando-5bfc261946e0fb00260a1cea.jpg)

What Is Supply Chain Management (SCM)?

Supply chain management (SCM) is the monitoring and optimization of the production and distribution of a company’s products and services. It seeks to improve and make more efficient all processes involved in turning raw materials and components into final products and getting them to the ultimate customer. Effective SCM can help streamline a company's activities to eliminate waste, maximize customer value, and gain a competitive advantage in the marketplace.

Key Takeaways

- Supply chain management (SCM) is the centralized management of the flow of goods and services to and from a company and includes all of the processes involved in transforming raw materials and components into final products.

- With SCM, companies can cut excess costs and deliver products to the consumer faster and more efficiently.

- Good SCM can help prevent expensive product recalls and lawsuits as well as bad publicity.

- The five most critical phases of SCM are planning, sourcing, production, distribution, and returns.

- A supply chain manager is tasked with controlling and reducing costs and avoiding supply shortages.

Investopedia / Alex Dos Diaz

How Supply Chain Management (SCM) Works

SCM represents an ongoing effort by companies to make their supply chains as efficient and economical as possible.

Typically, SCM attempts to centrally control or link the production, shipment, and distribution of a product . By managing the supply chain, companies can cut excess costs and needless steps and deliver products to the consumer faster. This is done by keeping tighter control of internal inventories , internal production, distribution , sales, and the inventories of company vendors.

SCM is based on the idea that nearly every product that comes to market does so as the result of efforts by multiple organizations that make up a supply chain. Although supply chains have existed for ages, a lot of companies didn't pay attention to them as a value-add to their operations until recently.

A supply chain manager's job is not only about traditional logistics and purchasing. They have to find ways to increase efficiency and keep costs down while also avoiding shortages and preparing for unexpected contingencies. Typically, the SCM process consists of these five phases:

1. Planning

To get the best results from SCM, the process usually begins with planning to match supply with customer and manufacturing demands. Companies must try to predict what their future needs will be and act accordingly. That means taking into account the raw materials or components needed during each stage of manufacturing, equipment capacity and limitations, and staffing needs.

Large businesses often rely on enterprise resource planning (ERP) software to help coordinate the process.

2. Sourcing

Effective SCM processes rely very heavily on strong relationships with suppliers. Sourcing entails working with vendors to supply the materials needed throughout the manufacturing process. Different industries will have different sourcing requirements. In general, SCM sourcing involves ensuring that:

- The raw materials or components meet the manufacturing specifications needed for the production of the goods.

- The prices paid to the vendor are in line with market expectations.

- The vendor has the flexibility to deliver emergency materials due to unforeseen events.

- The vendor has a proven record of delivering goods on time and of good quality.

SCM is especially critical when manufacturers are working with perishable goods.

When sourcing goods, companies should be mindful of lead times and how well equipped a supplier is to meet their needs.

3. Manufacturing

Using machinery and labor to transform the raw materials or components the company has received from its suppliers into something new is the heart of the supply chain management process. This final product is the ultimate goal of the manufacturing process, though it is not the final stage of SCM.

The manufacturing process may be further divided into sub-tasks such as assembly, testing, inspection, and packaging. During the manufacturing process, companies must be mindful of waste or other factors that may cause deviations from their original plans. For example, if a company is using more raw materials than planned and sourced for due to inadequate employee training, it must rectify the issue or revisit the earlier stages in SCM.

4. Delivery

Once products are made and sales are finalized, a company must get those products into the hands of its customers. A company with effective SCM will have robust logistic capabilities and delivery channels to ensure timely, safe, and inexpensive delivery of its products.

This includes having a backup or diversified distribution methods should one method of transportation temporarily be unusable. For example, how might a company's delivery process be impacted by record snowfall in distribution center areas?

The SCM process concludes with support for the product and customer returns.

The return process is often called reverse logistics, and the company must ensure it has the capabilities to receive returned products and correctly assign refunds for them. Whether a company is conducting a product recall or a customer is simply not satisfied with the product, the transaction with the customer must be remedied.

Returns can also be a valuable form of feedback, helping the company to identify defective or poorly designed products and to make whatever changes are necessary. Without addressing the underlying cause of a customer return, the SCM process will have failed, and returns will likely persist into the future.

Supply chain management does not look the same for all companies. Each business has its own goals, constraints, and strengths that will shape its SCM process. These are some of the models a company can adopt to guide its SCM efforts:

Continuous Flow Model

The continuous flow model relies on a manufacturer producing the same good over and over and expecting customer demand will show little variation. One of the more traditional supply chain methods, this model is often best for mature industries.

Agile Model

The agile model prioritizes flexibility, as a company may have a specific need at any given moment and must be prepared to pivot accordingly. This method works best for companies with unpredictable demand or custom-order products.

This model emphasizes the quick turnover of a product with a short life cycle. Using a fast chain model, a company strives to capitalize on a trend, quickly produce goods, and ensure the product is fully sold before the trend ends.

Flexible Model

The flexible model works best for companies affected by seasonality . Some companies may have much higher demand requirements during peak season and low volume requirements in others. A flexible model of supply chain management ensures that production can easily be ramped up or wound down.

Efficient Model

Companies competing in industries with very tight profit margins may strive to get an advantage by making their supply chain management process the most efficient. That could involve coming up with ways to do a better job of utilizing equipment and machinery, managing inventory, and processing orders.

Custom Model

If any model above doesn't suit a company's needs, it can always apply a custom model. This is often necessary for highly specialized industries with high technical requirements, such as an automobile manufacturer.

Understanding the importance of SCM to its business, Walgreens Boots Alliance Inc. decided to transform its supply chain by investing in technology to streamline the entire process. That included using big data , collected from its 9,000 stores and 20,000 suppliers, to help improve its forecasting capabilities and better manage sales and inventory. In 2019, it appointed its first-ever chief supply chain officer.

Walgreens Boots Alliance also incorporated SCM into its environmental, social, and governance (ESG) initiatives. For example, the company began asking suppliers to fill in an online survey that asks questions about their ESG practices, such as whether they have an emissions reduction target in place and the types of materials they use.

Why Is Supply Chain Management Important?

Supply chain management is important because it can help achieve several business objectives. For instance, controlling manufacturing processes can improve product quality, reducing the risk of recalls and lawsuits while helping to build a strong consumer brand. At the same time, control over shipping procedures can improve customer service by avoiding costly shortages or periods of inventory oversupply. Overall, supply chain management provides multiple opportunities for companies to improve their profit margins and is especially important for businesses with large and international operations.

How Are Ethics and Supply Chain Management Related?

Ethics has become an increasingly important aspect of supply chain management, even leading to the establishment of a set of principles called supply chain ethics. Many investors today want to know how companies produce their products, treat their workforce, and protect the environment. As a result, companies respond by instituting measures to reduce waste, improve working conditions, and lessen their impact on the environment—all of which can involve SCM.

How Much Do Supply Chain Management Jobs Pay?

Supply chain managers across the United States earn, as of May 28, 2024, average annual salaries in the range of $111,000 to $142,000, according to the website Salary.com.

A supply chain starts with the ordering of raw materials or components from a supplier and ends with the delivery of a finished product or service to the end consumer. In supply chain management, every link in that chain may offer an opportunity to add value or reduce inefficiency. A well-run SCM program can increase a company's revenues, decrease its costs, and bolster its bottom line .

Cision PR Newswire. " Walgreens Transforms Supply Chain Management with Kyvos, Tableau, and Big Data ."

Walgreens Boots Alliance. " Walgreens Boots Alliance Announces Key Leadership Appointments Live ."

Walgreens Boots Alliance. " Environmental, Social & Governance. "

Walgreens Boots Alliance. " Sustainable Marketplace ."

Salary.com. " Supply Chain Manager Salary in the United States ."

:max_bytes(150000):strip_icc():format(webp)/Term-Definitions_delivery-duty-paid-f7943b12b1b343faaf4f5bf7fef43f15.jpg)

- Terms of Service

- Editorial Policy

- Privacy Policy

Global Supply Chain Management Program

Get your brochure.

By clicking the button below, you agree to receive communications via Email/Call/WhatsApp/SMS from Wharton & Emeritus about this program and other relevant programs. Privacy Policy

Program Topics

This six-week program includes the following modules:

Who Is This Program For?

The Global Supply Chain Management Program is designed to provide fresh insights into a rapidly changing supply chain ecosystem—and help translate those insights into action. This course is for people who:

Seek to identify trends, new avenues, and opportunities to reinvent your organization's present global supply chain management

Are interested in learning the competitive advantages of socially and environmentally sustainable supply chains and incorporating them into their corporate strategies

Want to adopt an analytical approach to improving supply chain efficiency and creating better business output

Are looking to bring about a digital transformation in their organization's supply chain management techniques and processes

Program Features

Root Beer Game

Risk Management Maturity Model

Decision Tree Model

Strategic Fit Framework

Global Supply Chain Analytics Framework

Case Studies

Global Supply Chain Management Program draws on real-world case studies to illustrate how organizations are actually meeting the challenges of a volatile, interconnected global supply chain. Featured case studies include:

This apparel retailer resolved supply chain challenges that resulted from integrating ecommerce with its traditional sales channels.

This packaging supplier and equipment vendor made supply chain digitalization a key component of its digital transformation program.

This global company solved sourcing challenges involving innovative photovoltaics for its product line.

Program Experience

Live Sessions

Gauge your progress with a live faculty check-in.

Guest Speakers

Hear from global experts on today's most pressing supply chain challenges.

Discussions

Exchange insights with other participants each week and apply what you've learned to real-world scenarios.

Industry Examples

Examine case studies of how successful organizations are adapting to an ever-changing global supply chain.

Get a panoramic view of the perspectives, assumptions, and pain points that fellow participants are experiencing.

Simulations

Gain insights into supply chain dynamics by playing the Root Beer Game.

Program Faculty

Jeffrey A. Keswin Professor; Professor of Operations, Information and Decisions; Director, Jerome Fisher Program in Management & Technology, the Wharton School

Gad Allon teaches courses on scaling operations and operations strategy and has been an innovative leader in many educational technology initiatives. He is the co-founder of F...

Charles W. Evans Distinguished Faculty Scholar; Associate Professor of Operations, Information and Decisions, The Wharton School

Santiago Gallino studies both digital transformation and supply chain issues in retail. Professor Gallino has researched with and consulted for numerous organizations. In his ...

Associate Professor of Technology and Operations; Michael R. and Mary Kay Hallman Fellow, Stephen M. Ross School of Business

Jun Li is an associate professor of technology and operations at the University of Michigan's Ross School of Business. She conducts research on empirical operations management...

Outdoor Industry and Apparel Expert

Doug Freeman has more than 30 years of experience in global supply chain operations management. He served as Sourcing Manager, Asia, at Patagonia before becoming the organizat...

CEO, the Hong Kong Research Institute of Textiles and Apparel

In his 10 years as head of this prestigious global institution, Edwin has focused on bringing innovation and sustainability to supply chain management. His goal is to help the...

International Corporate and Nonprofit Leader; Co-Founder of Good Life Designed

An international business leader with more than 20 years of experience, Pernille is the author of Design Your Life, a book that encourages people to challenge assumptions abou...

Certificate

Get recognized! Upon successful completion of the program, the Wharton School grants a verified digital certificate of completion to participants.

Note: After successful completion of the online program, your verified digital certificate will be emailed to you in the name you used when registering for the program. All certificate images are for illustrative purposes only and may be subject to change at the discretion of the Wharton School. This online certificate program does not grant academic credit or a degree from the Wharton School of the University of Pennsylvania.

Didn't find what you were looking for? Write to us at [email protected] or Schedule a call with one of our Program Advisors or call us at +1 680 205 5118 (US) / +44 185 845 9995 (UK) / +65 3135 1422 (SG)

Early registrations are encouraged. Seats fill up quickly!

Flexible payment options available. View payment plans

IBM TechXchange Conference 2024 | October 21-24 in Las Vegas

Join the must-attend event for technologists using IBM products and solutions. Explore the growing session catalog of over 1,200 sessions and labs.

Supply chain management (SCM) is the coordination of a business’ entire production flow, from sourcing raw materials to delivering a finished item.

The global supply chain is a complex network of suppliers, manufacturers, distributors, retailers, wholesalers and customers. Effective SCM is about optimizing this network to ensure that everything gets where it needs to be, when it needs to be there—and as smoothly as possible. It includes obtaining the necessary components, manufacturing the product, storing it, transporting it and getting it to customers.

SCM also involves the coordination of external partners and both internal resources and operations management. According to the Council of Supply Chain Management Professionals (CSCMP), “in essence, supply chain management integrates supply and demand management within and across companies.” 1

This guide explores ways to help businesses increase visibility, intelligence and agility in their supply chain.

Effective supply chain management minimizes costs, waste and time in the production cycle. It directly impacts profitability and allows businesses to gain a competitive advantage in today's global marketplace. One study found that organizations with advanced SCM capabilities were 23% more profitable than their peers. 2

Supply chain management also helps companies anticipate and mitigate risks (such as supply chain disruptions) and track compliance with regulations and standards. By helping products arrive on time and in good condition, supply chain management can improve customer satisfaction and loyalty.

The importance of supply chain management is also evident amid growing awareness about climate change . Sustainable supply chain management can help companies reduce their carbon footprint and impact on the environment by optimizing logistics and energy management , and reducing waste .

Supply chain management consists of several main components, including:

Planning involves forecasting demand , arranging production and managing inventory levels to ensure that the right products are ready to meet customer demand. It also involves setting an overall SCM strategy by determining metrics to measure whether the supply chain is efficient, effective and meets company goals. And it includes adapting to new product needs.