Lean Manufacturing Tools

Lean manufacturing tools, techniques and philosophy | lean and related business improvement ideas.

5S Training Presentations

5s pptx and 5s pdf downloads.

If you want to learn all about 5S then the following 5S presentations in ppt (PowerPoint) format and PDF format are available to you for free download. Please note that these 5S Training presentation files are protected by copyright and are to be downloaded for your own personal use only.

- Any commercial use of these 5S presentations and the content therein is prohibited without prior permission. Requests for permission to use can be made through the contact page of http://leanmanufacturingtools.org/contact-page/

- These presentations are for personal use only and cannot be reproduced or circulated by anyone other than www.leanmanufacturingtools.org

- Content may be quoted or reproduced for private and educational assignments as long as a proper citation is given referring to leanmanufacturingtools.org

- The information within these presentations and website are for information purposes only and any action taken is at your own risk.

These lean manufacturing training presentations are organized so that you can tackle the ideas behind 5S one step at a time, for your own education or even to train others within your own organization. Breaking them up into bite sized chunks allows you to learn or teach 5S in manageable and understandable sections even if your available time is limited.

These presentations can be use in conjunction with the following pages here;

Running your own 5S program

How to approach 5S training

Run your own 5S training course in house

5S Training PowerPoint (pptx) Presentations;

Basic introduction to 5s presentations;.

What is 5S – Learn what is 5S.

Benefits of 5S – Learn the benefits of implementing 5S within your organization.

Presentations Detailing Each 5S Stage;

5S Seiri Sort – The first stage of implementing 5S.

5S Seiton Set in Order – The second stage of implementing 5S

5S Seiso Shine – The third stage of implementing 5S

5S Seiketsu Standardize – The forth stage of implementing 5S

5S Shitsuke Sustain – The fifth and final stage of 5S implementation

Lean 6S ppt Training Presentation;

6S – How does 6S differ from 5S and why?

Presentations Supporting Your 5S Training;

5S Red Tag – Learn how to use 5S Red Tags

Runners Repeaters Strangers – Learn how to apply RRS techniques when implementing 5S

Presentation Detailing How to Plan and Conduct Your 5S Implementation;

5S Program Implementation – Step by step guide to implementing 5S within your operations.

5S Training Exercise Presentation;

Training Exercise – 5S Paper exercise; a quick and simple training exercise designed for 5S which will demonstrate the simplicity and effectiveness of 5S.

5S Training PDF Files for Download;

All of the above 5S presentations are also available as 5S PDF files for download;

What is 5S Presentation

Benefits of 5S

5S Seiri or Sort – First stage of 5S

5S Seiton or Set In Order – Second stage of 5S

5S Seiso or Shine – Third stage of 5S

5S Seiketsu or Standardize – Forth stage of 5S

5S Shitsuke or Sustain – Final stage of 5S

5S Runners Repeaters and Strangers

Implementing 5S Program

5S Training Exercise

Should you require a personalized or editable version of these 5S PowerPoint presentations or 5S PDF files just contact the author through the contact page here; Leanmanufacturingtools.org contact page .

Suggestions for improvements or additions to the above 5S training presentations are welcomed.

Related posts:

- Lean Training, Coaching, and Presentations

- Free Lean Presentations

- 5S Training

Post navigation

13 comments for “ 5s training presentations ”.

i want fully details of 5s

Hi K.P. Feel free to download any of the presentations and PDF files here to provide you with all of the info that you need on 5S.

PLEASE BRIEF ON 5S / 6S , LATEST VERSION. 6 SIGMA.

let me know more about it

5’S means house keeping in our Indian language . each and every letters are starting from “S” letters .so,called 1s,2s 3s,4s&5s . on japan language India language 1) seiri -short out 2)seiton -set in order 3) seiso -shine 4)seiketshu -standardization 5)sitsuke -sustain short out -1)material segregated require /un require.if, unwanted material will be put red tag and remove from our working area 2)if,required material then will be put yellow tag .3)if,not required but,well material then will be through to red zone area . Set in Order – required material will be keep by rack /cup board /shelves etc 3)shine identified material clean daily /weekly/yearly 4)standardization this 1s,2s,3s will be keep regularly. 5)sustain this work will be make habit.

How can I download the course?

Samer, Just click on the links to download each of the 5S presentations.

hi Earley i would like develop on these 5 s principles using my domain knowledge in the Oil and Gas upstream sector and would like to conduct workshops to our fraternity please confirm if you have any objection regards Damodaran M

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

CAPTCHA Code *

What Is the 5S Methodology?

The 5S methodology is best summarized by the philosophy, “a place for everything and everything in its place.”

You may have heard of “KonMari,” a home organization system invented by Marie Kondo. The KonMari method transforms cluttered homes into tidy and simplified living spaces. The 5S principles are similar to KonMari. However, saying that 5S is just about tidying is like saying successful manufacturing is just about speed - there is much more depth. So, let’s explore the true intent and meaning of 5S.

5S Japanese Words

5S originated as 5 Japanese words:

5S Meaning in English

In English, these 5S meanings are:

- Sort (Seiri): Eliminate that which is not needed.

- Straighten (Seiton): Organize what remains after sorting.

- Shine (Seisou): Clean and inspect the work area.

- Standardize (Seiketsu): Write standards for 5S.

- Sustain (Shitsuke): Consistently apply the 5S standards.

At their core, these 5S activities build the discipline needed for substantial and continuous improvement by creating (and sustaining) efficient and effective work areas.

Why Is 5S Important in Manufacturing?

While 5S was first developed in the context of the automotive industry, it is now widely considered an essential step for any lean manufacturing program, regardless of industry.

Embedding 5S as part of daily tasks within your company means much more than improved organization, sustained cleaning routines, and efficient activity flows. By using the 5S methodology, operators are encouraged to improve their overall work environment and reduce muda or waste .

Adherence to 5S standards is considered the foundation of Total Productive Maintenance (TPM) and an integral part of the Toyota Production System (TPS) . 5S also creates a stable platform from which Kaizen activities can be launched.

The bottom line - 5S is a low-investment, high-impact lean manufacturing tool that is predicated on people. It engages operators in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement.

What Are the 5 Benefits of a 5S System?

The key benefits of a 5S system include:

- Creating space within your facility by removing unnecessary tools and equipment

- Reducing waste from unnecessary motion by organizing the workspace

- Reducing downtime and improving quality by consistently maintaining equipment

- Engaging operators by granting them more responsibility for their work environment

- Creating a safer work environment by ensuring it is clean and well-maintained

Now that you have a better understanding of why 5S is important and how it can benefit your manufacturing operations, let’s learn more about each of the 5S steps.

Sort (Seiri)

What is sort.

The Sort step separates items in your workspace that you know you need from items that you do not or may not need. Move the latter to a “red tag” holding area.

Why Do You Need Sort?

Sort enables you to have a more productive workspace by removing unneeded clutter (and eliminating distractions). It also is a first step towards opening up space that can be used for other things.

How Do You Implement Sort?

Separate necessary items (e.g., tools, parts, and materials) from unnecessary items. We recommend sorting items into four categories:

- Items needed in this work area. These are items you know that you regularly use in the context of this work area and thus will stay in this work area.

- Items needed in another work area. These are typically misplaced items. If an item is used in another work area, “sort” it into that area by delivering it to the team member responsible for that work area.

- Items you may need. For items you are unsure about, use the 5S “red tag” system. Mark such items with red tags, which at a minimum, should include the name of who tagged the item, why it is thought to no longer be needed, a proposed review date, and the name of the manager who must approve of disposal. Move the item to a red tag holding area, which should be organized by review month to make it easy to manage the area.

- Items you do not need. These are items that you are 100% confident are not needed. They should be immediately discarded, recycled, or donated, or sold if in good condition.

What Are Some Examples of Sort?

- Remove waste (or muda) from your workspace.

- Discard broken or old parts using 5S red tags.

- Responsibly recycle materials and papers.

- Separate everyday tools from special-case tools.

- Avoid overfilling your workspace with excess materials.

- Create an overflow area outside of the workspace for duplicate materials, tools, and parts.

Straighten (Seiton)

What is straighten.

The Straighten step thoroughly organizes the items that remain after sorting, making frequently used items easily accessible and providing every item a clear and easy-to-find home.

Why Do You Need to Straighten?

Straighten enables every item to have a specific home where it can be easily found and to which it can be easily returned. It reduces the waste from excess motion, as items are placed in more ergonomic locations. It is also the second step on the path to opening up space that can be used strategically toward the goal of improving production.

How Do You Implement Straighten?

After you’ve sorted items, it’s time to decide how you want to organize them. We recommend the following methodology:

- Provide easy access to frequently used items. The key to reducing waste from excess motion is to place frequently used items within easy reach.

- Group like items. Group the remaining items into logical categories and brainstorm the best way to organize and store each of these categories.

- Utilize visual designs. For each group, decide on the best way to make it clear when an item is missing or misplaced. A classic example is creating a shadow board for tools.

- Use containers. If it is appropriate for the type of item, consider organizing it within a container.

- Unleash the labeler. If an item is too big to put into a container, consider giving it a frame and putting a label on the item in addition to the frame.

- Be agile . Your initial straighten pass will likely deliver a significant improvement - but you are also likely to overlook some potential improvements. Plan a 5S team meeting with a focus on straightening at the one and two week points, and brainstorm further improvements as part of your initial implementation.

What Are Some Examples of Straighten?

- Give every item a distinct “home.”

- Use color as a way of organizing and creating meaning.

- Integrate shadow boards and other visual indicators into the plant floor.

- Dedicate a surface or area entirely to shadow boxes and tool storage.

- Dedicate another surface or area entirely to working.

Shine (Seisou)

What is shine.

The Shine step elevates the work area by ensuring thoroughly cleaned and inspected tools, equipment, and other items. It also can include routine maintenance on equipment, which is one of the ways it flows directly into TPM .

Why Do You Need to Shine?

Shine creates a work environment that engages and empowers operators by giving them more responsibility and agency over their work area. It also helps them to identify problems before they interfere with production. For example, in a clean work environment, it is much easier to spot emerging issues such as fluid leaks, material spills, metal shavings from unexpected wear, hairline cracks in mechanisms, etc.

How Do You Implement Shine?

After you’ve straightened items, it’s time to elevate the work area by cleaning, inspecting, and in some cases, performing routine maintenance. We recommend the following:

- Grab the metaphorical spray bottle. Using appropriate cleaners and cleaning tools, make the work area sparkle. With every sweep, mop, brush, wipe, wash, and wax, strive to return your workspace to its former glory. Be Miyagi.

- Find the source. The guiding principle of this 5S step is “clean to understand”. If there are any signs of leaks, spills, or unexpected debris, strive to understand the source. It is likely an early warning of a future problem.

- Inspect. After cleaning each item, take a moment to look it over and examine its condition. Does it need updating, maintenance, or repair?

What Are Some Examples of Shine?

- Wipe down equipment.

- Examine the wear of your tools.

- Disassemble larger objects to inspect the state of their parts.

- Investigate a recurring unclean spot or mess.

- Make sure to follow proper cleaning procedures to prevent damage to equipment.

Standardize (Seiketsu)

What is standardize.

The Standardize step is a bridge between the first three 5S steps (Sort, Straighten, Shine) and the last step (Sustain). In this step, your goal is to capture best practices for 5S as standardized work for your team.

Why Do You Need to Standardize?

Standardize makes 5S repeatable. It transforms 5S from a one-off project to a reproducible set of activities.

How Do You Implement Standardize?

It’s time to make sure all your hard work continues to pay dividends into the future. Set expectations for the future with a documented 5S process. To do so, we recommend that you:

- Document in pairs. Have one team member walk through each 5S task as another team member documents it to ensure nothing important is missed.

- Capture the essence. We are huge proponents of simplicity (and agile ). Capture the essence of each task and no more. Otherwise, your documentation will be difficult to maintain.

- Prefer checklists. Checklists feel easy. Short checklists feel even easier. A great format is providing a name for each task that serves as a quick reminder and a more detailed description for training.

- Organize to simplify. Organize your checklists by role, by shift, and by frequency (daily, weekly, monthly). This will make the 5S process much less intimidating to your team.

What Are Some Examples of Standardize?

- Write down your 5S practices.

- Create “implementation” checklists and “audit” checklists.

- Create “kits” that contain the materials needed to perform a specific task.

- Use photos and other simple visuals as part of your training materials.

- Build a schedule for tasks.

Sustain (Shitsuke)

What is sustain.

The Sustain step ensures that 5S is applied on an ongoing basis. It transforms your standardized 5S processes into regularly completed tasks.

Why Do You Need to Sustain?

Iterative 5S processes lock in your gains and ensure further and continued progress.

How Do You Implement Sustain?

Once you’ve standardized, it’s time to continually act upon those standards. We recommend you:

- Create a schedule. Embed 5S practices as scheduled tasks (by role, shift, and frequency).

- Teach through demonstration. Instruct employees on how to conduct 5S tasks through demonstration and training. Showing employees what is expected of them will prepare them to conduct tasks on their own.

- Supervise to solo. After initial 5S training for employees, gently supervise while they continue to form habits. It is easy to make mistakes or fall off course, so patiently and helpfully offer corrections when needed.

- Adapt as necessary. When giving or receiving feedback on tasks, see where changes can be made to make the tasks easier and more efficient. Standardized work is intended to be living documentation.

What Are Some Examples of Sustain?

- Hold a demonstration meeting to explain complex or multi-step processes.

- Perform periodic check-ins after initial training.

- Teach employees to run 5S audits.

- Respond to mistakes with additional training.

- Encourage supervisors and operators to communicate openly and constructively to find ways to improve your 5S implementation.

- Set quarterly audit reminders for reviewing the red tag holding area.

The Bonus S of 5S

Now that you know how to implement each step in the 5S methodology and foster a culture of continuous improvement in your factory, you are ready to learn the bonus S: Safety!

5S is meant to help you improve productivity in your factory, but it is also meant to help create a safe, positive work environment for your team. While preventing workplace injuries is very important - also important is that 5S will make your plant a great place to work. Everyone enjoys a safe, clean, and logically laid out work environment, and it will motivate your employees, leading to better results on the plant floor.

How Does Each of the 5S Steps Contribute to Safety?

- Sort removes items from the plant floor, creating more space. Of course, this space can be used to hold new tools and equipment, but it can also be used to create larger aisles and more open spaces in the factory, removing tripping hazards. Even something as simple as decluttering drawers can prevent injuries (e.g., accidental encounters with a sharp object when rummaging for the tool you need).

- Straighten gives every item a logical home near the location where operators will use it. This prevents operators from rushing around looking for what they need, avoiding chaos on the plant floor that could cause safety hazards. For example, operators could slip, trip, or bump into one another if they have to constantly hurry around looking for tools.

- Shine cleans the workspace and maintains equipment. This prevents leaks or spills from leaving slick spots on the floor and ensures operators have functioning tools so they don’t have to dangerously jerry-rig solutions.

- Standardize makes clear to everyone what needs to be done and to whom each task belongs so tasks are completed on a regular basis. Confusion regarding ownership of responsibilities can cause important jobs to be missed. For example, equipment that is not consistently maintained will likely create safety concerns.

- Sustain ensures your initial 5S efforts are not in vain, keeping your staff happy and on top of any new safety concerns as they arise. One of the most dangerous things you can have in your factory is unmotivated employees who do not care about maintaining the condition of their workplace. Ensuring their efforts to implement a 5S program are recognized and sustained will provide continued motivation.

Overall, the 5S process is worth the initial organizational work for the rewards in safety, production improvement, and employee motivation.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.

Sign up free

Free 5S Training Presentations for Powerpoint and Mobile Courses

We've taken the best 5S PowerPoint decks and turned them into free microlearning content that you can deploy to your teams in minutes.

Update your 5S training from boring PowerPoint presentations to mobile-friendly microlessons.

Modernize your 5S PowerPoint training presentation and make it accessible anytime, anywhere. Save valuable company time by making your 5S training PowerPoint mobile-friendly and completable in 5 minutes. We'll take your PowerPoint courses and automatically turn them into our proven microlearning, mobile format that's not only interactive but engaging, so your team can do their training on the go.

5S training powerpoint microlearning courses

Instantly convert your PowerPoint training to mobile – for free

Experience the magic of SC Training (formerly EdApp) on your own training content. Upload your PowerPoint file and our AI Doc Transformer (coming soon) will instantly make it mobile-friendly.

5s training PowerPoint files

5S and the Visual Workplace

https://www.5stoday.com/5s-powerpoint/

5S Basic Training

https://www.slideshare.net/parthdev/5s-training-presentation

5S for the Office

https://www.oeconsulting.com.sg/ppt-5s-for-the-office

1-866-402-4776 M-F 6am - 4pm PST

Label Samples | Floor Tape Samples

Free Resources

Oops, something went wrong. Please try again.

You are now logged in!

Lean 5S Methodology Overview

Description

DescriptionEven though 5S methodology has been around for a long time, many companies continue to misunderstand what it is, how it is used, and how it fits into the bigger picture of lean manufacturing practices and principles.

Video Introduction to 5S Methodology

5S is not complicated to understand or even to practice. The key is to do it everyday, with everyone participating, and in every place within your organization.

In this way, 5S connects deeply with the continuous improvement philosophy of kaizen .

Watch our introductory video for a six-minute overview of 5S.

Trial our Course: 5S Productivity

Start a 30-day trial of the Lean Smarts Academy and preview our 5S Productivity course.

A History of 5S Programs | Origins of 5S

The modern version of 5S is an English adaptation of an original program that has been popular in Japan for decades. There are five S’s in 5S due to the alliteration of the Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke .

Each of the five Japanese words have added meaning in Japanese culture that is difficult to capture in English translations. This is perhaps a reason for some of the confusion around the English equivalents, especially with “standardize” and “sustain.” ( See Michel Baudin’s explanation ).

Henry Ford’s CANDO Program

Some people believe that the Japanese program was inspired by an original five-step program promoted by Henry Ford called CANDO.

- Cleaning up

- Ongoing improvement

Variations of the 5S Words

Some of the imperfections of translating five Japanese words into English have led to variations of the 5S terms.

For example, “sweep” is commonly interchanged with “shine,” and “straighten” is commonly interchanged with “set in order.”

Regardless of the words that are used, we maintain that the function of these terms matters more than the title you give to them! How much does it matter what words you use as long as you: 1) still reap the intended benefits of 5S, and 2) can understand each other when speaking about 5S?

Reasons for Starting Lean with 5S

It is commonly expressed by consultants and lean literature that “if you can’t do 5S, you probably don’t have the discipline to do anything else.”

There is some merit to this! 5S is a rite-of-passage for organizations learning lean.

Aside from the fact that 5S programs are a common and easy introduction to lean practices, there are other good reasons for adopting 5S methodology early in your lean journey.

#1 It flushes out old mindsets and culture

While it is true that 5S leads to a physical transformation of your workplace, it also inspires an invisible transformation in the thinking and behavior of everyone working there.

When sorting and removing junk that doesn’t belong, organizing what remains so it’s easy to use, and taking pride in your work areas with regular cleaning, you also dislodge old beliefs, excuses, behaviors, and mindsets.

#2 You have to engage everyone

5S must involve every person in the organization for it to succeed. You have to engage everyone!

This is to your advantage in developing a lean culture of kaizen and continuous improvement.

If your intent is truly to develop and grow people (as it should be!), you can develop a kaizen culture of improvement “everyone, every day, everywhere” with 5S!

#3 It’s cheap and easy to do

You need almost no upfront investment of money to get started with 5S. All you need is some knowledge and time.

While you can purchase 5S supplies to support your efforts, many organizations discover a wealth of reusable materials, equipment, tools, and supplies already inside the building the moment they begin to 5S and sort.

In the majority of situations, you’re only limited by your creativity–not your wallet!

It’s also easy to do. In fact, in 30-60 minutes our 5S Productivity training course can prepare anyone with the skill and confidence needed to get started now.

#4 It’s the basics; it never goes away!

No matter what else you do that’s “lean,” you will never outgrow your need to 5S on a daily basis.

Entropy never takes a break causing mess, confusion, and equipment breakdown. Therefore, you’ll forever need to sort, set in order, and shine at your organization!

#5 It creates peace of mind and clarity

An orderly and clean work environment does help to reduce stress and confusion in the workplace.

The stress and confusion in many organizations is largely due to the disarray of information, tools, and materials. The clutter and clogging of a production floor creates needless searching, movement, transportation, defects, and other wastes.

It’s not necessary and should not be considered “normal” to struggle and stress at work. 5S methodology is a major first step for organizations to get control back of their environment.

The Meaning of Sort

5S methodology begins with the simple practice of sorting out all the unneeded items in a workplace.

Get rid of all the junk and clutter:

- extra inventory

- broken equipment

- extra tools

- outdated signage

- unfinished work

- leftover materials

Aspect Ratio: 4:3 Standard Screen

File Size: 35.8 MB

Number of Slides: 186

Terms of Usage

Training Presentation/Powerpoint:

5s techniques, five disciplines for high workplace productivity.

Description

5S good housekeeping and workplace organization is a set of basic management principles that are widely adopted in industries today. Also commonly known as "5S System," "5S Method" and "5S Pillars," the cornerstone of 5S is that untidy, cluttered work areas are unproductive. 5S is a powerful improvement process that gets impressive results. In a nutshell, the five principles or pillars are defined as Sort, Set in Order, Shine, Standardize, and Sustain . Because these words begin with S, they are commonly referred to as 5S.

The 5S System

5S can be applied to make your workplace cleaner and safer and your job simpler and more satisfying. It is about how to create a workplace that is clearly organized, free of clutter, arranged so you can easily find things, and sparkling clean--a place where anyone would be proud to work. In addition, 5S principles form the core elements of Lean thinking and a visual workplace and are a fundamental platform for world-class manufacturing.

In this 5S Techniques PPT training presentation targeted at both manufacturing and office staff, you will learn how to mobilize employees and align your management team to launch or improve a 5S and Visual Management implementation in your organization. The presentation covers 5S and Visual Management best practices, step-by-step implementation guidance, and the best ways to integrate lean 5S into the organization's culture to achieve sustainable world-class excellence.

Note: This training package includes:

5S Techniques PPT training presentation (PowerPoint format)

5S poster (PDF format, in color and monochrome, printable in A3 size)

Learning Objectives

Understand the benefits of working in a clean and neat environment

Define the 5S principles, and identify visual tools

Explain how to apply the 5S principles and visual tools to enhance workplace organization

Learn how to kick start and launch a 5S initiative

Define the critical success factors for 5S implementation

Introduction to 5S

The 5S Principles

Set In Order

Standardize

How to Conduct a Red-tag Sort Event

The Visual Workplace

5S for the Operations

5S for the Office

Implementing 5S

Sustaining 5S

You may also be interested in the following 5S-related training presentations and checklists (sold separately):

5S Implementation Guidebook

5S Audit Checklist for Manufacturing

Home PowerPoint Templates Diagrams 5S Diagram Template for PowerPoint

5S Diagram Template for PowerPoint

5S Diagram for PowerPoint is an application of the 5-step diagram design for PowerPoint presentations that you can download and use to create presentations on Lean Manufacturing and Kaizen using the 5S Methodology.

5S model is an organizational methodology to organize and monitor the flow of a process effectively. The 5S model and technique use 5 words: Sort, Straighten, Shine, Systemize, and Sustain. Each has its meaning, and the PowerPoint template depicts all of them in a sequence. Japanese started this concept of 5 stages, leading to the technique of Just in Time Manufacturing, one of the most used in the manufacturing industry. Different stages of the process are shown on the curved arrows .

This professional presentation template shows showing the flow of a process. The presentation template starts with an overview of the process, followed by a description of each stage. The first part elaborates on the Sort step dealing with selecting the necessary resources for the process and removing unnecessary ones. Required items can be listed in bullets for further analysis and monitoring. The next step is arranging all the resources appropriately and fully using them, the Straighten step. Shine includes the monitoring of the process and the environment around it. Systemize reflects quality inspection and modifications of the product to maintain a standard. The final stage is Sustain, which deals with storing and maintaining the products in a flow.

One thing to notice about this circular org chart template is the thin portion around the 5S diagram. It can add some text like the company’s motto or some motivational quote. The layout of this PPT template animates with each stage by focusing only on one stage at a time as the presentation goes on and dims the other stages. It completes a rotation by covering all the stages and highlighting the main points adjacent to the 5S diagram. It can also be used as a 30-60-90-day plan template , with each curved arrow showing a regular interval of some days to make a project timeline .

You must be logged in to download this file.

Favorite Add to Collection

Details (6 slides)

Supported Versions:

Subscribe today and get immediate access to download our PowerPoint templates.

Related PowerPoint Templates

5S Methodology PowerPoint Template

Kaizen PICK Chart Template for PowerPoint

5-Step Horizontal Infographic Diagram for PowerPoint

Newly Launched - World's Most Advanced AI Powered Platform to Generate Stunning Presentations that are Editable in PowerPoint

Researched by Consultants from Top-Tier Management Companies

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

Top 10 Templates to 5S Methodology Implementation, Take Your Profits Higher

Lakshya Khurana

The Japanese have been instrumental in inventing new and better management techniques that industries worldwide implement with glee, expecting improved profitability. The 5S Methodology is another such incredible framework that has the business world interested.

What is the 5S Methodology?

5S Methodology is a lean manufacturing tool to eliminate waste and increase efficiency. It is applicable to any work environment, but is highly suited to manufacturing settings; the 5S methodology offers a lot of scope to clean up waste and improve efficiency. The 5S also provides systemic solutions to organize and streamline work environments.

Why Use the 5S Methodology?

At the cost of repetition, please remember that the benefits of implementing the 5S methodology include increased productivity, reduced waste, improved safety, and enhanced quality. The implementation, however, must be done in a systematic and disciplined manner to enjoy these spectacular results, especially on the bottom line of organizations. The use of 5S can also help organizations save money and compete better in today’s global marketplace.

What Does 5S Stand For?

The 5S system originated in Japan as a way to improve efficiency and quality in manufacturing industries. It is derived from the Japanese words Seiri (整理), Seiton (整頓), Seisō (清掃), Shitsuke (躾), and Seiketsu (整備), which respectively mean ‘Sort,’ ‘Set in order,’ 'Shine,’ 'Standardize,’ and ‘Sustain.’

The 5S Methodology is based on five simple principles:

- Sort: Eliminate anything that is not needed at the workplace

- Set in order: Organize everything that remains, making it easy to find and use

- Shine: Keep the workplace clean and free of clutter

- Standardize: Develop procedures and systems, for smoother workplace functioning

- Sustain: Make sure 5S principles are implemented on an ongoing basis.

Templates To Implement the 5S

If you are interested in implementing the 5S methodology at your workplace, the first step is to get everyone on board and train them on the new system and procedures. Planning must also be done to ensure that 5S is made self-sustaining. Finally, flexibility is a key requirement to implementing the system.

Employees need to be made aware of the changes that will take place in the organization and their role in these changes. PowerPoint templates are the best medium to communicate this to a large group of people. We have selected 10 editable and content-ready PPT designs for you. Dig deep into these templates and see which suits you best.

Template 1: 5S Process Management in Finance

The 5S Process is a tool that can help you make your dollar work for longer and harder. This PPT layout helps you manage your finances and make smart financial decisions. It covers the 5S for business process management, financial planning, insurance succession, and more. Click the link below to download.

Download this template

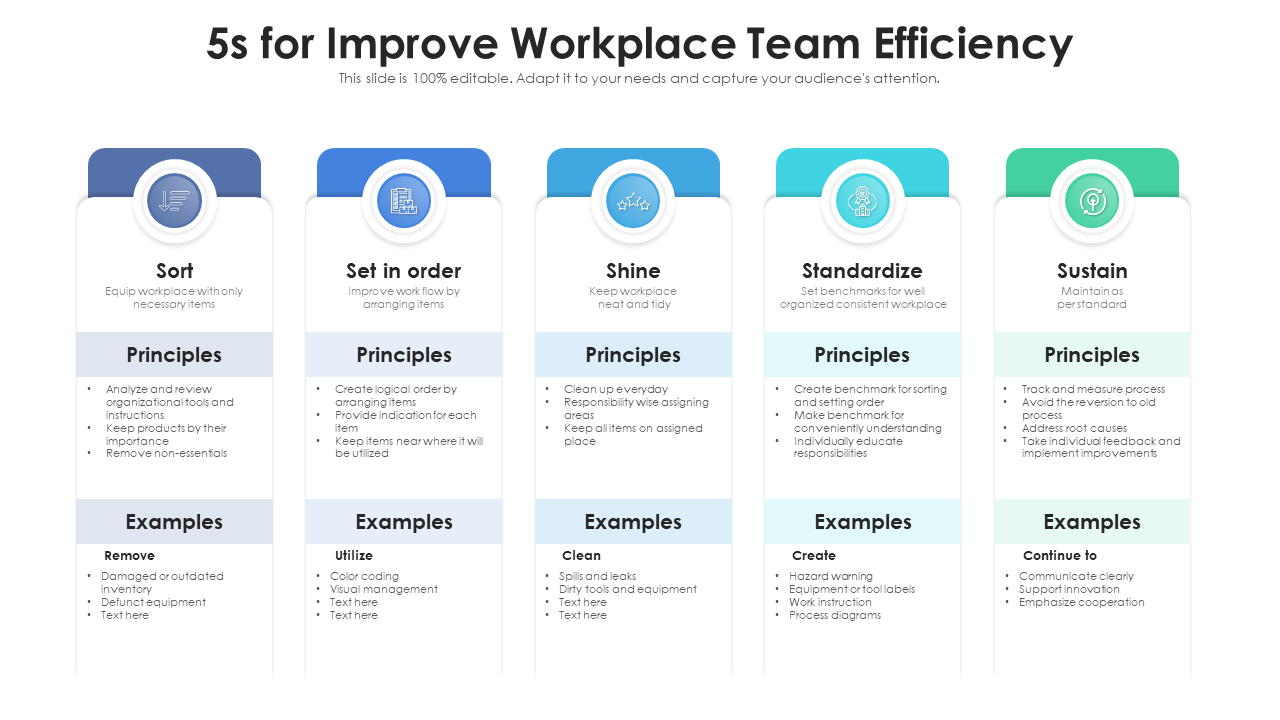

Template 2: 5S Workplace Efficiency Management

For years, 5S has been used as a workplace organization and improvement system in many industries, and it can be just as beneficial for warehouses. This PowerPoint design covers the 5S to improve team efficiency, model lean warehouse management, and maintain organizational procedures, etc. Get it right away!

Grab this template

Template 3: 5S Implementation Plan

The first step in implementing the 5S system is to establish goals. Then, you need to develop a framework for your 5S implementation plan. This PPT deck covers the implementation plan for the goals, workforce, business framework, etc. It also helps you standardize the 5S process. Deploy it now.

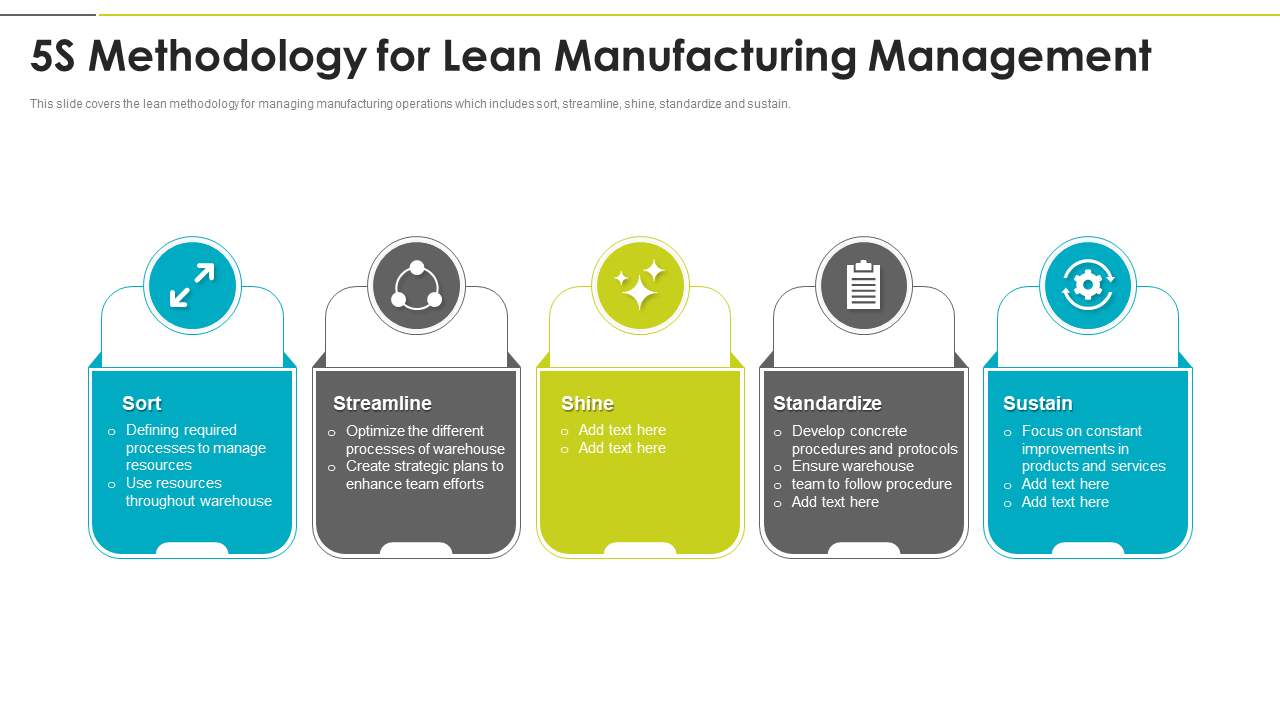

Template 4: 5S Methodology for Lean Manufacturing Management

If you are looking for a lean manufacturing management technique to help business performance, then the 5S methodology is worth considering. This PowerPoint slide helps you showcase these five steps in an attractive color palette to make for a convincing presentation. Download it now.

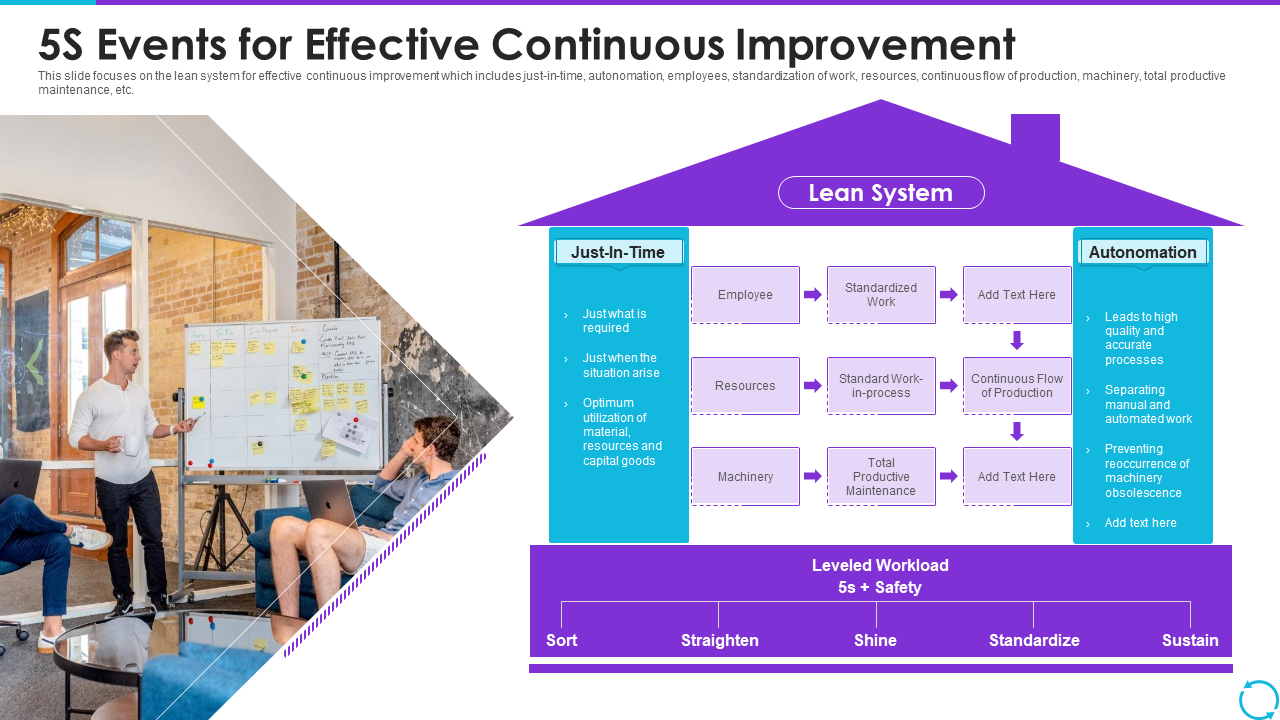

Template 5: 5S Events For Effective Continuous Improvement

This PPT preset helps organizations implement the 5S philosophy in their work environment. It is designed for a team-based setting and includes activities and tools to help organizations improve their work processes. It covers concepts like Just-In-Time, Employees, Automation, etc. Get it now.

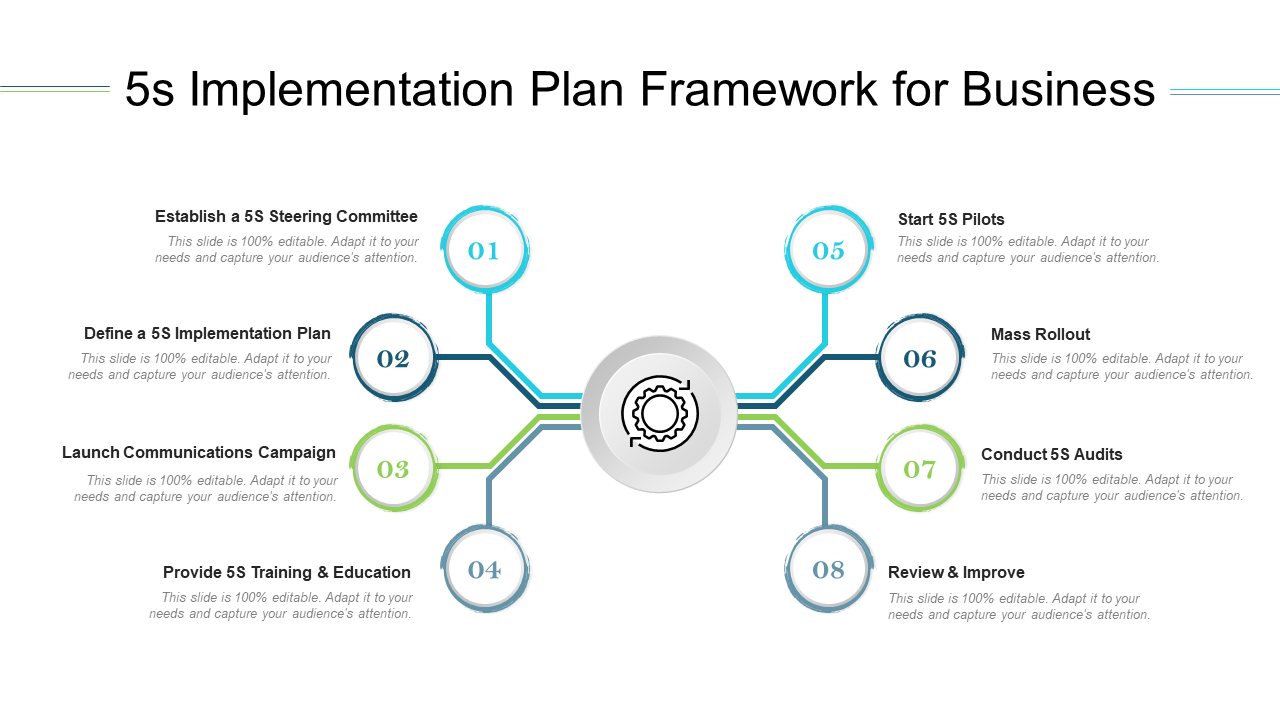

Template 6: 5S Implementation Plan Framework for Business

Our 5S implementation plan framework comes with instructions and explanations, so you can be sure that you are using it correctly. This web-structured 5S framework lists the plan for the implementation of the 5S process with steps such as establishing a committee, defining a plan, launching a communication campaign, and more. Download it right away.

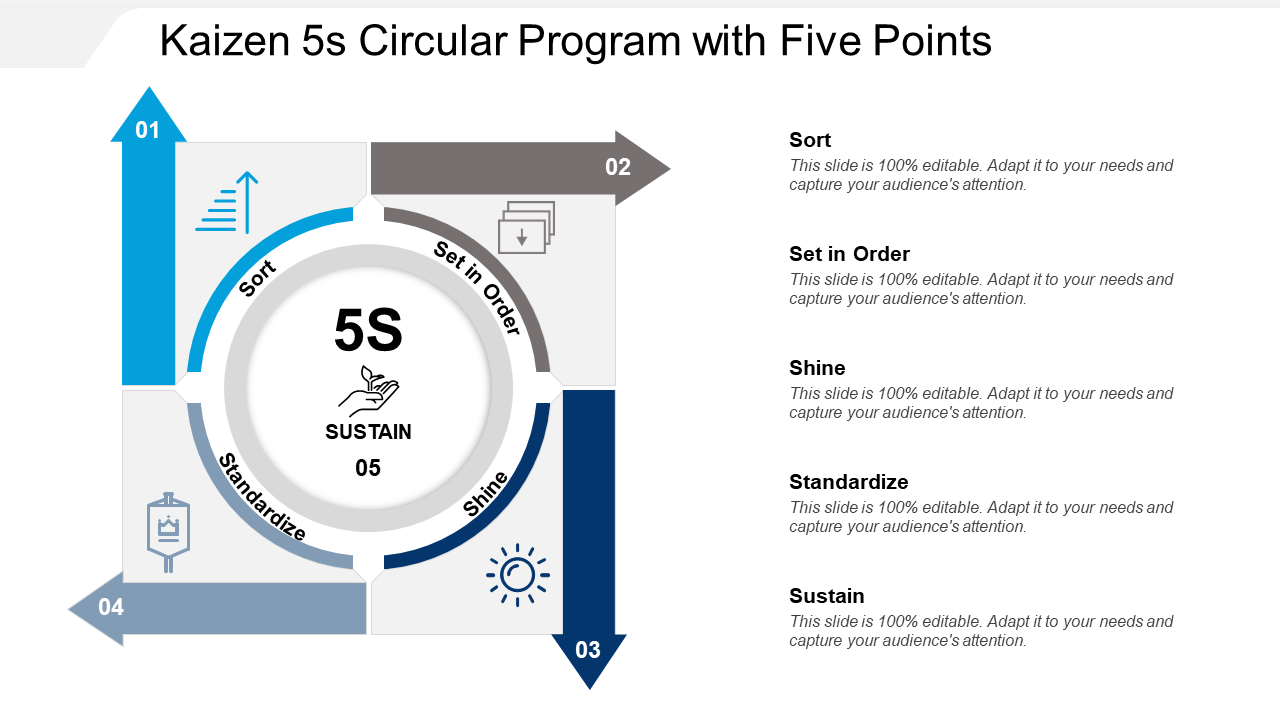

Template 7: Kaizen 5S Circular Program With Five Points

The benefits of the Kaizen 5S circular program are endless. This PPT layout presents the process in a circular layout to improve information retention. It will boost morale among your employees. If you want to take your business to the next level, then get this slide now!

Template 8: 5S to Improve Workplace Team Efficiency

By implementing the 5S system, you can create a system in which everyone knows their roles and responsibilities and has a clear workflow. This PowerPoint theme showcases the principles and examples to execute a 5S strategy. Download this slide now.

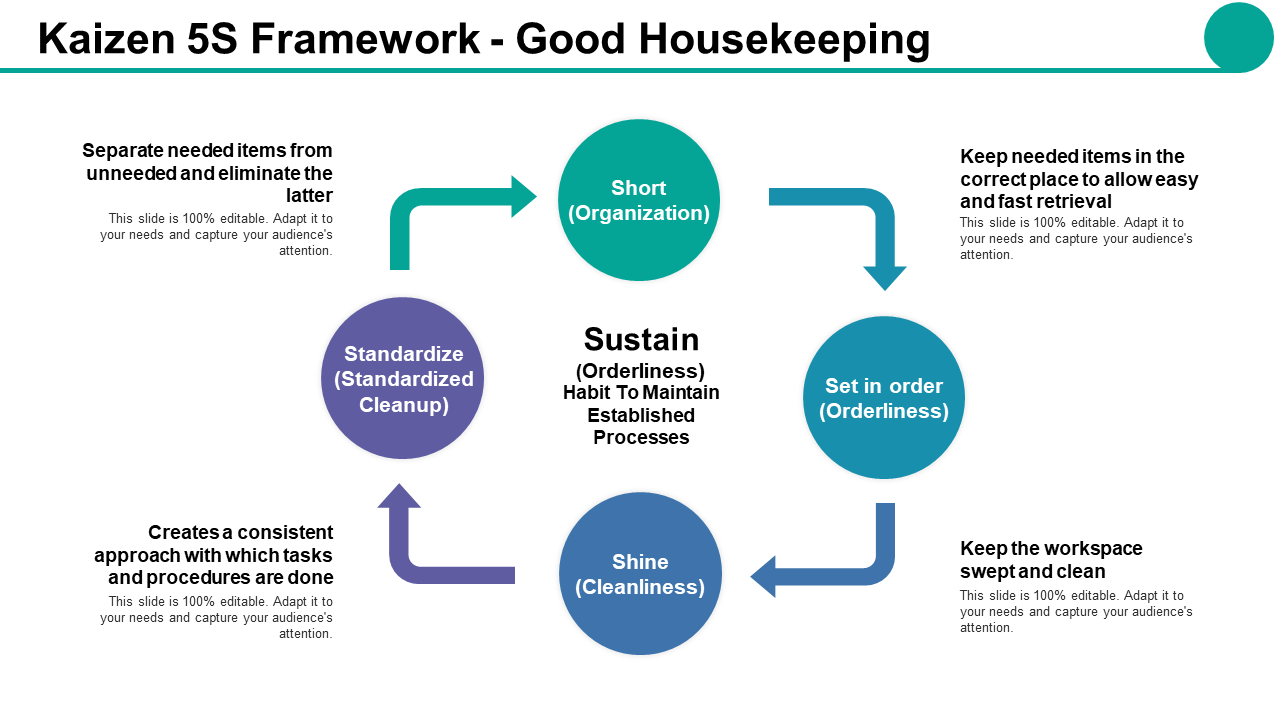

Template 9: Kaizen 5S Framework for Good Housekeeping

Using housekeeping as an example of 5S Methodology, this PPT set showcases steps to needed sustain cleanliness in a process. It is a practical framework that can be used in any business setting and is easy to implement and customize. Click the link below to download it now.

Template 10: Components of 5S Implementation Plan

It is said that successful implementation of any change initiative rests on the involvement and buy-in of those who are expected to enact the said change. This could not be more true regarding 5S or any sort of process improvement, for that matter. Get the 5S and let your employees learn how to implement it in a simple and practical manner with this PowerPoint bundle. Download it now.

Implementing the 5S methodology can be challenging, but the rewards are worth it. To do this, you need everyone to do their part, which is impossible if even a single individual remains unconvinced. Download our 5S Methodology templates and hit the ground running.

P.S: To make your work environment safer for the employees, check out our blog on the Poka-Yoke technique (with templates included), yet another Japanese gift to the business world.

Related posts:

- How to Design the Perfect Service Launch Presentation [Custom Launch Deck Included]

- Quarterly Business Review Presentation: All the Essential Slides You Need in Your Deck

- [Updated 2023] How to Design The Perfect Product Launch Presentation [Best Templates Included]

- 99% of the Pitches Fail! Find Out What Makes Any Startup a Success

Liked this blog? Please recommend us

[Updated 2023] Top 15 Presentation Templates to Showcase Your Management Consulting Services

Top 10 contract management templates to reach an agreement.

This form is protected by reCAPTCHA - the Google Privacy Policy and Terms of Service apply.

Digital revolution powerpoint presentation slides

Sales funnel results presentation layouts

3d men joinning circular jigsaw puzzles ppt graphics icons

Business Strategic Planning Template For Organizations Powerpoint Presentation Slides

Future plan powerpoint template slide

Project Management Team Powerpoint Presentation Slides

Brand marketing powerpoint presentation slides

Launching a new service powerpoint presentation with slides go to market

Agenda powerpoint slide show

Four key metrics donut chart with percentage

Engineering and technology ppt inspiration example introduction continuous process improvement

Meet our team representing in circular format

5S - BASIC TRAINING

Sep 27, 2014

27.02k likes | 44.52k Views

5S - BASIC TRAINING. What is 5S and why do we want to do it? . ALOK SHARMA 2262010. What is 5S ?. Seiri – Sort (housekeeping) Seiton – Systematic Arrangement (workplace organization)

Share Presentation

- seiri sorting

- broken items

- functional storage

- eliminating unwanted items

- respiratory system sorts oxygen

Presentation Transcript

5S - BASIC TRAINING What is 5S and why do we want to do it? ALOK SHARMA 22\06\2010

What is 5S ? • Seiri – Sort (housekeeping) • Seiton – Systematic Arrangement (workplace organization) • Seiso – Shine (Cleanup) • Seiketsu – Standardize • Shitsuke – Sustain (Self Discipline)

What is 5S ? 5S represents 5 disciplines for maintaining a visual workplace (visual controls and information systems). These are foundational to Kaizen (continuous improvement) and a manufacturing strategy based "Lean Manufacturing" (waste removing) concepts. 5S is one of the activities that will help ensure any company’s survival.

5S 1. Sort - All unneeded tools, parts and supplies are removed from the area 2. Set in Order - A place for everything and everything is in its place 3. Shine - The area is cleaned as the work is performed 4. Standardize - Cleaning and identification methods are consistently applied 5. Sustain - 5S is a habit and is continually improved Also - Work areas are safe and free of hazardous or dangerous conditions

Some New Words Lean Manufacturing-concepts that seek continuous improvement by removing waste in processes Some Japanese words one need to know: Kaizen-(pronounced “kai zen”) – Continual improvement Muda-(pronounced “moo da”) - waste Gemba-(pronounced “gim ba”) – workplace Kanban-(pronounced “kon bon”) - Pull type inventory control system. Items are only produced to meet customer needs. The request to produce more is signaled from an upstream operation and/or customer orders.

KAIZEN: What it is? • Process Improvement • Observation • Use of New Paradigms • Short Time • Zero Investment • Human Development & Empowerment • Profits & Savings - Plenty

KAIZEN KAI ZEN ALWAYS GOOD CONTINUAL IMPROVEMENT CHANGE FOR THE BETTER

KAIZEN IS A JOURNEY FROM: EVENT RESULT GROSS ENFORMENT OF CHANGE TO CAUSE TO PROCESS TO MICRO TO INDUCEMENT OF CHANGE

KAIZEN IS CONTINUAL IMPROVEMENT IMPROVEMENT IMPROVEMENT TIME TIME CONTINUOUS CONTINUAL

KAIZEN: KNOW THE REALITY THROUGH YOUR SENSE OBSERVATION INTELLIGENCE PHYSICAL EFFORT PARADIGM OF HIGH PRODUCTIVITY & QUALITY

KAIZEN AT GEMBA GEMBA: PLACE OF WORK • GEMBA is where . . . • Value is added • Actual work is done to meet customer requirement • Problems are solved • Staff is responsible for providing support, not for giving instruction

1. 5S Principles • Elimination of waste • Every body is involved, Co-operative effort • Attack root cause • Human being is not infallible

2. Objectives • Improve housekeeping • Make every individual responsible for housekeeping • Beautify by simple means • Productivity improvement by saving time, space etc.

SEIRI = Sorting Meaning Distinguish between necessary and unnecessary items and eliminate the unnecessary items Activity Establish a criteria for eliminating unwanted items Eliminate unwanted items either by disposing them or by relocating them. Success Area saved or percentage of space available Indicator

SEIRI = Sorting Japanese Meaning : The Japanese meaning of “Seiri” is to straighten and contain. - Get rid of waste and put it in order according to rules

1 ‘S’ - SEIRI Respiratory System 1 ‘S’ – Our respiratory system sorts oxygen and other gases. And exhales other gases which are unwanted for our body

1S – SEIRI : SORTING • Sort for . . . • Not Needed at All • Needed but not Now • Needed but not here • Needed but not so much Quantity 1 ‘ S’ WANTED UNWANTED

What is unnecessary Seiri = Sorting 1. Item is not needed 2. Item is needed however quantity in stock is more than what is needed for consumption in near future 3. Contingency Parts Critically decide the quantity of contingency parts to be retained and criteria for such parts

Organization Frequency of use Storage Method Throw them out *Things you have not used in the past one year LOW *Things you have used once in the last 6-12 months Store at distance OR Keep in store *Things you have used only once in the last 2-6 months Store it in central place in your zone AVERAGE *Things used more than once a month Store it in central place in your zone *Things used once a week Store near the workplace HIGH *Things used daily or hourly Store near the workplace

Identifying unnecessary Seiri = Sorting • 1. Parts & Work in Process (WIP) • Things fallen back behind the machine or rolled under it • Broken items inside the machine • Things under the racks/ platform • Extra WIP • Stock of rejected items • Items accumulated over period for rework • Material awaiting disposal decision • Material brought for some trial, still lying even after trial • Small qty of material no longer in use Contd..

Identifying unnecessary Seiri = Sorting • 2. Tools, Tooling, Measuring devices • Old jigs, tools not in use are lying • Modified tools, tooling for trial, are lying after trial • Worn out items like bushes, liners, toggles etc. lying • Broken tools, bits, etc. may be lying • Measuring equipment not required for the operation • being performed , is lying • 3. Contingency Parts • Many times storage place for contingency parts become • a last refuge for broken parts, surplus items and things • nobody is likely to use Contd..

Identifying unnecessary Seiri = Sorting • 4. Shelves and Lockers • Shelves and lockers tends to collect things that nobody • ever uses , like surplus, broken items etc. • 5. Passages and Corners • Dust, material not required seem to gather in corner • 6. Besides Pillars and under the stairs • These places tends to collect junk, spittoon etc. • 7. Walls and Bulletin Boards • Old out dated notices which have lost their relevance • Posters or bulletins on wall • Dust, remains of torn notices, cell tape pieces Contd..

Identifying unnecessary Seiri = Sorting • 8.Floor, Pits, Partitions • Defective parts • Protection caps, covers • Packing material • Hardware items , small items • Even tools, tooling • Items dropped on the floor are never picked • 9.Computer Hard Disk • Many unwanted, outdated, temporary files pile up

Improvement methods Seiri = Sorting 1. Flow Process Chart (Procedural Analysis) Drawing a process flow chart for the system e.g. How to make and use category wise grouping 2. Operational Analysis Preparing the sequence of operations for system e.g. How to perform Seiri (sorting) 3. Check List A check sheet is used to decide what sort of main system and sub system are necessary.

Dealing with papers Seiri = Sorting How to Reduce Papers on Your Table ? 1. Make a single pile of papers 2. Go through them and sort in following categories a) Immediate action b) Low priority c) Pending d) Reading material e) For information

Dealing with papers Seiri = Sorting How to Reduce Papers on Your Table ? 4 D Principle DO DELEGATE DELAY DUMP

2 ‘S’ Seiton : Systematic Arrangement PLACE FOR EVERYTHING, EVERYTHING IN ITS PLACE Arranging things in systematic way

2 ‘ S’ - SEITON 2 ‘S’ – In our body there is a fixed place for every organ.

SEITION = Systematic Arrangement Meaning To determine type of storage and layout that will ensure easy accessibility for everyone. Activity - Functional storage - Creating place for everything and putting everything in its place Success - Time saved in searching Indicator - Time saved in material handling

SEITION = Systematic Arrangement Japanese Meaning: Dictionary meaning of Seiton is “to be correctly prepared” and “to prepare correctly”. In short these means : (a) arrange correctly in accordance with the correct method of doing activities and (b) make thorough preparations so that activities can be done even if they occur abruptly

Seiton = Systematic Arrangement • How to achieve Systematic Arrangement ? • Decide where things belong • Decide how things should be put away • Obey the Put away rules

Seiton = Systematic Arrangement • How to achieve Systematic Arrangement ? • Decide where things belong • - Standardize Nomenclature • - Determine an analytical method of storage • Decide how things should be put away • -Name & locations to everything. • - Label both item and location • - Store material functionally • - Prevent mistakes with coding by • shapes & colour • contd..

Seiton = Systematic Arrangement • How to achieve Systematic Arrangement ? • Decide how things should be put away • - Follow (FIFO) first in first out rule • - If two identical items are to be located, • then store them separately, • - colour code them. • Obey the rules • - Put the things back to their location after • their use

Seiton = Systematic Arrangement USE : 1 ) Signboards 2) Colour codes 3) Outline markings 4) Labels

Seiton = Systematic Arrangement Usage Frequency • Store frequently used material • near the workplace and less • frequently at some distance • Heavy material should be • stored at lower levels/layers • Place directly on the material • handling device for ease of • handling Weight & Shape of the Material Functional Storage

Seiton = Systematic Arrangement • Same category of material • may be stored in one location. • e.g, Allen Screws, Oil Seals Category • All items required for an • operation may be stored in • one location. • e.g, Allen key, spanner etc • hand tools required for • setting m/c Operation Wise Functional Storage

Seiton = Systematic Arrangement • Outlining and Placement Marks • - Mark boundaries of dept., aisles, Machines • - Follow straight line, right angle rule • - Nothing shall be kept outside the boundaries • Stands and shelves • - Keep only required number of • stands and shelves • - Standardize height, size • - Provide casters where necessary so that • it can be moved

Seiton = Systematic Arrangement • Wires and Ducts • - Colour code • - When there are multiple connections – • bundle the wires, label them and make sure • that they are in straight line /right angle • and firmly anchored. • Machine-tools & Tools • - Put the tools in the order you need them • - Location of the tool should be such that • it can be put away with one hand • - Try to eliminate some hand tools by • permanently attaching it to the bolt head

Seiton = Systematic Arrangement • Blades, Dies, Other important consumables • - Store them in the protected place • - Maintain these things regularly by • applying rust preventive, oiling etc. • WIP- Work In Process • - Designate a place for each component/part • - Decide on how much quantity to be stored • - Ensure that there is no damage to good part • during transit, they do not get rusty and • they are not mislabeled

Seiton = Systematic Arrangement • Oils • - Reduce number of oils used (Standardize) • - Colour code for oil • - Safety aspects - fire prevention, • pollution, leak, spillage • Instrumentation & Measuring Devices • - Label them, show direction of flow

Before sort after sort

3 ‘S’ Seiso : Cleaning KITSUI KIKEN KITENOI (DANGER) (PROBLEM) (DIRT) Clean the surroundings !

3 ‘ S’ - SEISO 3 ‘S’ – We keep our body clean everyday by having bath and cutting nails etc

SEISO = Cleaning Meaning Cleaning trash, filth, dust and other foreign matter. Cleaning as a form of Inspection Activity - Keep workplace spotlessly clean - Inspection while cleaning - Finding minor problems with cleaning inspection Success - Reduction in machine down time Indicator - Reduction in no. of accidents

SEISO = Cleaning Japanese Meaning : Dictionary meaning “to clean up” and “getting rid of dirt and unclean items” While cleaning potential defects such as abrasion, damage, loose parts, deformities, leaks temp., vibration, abnormal sound etc. are revealed hence Seiso is Inspection

Seiso = Cleaning • Here cleaning means more than just keeping • things clean. Cleaning should be viewed as a • form of Visual Inspection • Preventive measures should be taken to tackle • problems of dust, grim, burrs, leakage etc. • Root cause of the problem should be identified • and it should be eliminated

Seiso = Cleaning • 5 Minutes Every day for cleaning • Devote 5 minutes everyday for cleaning your • work area • Participation of everyone is required • Attack hard to clean places regularly

- More by User

Commissioner Basic Training

Commissioner Basic Training. Welcome to One Day session Will include: Why Commissioners? The Commissioner’s Top Priority: the Unit How to Help a Unit. Commissioner Basic Training. Why Commissioners?. Session One. Learning Objectives. At the end of this session, you should be able to:.

1.05k views • 59 slides

ABC Basic Training

ABC Basic Training. September 15, 2007. The Activities Board at Columbia. ABC is the largest of six governing boards at Columbia. There are currently 154 student groups under ABC.

471 views • 19 slides

AWARENESS TRAINING ON 5S PRACTICE

5S BACK GROUND. SINCE THE EARLY'80'SJAPANESE INDUSTRIES WIDELY PRACTISED 5S AS A POWERFULTECHNIQUE TOIMPROVE PRODUCTIVITY

2.24k views • 39 slides

1.23k views • 55 slides

Basic Training

Basic Training. What is debating?. LUDS practice British parliamentary debate that is: A structured argument about a certain topic (motion) Between two sides and four teams. The proposition (Government) and the opposition.

389 views • 14 slides

5S Simplified 5S Audit Tool

5S Simplified 5S Audit Tool . 5S Audit Training. 5S Levels Of Achievement. What Color (Level) is your area?. 5S Audit Form – Scores & Levels of Achievement. 5S Audit Tool: Using the same Chart for the 5S Audit Rating Chart & 5S Levels of Achievement Chart

2.34k views • 6 slides

5S BASIC TRAINING

5S BASIC TRAINING. What is 5S and why do we want to do it? . What is 5S and why do we want to do it?. 5S is short for: Sort, Set in Order, Shine, Standardize and Sustain 5S represents 5 disciplines for maintaining a visual workplace (visual controls and information systems).

2.81k views • 15 slides

5S training

5S training. Office Environments. What is 5S?. 5S is a process for implementing and maintaining a clean, safe, and organized work area. 5S provides a way for organizations to operate efficiently and effectively.

2.1k views • 0 slides

BASIC TRAINING

BASIC TRAINING. Paradigma & sikap. Oleh : Novi Kurniawan ( Pengusaha Multimedia). Paradigma. Cara kita memandang sesuatu yang kemudian menjadi acuan berpikir , mengambil keputusan dan tindakan. Beda Paradigma , Beda Aksi … Apa yang Anda lihat ??? . Mengapa

2.22k views • 193 slides

5S Education &Training

5S Education &Training. Lean Methodology In The Office Created and Presented by Reginald Fuller. Agenda. Welcome and Introduction Restrooms Breaks and Lunch Pagers and Cell Phones Questions Participation Remain Comfortable Lean Methodology and Waste The 5S System Conclusion.

2.77k views • 46 slides

Basic Training. 듣기. Evaluation. Task Completion Organization Fluency Delivery Language Usage. □ 숨기기 ( 인쇄 제외 ). Basic Training. Evaluation. Task Completion Organization

178 views • 7 slides

Iphones 5s. What are IPhone 5s. An IPhone 5 is technology of today. People use it all the time, maybe not all the time, but most of the time. How can this device be used in a classroom?.

286 views • 6 slides

5S Essentials

5S Essentials . Five action verbs . Principle of 5 S. 5S Philosophy focuses on effective work place organization, simplifies work environment, reduces waste while improving quality and safety.

583 views • 13 slides

Basic Training. Getting Started. A free, unbiased service, sponsored by the Washington State Office of the Insurance Commissioner. Welcome to Basic. In the next two days you will be presented with an overview of the topics that you need to advise clients.

1.36k views • 103 slides

Basic Training. Update on Most Recent Pharmacy-Specific LTC Regulations Presented By: Martha M. Little, PharmD, Certified Geriatric Pharmacist Region IV Board of Directors, ASCP Director of Quality Improvement, Omnicare, Inc. Basic Training. Major medication-related F-Tags:

686 views • 53 slides

WELCOME TO. BASIC TRAINING. SOLDIER RESPONSIBILITIES AS A COLLEGE STUDENT. CSU. ARMY. COUGARNET. This is your communication tool to Columbus State University. CHECK COUGARNET OFTEN. CougarNet and GoArmyEd Do not work together!. Information sent to you regarding CSU information.

448 views • 23 slides

Basic Training. Clinical Risk Management In the Long Term Care Setting Jo Ann Fisher, MSN, FNP-C. Basic Training. Objectives List clinical areas of risk and strategies for managing risk for these areas. Define Quality Indicators Describe the role of the care plan as a communication tool.

296 views • 19 slides

Basic Training. Collaborative Practice in Long Term Care Setting Jo Ann Fisher, MSN, FNP-C. Basic Training. Objectives. Define the scope of practice of the NP/PA Describe the components of a collaborative agreement

242 views • 8 slides

BASIC Training

BASIC Training. OIMA: a Bible study method. Observation. Observation : What do I see ?. The Skill of Observation. Examples of Good Observations. Key Words Words that are repeated Therefore, but, so Structure Grammatical – Subject and verb of the passage.

607 views • 18 slides

Basic Training. Tile Laying System. MUREXIN AG / Michael Maier Version: Oktober 2007. Tile Laying System. Preparation. TLS - Preparation. Penetrating Primer LF. for absorbent substrates ready-to-use one component solvent free Consumption: appr. 0,15 kg/m² Delivery units: 1 and 5 kg

307 views • 18 slides

5S Methodology | What Is 5S Methodology? | 5S Methodology Explanation | Simplilearn

This presentation on 5S Methodology will take you through everything you need to know about the workplace organization method, 5S. This video also covers a number of different topics like the basics of the 5S methodology, its benefits and the process of 5S, like Sort, Set in order, Shine, Standardize, and Sustain. So now, let's jump in and learn about the 5S methodology. Learn to develop your organizational projects with the Lean Six Sigma Green Belt certification online program. Aligned to the IASSC exam, this online six sigma certification integrates lean and the DMAIC methodology with case studies to provide you the skills required for an organization's growth. About Simplilearn SIx Sigma green belt course: This Lean Six Sigma Green Belt course provides an overview of Six Sigma and the DMAIC methodology and is aligned to the leading Green Belt certifications at ASQ and IASSC. In this Lean Six Sigma Green Belt course, you will learn how to measure current performance to identify process issues and how to formulate solutions. Six Sigma Green Belt Training Key Features: - 56 hours of high-quality blended learning - 33 PDUs offered - 4 simulation test papers, 4 real-life projects - Aligned to ASQ and IASSC Eligibility: Lean Six Sigma professionals are in high demand due to their ability to use problem-solving techniques to reach business solutions and assuring quality control throughout the process. The Lean Six Sigma Green Belt certification is ideal for Quality system managers, Quality engineers, Quality supervisors, Quality analysts and managers, Quality auditors, and any individual wishing to improve quality and process within an organization. Learn more at https://www.simplilearn.com/quality-management/lean-six-sigma-green-belt-training

1.67k views • 59 slides

Free AI Presentation Maker for Generating Projects in Minutes

- Generate ready-to-use presentations from a text prompt.

- Select a style and Visme’s AI Presentation Maker will generate text, images, and icon.

- Customize your presentation with a library of royalty-free photos, videos, & graphics.

Generate a presentation with AI

Brought to you by Visme

A leading visual communication platform empowering 27,500,000 users and top brands.

Presentations Engineered With Visme’s AI Presentation Maker

Ai presentation prompt 1.

Craft a presentation outlining a leading company’s cutting-edge innovations in AI-powered hardware, emphasizing their impact on enhancing workplace productivity and efficiency.

AI Presentation Prompt 2

Generate a comprehensive presentation highlighting the latest digital marketing trends, focusing on strategies for enhancing brand visibility and customer engagement across diverse platforms.

AI Presentation Prompt 3

Create a detailed presentation elucidating a company’s diversified investment portfolio, emphasizing its robust performance, risk mitigation strategies, and the potential for sustainable long-term growth.

AI Presentation Prompt 4

Develop a compelling presentation showcasing a company’s groundbreaking medical devices and software solutions, emphasizing their role in revolutionizing patient care, treatment efficacy, and healthcare accessibility worldwide.

How it works

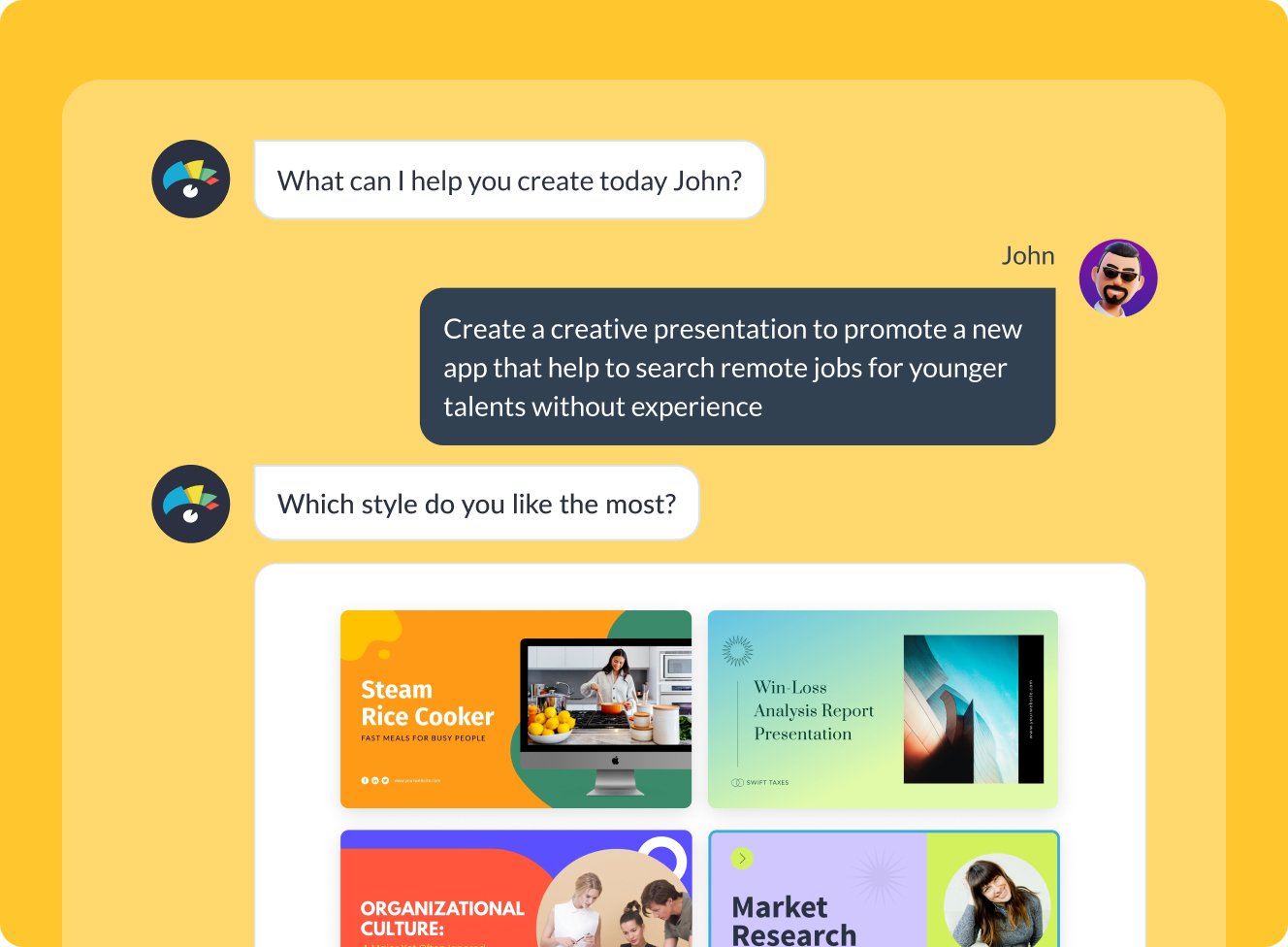

How to generate AI presentations with Visme

Save time and create beautiful designs quickly with Visme AI Designer. Available inside the Visme template library, this generator tool is ready to receive your prompts and generate stunning ready-to-use presentations in minutes.

- Log in to the Visme dashboard, and open the template library by clicking on Create New button -> Project -> Presentations. Inside the template library, scroll down and click on the Generate with AI option.

- In the popup that opens, type in a prompt and describe in detail what aspects your presentation should feature. If you don’t provide enough information, chatbot will ask you follow-up questions.

- Visme Chatbot will suggest template styles; choose the most relevant for your presentation, and wait for the AI to create the design. Preview, regenerate or open your project in the Visme editor.

- Customize your project in Visme: Pick a color theme or create your own, edit text, and use assets from Visme’s royalty-free library of photos, videos, and graphics, or create your own with AI tools.

Features of the AI Presentations Maker

Ready-to-use presentations in minutes.

Starting is often the hardest part of a project. Visme’s free AI presentation maker helps you overcome this block and generates results within minutes. It gives you a headstart and a good first draft that is ready-to-use with minimal or no customization.

Customize every part of your presentation

Visme editor is easy to use and offers you an array of customization options. Change the color theme of your presentation, text, fonts, add images, videos and graphics from Visme royalty-free library of assets or generate new ones with AI image generator, AI image touchup tools, or add your own. For more advanced customization, add data visualizations, connect them to live data, or create your own visuals.

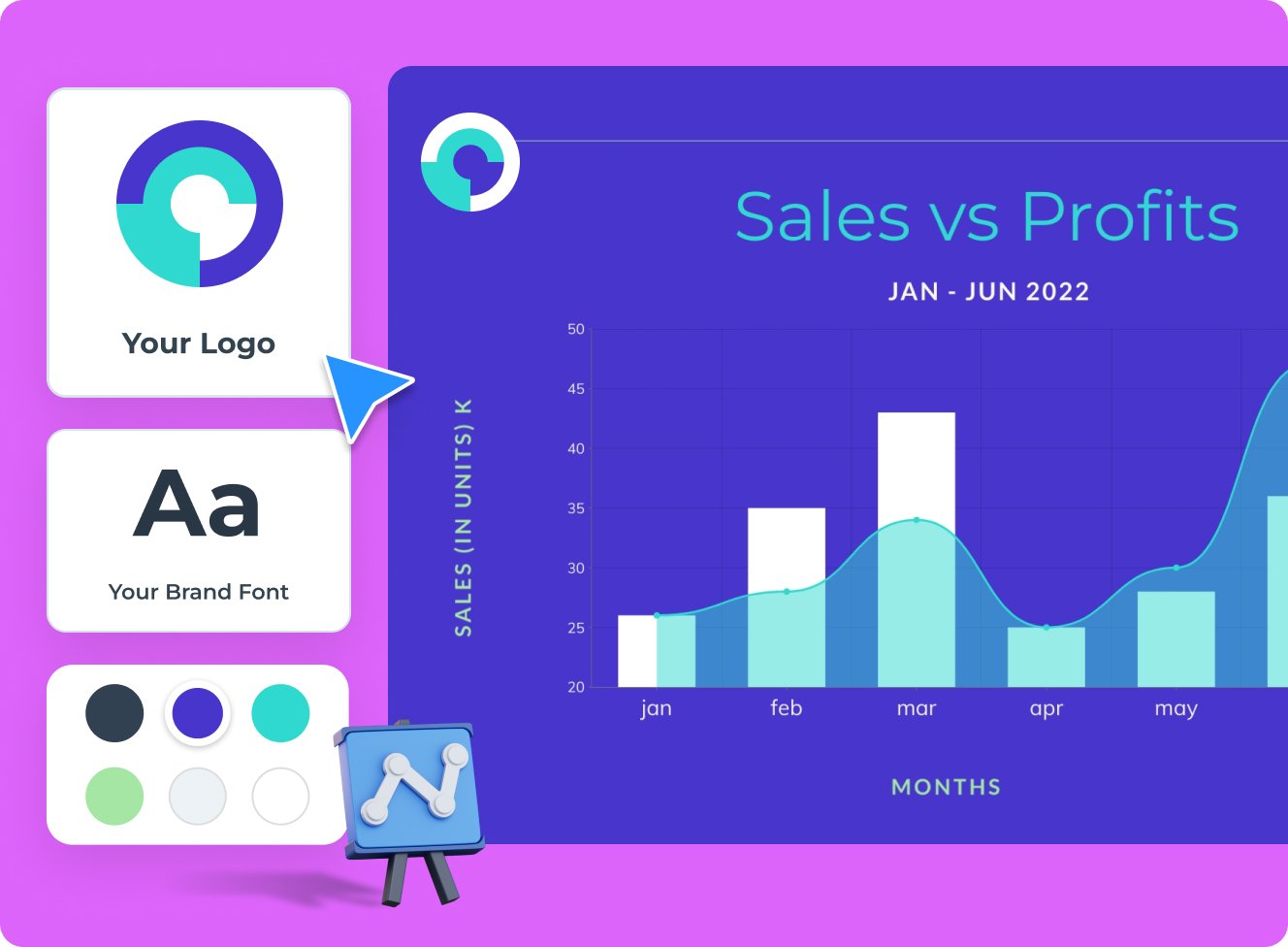

Add your branding

Stay on-brand even with AI-generated presentations. Quickly and easily set up your brand kit using AI-powered Visme Brand Wizard or set it up manually. Use your brand colors and fonts in AI-generated presentations. Add your logo and upload your brand assets to make a presentation match your company’s branding.

Download, share or schedule your presentation

Share your presentations generated with Visme AI Designer in many ways. Download them in various formats, including PPTX, PDF and HTML5, present online, share on social media or schedule them to be published as posts on your social media channels. Additionally, you can share your presentations as private projects with a password entry.

More than just an AI Presentation Maker

Beautify your content

Unique Elements & Graphics

Browse through our library of customizable, one-of-a-kind graphics, widgets and design assets like icons, shapes, illustrations and more to accompany your AI-generated presentations.

Visualize your data

Charts & Graphs

Choose from different chart types and create pie charts, bar charts, donut charts, pyramid charts, Mekko charts, radar charts and much more.

Make it engaging

Interactivity

Share AI-generated presentations online with animated and interactive elements to grab your audience’s attention and promote your business.

More AI tools in Visme

Ai image generator.

The Visme AI Image generator will automatically create any image or graphic. All you need to do is write a prompt and let AI magic do the rest.

Visme AI Writer helps you write, proofread, summarize and tone switch any type of text. If you’re missing content for a project, let AI Writer help you generate it.

Save yourself hours of work with AI Resize. This feature resizes your project canvas and adjusts all content to fit the new size within seconds.

AI TouchUp Tools

The Visme AI TouchUp Tools are a set of four image editing features that will help you change the appearance of your images inside any Visme project. Erase and replace objects that you don’t want in your photos.

The Brand Wizard

The AI-based Visme Brand Wizard populates your brand fonts and styles across a beautiful set of templates.

Make the most of Visme’s features

Choose the perfect visual from our extensive photo and video library . Search and find the ideal image or video using keywords relevant to the project. Drag and drop in your project and adjust as needed.

Incorporate 3D illustrations and icons into all sorts of content types to create amazing content for your business communication strategies. You won’t see these 3D designs anywhere else as they’re made by Visme designers.

When you share your Visme projects, they’ll display with a flipbook effect . Viewers can go from page to page by flipping the page like a digital magazine. If you don’t want the flipbook effect, you can disable it and share as a standard project.

Remove the background from an image to create a cutout and layer it over something else, maybe an AI-generated background. Erase elements of the image and swap them for other objects with AI-powered Erase & Replace feature.

Create scroll-stopping video and animation posts for social media and email communication. Embed projects with video and animation into your website landing page or create digital documents with multimedia resources.

With Visme, you can make, create and design hundreds of content types . We have templates for digital documents, infographics, social media graphics, posters, banners, wireframes, whiteboards, flowcharts.

Design and brainstorm collaboratively with your team on the Visme whiteboard . Build mind maps and flowcharts easily during online planning and strategy sessions. Save whiteboards as meeting minutes and ongoing notes for projects.

Edit your images , photos, and AI image-generated graphics with our integrated editing tools. On top of the regular editing features like saturation and blur, we have 3 AI-based editing features. With these tools, you can unblur an image, expand it without losing quality and erase an object from it.

Frequently Asked Questions (FAQs)

How can i get better results with the ai presentations maker.

Like any AI generator from a text tool, the prompt is everything. To get better results with the AI Presentation maker, you need better prompts. Write the prompt to be as detailed as possible. Include all the content topics you want the presentation to cover. As for style elements, there’s no need to include it in the prompt. Focus on choosing the style that you like from the Chatbot suggestions. Try to select the style that already features the color palette and shapes that you like. AI will change icons and photos based on text it generates.

How many AI Presentations can I generate?

Visme AI Presentation maker is available in all plans with higher credits/usage available in Premium plans. Note: AI credits are spread amongst all AI features. So if you use other AI features, your credits will be deducted.

Is the Visme AI Designer a third-party API?

No, Visme AI Presentation maker was developed in-house and is a unique tool. However, it does use third-party APIs: ChatGPT and Unsplash.

This website uses cookies to improve the user experience. By using our website you consent to all cookies in accordance with our cookie policies included in our privacy policy.

Summer Game Fest 2024: Everything Announced

Putting a spotlight on the biggest summer game fest reveals..

The 2024 Summer Game Fest showcase has come to a close after bringing out a steaming plate of game reveals, trailers, and surprises. It was a presentation jam-packed with nearly every kind of video game from across the industry.

Summer Game Fest 2024 Games

The show put the spotlight on games of every shape and size throughout its two-hour runtime, with some highlights bringing first looks at new titles like Lego Horizon Adventures, Harry Potter: Quidditch Champions, and everything Blumhouse Games is cooking up. We’ve gathered everything you need to know here.

Lego Horizon Adventures is coming to PlayStation 5

The long-rumored Lego Horizon Adventures game kicked off Summer Game Fest, revealing brick versions of Aloy and the robot dinosaurs fans have come to know over recent years. First footage of the project revealed a Lego adventure that’s a bit more family-friendly than Guerrilla Games’ mainline series, including what seems to be the option to play co-op with a friend. The footage also teases customization options to enjoy when Lego Horizon Adventures comes to PC via Steam and the Epic Games Store, Nintendo Switch, and PS5 this holiday season.

Quidditch Champions launches this year

Harry Potter fans looking for something to tide them over after the release of Hogwarts Legacy last year can finally look forward to Harry Potter: Quidditch Champions when it launches for PC via the Epic Games Store and Steam, Nintendo Switch, PlayStation, and Xbox on September 3, 2024.

No More Room in Hell Early Access arrives this Halloween

No More Room in Hell 2 is bringing its first-person shooter zombie gameplay to Early Access this Halloween. Gameplay for the gory action title revealed brutal combat and gruesome enemies that will stop at nothing to take you down. The trailer, which also highlighted dismemberment mechanics and a handful of weapons, also teased eight-player co-op in a world with plenty of replayability.

Star Wars Outlaws teaser trailer reveals more gameplay

Ubisoft’s first crack at an open-world Star Wars game, Star Wars Outlaws, warped into Summer Game Fest 2024 to show players a new swash-buckling gameplay trailer. Quick cuts of the scoundrel-centered sci-fi game showed off locations both old and new as protagonist Kay Vess made her way through and around the Empire. We’ll learn more at the upcoming Ubisoft Forward, but until then, Star Wars Outlaws is expected to launch on August 30.

Sid Meier's Civilization VII is coming to consoles in 2025

Developer Firaxis Games and 2K announced that its long-awaited strategy game, Sid Meier’s Cvilization 7 is coming to PC and consoles in 2025. The project’s reveal trailer understandably didn’t show off any gameplay yet, but it did give fans an atmospheric trailer to keep them waiting for a few months. Come August, Firaxis will host a gameplay showcase, meaning players don’t have much longer to wait before learning more.

Dragon Ball: Sparking! Zero release date set for October

The Dragon Ball franchise will continue to deliver frenetic Super Sayain gameplay when Dragon Ball: Sparking Zero launches for PC via Steam, PS5, and Xbox Series X | S on October 11, 2024. Our latest look at the anime spinoff game revealed destructive gameplay for iconic characters like Goku, Frieza, Buu, Vegeta, and more. The footage also promised six early character unlocks for those who pre-order their copy, including another mystery fighter to play as, too.

Batman: Arkham Shadow trailer introduces players to VR Gotham City

The Meta Quest 3-exclusive Batman: Arkham Shadow finally stepped out of the darkness to give DC fans a better look at its younger Batman and the new threats he faces. The new footage of the VR spinoff game arrived during Summer Game Fest, revealing a cinematic look at a Bruce Wayne that might seem a bit familiar to Arkham fans. Its trailer, which sets up the Rat King as its main villain, also packs in a few Easter Eggs for those looking for nods to the rest of Gotham’s criminals.

For more, be sure to check out our interview with developer Camouflaj .

Street Fighter 6 Is Getting a Fatal Fury Crossover

More Street Fighter 6 content is on the way, as Capcom is promising to deliver four new characters with Season 2 . The upcoming season promises to be one of the classic fighting game’s busiest yet, as the new roster includes a crossover with Fatal Fury that will see fighters Terry and Mai joining the battle. Also on the way are classic Street Fighter characters M. Bison, who seems to be sporting a new look, and Elena. The content will rollout throughout the remainder of the year.

Blumhouse Games unveils Crisol Theater of Idols, Fear the Spotlight, and More

Blumhouse, a studio that has made a name for itself over the last decade with horror movies like M3GAN and Five Nights at Freddy’s, is entering the games business . Instead of launching the new endeavor with just one video game project, the studio announced a variety of horror games from teams like Eyes Out, Half Mermaid, Cozy Game Pals, Perfect Garbage, PlayMe Studio, and Vermila. Blumhouse explained that its goal is to offer games for more than one kind of player. It kicks off with Fear the Spotlight, but other titles, like Grave Seasons, Sleep Awake, Crisol Theater of Idols, are on the way, too.

Power Rangers: Rita’s Rewind reveals new old-school-style beat-em-up

Beat-em-up gaming fans time traveled back to the ‘90s when Power Rangers: Rita’s Rewind was revealed at Summer Game Fest 2024. This old-school-style video game sees players team up to fight off Putties and other iconic villains while playing as the original Rangers themselves. So far, the game’s strength seems to be the variety of activities it offers, as players can be seen switching between beat-em-up, FPS, and racing gameplay.

MECHA Break sets beta test date for this August

MECHA Break appeared during Summer Game Fest 2024 to show off a new trailer while promising to let players join in on the action this August. No specific date for the beta test was revealed, but the presentation also revealed that Takayuki Yanase (Metal Gear, Gundam, Armored Core) and Junya Ishigaki (Xenogears, Gundam) provided their talents to help design some of the game’s mechs. We’ll learn more about what MECHA Break has in store as we inch closer to that August beta test.

The First Descendant gets July release date

Nexon’s free-to-play sci-fi looter shooter, The First Descendant, has locked down a release date of July 2, 2024, for PC via Steam, PS4, PS5, Xbox One, and Xbox Series X | S. It’s a date that was revealed with a new trailer highlighting the project’s fast-paced exo-suit action. Additionally, Nexon says fans can expect to hear more details about “launch elements and events” as launch grows closer. With only a few weeks to go, it shouldn’t be much longer before we hear more.

Alan Wake 2 Night Springs DLC is out tomorrow

Remedy Entertainment’s Sam Lake took the stage at Summer Game Fest 2024 to announce that the first Alan Wake 2 DLC, Night Springs, is out in less than 24 hours . It was a surprise reveal for the studio’s otherworldly horror game, and its trailer teases some interesting ties to its grand video game universe. Specifically, Control’s Jesse Faden makes an appearance in the footage, though it’s unclear how exactly she'll fit in. Of course, all will be revealed when players get their hands on Alan Wake 2 Night Springs tomorrow, June 8.

Skate gameplay reveals console playtests are on the way