Assignment Problem: Meaning, Methods and Variations | Operations Research

After reading this article you will learn about:- 1. Meaning of Assignment Problem 2. Definition of Assignment Problem 3. Mathematical Formulation 4. Hungarian Method 5. Variations.

Meaning of Assignment Problem:

An assignment problem is a particular case of transportation problem where the objective is to assign a number of resources to an equal number of activities so as to minimise total cost or maximize total profit of allocation.

The problem of assignment arises because available resources such as men, machines etc. have varying degrees of efficiency for performing different activities, therefore, cost, profit or loss of performing the different activities is different.

Thus, the problem is “How should the assignments be made so as to optimize the given objective”. Some of the problem where the assignment technique may be useful are assignment of workers to machines, salesman to different sales areas.

Definition of Assignment Problem:

ADVERTISEMENTS:

Suppose there are n jobs to be performed and n persons are available for doing these jobs. Assume that each person can do each job at a term, though with varying degree of efficiency, let c ij be the cost if the i-th person is assigned to the j-th job. The problem is to find an assignment (which job should be assigned to which person one on-one basis) So that the total cost of performing all jobs is minimum, problem of this kind are known as assignment problem.

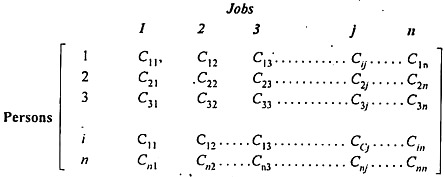

The assignment problem can be stated in the form of n x n cost matrix C real members as given in the following table:

- Kopere Dashboard

- Online Resources University Website AMS Students Module AMS Lectuter's Module (LAN ONLY) Attachment System Clearance System University Intranet (LAN ONLY) Safe Exam Browser (Windows) Safe Exam Browser (macOS) Password Reset (Staff) Password Reset (Students)

- University Library Library Catalog Off-Campus Access SU Digital Repository ExamsBank (On-Campus) ExamsBank (Off-Campus) eBooks+ BigBlueButton

- SBS eLearning

- MAPE eLearning

- Help Usage Tutorials FAQs+

Log in to Strathmore University eLearning System

CS 482 - Spring 2005

Due: friday, apr 22.

Note: Include your Cornell NetID on your each section of your homework. This simplifies the process of recording your grades.

Suppose we are given a directed graph G = (V,E), with V = {v 1 , v 2 , ..., v n }, and we want to decide whether G has a Hamiltonian path from v 1 to v n . (That is, is there a path in G that goes from v 1 to v n , passing through every other vertex exactly once?)

Since the Hamiltonian path problem is NP-complete, we do not expect that there is a polynomial-time solution for this problem. However, this does not mean that all non-polynomial-time algorithms are equally "bad." For example, here's the simplest brute-force approach: for each permutation of the vertices, see if it forms a Hamiltonian path from v 1 to v n . This takes time roughly proportional to n!, which is about 3 times 10 17 when n = 20.

Suppose you're acting as a consultant for the Port Authority of a small Pacific Rim nation. They're currently doing a multi-billion dollar business per year, and their revenue is constrained almost entirely by the rate at which they can unload ships that arrive in the port.

Here's a basic sort of problem they face. A ship arrives, with n containers of weight w 1 , w 2 , ..., w n . Standing on the dock is a set of trucks, each of which can hold K units of weight. (You can assume that K and each w i is an integer.) You can stack multiple containers in each truck, subject to the weight restriction of K; the goal is to minimize the number of trucks that are needed in order to carry all the containers. This problem is NP-complete (you don't have to prove this).

- Give an example of a set of weights, and a value of K, where this algorithm does not use the minimum possible number of trucks.

- Show that the number of trucks used by this algorithm is within a factor of 2 of the minimum possible number, for any set of weights and any value of K.

Recall that in the basic load balancing problem from lecture, we're interested in placing jobs on machines so as to minimize the makespan --- the maximum load on any one machine. In a number of applications, it is natural to consider cases in which you have access to machines with different amounts of processing power, so that a given job may complete more quickly on one of your machines than on another. The question then becomes: how should you allocate jobs to machines in these more heterogeneous systems?

Here's a basic model that exposes these issues. Suppose you have a system that consists of m slow machines and k fast machines. The fast machines can perform twice as much work per unit time as the slow machines. Now, you're given a set of n jobs; job i takes time t i to process on a slow machine and time t i / 2 to process on a fast machine. You want to assign each job to a machine; as before, the goal is to minimize the makespan --- i.e. the maximum, over all machines, of the total processing time of jobs assigned to that machine.

Stack Exchange Network

Stack Exchange network consists of 183 Q&A communities including Stack Overflow , the largest, most trusted online community for developers to learn, share their knowledge, and build their careers.

Q&A for work

Connect and share knowledge within a single location that is structured and easy to search.

a generalized job assignment problem

The following problem is from a past algorithms course exam and I'm using it to test my knowledge.

There are m machines and n jobs. Each machine can doing a subset of jobs. Each machine i has a capacity $C_i$ , meaning that it has $C_i$ units of processing time. Each job $j$ has a demand $D_j$ , meaning that it requires $D_j$ units of processing time to complete. We'd like to assign all the jobs to the machines, so that each job is assigned to only one machine, and no machine is overloaded (i.e. the total demands assigned to machine i doesn't exceed its capacity $C_i$ ).

Input: $m$ positive numbers $C_1,\cdots, C_m$ , n positive numbers $D_1,\cdots, D_n$ , and for each $1\leq i\leq m$ and $1\leq j\leq n,$ a boolean variable $x_{i,j}$ indicating whether machine $i$ can do job $j$ .

Output: Does there exist an assignment such that all the jobs are assigned to machines, so that each job is assigned to only one machine and no machine is overloaded?

Question: prove the above problem is NP-complete, or give an algorithm to solve the decision problem in polynomial time.

I think the problem might be NP-complete. The decision problem asks whether an assignment assigns at least k jobs, where k is a parameter to the decision problem. Clearly the problem is in NP; one can verify in polynomial time that an assignment satisfies that no machine is overloaded and each job is assigned to one machine. One can do this by checking the jobs assigned to machine i and verifying that the total sum of the $D_j$ 's associated with machine i is at most $C_i$ . One can then check at the same time that no job is assigned to two different machines.

But I'm not sure which NP-complete problem to reduce from. For instance, I know the following well-known problems are NP-complete: vertex cover, 3-SAT, hamiltonian cycle, set cover, hamiltonian path, clique, independent set, 3 coloring, subset sum etc.

Maybe Vertex cover would be useful?

- np-complete

This problem is a generalization of the decision version of the bin packing problem (BPP) . While all bins in BPP have the same given capacity, the capacities of the machines in this problem are variable.

The decision version of BPP is $\mathsf{NP}$ -complete. So you have guessed correctly: this problem is $\mathsf{NP}$ -complete since this problem is in $\mathsf{NP}$ as proved in the question.

Your Answer

Sign up or log in, post as a guest.

Required, but never shown

By clicking “Post Your Answer”, you agree to our terms of service and acknowledge you have read our privacy policy .

Not the answer you're looking for? Browse other questions tagged algorithms graphs np-complete or ask your own question .

- Featured on Meta

- Bringing clarity to status tag usage on meta sites

- Announcing a change to the data-dump process

Hot Network Questions

- Star Trek: The Next Generation episode that talks about life and death

- Why is there so much salt in cheese?

- Referencing an other tikzpicture without overlay

- How to run only selected lines of a shell script?

- Does the USA plan to establish a military facility on Saint Martin's Island in the Bay of Bengal?

- Numbering Equations in a Closed Bracket

- What's "the archetypal book" called?

- Is response variable/dependent variable data required for simr simulation?

- In Lord Rosse's 1845 drawing of M51, was the galaxy depicted in white or black?

- If a Palestinian converts to Judaism, can they get Israeli citizenship?

- How best to cut (slightly) varying size notches in long piece of trim

- What's the benefit or drawback of being Small?

- Is it a good idea to perform I2C Communication in the ISR?

- Using rule-based symbology for overlapping layers in QGIS

- Why is Haji Najibullah's case being heard in federal court in the Southern District of NY?

- Directory of Vegan Communities in Ecuador (South America)

- Fusion September 2024: Where are we with respect to "engineering break even"?

- Current in a circuit is 50% lower than predicted by Kirchhoff's law

- How can I play MechWarrior 2?

- How do I learn more about rocketry?

- Libsodium: Why hiding the field arithmetics?

- Why are poverty definitions not based off a person's access to necessities rather than a fixed number?

- Is it safe to install programs other than with a distro's package manager?

- Maximisation of product

Assignment Problem: Linear Programming

The assignment problem is a special type of transportation problem , where the objective is to minimize the cost or time of completing a number of jobs by a number of persons.

In other words, when the problem involves the allocation of n different facilities to n different tasks, it is often termed as an assignment problem.

The model's primary usefulness is for planning. The assignment problem also encompasses an important sub-class of so-called shortest- (or longest-) route models. The assignment model is useful in solving problems such as, assignment of machines to jobs, assignment of salesmen to sales territories, travelling salesman problem, etc.

It may be noted that with n facilities and n jobs, there are n! possible assignments. One way of finding an optimal assignment is to write all the n! possible arrangements, evaluate their total cost, and select the assignment with minimum cost. But, due to heavy computational burden this method is not suitable. This chapter concentrates on an efficient method for solving assignment problems that was developed by a Hungarian mathematician D.Konig.

"A mathematician is a device for turning coffee into theorems." -Paul Erdos

Formulation of an assignment problem

Suppose a company has n persons of different capacities available for performing each different job in the concern, and there are the same number of jobs of different types. One person can be given one and only one job. The objective of this assignment problem is to assign n persons to n jobs, so as to minimize the total assignment cost. The cost matrix for this problem is given below:

The structure of an assignment problem is identical to that of a transportation problem.

To formulate the assignment problem in mathematical programming terms , we define the activity variables as

| x = | 1 if job j is performed by worker i | |

| 0 otherwise |

for i = 1, 2, ..., n and j = 1, 2, ..., n

In the above table, c ij is the cost of performing jth job by ith worker.

Generalized Form of an Assignment Problem

The optimization model is

Minimize c 11 x 11 + c 12 x 12 + ------- + c nn x nn

subject to x i1 + x i2 +..........+ x in = 1 i = 1, 2,......., n x 1j + x 2j +..........+ x nj = 1 j = 1, 2,......., n

x ij = 0 or 1

In Σ Sigma notation

x ij = 0 or 1 for all i and j

An assignment problem can be solved by transportation methods, but due to high degree of degeneracy the usual computational techniques of a transportation problem become very inefficient. Therefore, a special method is available for solving such type of problems in a more efficient way.

Assumptions in Assignment Problem

- Number of jobs is equal to the number of machines or persons.

- Each man or machine is assigned only one job.

- Each man or machine is independently capable of handling any job to be done.

- Assigning criteria is clearly specified (minimizing cost or maximizing profit).

Share this article with your friends

Operations Research Simplified Back Next

Goal programming Linear programming Simplex Method Transportation Problem

- Stack Overflow for Teams Where developers & technologists share private knowledge with coworkers

- Advertising & Talent Reach devs & technologists worldwide about your product, service or employer brand

- OverflowAI GenAI features for Teams

- OverflowAPI Train & fine-tune LLMs

- Labs The future of collective knowledge sharing

- About the company Visit the blog

Collectives™ on Stack Overflow

Find centralized, trusted content and collaborate around the technologies you use most.

Q&A for work

Connect and share knowledge within a single location that is structured and easy to search.

Get early access and see previews of new features.

Job scheduling with n tasks and m machines

Problem description:

I have n precedence constrained jobs and m independent machines. Each job has a cost c assigned to it (the number of machines required to finish the job in 1 time unit). It takes 1 time unit to finish a job, a job can only be finished if c machines are assigned to it (jobs are atomic, it's not possible to finish half of the job).

So in short, there are n jobs and their precedence constrains, m machines and a deadline d (some number of time units).

I want to check if it is possible to assign the jobs to the machines such that all of the jobs are finished within d time units. If this is possible then I want to print out a schedule which assigns a time unit to each job (the time unit in which the job is processed, see example below).

My current approach: (second try thanks to @Ole V.V.'s counterexample)

I want to do a backtracking approach (best approach that I can come up with). Currently I have troubles implementing it.

I want to store the jobs and their precedences. Then I identify a set A which contains all jobs that can be solved during the current time unit. Then I find a set B (it contains all sets of jobs which I consider solving during this time unit) which contains all subsets of A which are solvable with the limited number of machines m such that no other job can be added to each subset (by adding a job to one of the subsets the cost of all jobs in that subset exceeds 'm'). Then I repeat the procedure but without the solved jobs (A\B), I do a recursive call for every subset in B. I stop when the passed set of leftover jobs (A\B) is empty (all jobs finished), at that point I return the found schedule if the depth of recursion is <= d (if the deadline is met).

Example of this approach on the example provided by @Ole V.V. :

The steps refer to the depth of recursion, the boxes refer to the jobs (first number is job ID, second is cost in time units. At step 0 I explicitly wrote out the subsets (sets of jobs which I consider solving during this step).

Now my problem is storing the jobs and their precedences, finding the jobs which can be solved in the current time unit (set A), finding the subsets of jobs which I consider solving during the current time unit (set B), and putting it all together in a recursive function which in the end outputs the found schedule or "no schedule found" if there is no schedule which meets the deadline.

- job-scheduling

3 Answers 3

I believe that your greedy algorithm will not always give you the correct result.

Number of machines is 7.

Precedences are

Deadline is 3.

I believe your algorithm will choose

Now job 5 has not been run and the deadline is reached. Your program will says this is impossible.

The following schedule is possible

- 1 Right you are @AnnaVopureta. I have now raised the cost of job 4 to 5 machines, so you can no longer pick jobs 1 and 4 from the start. Please check if my argument holds this time. – Anonymous Commented Jun 19, 2017 at 11:03

- 1 You are right! In this case my algorithm would say that there is no such schedule (even tho there is one). So my approach doesn't work in the general case :/ – PlsWork Commented Jun 19, 2017 at 11:06

- 1 There are a couple of opportunities for pruning your search. One, there is no need to try a proper subset of a set you have already tried since postponing a job you had capacity for will never help you. Two, in my example the jobs 4, 3 and 5 need to run in this order, so with a deadline of 3 their step numbers are fixed. Generally you can use the longest chain of subsequent jobs to determine the latest step a given job can be scheduled. – Anonymous Commented Jun 19, 2017 at 11:20

- 1 First I am thinking at this point you can safely post a new question. I understand you’re probably hesitating after you did that a bit early last time. This time your approach has changed completely, so I should say a new question is clearly warranted. – Anonymous Commented Jun 19, 2017 at 16:08

- 1 Let us continue this discussion in chat . – Anonymous Commented Jun 19, 2017 at 16:11

The problem you are looking at is clearly NP-hard, we can do a reduction from the partition problem as follows: Imagine you have a partition problem with integers s1, s2..., sn. The aim is to find a partition of this set into two sets S1 and S2 such that the sum over S1 is equal to the sum over S2.

We can transform this problem to your problem, by defining a job for each integer (whose cost is the value of the integer), and we add an additional job, that has to be done after all the other jobs. We set d=3

We can easily show that there is a solution to the partition problem if and only if there is a solution to your problem, hence your problem is NP-hard.

- If you agree with the answer, could you please validate it to make it clearer plse ? – Damien Prot Commented Jun 26, 2017 at 15:40

Your approach seems to be fine, but I believe that there is a simpler way. I would suggest you using constraint saisfaction approach. There are quite a few ways of formulating your problem, e.g. mixed-integer programming , MaxSAT . Your task seems to be rather simple and you're sure that there won't be any large numbers, so you can try Minizinc . For example, consider this scheduling example.

If we are talking about Java-specific tools, look at Choco solver .

Your Answer

Reminder: Answers generated by artificial intelligence tools are not allowed on Stack Overflow. Learn more

Sign up or log in

Post as a guest.

Required, but never shown

By clicking “Post Your Answer”, you agree to our terms of service and acknowledge you have read our privacy policy .

Not the answer you're looking for? Browse other questions tagged java algorithm job-scheduling or ask your own question .

- The Overflow Blog

- Best practices for cost-efficient Kafka clusters

- The hidden cost of speed

- Featured on Meta

- Announcing a change to the data-dump process

- Bringing clarity to status tag usage on meta sites

- What does a new user need in a homepage experience on Stack Overflow?

- Feedback requested: How do you use tag hover descriptions for curating and do...

- Staging Ground Reviewer Motivation

Hot Network Questions

- Why doesn’t dust interfere with the adhesion of geckos’ feet?

- Why would autopilot be prohibited below 1000 AGL?

- Work required to bring a charge from an infinite distance away to the midpoint of a dipole

- Word for when someone tries to make others hate each other

- Can Christian Saudi Nationals visit Mecca?

- Short story - disease that causes deformities and telepathy. Bar joke

- Long and protected macros in LaTeX3

- Fusion September 2024: Where are we with respect to "engineering break even"?

- What other marketable uses are there for Starship if Mars colonization falls through?

- Could an empire rise by economic power?

- Is it safe to install programs other than with a distro's package manager?

- Why do sentences with いわんや often end with をや?

- How to run only selected lines of a shell script?

- Microsoft SQL In-Memory OLTP in SQL Express 2019/2022

- Deleting all files but some on Mac in Terminal

- How should I tell my manager that he could delay my retirement with a raise?

- Why is Haji Najibullah's case being heard in federal court in the Southern District of NY?

- Are all citizens of Saudi Arabia "considered Muslims by the state"?

- Risks of exposing professional email accounts?

- What's "the archetypal book" called?

- What is an overview of utilitarian arguments in support of exclusive relationships?

- How do I safely download and run an older version of software for testing without interfering with the currently installed version?

- A bijection of a connected graph that preserves 2-distances but is not an automorphism

- Libsodium: Why hiding the field arithmetics?

Trending Courses

Course Categories

Certification Programs

- Free Courses

Capital Budgeting Resources

- Free Practice Tests

- On Demand Webinars

Assignment Method

Published on :

21 Aug, 2024

Blog Author :

Edited by :

Reviewed by :

Dheeraj Vaidya

What Is The Assignment Method?

The assignment method is a strategic approach to allocating organizational resources, including tasks and jobs to various departments like people, machines, or teams. It aims to minimize total costs or completion time and gain maximum efficiency, by assigning resources to corresponding units.

The assignment procedure's importance stems from its capacity to optimize resource allocation procedures in a business. Organizations may guarantee that resources are used optimally, reducing waste and increasing productivity by implementing a systematic method. It facilitates the decision-making process for the efficient and economical use of resources by helping to make well-informed choices.

Table of contents

Assignment method explained, methodology, advantages & disadvantages, frequently asked questions (faqs), recommended articles.

- The assignment method strategically allocates resources to tasks, jobs or teams to minimize costs or completion time. It optimizes resource utilization, reduces waste, and improves operational efficiency.

- It involves using methods like complete enumeration, simplex, transportation, or the Hungarian method. It involves using the assignment method of linear programming .

- The Hungarian assignment method efficiently solves assignment problems by determining optimal assignments using a cost matrix.

- Advantages include structured resource allocation, enhanced resource utilization, and improved operational effectiveness. Limitations include data accuracy requirements and limited flexibility for dynamic changes.

The assignment method in operation research is a strategy for allocating organizational resources to tasks to increase profit via efficiency gains, cost reductions , and improved handling of operations that might create bottlenecks . It is an operations management tool that, by allocating jobs to the appropriate individual, minimizes expenses , time, and effort.

The technique is an essential tool for project management and cost accounting . It assists in allocating indirect expenses , such as overhead, to objects or cost centers according to predetermined standards, such as direct labor hours or required machine hours. The method helps determine the overall cost of every good or service, which helps with pricing, output, and resource distribution decisions. It also guarantees effective work allocation, on-time project completion, and economical use of resources. In short, it solves assignment problems.

Assignment problems involve assigning workers to specific roles, such as office workers or trucks on delivery routes, or determining which machines or products should be used in a plant during a specific period. Transportation problems involve distributing empty freight cars or assigning orders to factories. Allocation problems also involve determining which machines or products should be used to produce a given product or set of products. Unit costs or returns can be independent or interdependent, and if allocations affect subsequent periods, the problem is dynamic, requiring consideration of time in its solution.

The assignment problem can be solved using four methods: The complete enumeration method, the simplex method, the transportation method, and the Hungarian method.

The complete enumeration approach generates a list of potential assignments between resources and activities, from which the best option is chosen based on factors like cost, distance, time, or optimum profit. If the minimum cost, time, or distance for two or more assignments is the same, then this approach offers numerous optimal solutions. However If there are a lot of assignments, it is no longer appropriate for manual calculations. Assignment method calculators, if reliable, can be used for the same.

The simplex method can be solved as a linear programming problem using the simplex algorithm. The transportation method is a special case of the assignment problem. The method is, however, computationally inefficient for solving the assignment problem due to the solution's degeneracy problem.

The Hungarian assignment method problem, developed by mathematician D. Konig, is a faster and more efficient approach to solving assignment problems. It involves determining the cost of making all possible assignments using a matrix. Each problem has a row representing the objects to be assigned and columns representing assigned tasks. The cost matrix is square, and the optimum solution is to have only one assignment in a row or column. This method is a variation of the transportation problem, with the cost matrix being square and the optimum solution being one assignment in a row or column of the cost matrix.

Let us look into a few examples to understand the concept better.

TechLogistics Solutions, an imaginary delivery company, employs the assignment method to optimize the distribution of its delivery trucks. They meticulously consider distance, traffic conditions, and delivery schedules. TechLogistics efficiently allocates trucks to routes through strategic assignments, effectively reducing fuel costs and ensuring punctual deliveries. This method significantly enhances the company's operational efficiency and optimizes the utilization of its delivery resources.

Suppose XYZ Inc., a manufacturing company, is challenged to efficiently assign tasks to its machines (A, B, and C). Using the assignment method, XYZ calculates the cost matrix, reflecting the cost associated with each task assigned to each machine. Leveraging advanced algorithms like the Hungarian method, the company identifies optimal task-machine assignments, minimizing overall costs. This approach enables XYZ to streamline its production processes and enhance cost-effectiveness in manufacturing operations .

Advantages of the assignment method include:

- Resource allocation is carried out in a structured and organized manner.

- Enhancement of resource utilization to achieve optimal outcomes.

- Facilitation of efficient distribution of tasks.

- Improvement in operational effectiveness and productivity.

- Economical allocation of resources.

- Reduction in project completion time.

- Consideration of multiple factors and constraints for informed decision-making.

The disadvantages of the assignment method are as follows:

- Dependence on accurate and up-to-date data for effective decision-making.

- Complexity when dealing with resource allocation on a large scale.

- Subjectivity is involved in assigning values to the resource-requirement matrix.

- Limited flexibility in accommodating dynamic changes or unforeseen circumstances.

- Applicable primarily to quantitative tasks, with limitations in addressing qualitative aspects.

Johnson's rule is an operations research method that aims to estimate the optimal sequence of jobs in two work centers to reduce makespan. It optimizes the overall efficiency of the process. In contrast, the assignment method is useful for resource allocation, matching resources to specific tasks or requirements to optimize efficiency.

The study assignment method refers to the process of allocating students to specific courses or study programs based on their preferences, skills etc. It involves matching students with appropriate courses or programs to ensure optimal utilization of educational resources and meet individual student needs.

The assignment method is frequently employed when there is a requirement to allocate restricted resources like personnel, equipment, or budget to particular tasks or projects. It aids in enhancing resource utilization operational efficiency, and enables informed decision-making regarding resource allocation considering various factors and constraints.

This article has been a guide to what is Assignment Method. Here, we explain its methodologies, examples, advantages, & disadvantages. You may also find some useful articles here -

- Cost Allocation Methods

- Propensity Score Matching

- Regression Discontinuity Design

- Engineering Mathematics

- Discrete Mathematics

- Operating System

- Computer Networks

- Digital Logic and Design

- C Programming

- Data Structures

- Theory of Computation

- Compiler Design

- Computer Org and Architecture

Johnson’s Rule in Sequencing Problems

The sequencing problem deals with determining an optimum sequence of performing a number of jobs by a finite number of service facilities (machine) according to some pre-assigned order so as to optimize the output. The objective is to determine the optimal order of performing the jobs in such a way that the total elapsed time will be minimum.

Consider there are jobs 1,2,3,…….,n to be processed through m machines. (Machine A, Machine B, Machine C, ……, Machine n). The objective is to find a feasible solution, such that the total elapsed time is minimum. We can solve this problem using Johnson’s method. This method provides solutions to n job 2 machines, n job 3 machines, and 2 jobs m machines.

Johnson’s Algorithm:

Johnson’s rule in sequencing problems is as follows:

- Find the smallest processing time on Machine 1 and Machine 2.

- a) If the smallest value is in Machine 1 process that job first. b) If the smallest value is in the Machine 2 process that job last.

- a) if the minimum time for both Machine 1 and Machine 2 is equal, then perform the job of Machine 1 first and then the job of Machine 2. b) if there is a tie for a minimum time among jobs in Machine 1, select the job corresponding to the minimum of Machine 2 and process it first. c) if there is a tie for a minimum time among jobs in Machine 2, select the job corresponding to the minimum of Machine 1 and process it last.

- And then calculate the total elapsed time( the time interval between starting the first job and completing the last job) and Idle time( the time during which the machine remains idle during the total elapsed time.

In this article, we will understand this problem through n job 2 machines. We have to find the sequence of jobs to be executed in different machines to minimize the total time.

| Jobs | Machine 1 | Machine 2 |

|---|---|---|

| J1 | 9 | 7 |

| J2 | 5 | 4 |

| J3 | 10 | 9 |

| J4 | 1 | 5 |

| J5 | 3 | 2 |

Solution: The smallest time is 1 for Machine 1, process it first.

| J4 |

|---|

Next, the smallest time is 2 for Machine 2, process it last

| J4 | J5 |

|---|

The next smallest time is 3 of job 5 but Job 5 is already being processed by Machine 2. Discard it.

Next, the smallest time is 4 for Machine 2, process it last just before J5.

| J4 | J2 | J5 |

|---|

The next smallest time is 5 for job 2 but job 2 is already being processed by Machine 2. Discard it.

Next, the smallest value is 7 for Machine 2, process it last just before J2.

| J4 | J1 | J2 | J5 |

|---|

Next, the smallest value is for Machine 1 & Machine 2, J1 of Machine 1 is already being processed on Machine 2 . So, take J3 of Machine 2 and process it last just before J3.

| J4 | J3 | J1 | J2 | J5 |

|---|

So, the final sequence of processing the jobs is J4, J3, J1, J2, and J5.

| Job | Machine 1 | Machine 2 | ||

|---|---|---|---|---|

| In Time | Out Time | In Time | Out Time | |

| J4 | 0 | 0+1=1 | 1 | 1+5=6 |

| J3 | 1 | 1+10=11 | 6 | 6+9=15 |

| J1 | 11 | 11+9=20 | 15 | 15+7=22 |

| J2 | 20 | 20+5=25 | 22 | 22+4=26 |

| J5 | 25 | 25+3=28 | 26 | 26+2=28 |

Please Login to comment...

Similar reads.

- Computer Subject

- Operating Systems

- Top Android Apps for 2024

- Top Cell Phone Signal Boosters in 2024

- Best Travel Apps (Paid & Free) in 2024

- The Best Smart Home Devices for 2024

- 15 Most Important Aptitude Topics For Placements [2024]

Improve your Coding Skills with Practice

What kind of Experience do you want to share?

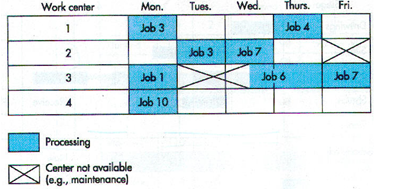

Loading and Sequencing

Loading refers to the assignment of jobs to processing (work) centers and to various machines in the work centers. Problems arise when two or more jobs are to be processed and there are a number of work centers capable of performing the required work. Managers often seek an arrangement that will minimize processing and setup costs, minimize idle time among work centers, or minimize job completion time.

Loading involves specific tasks being allocated to specific teams, individuals, or facilities. Once there is adequate capacity, loading is used to assign each worker the task they can perform best. In the case of a machine or a facility, loading is used to assign the process to the one that can carry it out most efficiently.

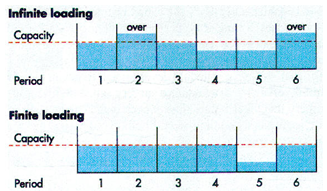

There are two approaches used to load work centers:

- infinite – The infinite loading method assigns work to work centers without that center’s capacity being taken into account. With the infinite loading approach, priority rules are suitable. This means that jobs are loaded at work centers according to the predefined priority rule. This approach is known as vertical loading. If an organization has limited capacity and uses infinite loading, it may have to increase capacity through overtime, subcontracting, or expansion.

- finite – With finite loading, the start and stop time of each job at the work center is projected.

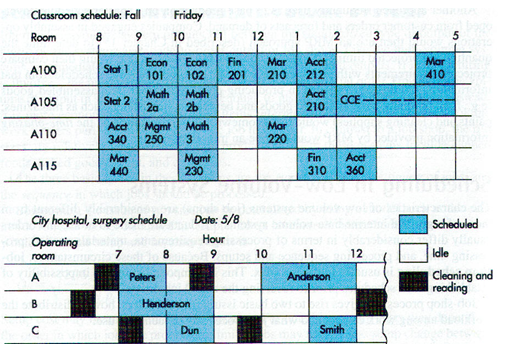

Gantt Chart

Gantt charts are used as visual aid for loading and scheduling purposes. The name was derived from Henry Gantt in the early 1900s. The purpose of Gantt charts is to organize and clarify the actual or intended use of resources in a time framework. In most cases, a time scale is represented horizontally, and resources to be scheduled are listed vertically. The use of resources is reflected in the body of the chart.

There are a number of different types of Gantt charts. Two of the most commonly used are the load chart and the schedule chart.

A load chart depicts the loading and idle times for a group of machines or a list of departments. The chart shows when certain jobs are scheduled to start and finish, and where to expect idle time. If all centers perform the same kind of work, the manager might want to free one center for a long job or a rush order.

Two different approaches are used to load work centers, infinite loading and finite loading . Infinite loading assign jobs to work centers without regard to the capacity of the work center. One possible result of infinite loading is the formation of queues in some work centers. Finite loading projects actual job starting and stopping times at each work center, taking into account the capacities of each work center and the processing times of jobs, so that capacity is not exceeded. Schedules based on finite loading may have to be updated often, perhaps daily, due to processing delays at work centers and the addition of new jobs or cancellation of current jobs. The following diagram illustrates these two approaches.

Loading can be done in various ways. Vertical loading refers to loading jobs at a work center job by job, usually according to some priority criterion. Vertical loading does not consider the work center’s capacity (i.e., infinite loading). With vertical loading, a manager may need to make some response to overloaded work centers. Among the possible responses are shifting work to other periods or other centers, working overtime, or contracting out a portion of the work. In contrast, horizontal loading involves loading the job that has the highest priority on all work centers it will require, then the job with the next highest priority, and so on. Horizontal loading is based on finite loading.

One possible result of horizontal loading is keeping jobs waiting at a work center even though the center is idle, so the center will be ready to process a higher priority job that is expected to arrive shortly. That would not happen with vertical loading; the work center would be fully loaded, although a higher priority job would have to wait if it arrived while the work center was busy. So, the horizontal loading takes a more global approach to scheduling, while vertical loading uses a local approach.

Which approach is better? That depends on various factors: the relative costs of keeping higher priority jobs waiting, the cost of having work centers idle, the number of jobs, the number of work centers, the potential for processing disruptions, the potential for new jobs and job cancellations, and so on.

Schedule Chart

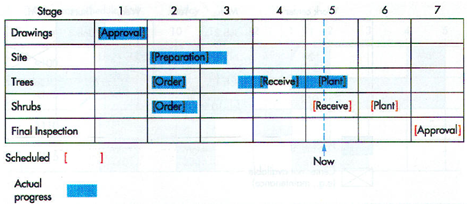

There are two general approaches to scheduling: forward scheduling and backward scheduling. Forward scheduling means scheduling ahead from a point in time; backward scheduling means scheduling backward from a due date. Forward scheduling is used if the issue is “How long will it take to complete this job?” Backward scheduling would be used if the issue is ” When is the latest job can be started and still be completed by the due date?” A manager often uses a schedule chart to monitor the progress of jobs. A typical schedule chart is illustrated below for a landscaping job.

The chart shows planned and actual starting and finishing times for the five stages of the job. The chart indicates that approval and ordering of trees and shrubs was on schedule. The site preparation was a little behind schedule The trees were received earlier than expected, and planting is ahead of schedule. However, the shrubs have not yet been received. The chart indicates some slack between scheduled receipt of shrubs and shrub planting, so if the shrubs arrive by the end of the week, it appears the schedule can still be met.

The Gantt charts possess certain limitations. The chief one is the need to repeatedly update a chart to keep it current. In addition, a chart does not directly reveal costs associated with alternative loading. Finally, a job’s processing time may vary depending on the work center; certain work stations or work centers may be capable of processing some jobs faster than other stations.

Input / Output Control

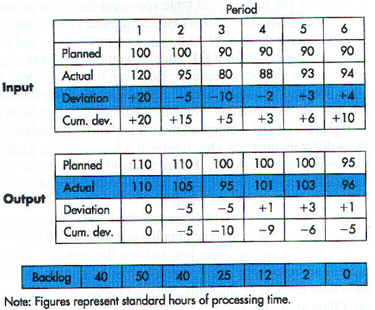

Input / output (I/O) control refers to monitoring the work flow and queue length at work centers. The purpose is to manage work flow so that queues and waiting times are kept under control. A simple example of I/O control is the use of stoplights on some expressway on ramps. These regulate the flow of entering traffic according to the current volume of expressway traffic. The following figure illustrates an input / output report for a work center. The deviation in each period are determined by subtracting “planned” from “actual”. The backlog for each period is determined by subtracting the “actual output” from the “actual input” and adjusting the backlog from the previous period by that amount.

Assignment Method of Linear Programming

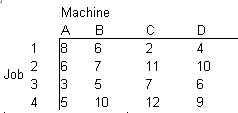

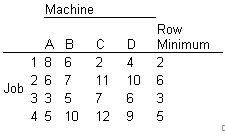

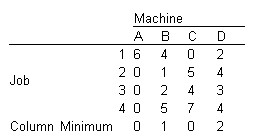

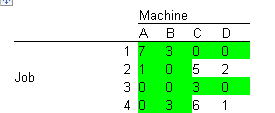

The following table illustrates a typical problem, where four jobs are to be assigned to four machines

The numbers in the body of the table represent the value or cost associated with each job machine combination. In this case, the numbers represent costs. If the problem involved minimizing the cost for job 1 alone, it would clearly be assigned to machine C. For n machines, there are n! different possibilities. For 12 jobs, there would be 479 million different matches! A simple solution method for one-to-one matching is called the Hungarian method to identify the lowest-cost solution. The method assumes that every machine is capable of handling every job, and that the costs or values associated with each assignment combination are known and fixed. When profits instead of costs are involved, the profits can be converted into relative costs by subtracting every number in the table from the largest number and then processing as in a minimization problem. In addition, specific combinations can be avoided by assigning a relatively high cost to that combination. The basic procedure of the Hungarian method is:

- Row reduction: Subtract the smallest number in each row from every number in the row.

- Column reduction: Subtract the smallest number in each column of the new table from every number in the column.

- Test whether an optimum assignment can be made by determining the minimum number of lines (horizontal or vertical) needed to cross out all zeros. If the number of lines equals the number of rows, an optimum assignment is possible. In that case, go to step 6. Otherwise, go on to step 4.

- If the number of lines is less than the number of rows, modify the table in this way:

- Subtract the smallest uncovered number from every uncovered number in the table.

- Add the smallest uncovered number to the numbers at intersections of cross-out lines.

- Numbers crossed out but not at intersections of cross-out lines carry over unchanged to the next table.

- Repeat steps 3 and 4 until an optimal table is obtained.

- Make the assignments. Begin with rows and columns with only one zero. Match items that have zeros, using only one match for each row and each column. Eliminate both the row and the column after the match.

Determine the optimum assignment of jobs to machines for the following data.

Subtract the smallest number in each row from every number in the row, and enter the result in a new table. The result of this row reduction is

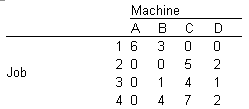

Subtract the smallest number in each column from every number in the column, and enter the results in a new table. The result of this column reduction is

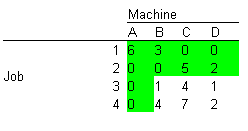

Determine the minimum number of lines (in green background) needed to cross out all zeros. (Try to cross out as many zeros as possible when drawing lines.)

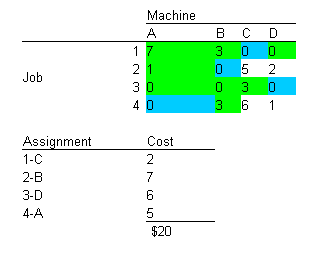

Since only three lines are needed to cross out all zeros and the table has four rows, this is not the optimum. Subtract the smallest value that hasn’t been crossed out (in this case, 1) from every number that hasn’t been crossed out, and add it to numbers that are at the intersections of covering lines. The results are

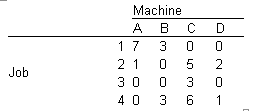

Determine the minimum number of lines needed to cross out all zeros (four). Since this equals the number of rows, you can make the optimum assignment.

Make assignments: Start with rows and columns with only one zero. Match jobs with machines that have a zero cost.

Sequencing is concerned with determining both the order in which jobs are processed at various work centers and the order in which jobs are processed at individual workstations within the work centers. When work centers are heavily loaded, the order of processing can be very important in terms of costs associated with jobs waiting for processing and in terms of idle time at the work centers.

Priority rules are simple heuristics used to select the order in which the jobs will be processed. Some of the most common are listed below.

- FCFS (first come, first served): Jobs are processed in the order in which they arrive at a machine or work center.

- Last Come First Served (LCFS) – The first job loaded to a machine in a work center will be the last one that arrives.

- SPT (shortest processing time): Jobs are processed according to processing time at a machine or work center, shortest job first.

- EDD (earliest due date): Jobs are processed according to due date, earliest due date first.

- CR (critical ratio): Jobs are processed according to smallest ratio of time remaining until due date to processing time remaining.

- S/O (slack per operation): Jobs are processed according to average slack time (time until due date minus remaining time to process). Compute by dividing slack time by number of remaining operations, including the current one.

- Rush: Emergency or preferred customers first.

The rules generally rest on the following assumptions.

- The set of jobs is known; no new jobs arrive after processing begins; and no jobs are canceled.

- Setup time is independent of processing sequence.

- Setup time is deterministic.

- Processing time is deterministic rather than variable.

- There will be no interruptions in processing such as machine breakdowns, accidents, or work illness.

Job time usually includes setup and processing times. Jobs that require similar setups can lead to reduced setup times, if the sequencing rule takes this into account (the rules here do not).

Due dates may be the result of delivery times promised to customers, MRP processing, or managerial decisions. They are subject to revision and must be kept current to give meaning to sequencing choices. It should be noted that due date associated with all rules except S/O and CR are for the operation about to be performed; due dates for S/O and CR are typically final due dates for orders rather than intermediate, departmental deadlines.

The priority rules can be classified as either local or global. Local rules take into account information pertaining only to a single workstation; global rules take into account information pertaining to multiple workstations. FCFS, SPT, and EDD are local rules; CR and S/O are global rules. Rush can be either local or global. Global rules require more effort than local rules. A major complication in global sequencing is that not all jobs require the same processing or even the same order of processing. As a result, the set of jobs is different for different workstations. Local rules are particularly useful for bottleneck operations, but they are not limited to those situations. The effectiveness of any given sequence is frequently judged in terms of one or more performance measures. The most frequently used performance measures are:

Job flow time: Job flow time is the length of time that begins when a job arrives at the shop, workstation, or work center, and ends when it leaves the shop, workstation, or work center. It includes not only actual processing time but also any time waiting to be processed, transportation time between operations, and any waiting time related to equipment breakdowns, unavailable parts, quality problems, and so on. The average flow time for a group of jobs is equal to the total flow time for the jobs divided by the number of jobs.

Job lateness: This is the length of time the job completion date is expected to exceed the date the job was due or promised to a customer. If we only record differences for jobs with completion times that exceed due dates, and assign zeros to jobs that are early, the term we use to refer to that is job tardiness.

Makespan: Makespan is the total time needed to complete a group of jobs. It is the length of time between the start of the first job in the group and the completion of the last job in the group.

Average number of jobs: Jobs that are in a shop are considered to be work-in-process inventory. If the jobs represent equal amounts of inventory, the average number of jobs will also reflect the average work-in-process inventory. The average work-in-process for a group of jobs can be computed using the following formula:

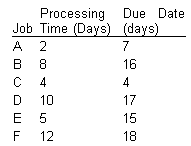

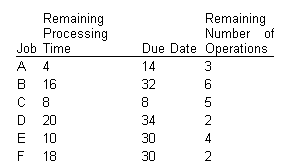

Processing times (including setup times) and due dates for six jobs waiting to be processed at a work center are given in the following table. Determine the sequence of jobs, the average flow time, average days late, and average number of jobs at the work center, for each of these rules:

Assume jobs arrived in the order shown.

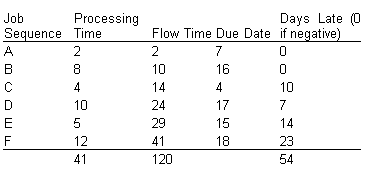

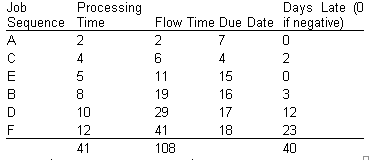

The FCFS sequence is simple A-B-C-D-E-F. The measures of effectiveness are (see table below):

Average flow time: 120/6 = 20 days.

Average tardiness: 54/6 = 9 days.

The makespan is 41 days. Average number of jobs at the work center: 120/41=2.93.

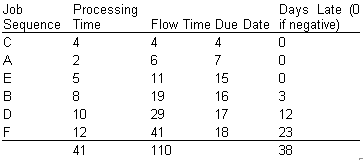

Using the SPT rule, the job sequence is A-C-E-B-D-F (see the following table). The resulting values for the three measures of effectiveness are

Average flow time: 108/6 = 18 days.

Average tardiness: 40/6 = 6.67 days.

The makespan is 41 days. Average number of jobs at the work center: 108/41=2.63.

Using earliest due date as the election criterion, the job sequence is C-A-E-B-D-F. The measures of effectiveness are (see table):

Average flow time: 110/6 = 18.33 days.

Average tardiness: 38/6 = 6.33 days.

The makespan is 41 days. Average number of jobs at the work center: 110/41=2.68.

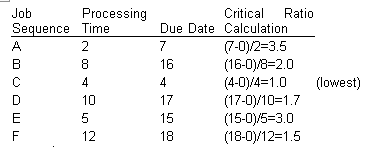

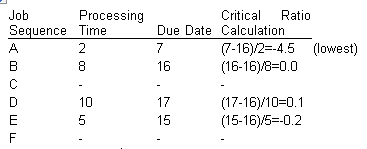

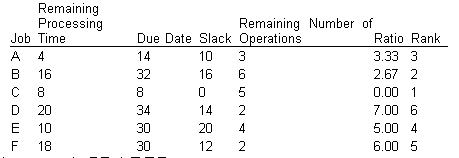

Using the critical ratio we find:

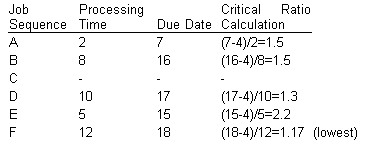

At day 4 [C completed], the critical ratios are:

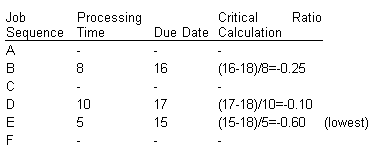

At day 16 [C and F completed], the critical ratios are:

At day 18 [C, F, and A completed], the critical ratios are:

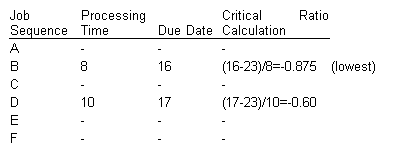

At day 23 [C, F, A, and E completed], the critical ratios are:

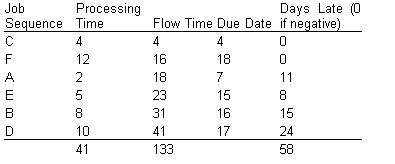

The job sequence is C-F-A-E-B-D, and the resulting values for the measures of effectiveness are:

Average flow time: 133/6 = 22.17 days.

Average tardiness: 58/6 = 9.67 days.

The makespan is 41 days. Average number of jobs at the work center: 133/41=3.24.

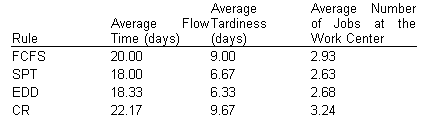

The results of these four rules are summarized below.

Generally speaking, SPT is superior in terms of minimizing flow time and, hence, in terms of minimizing the average number of jobs at the work center and completion time. The FCFS rule and the CR rule turn out to be the least effective of the rules.

The primary limitation of FCFS rule is that long jobs will tend to delay their jobs. However, for service systems in which customers are directly involved, the FCFS rule is by far the dominant priority rule, mainly because of the inherent fairness but also because of the inability to obtain realistic estimates of processing time for individual jobs. The FCFS rule also has the advantage of simplicity. If other measures are important when there is high customer contact, companies may adopt the strategy of moving processing to the “backroom” so they don’t necessarily have to follow FCFS.

Because the SPT rule always results in the lowest (i.e., optimal) average completion (flow) time, it can result in lower in-process inventories. And, because it often provides the lowest (optimal) average tardiness, it can result in better customer levels. Finally, since it always involves a lower average number of jobs at the work center, there tends to be less congestion in the work area. SPT also minimizes downstream idle time. However, due dates are often uppermost in managers’ minds, so they may not use SPT, because it doesn’t incorporate due dates. The major disadvantage of the SPT rule is that it tends to make long jobs wait, perhaps for rather long times (especially if new, shorter jobs are continuously added to the system). Various modifications may be used in an effort to avoid this. For example, after waiting for a given time period, any remaining jobs are automatically moved to the head of the line. This is known as the truncated SPT rule.

The EDD rule directly addresses due dates and usually minimizes lateness. Although it has intuitive appeal, its main limitation is that it does not take processing time into account. One possible consequence is that it can result in some jobs waiting a long time, which adds to both in-process inventories and shop congestion.

The CR rule is easy to use and has intuitive appeal. Although it had the poorest showing in the example for all three measures, it usually does quite well in terms of minimizing job tardiness. Therefore, if jab tardiness is important the CR rule might be the best choice among the rules.

Use S/O (slack per operation) rule to schedule the following jobs. Note that processing time includes the time remaining for the current and subsequent operations. In addition, you will need to know the number of operations remaining, including the current one.

Determine the difference between the due date and the processing time for each operation. Divide the amount by the number of remaining operations, and rank them from low to high. This yields the sequence of jobs:

The indicated sequence is C-B-A-E-F-D.

Using the S/O rule, the designated job sequence may change after any given operation, so it is important to re-evaluate the sequence after each operation. Note that any of the previously mentioned priority rules could be used on a station-by-station basis for this situation; the only difference is that the S/O approach incorporates downstream information in arriving at a job sequence.

Sequencing Jobs Through Two Work Centers

Johnson’s rule is a technique that managers can use to minimize the makespan for a group of jobs to be processed on two machines or at two successive work centers (sometimes referred to as a two-machine flow shop). It also minimizes the total idle time at the work centers. For the technique to work, several conditions must be satisfied:

- Job time (including setup and processing) must be known and constant for each job at each work center.

- Job times must be independent of the job sequence.

- All jobs must follow the same two-step work sequence.

- Job priorities cannot be used.

- All units in a job must be completed at the first work center before the job moves on to the second work center.

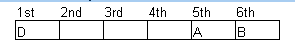

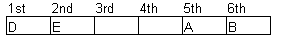

Determination of the optimum sequence involves these steps:

- List the jobs and their times at each work center.

- Select the job with the shortest time. If the shortest time is at the first work center, schedule that job first; if the time is at the second work center, schedule the job last. Break ties arbitrarily.

- Eliminate the job and its time from further consideration.

- Repeat steps 2 and 3, working toward the center of the sequence until all jobs have been scheduled.

When significant idle time at the second work center occurs, job splitting at the first center just priori to the occurrence of idle time may alleviate some of it and also shorten throughput time.

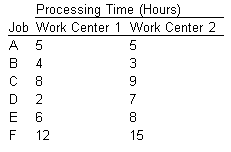

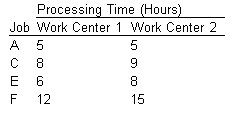

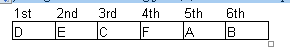

A group of six jobs is to be processed through a two-machine flow shop. The first operation involves cleaning and the second involves painting. Determine a sequence that will minimize the total completion time for this group of jobs. Processing times are as follows:

Select the job with the shortest processing time. It is job D with a time of 2 hours.

Since the time is at the first center, schedule job D first. Eliminate job D from further consideration.

Job B has the next shortest time. Since it is at the second work center, schedule it last and eliminate job B from further consideration. We now have

The remaining jobs and their times are

Note that there is a tie for the shortest remaining time: job A has the same time at each work center. It makes no difference, then, whether we place it toward the beginning or the end of the sequence. Suppose it is placed arbitrarily toward the end. We now have

The shortest remaining time is 6 hours for job E at work center 1. Thus, schedule that job toward the beginning of the sequence (after job D). Thus,

Job C has the shortest time of the remaining two jobs. Since it is for the first work center, place it third in the sequence. Finally, assign the remaining job (F) to the fourth position and the result is

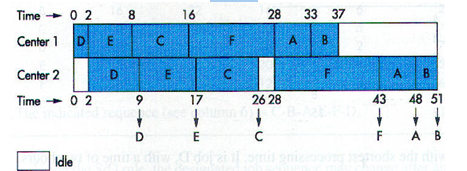

One way to determine the throughput time and idle times at the work centers is to construct a chart:

Thus, the group of jobs will take 51 hours to complete. The second work center will wait 2 hours for its first job and also wait 2 hours after finishing job C. Center 1 will be finished in 37 hours. Of course, idle periods at the beginning or end of the sequence could be used to do other jobs or for maintenance or setup/teardown activities.

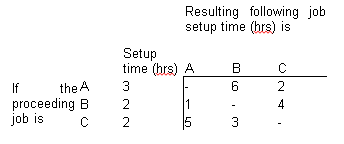

Sequence Jobs When Setup Times Are Sequence-Dependent

The simplest way to determine which sequence will result in the lowest total setup time is to list each possible sequence and determine its total setup time. As the number of jobs increases, a manager would use a computer to generate the list and identify the best alternative(s).

Important Guidelines

- Setting realistic due dates.

- Focusing on bottleneck operations: First, try to increase the capacity of the operations. If that is not possible or feasible, schedule the bottleneck operations first, and then schedule the non-bottleneck operations around the bottleneck operations.

- Considering lot splitting for large jobs. This probably works best when there are relatively large differences in job times.

Get Govt. Certified Secure Assured Job Interview

Government certificate

Lifetime Valid

Job Support

Industry Recognized

Advance Your Career: Upskill Now!

Get industry recognized certification – contact us.

An official website of the United States government

VENDING MACHINE ATTENDANT A04

Marine Corps Community Services (MCCS) is looking for the best and brightest to join our Team! MCCS is a comprehensive program that supports and enhances the quality of life for Marines, their families, and others in the Marine Corps Community. We offer a team oriented environment comprised of military personnel, civilian employees, contractors and volunteers who keep the organization functioning smoothly and effectively.

- Accepting applications

Open & closing dates

09/04/2024 to 09/25/2024

$20.60 - $20.60 per hour

Pay scale & grade

1 vacancy in the following location:

- Washington, DC 1 vacancy

Telework eligible

Travel required.

25% or less - Varies

Relocation expenses reimbursed

Appointment type, work schedule.

Competitive

Promotion potential

Job family (series).

- 4801 Miscellaneous General Equipment Maintenance

Supervisory status

Security clearance.

Not Required

Announcement number

Control number, this job is open to.

U.S. Citizens, Nationals or those who owe allegiance to the U.S.

Clarification from the agency

Open to Public

Receives and loads vending items for delivery to vending machine locations. Removes aged food or other merchandise from the machines; replenish merchandise; and make appropriate notations on required documents. Monitors brands and sales prices to ensure adequate stocking levels and compliance with approved selling prices. Cleans interior and exterior machines to ensure compliance with sanitation regulations. May make minor repairs such as removing coins that have jammed or clearing dispensing paths. Collects money and turns it into supervisor or designated cashier upon end of route. Drives motor vehicles with a gross vehicle weight up to 10,000 pounds through installation under limited traffic conditions at low speeds.

Provides World Class customer service with an emphasis on courtesy. Assists customers and communicates positively in a friendly manner. Takes action to solves problems quickly. Alerts the higher-level supervisor, or proper point of contact for help when problems arise. Adheres to safety regulations and standards. Promptly reports any observed workplace hazard and any injury, occupational illness, and/or property damage resulting from workplace mishaps to the immediate supervisor. Adheres to established standards of actively supporting the principles of EEO program and prevention of sexual harassment..

Performs other related duties.

Requirements

Conditions of employment.

- See Duties and Qualifications

EVALUATIONS:

Qualifications

Skills and Knowledge: Basic skills sufficient to start and stop and back up a motor vehicle. Knowledge of the height, width, length and weight of vehicle to operate safely. Ability to read and understand installation maps and other locator documents for finding various buildings and facilities. Ability to load and arrange cargo to prevent shifting, falling, and breakage. Driver's license required.

Responsibility: Receives instructions from supervisor on route or specific trip assignment. Independently fills and cleans machines. Work is checked and evaluated for timelines, adequate stocking of merchandise, and the safe and accurate recording and transport of funds/

Physical effort: Light to moderate effort is required in bending, stooping, lifting, and stocking. Lifts and carries objects up to 45 pounds independently and objects over 45 pounds with assistance.

Working Conditions: Works both inside and outside and occasionally is exposed to bad weather conditions. Drives in all types of weather and is expected to possibility of cuts, bruises, and broken bones. Must wear issued protective gear.

Additional information

GENERAL INFORMATION: Applicants are assured of equal consideration regardless of race, age, color, religion, national origin, gender, GINA, political affiliation, membership or non-membership in an employee organization, marital status, physical handicap which has no bearing on the ability to perform the duties of the position. This agency provides reasonable accommodations to applicants with disabilities. If you need a reasonable accommodation for any part of the application and hiring process, please notify the agency. The decision on granting reasonable accommodation will be on a case-by-case basis.

It is Department of Navy (DON) policy to provide a workplace free of discrimination and retaliation. The DON No Fear Act policy link is provided for your review: https://www.donhr.navy.mil/NoFearAct.asp.

A career with the U.S. government provides employees with a comprehensive benefits package. As a federal employee, you and your family will have access to a range of benefits that are designed to make your federal career very rewarding. Opens in a new window Learn more about federal benefits .

The Federal government offers a number of exceptional benefits to its employees. Benefits you get to enjoy while working at MCCS include but are not limited to:

• Stability of Federal Civilian Service

• People with passion for doing work that matters

• Quality of Work Life Balance

• Competitive Pay

• Comprehensive Benefit Packages

• Marine Corps Exchange and Base Facility Privileges

Review our benefits

Eligibility for benefits depends on the type of position you hold and whether your position is full-time, part-time or intermittent. Contact the hiring agency for more information on the specific benefits offered.

How You Will Be Evaluated

You will be evaluated for this job based on how well you meet the qualifications above.

Your application/resume and supporting documentation will be used to determine whether you meet the job qualifications listed on this announcement. This vacancy will be filled by the best qualified applicant as determined by the selecting official.

As a new or existing federal employee, you and your family may have access to a range of benefits. Your benefits depend on the type of position you have - whether you're a permanent, part-time, temporary or an intermittent employee. You may be eligible for the following benefits, however, check with your agency to make sure you're eligible under their policies.

Varies - Review "OTHER INFORMATION"

If you are relying on your education to meet qualification requirements:

Education must be accredited by an accrediting institution recognized by the U.S. Department of Education in order for it to be credited towards qualifications. Therefore, provide only the attendance and/or degrees from schools accredited by accrediting institutions recognized by the U.S. Department of Education .

Failure to provide all of the required information as stated in this vacancy announcement may result in an ineligible rating or may affect the overall rating.

All applications must be submitted online via the MCCS Careers website: https://careers.usmc-mccs.org

Resumes/applications emailed or mailed will not be considered for this vacancy announcement. To be considered for employment, the application or resume must be submitted online by 11:59 PM (ET) on the closing date of the announcement.

Note: To check the status of your application or return to a previous or incomplete application, log into your MCCS user account and review your application status.

Agency contact information

All applicants who submit an application via our Careers page at https://careers.usmc-mccs.org will be able to view their application status online.

The Federal hiring process is set up to be fair and transparent. Please read the following guidance.

- Criminal history inquiries

- Equal Employment Opportunity (EEO) Policy

- Financial suitability

- New employee probationary period

- Privacy Act

- Reasonable accommodation policy

- Selective Service

- Signature and false statements

- Social security number request

Required Documents

How to apply, fair & transparent.

This job originated on www.usajobs.gov . For the full announcement and to apply, visit www.usajobs.gov/job/807823200 . Only resumes submitted according to the instructions on the job announcement listed at www.usajobs.gov will be considered.

Learn more about

U.S. Marine Corps

Serving Those Who Serve

Visit our careers page

Learn more about what it's like to work at U.S. Marine Corps, what the agency does, and about the types of careers this agency offers.

https://careers.usmc-mccs.org/

Your session is about to expire!

Your USAJOBS session will expire due to inactivity in eight minutes. Any unsaved data will be lost if you allow the session to expire. Click the button below to continue your session.

Production Assembler I

Responsibilities for this position.

Performs project tasks/assignments of a basic nature ranging from repetitive to non-repetitive production assembly operations on electronic and/or mechanical assemblies and subassemblies such as modules, boards, panels, drawers, frames, and cables.

Follows methods, techniques, and sequence of operations in performing wiring, component installation, hand soldering, & cable harnessing on sub-assemblies and units

- Read and interpret basic blueprints and drawings. Perform single tasks for extended periods of time. Work with basic hand tools. Accurately complete process paperwork and entering data into the applicable work order management system. May perform mixing of epoxies per specification. Able to work with chemicals without limitations, while adhering to the prescribed PPE. Must comply with all safety requirements such as but limited to PPE, chemical handling and safety related trainings. Read and interpreting basic schematics and drawings.

- Able to focus on single tasks for extended periods of time. Able to sit for extended periods of time. Basic English Strong hand/eye coordination and manual dexterity. Comfortable working with small/delicate components. General communication skills, both written and verbal. Ability to frequently sit, stand, walk reach within hands and arms length, stoop, kneel, and crouch. Ability to regularly lift and/or move up to 10 pounds, occasionally lift and/or move up to 25 pounds. Basic math knowledge. Ability to interpret basic documents and work instructions.Physical Demands:

- Requires regular movement throughout GD-OTS facilities.

- Must be able to remain in a stationary position at a desk and/or computer for extended periods of time.

- May need to stand for long periods of time.

- Must be able to lift up to 45 pounds.

- Work may require employee to work inside and outside with exposure to changing climate and/or operate machinery.

- May be requested to work a different shift

- Must be willing to work outside of normal business hours as required.

PI248965769

General Dynamics Ordnance and Tactical Systems is a global leader in the design, engineering and production of munitions, weapons, lightweight tactical vehicles, missile components and armament systems around the world.

Share this job

We use cookies to enhance your website experience. By continuing to visit this site, you agree to our use of cookies. Learn More

COMMENTS

A typical assignment problem, presented in the classic manner, is shown in Fig. Here there are five machines to be assigned to five jobs. The numbers in the matrix indicate the cost of doing each job with each machine. Jobs with costs of M are disallowed assignments. The problem is to find the minimum cost matching of machines to jobs.

Find an optimum assignment of jobs to the machines to minimize the total processing time and also find for which machine no job is assigned. What is the total processing time to complete all the jobs. Solution: Since the cost matrix is not a square matrix the problem is unbalanced. We add a dummy job 5 with corresponding entries zero. Modified ...

Machineco has four machines and four jobs to be completed. Each machine must be assigned to complete one job. ... Based on the assignment proposed above, the set up times for the machines have ...

Step 7- F or assigning the job, find minimum number of zero in each row or. column, allocate that zero to the respective machine and subtract the. actual time of allocated job to the available ...

1.1 Formulation of Nash equilibria. A feasible assignment A is a Nash equilibrium if no user i (assume (i, j) ∈ A) has unilateral incentive to put his job on a machine k 6= j where k ∈ Si. In other words, assignment A is at Nash if and only if for all i (assuming (i, j) ∈ A) and all k ∈ Si: rj(Lj) ≤ rk(Lk + pi) Example.

The goal is to assign the jobs to the machines at the least total cost. The situation is known as the assignment problem. An assignment problem is a balanced transportation problem in which all supplies and demands equal to 1. In this model jobs represent supplies and machines represent demands.

But what if there are multiple jobs to be performed on multiple machines? For this, a Hungarian mathematician developed a method called the assignment model, which can be used to solve such problems. (Note that this method is useful when the number of sources equals the number of destinations and the capacity & demand value is 1 unit).

You want to assign each job to a machine; as before, the goal is to minimize the makespan --- i.e. the maximum, over all machines, of the total processing time of jobs assigned to that machine. Give a polynomial-time algorithm that produces an assignment of jobs to machines with a makespan that is at most three times the optimum.

Download scientific diagram | Optimal assignment of jobs to machines with respect to problem (1) from publication: Flow-based formulations for operational fixed interval scheduling problems with ...

Step 6- Repeat 4 and 5 until the number of lines becomes equal to the number of rows. Step 7- For assigning the job, find minimum number of zero in each row or column, allocate that zero to the ...

The decision problem asks whether an assignment assigns at least k jobs, where k is a parameter to the decision problem. Clearly the problem is in NP; one can verify in polynomial time that an assignment satisfies that no machine is overloaded and each job is assigned to one machine.

The assignment model is useful in solving problems such as, assignment of machines to jobs, assignment of salesmen to sales territories, travelling salesman problem, etc. It may be noted that with n facilities and n jobs, there are n! possible assignments. One way of finding an optimal assignment is to write all the n! possible arrangements ...

over all machines, of the total processing time of jobs assigned to that machine. Give a polynomial-time algorithm that produces an assignment of jobs to machines with a makespan that is at most three times the optimum. Problem 2 Suppose you are given a set of positive integers A = fa 1;a

AMRs are responsible for transporting materials between machines in automated factories. The material transportation process involves the assignment of jobs related to materials. Therefore, the problems of AMR routing and job assignment are intertwined. On one hand, existing industrial software manages routing and assignment problems separately ...

Algorithm Greedy-Balance produces an assignment of jobs to machines with max load T 2T . Proof. Consider the time we add job j into machine M i. The load of machine M i was T i t j before adding J j to M i. Also T i t j was the smallest load. Every other machine has load at least T i t j. Therefore : m(T i t i) X k T k Also we know that P k T k ...

Solution 1: Brute Force. We generate n! possible job assignments and for each such assignment, we compute its total cost and return the less expensive assignment. Since the solution is a permutation of the n jobs, its complexity is O (n!). Solution 2: Hungarian Algorithm. The optimal assignment can be found using the Hungarian algorithm.

Problem description: I have n precedence constrained jobs and m independent machines. Each job has a cost c assigned to it (the number of machines required to finish the job in 1 time unit). It takes 1 time unit to finish a job, a job can only be finished if c machines are assigned to it (jobs are atomic, it's not possible to finish half of the job).. So in short, there are n jobs and their ...

The assignment method is a strategic approach to allocating organizational resources, including tasks and jobs to various departments like people, machines, or teams. It aims to minimize total costs or completion time and gain maximum efficiency, by assigning resources to corresponding units.

Johnson's Algorithm: Johnson's rule in sequencing problems is as follows: Find the smallest processing time on Machine 1 and Machine 2. a) If the smallest value is in Machine 1 process that job first. b) If the smallest value is in the Machine 2 process that job last. a) if the minimum time for both Machine 1 and Machine 2 is equal, then ...

Loading refers to the assignment of jobs to processing (work) centers and to various machines in the work centers. Problems arise when two or more jobs are to be processed and there are a number of work centers capable of performing the required work. Managers often seek an arrangement that will minimize processing and setup costs, minimize ...

J.C. Howard's medical testing company in Kansas wishes to assign a set of jobs to a set of machines. The following table provides the production data of each machine ...

Question: a) The optimal assignment of jobs to machine that will maximize total production is: Machine A Machine B Machine C Machine D →→→→ b) The total production of the assignment = units (enter your response as a whole number). Try focusing on one step at a time. You got this!

Cleans interior and exterior machines to ensure compliance with sanitation regulations. May make minor repairs such as removing coins that have jammed or clearing dispensing paths. ... Receives instructions from supervisor on route or specific trip assignment. Independently fills and cleans machines. Work is checked and evaluated for timelines ...

Job Type: Considered full time for benefits offered-6.5 hours per day with 1/2 hour unpaid lunch. 187 days per school year. No night or weekends and summer off! Job Types: Full-time, Contract. Pay: $15.75 - $21.00 per hour. Expected hours: 32.5 per week. Benefits: Dental insurance; Employee assistance program; Flexible spending account; Health ...

Gain insights from industry professionals with the Analytics Power Hour podcast or read Andriy Burkov's The Hundred-Page Machine Learning Book to get the full picture of machine learning. 17 Data Science Podcasts to Listen to in 2024. 18 IT and Tech Podcasts for Tech Professionals. 8 Machine Learning Books for Beginners: A 2024 Reading List

The Role: As a Machine Repair Journeyperson, you will work under minimal supervision with a high level of independent judgement and problem solving. You should be flexible enough to take on and tackle multiple job assignments in a shift. Preferred Experience Includes: Experience with planned maintenance systems and predictive technologies Experience with industrial robotics, automation, and…

Responsibilities for this Position Production Assembler I US-CA-San Diego Job ID: 2024-32232 Type: Full Time # of Openings: 1 Category: Manufacturing and Production San Diego, CA Overview. Performs project tasks/assignments of a basic nature ranging from repetitive to non-repetitive production assembly operations on electronic and/or mechanical assemblies and subassemblies such as modules ...