Need a business plan? Call now:

Talk to our experts:

- Business Plan for Investors

Bank/SBA Business Plan

- Operational/Strategic Planning

- L1 Visa Business Plan

- E1 Treaty Trader Visa Business Plan

- E2 Treaty Investor Visa Business Plan

- EB1 Business Plan

- EB2 Visa Business Plan

- EB5 Business Plan

- Innovator Founder Visa Business Plan

- UK Start-Up Visa Business Plan

- UK Expansion Worker Visa Business Plan

- Manitoba MPNP Visa Business Plan

- Start-Up Visa Business Plan

- Nova Scotia NSNP Visa Business Plan

- British Columbia BC PNP Visa Business Plan

- Self-Employed Visa Business Plan

- OINP Entrepreneur Stream Business Plan

- LMIA Owner Operator Business Plan

- ICT Work Permit Business Plan

- LMIA Mobility Program – C11 Entrepreneur Business Plan

- USMCA (ex-NAFTA) Business Plan

- Franchise Business Planning

- Landlord Business Plan

- Nonprofit Start-Up Business Plan

- USDA Business Plan

- Cannabis business plan

- eCommerce business plan

- Online Boutique Business Plan

- Daycare business plan

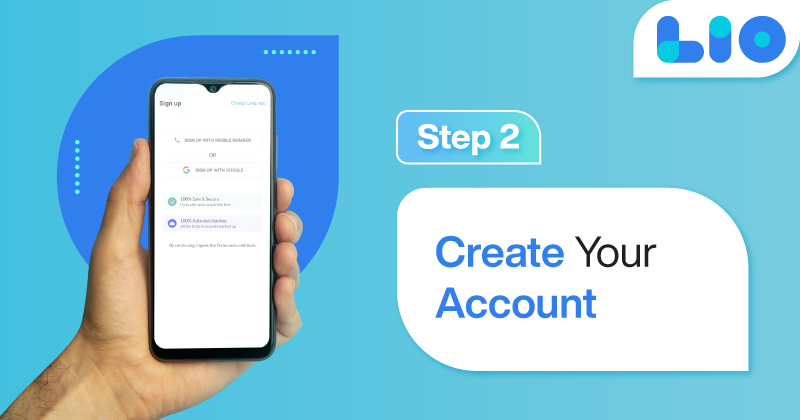

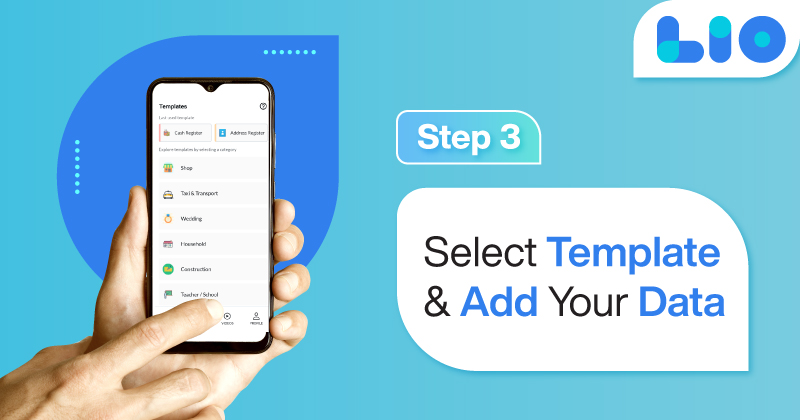

- Mobile Application Business Plan

- Restaurant business plan

- Food Delivery Business Plan

- Real Estate Business Plan

- Business Continuity Plan

- Buy Side Due Diligence Services

- ICO whitepaper

- ICO consulting services

- Confidential Information Memorandum

- Private Placement Memorandum

- Feasibility study

- Fractional CFO

- How it works

- Business Plan Templates

How To Write A Textile Manufacturing Business Plan

Published Mar.29, 2024

Updated Apr.23, 2024

By: Alex Silensky

Average rating 5 / 5. Vote count: 2

No votes so far! Be the first to rate this post.

Table of Content

Textile Manufacturing Business Plan Sample

According to a report by Grand View Research, the global textile market size was valued at USD 1.25 trillion in 2023 and might reach USD 1.84 trillion in 2030. In this booming sector, preparing a professional textile manufacturing business plan is not just a formality; it’s a strategic move that can determine the success or failure of your venture.

This article is crucial for entrepreneurs who aim to enter the textile market. By the end of this article, you will have a clear understanding of how to write a business plan for the textile industry and its key components, including:

Executive Summary

Company overview, industry analysis, customer analysis, competitive analysis, marketing plan, operations plan, financial plan.

We will use FabriCo as a sample textile manufacturing business as a practical example. This will give you a clear understanding of what a textile manufacturing business plan looks like, and you’ll be able to use FabriCo’s textile business plan template for your business. You can also refer to our fabric store business plan here.

Business Overview

Name: FabriCo

Location: Los Angeles, California

Legal Structure: Limited Liability Company (LLC)

Mission: To produce high-quality, eco-friendly, and affordable textile products for the domestic and international markets

Vision: To become a leading textile manufacturer and exporter in the US and beyond

Objectives: To achieve the following goals in the next five years:

- Increase annual revenue by 20%

- Expand production capacity by 50%

- Diversify product portfolio by adding new categories and designs

- Enter new markets in Europe, Asia, and Africa

- Enhance brand awareness and customer loyalty

FabriCo’s products are divided into two main categories:

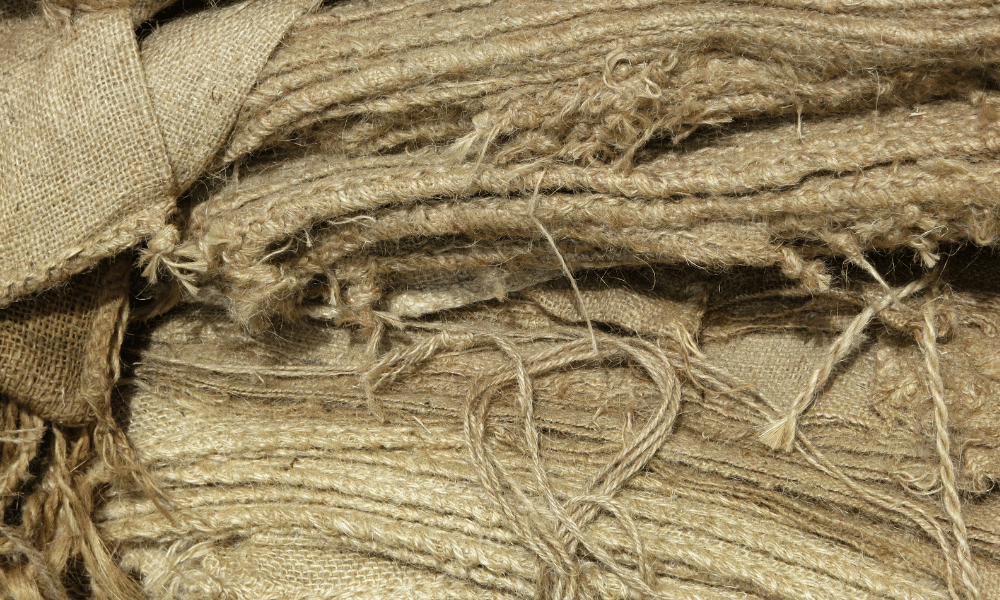

FabriCo produces fabrics using various types of natural and synthetic fibers. FabriCo also creates fabrics with different patterns, colors, textures, and finishes as explained in our clothing retail business plan . FabriCo’s fabrics are categorized into four segments:

- Basic fabrics

- Premium fabrics

- Luxury fabrics

- Eco-friendly fabrics

2. Garments

FabriCo manufactures garments using its own fabrics. FabriCo can produce various types of garments for:

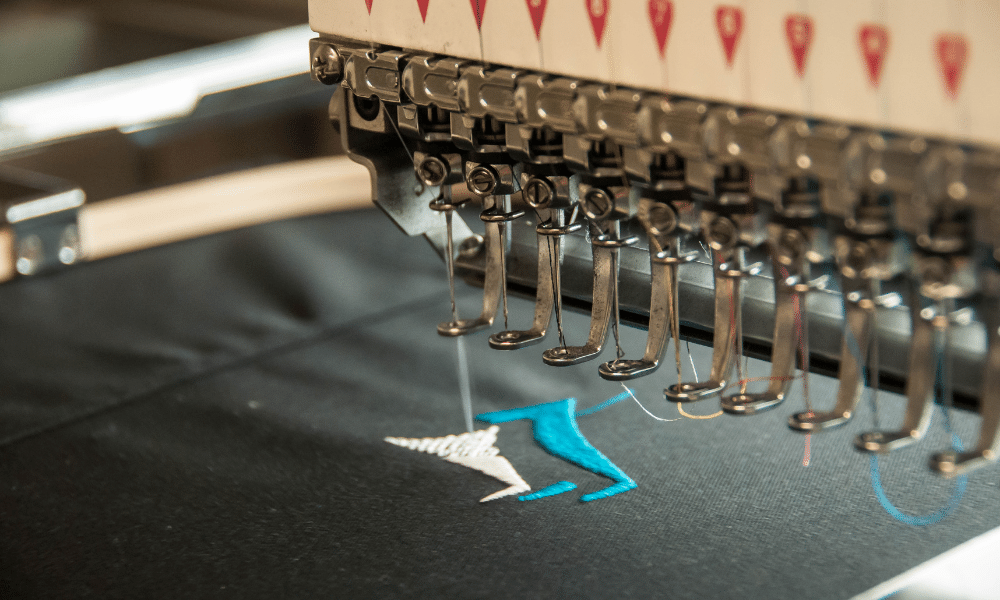

FabriCo also offers services such as:

- Sewing (use our sewing business plan )

- Embroidery (use our embroidery business plan )

- Embellishment

- Quality control.

FabriCo’s garments are categorized into three segments:

- Casual garments

- Formal garments

- Custom garments

Customer Focus

FabriCo’s target customers are fashion brands, retailers, and wholesalers looking for high-quality, sustainable, and innovative fabrics and garments for their collections.

FabriCo’s target customers are mainly located in the US and Europe, where the demand for textile products is high, and the awareness of environmental and social issues is increasing.

FabriCo’s target customers are segmented into four groups:

- Small and medium-sized fashion brands

- Large and established fashion brands

- Fashion retailers and wholesalers

- Eco-friendly and ethical fashion brands, retailers, and wholesalers

Management Team

FabriCo’s management team consists of the following key members:

- Emily Thompson, CEO and Founder

- David Wong, Chief Operating Officer

- Jessica Lee, Creative Director

Success Factors

Success factors are the areas that FabriCo will focus on and excel at, and that will differentiate FabriCo from its competitors. FabriCo’s success factors are:

- Eco-friendly production processes

- Sustainable sourcing

- Innovative textile designs

- Cutting-edge technology

- Strong partnerships with fashion brands and retailers

- Efficient supply chain and operations

- Commitment to ethical labor practices and social responsibility

Financial Highlights

FabriCo has a solid and profitable financial performance, as shown by the following financial highlights:

- Generate $1.2 million in revenue in the first year of operation, growing at a CAGR of 25% to reach $2.4 million in the third year.

- Achieve a gross profit margin of 50% in the first year of operation, increasing to 54% in the third year.

- Achieve an operating profit margin of 25% in the first year of operation, increasing to 33% in the third year.

- Achieve a net profit margin of 20% in the first year of operation, increasing to 27% in the third year.

Who is FabriCo?

FabriCo is a textile manufacturing company founded in 2024 by Emily Thompson. The mission is to produce:

- High-quality

- Eco-friendly

- Innovative fabrics for various industries and customers.

The company’s vision is to become a leader and a pioneer in the textile industry by offering products and services that are superior, sustainable, and creative.

FabriCo Textile History

2020 – Emily and David met at a textile conference and decided to start a business together.

2021 – Developed a smart e-textile business plan and a prototype of their products.

2022 – Secured funding from angel investors and venture capitalists.

2023 – Leased a warehouse and machinery in Los Angeles, California.

2024 – Launched their products and services and started selling fabrics and garments.

The global textile manufacturing industry is a multi-billion dollar market. According to a report by Mordor Intelligence:

- The Textile Market size is estimated at USD 748 billion in 2024

- It is expected to reach USD 889.24 billion by 2029

- The CAGR is estimated to be 3.52% during the forecast period (2024-2029)

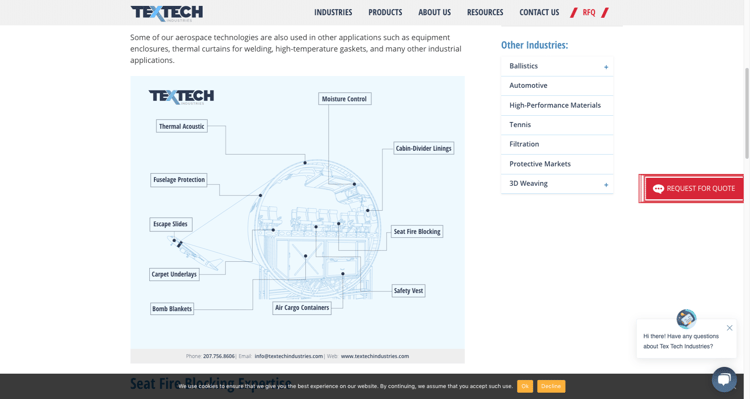

Image Source: Mordor Intelligence

The textile industry is influenced by several factors, such as:

- Raw material availability and prices

- Labor costs and availability of skilled labor

- Technological advancements

- Consumer preferences and fashion trends

- Environmental regulations and sustainability concerns

- Trade policies and international trade agreements

Demographic Profile of Target Market

FabriCo’s target market consists of customers interested in buying high-quality, eco-friendly, and innovative fabrics for various purposes and applications. The demographic profile of FabriCo’s target market is:

| Age | 25-54 years old |

| Gender | Primarily female-led brands and designers |

| Income | Middle to high-income ($50,000 to $200,000 or above) |

| Education | College degree or higher |

| Location | Urban and suburban areas |

| Lifestyle | Eco-conscious, socially responsible, health-conscious |

| Values | Prioritize sustainability, ethical practices, transparency |

Customer Segmentation

FabriCo’s customer base is segmented into the following groups:

- Fashion Brands: Includes eco-friendly fashion labels, designer brands, and apparel retailers that prioritize sustainable and ethically produced textiles.

- Home Furnishing Retailers: Includes home furnishing stores, interior design firms, and retailers that offer eco-friendly home textiles.

- Conscious Consumers: Includes environmentally conscious individuals and prefer to purchase sustainable and ethically produced products.

Table: Demographic Data

| Fashion Brands | 25-45 | Male & Female | $60,000 – $150,000 | Urban areas |

| Home Furnishing Retailers | 35-55 | Male & Female | $80,000 – $200,000 | Suburban areas |

| Conscious Consumers | 25-45 | Female | $50,000 – $120,000 | Urban and suburban areas |

Direct and Indirect Competitors

FabriCo faces competition from direct and indirect competitors who offer similar or substitute products and services in the textile industry. Some of the main competitors are:

Direct Competitors

Direct competitors produce and sell fabrics for the same or similar industries and customers as FabriCo. Some of the direct competitors are:

1. TextiCo (Los Angeles, CA)

TextiCo is a well-established player in the sustainable textile manufacturing industry, headquartered in Los Angeles. TextiCo specialize in producing a range of eco-friendly fabrics for the fashion and apparel market.

- Long-standing reputation in the industry

- Diverse product portfolio catering to various market segments

- Established relationships with major fashion brands

- Perceived as a more traditional player, lacking innovation

- Limited focus on cutting-edge fabric technologies

- Relatively higher production costs due to legacy systems

2. Fabrica (Portland, OR)

Fabrica is a leading manufacturer of sustainable textiles based in Portland, Oregon. They specialize in producing high-performance fabrics from recycled and biodegradable materials, primarily targeting the activewear and athleisure markets.

- Cutting-edge research and development capabilities

- Strong focus on performance and functional fabrics

- Established partnerships with leading activewear brands

- Limited product offerings for the high-end fashion market

- Relatively smaller scale of operations compared to larger competitors

- Geographical concentration in the Pacific Northwest region

Indirect Competitors

Indirect competitors produce and sell fabrics for different or complementary industries and customers as FabriCo. Some of the indirect competitors are:

1. Traditional Textile Manufacturers

Traditional manufacturers have been operating in the industry for decades, producing fabrics using conventional materials and processes. While they may not specifically focus on sustainable textiles, they offer alternative fabric options for various market segments.

- Large production capacities and global reach

- Diversified product offerings catering to various industries

- Established relationships with major brands and retailers

- Perceived as less environmentally friendly due to traditional manufacturing processes

- Slower adaptation to sustainable practices and consumer trends

- Limited focus on innovative and specialized fabric solutions

2. Imported Fabrics from Overseas Markets (e.g., China, India)

Textile manufacturing is a significant industry in many overseas markets, where fabrics are produced at lower costs and exported globally. While not necessarily focused on sustainability, these imported fabrics can compete on price and availability.

- Cost advantages due to lower labor and production costs

- Ability to quickly scale production to meet high-volume demands

- Access to diverse raw materials and manufacturing capabilities

- Longer lead times and potential supply chain disruptions

- Varying quality standards and limited transparency

- Potential challenges in adhering to sustainable and ethical practices

Competitive Advantage

FabriCo highly focuses on sustainability and innovation. FabriCo differentiates itself through the following strengths:

- Advanced Technology – FabriCo invests heavily in modern technology that minimizes environmental impact while ensuring superior product quality.

- Innovative Material Sourcing – FabriCo uses renewable and recycled materials and new sustainable fibers.

- Strong Partnerships – FabriCo has established strategic partnerships with suppliers, ensuring a reliable and responsible supply chain.

- Continuous Research and Development – FabriCo’s in-house research team continuously explores new fabric solutions to stay ahead of market trends.

- Exceptional Customer Service – FabriCo prioritizes building strong customer relationships and offering personalized support.

Promotions Strategy

FabriCo’s promotional strategy is to raise awareness, generate interest, and increase sales of its products and services. FabriCo’s promotions strategy consists of the following tactics:

1. Digital Marketing

- Social media campaigns

- Influencer collaborations with sustainable fashion influencers

- Targeted online advertising campaigns

- Content marketing

2. Trade Shows and Exhibitions

- Participation in key industry events

- Showcasing products and networking

- Organizing product demonstrations and seminars

3. Strategic Partnerships

- Collaborations with like-minded organizations, influencers, and industry associations

- Co-marketing campaigns and cross-promotions

- Sponsorships and endorsements

4. Sustainable Fashion Events

- Organizing or sponsoring eco-friendly fashion shows

- Engaging with the local sustainable fashion community

- Showcasing our products and thought leadership

5. Public Relations

- Press releases and media outreach

- Guest articles and interviews in industry publications

- Speaking opportunities at relevant conferences and events

FabriCo’s total annual marketing budget is $400,000 , 8% of its projected revenue for the first year. FabriCo’s marketing budget will be used as follows:

FabriCo’s pricing strategy is to offer competitive and value-based prices for its products and services. FabriCo’s prices vary depending on the products and services type, quantity, and quality. The average prices are:

- Cotton fabrics: $10 per yard

- Synthetic fabrics: $8 per yard

- Blended fabrics: $9 per yard

- Design service: $100 per hour

- Customization service: $50 per hour

- Delivery service: $20 per order

Operation Functions

FabriCo’s operations are designed to ensure efficient and sustainable textile manufacturing processes. FabriCo’s operation functions include:

1. Sourcing

- Identifying and selecting the best suppliers

- Negotiating the terms and prices

- Maintaining a good relationship and communication

- Receiving and inspecting the materials

2. Production

- Spinning the fibers into yarns

- Knitting or weaving the yarns into fabrics

- Dyeing the fabrics using environmentally friendly dyes

- Finishing the fabrics using finishing machines and treatments

- Testing the fabrics for quality, durability, and performance

- Generating and developing design concepts

- Presenting and discussing the designs with the customers

- Revising and finalizing the designs according to the feedback

4. Customization

- Understanding and analyzing the customer’s needs

- Using techniques and treatments to enhance the fabrics

- Checking and confirming the quality and accuracy

- Delivering the customized fabrics, if needed

5. Delivery

- Packing the fabrics in secure packages

- Labeling the packages properly

- Shipping the packages using the chosen method

- Receiving and verifying the delivery confirmation and feedback

FabriCo’s milestones are the goals and objectives that company aims to achieve in the short-term and long-term. FabriCo’s milestones for the next two years are:

| Q1 2024 | Official launch of FabriCo’s online store and first product line |

| Q2 2024 | Achieve break-even point |

| Q3 2024 | Introduce a second line of eco-friendly fabrics |

| Q4 2024 | Expand production capacity by 25% |

| Q1 2025 | Launch a partnership program with fashion designers |

| Q2 2025 | Begin international shipping to select countries |

| Q3 2025 | Open a physical showroom in Los Angeles for B2B clients |

| Q4 2025 | Introduce a recycling program for fabric scraps |

Key Revenue & Costs

FabriCo’s key revenue will come from:

- Fabric Sales: Primary source of revenue, projected to account for 80% of total revenue.

- Custom Design Services: Offering bespoke design solutions, estimated to contribute 10% of revenue.

- Consultation Services: Providing industry expertise, expected to generate 5% of revenue.

- Workshops and Training: Hosting educational events, potentially bringing in 3% of revenue.

- Licensing and Partnerships: Collaborating with other brands that could account for 2% of revenue.

FabriCo’s key cost includes:

1. Startup Costs

- Acquisition of manufacturing equipment and facility setup

- Initial working capital and inventory

- Initial research

- Branding and marketing

2. Fixed Costs

- Rent or lease payments

- Salaries and benefits for employees

- Insurance premiums

- Administrative expenses

3. Variable Costs

- Raw material procurement

- Packaging and labeling materials

- Shipping and logistics costs

- Sales commissions or incentives

- Marketing and promotion

- Development expenses

Funding Requirements and Use of Funds

Funding requirements: FabriCo requires $1.5 million to start and operate its business. FabriCo has secured $1 million in funding from angel investors and venture capitalists and is seeking another $500,000 from banks and other sources.

Use of funds: FabriCo plans to use the funds for the following purposes:

| Equipment and machinery | $500,000 |

| Raw materials and inventory | $300,000 |

| Rent and utilities | $200,000 |

| Labor and salaries | $200,000 |

| Marketing and advertising | $100,000 |

| Research and development | $100,000 |

| Legal and accounting | $50,000 |

| Contingency | $50,000 |

Key Assumptions

FabriCo’s assumptions are based on market research, industry trends, and our strategic plan, providing a solid foundation for our financial projections:

- 20% year-over-year increase in sales volume.

- 5% annual increase in the cost of raw materials and overheads.

- Inventory turnover ratio of 6 times per year.

- Averaging 45 days for the collection of receivables.

- Allocating 10% of annual profits towards capital investments.

- Interest rates on borrowed capital are assumed to be at 7% annually.

- Corporate tax rate is assumed to be 25% of pre-tax profits.

Financial Projections

FabriCo’s financial projections are the forecasts and calculations of its financial performance and position. FabriCo’s financial projections include:

- Projected Income Statement

- Projected Balance Sheet

- Projected Cash Flow Statement

Need Help with Your Textile Manufacturing Business Plan? OGSCapital Can Help

At OGSCapital, we pride ourselves on our extensive experience and deep expertise in crafting bespoke business plans like the maternity clothing business plan . We understand how much it costs to start a textile manufacturing venture, and we’re here to guide you through every step.

We go beyond templates and generic software to provide personalized strategies, in-depth market research, and financial projections that align with your objectives. Our expertise lies in transforming your entrepreneurial ideas into compelling textile recycling business plans that attract investors and secure funding.

Contact Us today, and let’s create a business plan that sets you up for success.

Frequently Asked Questions

Are textiles profitable?

Textile manufacturing is a profitable industry, with the global market size valued at USD 993.6 billion in 2021 and expected to grow at a compound annual growth rate of 4.0% from 2022 to 2030.

What are examples of textile businesses?

Textile businesses encompass a wide range of companies, including Milliken & Company, Hanesbrands Inc., Culp Inc., Burlington Industries, Glen Raven Inc., W.L. Gore & Associates, and more.

OGSCapital’s team has assisted thousands of entrepreneurs with top-rate business plan development, consultancy and analysis. They’ve helped thousands of SME owners secure more than $1.5 billion in funding, and they can do the same for you.

Bowling Alley Business Plan Sample

Nightclub Business Plan (2024): A Comprehensive Guide

Rabbit Farming Business Plan

Beverages Business Plan

Private Schools Business Plan

Business Plan for a Lounge

Any questions? Get in Touch!

We have been mentioned in the press:

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Search the site:

How To Start A Textile Business

If you’re passionate about textiles and are ready to take the leap into entrepreneurship, starting a textile business can be a fulfilling and lucrative venture. However, it takes more than just a love for fabrics and designs to succeed in this industry. It requires careful planning, research, and execution to create a successful textile business.

In this article, you’ll learn the essential steps to start your textile business, from researching the market and developing a business plan to creating your brand and promoting your business.

Whether you’re a seasoned textile professional or a newcomer to the industry, this guide will provide you with the tools and knowledge you need to turn your passion into a thriving business.

So, let’s get started and turn your dream of owning a textile business into a reality.

Table of Contents

Research the Textile Market

You gotta research the textile market to figure out what fabrics and designs are in demand. This is the first step to starting your textile business.

Conducting market research will help you understand the current trends, the target audience, and the competition in your area. You can also identify the gaps in the market and decide on what kind of fabric or design you want to offer.

To conduct market research, you can start by visiting popular textile shops in your area and observing what fabrics and designs are selling the most. You can also attend textile trade shows, browse online marketplaces, and read industry publications to gain insights into the latest trends.

Analyzing the data you collect will help you make informed decisions on what kind of textile products to offer.

Once you have identified the demand and trends in the textile market, you can start planning your business accordingly. You can create a business plan that outlines your product offerings, target market, marketing strategies, and financial projections. Having a clear roadmap will help you stay focused and organized while starting your textile business.

Remember, researching the textile market is crucial to starting a successful textile business.

Develop a Business Plan

Developing a solid plan is crucial for the success of any venture in the textile industry. A business plan will help you identify your target market, analyze your competition, and set achievable goals. It’ll also help you secure funding from investors or lenders.

Your business plan should include a description of your company, the products or services you offer, and your target market. You should also include a detailed analysis of your competition, including their strengths and weaknesses. This will help you identify opportunities to differentiate yourself from your competitors.

In addition, your business plan should include financial projections, including your expected revenue and expenses for the first few years of operation. This will help you determine how much funding you need to start your business and when you can expect to break even.

With a solid business plan in place, you’ll be well on your way to starting a successful textile business.

Choose Your Textile Niche

Choosing your textile niche is essential for success in the industry. You need to identify the market demand and your expertise to find the right niche.

There are various textile niches, including clothing, home decor, and accessories. Choose the one where you can add value and differentiate yourself from competitors.

If you’re passionate about fashion and have experience in designing clothes, then the clothing niche can be the right fit for you. You can create your clothing line or collaborate with other designers to offer unique and trendy designs.

The home decor niche is another popular option, where you can design and sell products such as curtains, beddings, and rugs. The accessories niche is also worth considering, where you can make and sell items such as bags, hats, and scarves.

It’s crucial to research your chosen niche and understand the market trends, customer preferences, and competition. Analyze the pricing, quality, and style of the products offered by your competitors to identify gaps and opportunities.

Additionally, consider the availability of raw materials and manufacturing facilities, as they can affect the production cost and quality.

Overall, choosing the right textile niche is the first step towards building a successful textile business.

Create Your Textile Brand

Establishing a unique identity and reputation in the textile industry can be achieved through creating your own brand. Your brand is what sets you apart from your competitors and makes your business memorable. It’s essential to carefully create your brand and ensure it accurately represents your business.

To create your textile brand, consider the following tips:

Define your brand’s values and mission statement. This will help you create a consistent message for your brand and give your customers a clear understanding of what your business stands for.

Choose a name and logo that reflects your brand’s values and mission statement. A memorable and visually appealing logo can help your business stand out and be easily recognizable.

Additionally, it’s important to create a consistent visual identity for your brand. This includes the colors, fonts, and imagery that you use on your website, social media, and marketing materials. Consistency is key, as it helps to establish a cohesive look and feel for your brand.

By creating a strong and memorable brand, you can establish a loyal customer base and set yourself up for long-term success in the textile industry. Take the time to carefully consider and craft your brand, and it’ll pay off in the long run.

Set up Your Textile Business

Now it’s time to get your textile venture up and running. The first step to setting up your textile business is to register it legally. You’ll need to choose a business structure, such as a sole proprietorship, partnership, or corporation, and register with your state’s government. This will give you a tax ID and allow you to legally operate your business.

Once your business is registered, you can start setting up your physical space. This includes finding a location, setting up your equipment, and creating a workspace that is efficient and functional. You’ll also need to start building your team by hiring employees or contractors who can help you with the day-to-day tasks of running your textile business.

To give you an idea of what you’ll need, take a look at this table:

| Equipment | Description |

|---|---|

| Sewing Machines | Used for stitching fabrics together |

| Cutting Tables | Used for measuring and cutting fabrics |

| Irons and Ironing Boards | Used for pressing fabrics |

| Embroidery Machines | Used for adding designs to fabrics |

| Serger Machines | Used for finishing seams on fabrics |

By following these steps and equipping yourself with the right tools, you’ll be well on your way to setting up a successful textile business. Remember to take your time and make informed decisions, as this will help you establish a solid foundation for your venture. Good luck!

Promote Your Textile Business

Now that you’ve set up your textile business, it’s time to promote it.

You can start by developing a marketing strategy that includes social media platforms, print ads, and email marketing. Creating an online presence through a website and social media accounts will help you reach a wider audience.

Don’t forget to attend textile trade shows and events to showcase your products and network with potential clients.

Develop Your Marketing Strategy

To get your textile business off the ground, you’ll want to focus on developing a marketing strategy that speaks directly to your target audience. Here are three steps to help you get started:

Identify your target audience: Before you can create a marketing strategy, you need to know who your ideal customer is. Consider factors such as age, gender, income, and lifestyle when determining your target audience. This will help you tailor your messaging and reach the right people.

Define your unique selling proposition: What sets your textile business apart from your competitors? Figure out what makes your products or services unique and use that to your advantage in your marketing efforts. Highlight your strengths and use them to differentiate yourself in a crowded market.

Choose your marketing channels: There are many ways to reach your target audience, from social media to print advertising. Consider your budget, your audience’s preferences, and your business goals when choosing which channels to focus on. Remember to track your results and adjust your strategy as needed to maximize your return on investment.

By following these steps, you can develop a marketing strategy that effectively promotes your textile business and helps you attract and retain customers.

Create Your Online Presence

Establishing your online presence is crucial for reaching your target audience and growing your brand, so make sure you create a website and social media accounts that showcase your unique selling proposition. Your website should be visually appealing, easy to navigate, and provide all the necessary information about your business. Make sure to include high-quality product images, detailed descriptions, and customer reviews. You can also add a blog section to your website where you can share industry news, product updates, and other relevant content that your target audience would find interesting and engaging.

In addition to your website, you should also create social media accounts on platforms like Facebook, Instagram, Twitter, and LinkedIn. Social media is a powerful tool for building brand awareness, driving traffic to your website, and engaging with your target audience. Use social media to share product images, run promotions, and interact with your followers. To help you get started, here is a table that shows the benefits of having a strong online presence for your textile business:

| Benefit | Emotional Response | Example | ||

|---|---|---|---|---|

| Increased brand visibility | Excitement | More people will discover and recognize your brand | ||

| Improved customer engagement | Trust | Customers will feel more connected to your brand and be more likely to make a purchase | ||

| Higher website traffic | Satisfaction | More people visiting your website means more potential customers | ||

| Greater competitive advantage | Confidence | Having a strong online presence can set you apart from competitors and position you as a leader in the industry | Ultimately, a strong online presence can lead to increased brand awareness, customer loyalty, and revenue growth. |

Attend Textile Trade Shows and Events

Attending textile trade shows and events can be a valuable opportunity for networking and gaining industry insights. It’s a chance to meet other business owners, buyers, and suppliers who can provide useful information and contacts.

You can learn about the latest trends and technologies in the industry, as well as see new products and designs. To make the most of your time at a textile trade show or event, here are three tips to keep in mind:

Plan ahead: Research the event beforehand and make a list of the exhibitors and seminars you want to visit. This will help you stay focused and make the most of your time.

Bring business cards: Make sure to bring plenty of business cards to hand out to potential contacts and vendors. This will help you stay in touch after the event and build long-lasting relationships.

Be open to new ideas: Keep an open mind and be willing to learn about new products and trends. This can help you stay competitive and innovative in your own business.

Manage Your Textile Business

Managing a textile business can be challenging, but it can also be incredibly rewarding with the right strategies and team in place. One of the most important things you can do is to stay organized. This means keeping track of inventory, finances, and orders. Consider investing in a good software system to help you manage these aspects of your business efficiently.

Another key aspect of managing a textile business is building strong relationships with your suppliers and customers. This means communicating effectively, responding promptly to inquiries or concerns, and delivering on your promises. It’s also important to stay up-to-date with industry trends, so you can offer the latest styles and designs to your customers.

Don’t forget to take care of yourself and your team. Running a business can be stressful, so it’s important to make time for self-care and relaxation. Consider offering benefits like flexible schedules, paid time off, or wellness programs to help your employees stay healthy and happy. By taking care of your team, you’ll create a positive work environment that will ultimately benefit your business.

- Recent Posts

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024

Related Posts:

How to start textile business and scale it up by effective planning in 2024

Introduction

Embarking on the journey of establishing a textile business requires a meticulous blend of strategic planning, industry insight, and an unwavering passion for the realm of fabrics. Initiating a textile business involves traversing diverse stages, from the inception of ideas to their tangible execution, all with the ultimate aim of crafting a prosperous and sustainable venture. Within this comprehensive guide, we will explore pivotal elements such as conducting thorough market research, adeptly sourcing raw materials, establishing a robust supply chain, and crafting effective marketing strategies tailored to the dynamic textile landscape.

Grasping the intricacies of the textile industry is paramount, and this guide aims to furnish you with invaluable insights to make judicious decisions at every juncture. Whether you’re a seasoned entrepreneur venturing into a new sector or an enthusiastic newcomer with a fervour for textiles, consider this guide your steadfast companion, poised to aid you in the pursuit of launching and nurturing a flourishing textile business.

Textile Supply Chain Process

The textile supply chain process is a dynamic and intricate system that intricately weaves together various stages, ensuring the seamless production and distribution of textiles globally. From the meticulous sourcing of raw materials to the final delivery of finished products, understanding the nuances of this process is paramount for industry players aiming to optimise efficiency and respond to market demands.

Raw Material Sourcing:

At the core of the textile supply chain process lies raw material sourcing — the foundational stage that significantly influences the quality and characteristics of the end product. Choosing the right materials, whether natural fibres like cotton or synthetic alternatives, is pivotal. This initial step sets the tone for the entire process and emphasises the need for responsible sourcing practices that align with sustainability and ethical considerations.

In the realm of the textile supply chain process, raw material sourcing emerges as a critical determinant of product quality and market competitiveness. Companies must meticulously evaluate suppliers, considering factors such as cost, environmental sustainability, and ethical practices. Prioritising responsible sourcing not only ensures the production of high-quality textiles but also contributes to a more sustainable and socially conscious industry.

Manufacturing and Processing:

Once the raw materials are secured, the textile supply chain process moves to the manufacturing and processing stage. Here, various intricate processes like spinning, weaving, knitting, dyeing, and finishing come into play, shaping the raw materials into the final textile product. Advanced machinery and technology play a pivotal role, emphasising the industry’s commitment to efficiency and precision.

In the manufacturing and processing stage of the textile supply chain process, companies constantly strive for innovation to enhance productivity and reduce waste. Embracing cutting-edge technologies and sustainable practices not only streamlines production but also aligns with the industry’s increasing focus on eco-friendly and cost-effective manufacturing methods.

Distribution and Logistics:

The journey of textiles continues with the distribution and logistics phase, where products move from manufacturing facilities to distribution centres and, eventually, to retailers or consumers. Effective logistics management is crucial for minimising lead times, reducing costs, and ensuring timely delivery.

Distribution and logistics within the textile supply chain process require constant optimization. Companies invest in advanced tracking systems, inventory management software, and strategic partnerships with logistics providers to gain visibility and control over the entire supply chain. This proactive approach is instrumental in mitigating potential disruptions and maintaining a seamless flow of products from production to consumption.

Retail and Consumer Engagement:

The final stages of the textile supply chain process unfold in retail and consumer engagement. Retailers play a key role in presenting and selling the finished textile products to consumers. Success in this stage hinges on effective marketing strategies, responsive customer service, and adaptability to market trends.

In the textile supply chain process, retail and consumer engagement underscore the significance of staying attuned to market preferences. Companies leverage data analytics and consumer feedback to tailor their offerings, meeting evolving demands. Effective communication with consumers enhances brand loyalty, fostering a positive reputation within the industry.

The textile supply chain process is a multifaceted journey from raw material sourcing to consumer engagement. The keyword “textile supply chain process” encapsulates the intricate steps involved in bringing textiles from conception to consumption, highlighting the industry’s commitment to quality, sustainability, and continuous evolution.

How Much Investment Needed To Start A Textile Industry

Investing in a textile industry can be a lucrative venture, but determining the exact amount needed to start such a business requires a comprehensive understanding of various factors. The keyword, “how much investment needed to start a textile industry,” emphasises the critical aspect of financial planning in this endeavour.

Initial Capital Requirements:

The first consideration is the scale of your textile industry. Starting on a smaller scale may require less initial investment, but if you aim for a larger and more sophisticated operation, a substantial capital infusion becomes imperative. The keyword, “how much investment needed to start a textile industry,” underscores the significance of estimating this initial capital.

Plant and Machinery:

A significant portion of your investment will be allocated to acquiring and setting up the necessary machinery and equipment. Modern textile manufacturing often involves advanced technology and automation, which can impact the overall cost. Ensuring that the machinery meets industry standards and is capable of handling the volume you intend to produce is crucial for the success of your venture.

Raw Materials:

Procuring raw materials is another pivotal factor. The type of textiles you plan to manufacture will determine the nature and quantity of raw materials required. Your investment needs to account for securing a stable supply chain and maintaining an inventory to sustain production without interruptions.

Infrastructure and Facilities:

Building a suitable infrastructure is a non-negotiable aspect of starting a textile industry. This includes constructing or adapting a facility that meets regulatory standards, ensures worker safety, and facilitates efficient production processes. Allocating funds for infrastructure development is crucial for a seamless and sustainable operation.

Labour and Training:

Investing in skilled and semi-skilled labour is paramount. Adequate funds must be allocated for recruiting, training, and retaining a competent workforce. Labour costs can significantly impact your budget, and ensuring a fair and safe working environment is essential for long-term success.

Market Research and Marketing:

The keyword, “how much investment needed to start a textile industry,” extends beyond the physical aspects of production. Adequate funds must be reserved for thorough market research to understand consumer needs and preferences. Developing a robust marketing strategy is equally crucial to ensure your products reach the target audience.

Contingency Fund:

Finally, it’s wise to set aside a contingency fund for unforeseen circumstances. Economic fluctuations, market trends, or unexpected challenges can arise, and having a financial buffer will help your textile industry weather uncertainties.

Determining how much investment is needed to start a textile industry requires a meticulous examination of various factors. The keyword emphasises the importance of financial planning, considering not only the tangible assets but also the intangible elements crucial for the sustained success of your venture.

Supply Chain Management In Textile Industry

In the intricate tapestry of the textile industry, the pivotal thread that weaves efficiency and success is none other than supply chain management (SCM). This strategic orchestrator, the linchpin of streamlined operations, acts as the beacon guiding the industry towards a future defined by precision and innovation.

Supply Chain Management in Textile Industry:

Supply chain management in the textile industry isn’t just a phrase; it’s the symphony that harmonises the procurement, production, and distribution notes. Repeated throughout this discourse is the mantra “supply chain management in textile industry,” echoing the industry’s commitment to synchronising every chord in its intricate composition.

Precision Crafting:

Repeated articulation of the keyword underscores the industry’s dedication to precision crafting. It’s about more than just sourcing raw materials; it’s about optimising processes for maximum efficiency. By seamlessly aligning every stage of the supply chain, from the loom to the showroom, textile companies can create a masterpiece of resource utilisation, reduce lead times, and leave an indelible mark of satisfaction on their customers.

Navigating the Loom of Risks:

The repetitive inclusion of the keyword accentuates the textile industry’s commitment to navigating the loom of risks. In a landscape where market fluctuations and unforeseen disruptions are as common as warp and weft, supply chain resilience is the key. Diversifying suppliers, fortifying contingency plans, and utilising technology for real-time monitoring become the threads of resilience that ensure the fabric of the industry remains unbroken even in the face of adversity.

Technological Tapestry:

Repeatedly echoing the keyword highlights the industry’s relentless pursuit of a technological tapestry. It’s about more than just embracing innovation; it’s about leveraging technology for strategic advantage. The integration of IoT devices, the embrace of data analytics for demand forecasting – these are the tools that allow the textile industry to not only keep pace with change but to set the pace.

Textile Industry Business Plan

In the intricate tapestry of business, a well-crafted textile industry business plan is the thread that binds success. As you embark on this journey, it is essential to understand the significance of meticulous planning to seamlessly navigate the complexities of the textile sector.

The textile industry, a dynamic and ever-evolving sector, demands a comprehensive business plan that serves as the compass for entrepreneurs. A textile industry business plan lays the foundation for success by outlining the vision, mission, and strategies that will drive the business forward.

Market Analysis:

A robust textile industry business plan begins with a detailed market analysis. Identifying key trends, consumer preferences, and competitor landscapes are pivotal. By integrating this keyword – ‘Textile Industry Business Plan’ – into the market analysis section, you ensure a continual focus on the core document that will shape your business’s destiny.

Operational Framework:

Efficient operations are the loom upon which a successful textile business is woven. Detailing the production processes, supply chain logistics, and quality control measures is crucial. This keyword, ‘Textile Industry Business Plan,’ serves as a constant reminder of the overarching strategy embedded in every operational facet.

Financial Projections:

Financial viability is the warp and weft of any business. Integrating the ‘Textile Industry Business Plan’ keyword into the financial projections section emphasises the financial foresight that is integral to your textile venture’s sustainability. From startup costs to revenue projections, this keyword underscores the financial intricacies that must be woven into the fabric of your business plan.

Marketing and Sales Strategy:

In a competitive market, effective marketing and sales strategies are akin to the vibrant colours that make a fabric stand out. Weave the ‘Textile Industry Business Plan’ keyword into this section to highlight how your business will position itself, reach target customers, and drive sales. This keyword serves as a constant reminder that every marketing initiative is aligned with the overarching business plan.

Risk Management:

No business is immune to risks, and the textile industry is no exception. The ‘Textile Industry Business Plan’ keyword, when integrated into the risk management section, emphasises your proactive approach to identifying and mitigating potential challenges. It showcases your commitment to adaptability and resilience, crucial qualities in a rapidly changing industry.

How to Start a Textile Business?

Begin by researching the textile supply chain process, determining the required investment, and crafting a comprehensive business plan. Execute your plan systematically.

What is the Textile Supply Chain Process?

The textile supply chain includes raw material sourcing, production, quality control, and distribution. Understanding each stage is crucial for efficient business operations.

How Much Investment Needed to Start a Textile Industry?

The investment varies, but a detailed analysis considering machinery, raw materials, and operational costs is essential. Seek professional advice to determine an accurate figure.

Importance of Supply Chain Management in Textile Industry?

Efficient supply chain management ensures timely production, reduces costs, and enhances customer satisfaction. It’s a critical factor in maintaining a competitive edge.

What Should a Textile Industry Business Plan Include?

A business plan should outline your goals, target market, competition analysis, marketing strategies, and financial projections. It serves as a roadmap for success.

Conclusion:

In conclusion, launching and growing a textile business in 2024 demands meticulous planning. Qodenext brand stands as a testament to successful planning and execution in the textile industry. Follow these guidelines to make your mark in the competitive textile market.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

24x7. With Multiplier Effect.

Textile Business Plan Template & Guidebook

Have you always wondered how to write a business plan for your textile business? Over the years, I have helped hundreds of entrepreneurs in launching their businesses through my online courses and textile workshops. Now you can learn how to write a business plan for your own textile business with this 7-step guide.

Get worry-free services and support to launch your business starting at $0 plus state fees.

- How to Start a Profitable Textile Business [11 Steps]

- 10+ Best & Profitable Textile Business Ideas [2023]

- 25 Catchy Textile Business Names:

- List of the Best Marketing Ideas For Your Textile Business:

How to Write a Textile Business Plan in 7 Steps:

1. describe the purpose of your textile business..

The first step to writing your business plan is to describe the purpose of your textile business. This includes describing why you are starting this type of business, and what problems it will solve for customers. This is a quick way to get your mind thinking about the customers’ problems. It also helps you identify what makes your business different from others in its industry.

It also helps to include a vision statement so that readers can understand what type of company you want to build.

Here is an example of a purpose mission statement for a textile business:

Our purpose at Textile Inc. is to provide our clients with a wide range of high-quality, stylish, and comfortable textile products that help them enhance the beauty and functionality of their homes, offices, and lives. Our mission is to become the leading provider of textile products in the region, offering a wide range of fabrics, colors, and designs to suit every taste and preference. We are committed to using only the finest materials and latest technology, and to providing exceptional customer service, with knowledgeable and friendly staff who can help clients understand their options and make the best choices for their needs. We aim to provide a safe, efficient, and enjoyable working environment for our team, and to deliver exceptional results that exceed our clients' expectations. We believe that everyone deserves to have access to high-quality, stylish, and comfortable textile products, and we strive to provide our clients with the best products and services available.

2. Products & Services Offered by Your Textile Business.

The next step is to outline your products and services for your textile business.

When you think about the products and services that you offer, it's helpful to ask yourself the following questions:

- What is my business?

- What are the products and/or services that I offer?

- Why am I offering these particular products and/or services?

- How do I differentiate myself from competitors with similar offerings?

- How will I market my products and services?

You may want to do a comparison of your business plan against those of other competitors in the area, or even with online reviews. This way, you can find out what people like about them and what they don’t like, so that you can either improve upon their offerings or avoid doing so altogether.

3. Build a Creative Marketing Stratgey.

If you don't have a marketing plan for your textile business, it's time to write one. Your marketing plan should be part of your business plan and be a roadmap to your goals.

A good marketing plan for your textile business includes the following elements:

Target market

- Who is your target market?

- What do these customers have in common?

- How many of them are there?

- How can you best reach them with your message or product?

Customer base

- Who are your current customers?

- Where did they come from (i.e., referrals)?

- How can their experience with your textile business help make them repeat customers, consumers, visitors, subscribers, or advocates for other people in their network or industry who might also benefit from using this service, product, or brand?

Product or service description

- How does it work, what features does it have, and what are its benefits?

- Can anyone use this product or service regardless of age or gender?

- Can anyone visually see themselves using this product or service?

- How will they feel when they do so? If so, how long will the feeling last after purchasing (or trying) the product/service for the first time?

Competitive analysis

- Which companies are competing with yours today (and why)?

- Which ones may enter into competition with yours tomorrow if they find out about it now through word-of-mouth advertising; social media networks; friends' recommendations; etc.)

- What specific advantages does each competitor offer over yours currently?

Marketing channels

- Which marketing channel do you intend to leverage to attract new customers?

- What is your estimated marketing budget needed?

- What is the projected cost to acquire a new customer?

- How many of your customers do you instead will return?

Form an LLC in your state!

4. Write Your Operational Plan.

Next, you'll need to build your operational plan. This section describes the type of business you'll be running, and includes the steps involved in your operations.

In it, you should list:

- The equipment and facilities needed

- Who will be involved in the business (employees, contractors)

- Financial requirements for each step

- Milestones & KPIs

- Location of your business

- Zoning & permits required for the business

What equipment, supplies, or permits are needed to run a textile business?

To run a textile business, you will need a few key pieces of equipment, supplies, and permits. These include:

- Textile production equipment and supplies

- Packaging and labeling equipment

- A permit to operate your business (depending on location)

- Business licenses and permits for business activities (if applicable)

You may also need to hire and train staff to manage the textile production and provide customer service.

5. Management & Organization of Your Textile Business.

The second part of your textile business plan is to develop a management and organization section.

This section will cover all of the following:

- How many employees you need in order to run your textile business. This should include the roles they will play (for example, one person may be responsible for managing administrative duties while another might be in charge of customer service).

- The structure of your management team. The higher-ups like yourself should be able to delegate tasks through lower-level managers who are directly responsible for their given department (inventory and sales, etc.).

- How you’re going to make sure that everyone on board is doing their job well. You’ll want check-ins with employees regularly so they have time to ask questions or voice concerns if needed; this also gives you time to offer support where necessary while staying informed on how things are going within individual departments too!

6. Textile Business Startup Expenses & Captial Needed.

This section should be broken down by month and year. If you are still in the planning stage of your business, it may be helpful to estimate how much money will be needed each month until you reach profitability.

Typically, expenses for your business can be broken into a few basic categories:

Startup Costs

Startup costs are typically the first expenses you will incur when beginning an enterprise. These include legal fees, accounting expenses, and other costs associated with getting your business off the ground. The amount of money needed to start a textile business varies based on many different variables, but below are a few different types of startup costs for a textile business.

Running & Operating Costs

Running costs refer to ongoing expenses related directly with operating your business over time like electricity bills or salaries paid out each month. These types of expenses will vary greatly depending on multiple variables such as location, team size, utility costs, etc.

Marketing & Sales Expenses

You should include any costs associated with marketing and sales, such as advertising and promotions, website design or maintenance. Also, consider any additional expenses that may be incurred if you decide to launch a new product or service line. For example, if your textile business has an existing website that needs an upgrade in order to sell more products or services, then this should be listed here.

7. Financial Plan & Projections

A financial plan is an important part of any business plan, as it outlines how the business will generate revenue and profit, and how it will use that profit to grow and sustain itself. To devise a financial plan for your textile business, you will need to consider a number of factors, including your start-up costs, operating costs, projected revenue, and expenses.

Here are some steps you can follow to devise a financial plan for your textile business plan:

- Determine your start-up costs: This will include the cost of purchasing or leasing the space where you will operate your business, as well as the cost of buying or leasing any equipment or supplies that you need to start the business.

- Estimate your operating costs: Operating costs will include utilities, such as electricity, gas, and water, as well as labor costs for employees, if any, and the cost of purchasing any materials or supplies that you will need to run your business.

- Project your revenue: To project your revenue, you will need to consider the number of customers you expect to have and the average amount they will spend on each visit. You can use this information to estimate how much money you will make from selling your products or services.

- Estimate your expenses: In addition to your operating costs, you will need to consider other expenses, such as insurance, marketing, and maintenance. You will also need to set aside money for taxes and other fees.

- Create a budget: Once you have estimated your start-up costs, operating costs, revenue, and expenses, you can use this information to create a budget for your business. This will help you to see how much money you will need to start the business, and how much profit you can expect to make.

- Develop a plan for using your profit: Finally, you will need to decide how you will use your profit to grow and sustain your business. This might include investing in new equipment, expanding the business, or saving for a rainy day.

Frequently Asked Questions About Textile Business Plans:

Why do you need a business plan for a textile business.

A business plan is a document that outlines the goals and objectives of a business, as well as the strategies and tactics that will be used to achieve those goals. It is important to have a business plan for your textile business because it helps to focus the efforts of the company, communicate the business's goals and objectives to potential investors, and provide a roadmap for the business to follow. Additionally, a business plan can be used to help secure funding from investors or lenders, who will want to see that the business has a solid plan in place before they provide funding.

How to write a business plan for your textile business?)

To build a business plan for your textile business, start by researching your industry, competitors, and target market. Use this information to define your business's goals and objectives, as well as the strategies and tactics that you will use to achieve those goals. Next, create a financial plan that outlines your projected income, expenses, and profit. This should include a projected income statement, cash flow statement, and balance sheet. Once you have all of this information, you can use it to create a comprehensive business plan that outlines the goals and objectives of your business, as well as the strategies and tactics that you will use to achieve those goals. A well-written textile business plan contains the following sections: Purpose, Products & Services, Marketing Plan (including Marketing Strategy), Operations/Management Plan (including Operations/Management Strategy), Financial Plan (including Financial Forecasts), and Appendixes.

Can you write a textile business plan yourself?

Yes, you can write a textile business plan yourself. Writing a business plan is a valuable exercise that can help you clarify your business idea, identify potential challenges and opportunities, and develop a roadmap for success. While there are many resources and templates available to help you write a business plan, the process of creating one is ultimately up to you.

Related Business Plans

Home Inventory Business Plan Template & Guidebook

Home Inspection Business Plan Template & Guidebook

Home Decor Business Plan Template & Guidebook

Health And Wellness Business Plan Template & Guidebook

Hauling Business Plan Template & Guidebook

Hardware Business Plan Template & Guidebook

Handyman Business Plan Template & Guidebook

Hair Extension Business Plan Template & Guidebook

Handbag Business Plan Template & Guidebook

We're newfoundr.com, dedicated to helping aspiring entrepreneurs succeed. As a small business owner with over five years of experience, I have garnered valuable knowledge and insights across a diverse range of industries. My passion for entrepreneurship drives me to share my expertise with aspiring entrepreneurs, empowering them to turn their business dreams into reality.

Through meticulous research and firsthand experience, I uncover the essential steps, software, tools, and costs associated with launching and maintaining a successful business. By demystifying the complexities of entrepreneurship, I provide the guidance and support needed for others to embark on their journey with confidence.

From assessing market viability and formulating business plans to selecting the right technology and navigating the financial landscape, I am dedicated to helping fellow entrepreneurs overcome challenges and unlock their full potential. As a steadfast advocate for small business success, my mission is to pave the way for a new generation of innovative and driven entrepreneurs who are ready to make their mark on the world.

Get instant access to detailed competitive research, SWOT analysis, buyer personas, growth opportunities and more for any product or business at the push of a button, so that you can focus more on strategy and execution.

Table of contents, textile manufacturing business plan essentials.

- 3 June, 2024

Starting a Textile Manufacturing Business

Before diving into the process of starting a textile manufacturing business, it’s crucial to have a comprehensive understanding of the industry and the importance of market research.

Industry Overview

The textile manufacturing industry plays a vital role in the global economy, encompassing the production of a wide range of textiles and fabrics used in various sectors, including fashion, home furnishings, automotive, and more. This industry involves the transformation of raw materials into finished textile products through processes like spinning, weaving, knitting, dyeing, and finishing.

The textile manufacturing industry is highly competitive and constantly evolving. To thrive in this industry, entrepreneurs need to stay informed about the latest trends, technologies, and consumer demands. Understanding the textile manufacturing industry overview is essential for making informed decisions and developing effective business strategies.

Market Research Importance

Market research is a crucial step in starting a successful textile manufacturing business. It provides valuable insights into the market landscape, consumer preferences, trends, and potential opportunities. Conducting thorough market research enables entrepreneurs to make informed decisions, identify target customers, and develop effective marketing strategies.

Market research can be conducted through primary and secondary research methods. Primary research involves gathering information directly from potential customers and obtaining specific data to identify trends and opportunities. This can be done through surveys, interviews, focus groups, and observations.

On the other hand, secondary research involves gathering data that has been collected by others. This can include industry reports, government publications, trade journals, and online databases. Secondary research provides broader and high-quality data that can save time and provide a broader understanding of the market.

Combining data from both primary and secondary research helps decision-makers analyze and understand the market scenario, identify consumer preferences, and update marketing strategies to meet market demands effectively.

To effectively start a textile manufacturing business, entrepreneurs must have a clear understanding of the industry, its dynamics, and the market they intend to target. By conducting thorough market research, entrepreneurs can gather valuable insights that will guide them in formulating a solid business plan, identifying target customers, and positioning their business for success.

In the next section, we will explore the essential steps to begin a textile manufacturing business, including formulating a business plan, acquiring equipment and machinery, and setting up manufacturing facilities.

Essential Steps to Begin

Starting a textile manufacturing business requires careful planning and execution. Here are the essential steps to consider when embarking on this venture.

Formulating a Business Plan

Before diving into the world of textile manufacturing, it is crucial to formulate a comprehensive business plan. This plan serves as a roadmap for your business, outlining your goals, strategies, and financial projections. It helps you identify potential challenges and opportunities in the textile manufacturing industry.

Your business plan should include:

- Executive Summary: A concise overview of your business, its mission, and key objectives.

- Company Description: Detailed information about your company, including its legal structure, location, and target market.

- Market Analysis: Research and analysis of the textile manufacturing industry, including market trends, competition, and customer demands.

- Product Line: Description of the textile products you plan to manufacture, including their unique selling points and target customers.

- Marketing and Sales Strategy: Strategies for promoting and selling your products, including pricing, distribution channels, and marketing campaigns.

- Operations and Management: Detailed information on manufacturing processes, supply chain management, and key personnel.

- Financial Projections: Financial forecasts, including startup costs, revenue projections, and profit margins.

By formulating a well-structured business plan, you can effectively communicate your vision to potential investors, lenders, and partners. It serves as a crucial document for securing funding and guiding your business decisions.

Acquiring Equipment and Machinery

Acquiring the necessary equipment and machinery is a vital step in setting up your textile manufacturing business. The cost of purchasing manufacturing equipment can vary widely depending on the size and scope of your operation. According to Fin Models Lab , the cost can range from $100,000 to $5 million.

Some of the essential equipment and machinery for textile manufacturing include:

- Weaving and knitting machines

- Cutting and pressing equipment

- Sewing machines

- Textile printing machines

It is important to choose reliable and high-quality equipment that aligns with your production needs. Consider factors such as production capacity, efficiency, and maintenance requirements when making equipment purchasing decisions.

Setting Up Manufacturing Facilities

Creating appropriate manufacturing facilities is a critical aspect of starting a textile manufacturing business. The cost of setting up facilities can vary depending on factors such as location, size, and construction materials. According to Fin Models Lab , the average cost of constructing a textile factory is around $20 million.

Key considerations for setting up manufacturing facilities include:

- Space Requirements: Assess the space needed for your manufacturing processes, including production lines, storage areas, and administrative offices.

- Infrastructure: Ensure your facilities have reliable power supply, water, and waste management systems.

- Safety Measures: Implement proper safety protocols to ensure a safe working environment for your employees, including fire safety measures and ergonomic considerations.

- Quality Control: Establish quality control processes and inspection procedures to maintain product standards.

Additionally, consider the layout and workflow of your manufacturing facilities to maximize operational efficiency and productivity.

By following these essential steps of formulating a business plan, acquiring the necessary equipment and machinery, and setting up manufacturing facilities, you can lay a strong foundation for your textile manufacturing business. Remember to conduct thorough research, seek expert advice, and adapt your plans as needed to navigate the complexities of this industry.

Financial Considerations

Starting a textile manufacturing business involves various financial considerations that need to be carefully planned and managed. This section explores three key aspects: initial investment costs, budgeting for operations, and hiring a skilled workforce.

Initial Investment Costs

Launching a textile manufacturing business requires a significant initial investment. The costs involved can vary depending on the size and scope of the operation. Some of the key expenses to consider include:

Equipment and Machinery : The cost of purchasing manufacturing equipment and machinery can range from $100,000 to $5 million, depending on the scale of the business. This includes machines such as weaving and knitting machines, cutting and pressing equipment, sewing machines, and textile printing machines ( Fin Models Lab ).

Facilities : The average cost of constructing a textile factory is around $20 million, while the cost of setting up a warehouse ranges from $10,000 to $100,000, depending on its size and location ( Fin Models Lab ). It’s important to consider expenses related to land acquisition, construction, utilities, and other infrastructure requirements.

Raw Materials : As a textile manufacturer, you’ll need to budget for the procurement of raw materials such as fibers, yarns, dyes, chemicals, and other supplies. The cost of raw materials will depend on the type of textiles you intend to produce and the sourcing strategy you adopt.

Licensing and Compliance : Obtaining the necessary licenses and permits is a crucial step in starting a textile manufacturing business. Factor in the costs associated with obtaining these licenses, complying with regulations, and meeting safety standards.

Budgeting for Operations

To ensure the smooth operation of your textile manufacturing business, it’s essential to develop a comprehensive budget that covers ongoing expenses. This includes:

Operating Costs : Account for expenses such as utilities, maintenance, repairs, insurance, and taxes. It’s important to analyze these costs carefully and make appropriate provisions to maintain profitability.

Raw Materials and Supplies : Estimate the ongoing costs of purchasing raw materials, chemicals, packaging materials, and other supplies necessary for production.

Labor Costs : Hiring a skilled workforce is an integral part of a successful textile manufacturing business. The cost of hiring skilled workers for design, production, and management can range between $40,000 to $150,000 per year per employee ( Fin Models Lab ). Consider the number of employees required and factor in their salaries, benefits, and training costs.

Marketing and Advertising : Allocate a budget for marketing and advertising activities to promote your textile products, build brand awareness, and attract customers. This may include expenses related to online and offline marketing campaigns, trade shows, and promotional materials.

Hiring a Skilled Workforce

A skilled and knowledgeable workforce is crucial for the success of your textile manufacturing business. Hiring the right talent with expertise in textile design, production, quality control, and management is essential. Consider the following aspects:

Job Roles : Identify the roles and responsibilities required for your business, such as textile designers, production supervisors, machine operators, quality control specialists, and administrative staff.

Recruitment : Develop a recruitment strategy to attract qualified candidates. This may involve advertising job openings, conducting interviews, and assessing candidates’ qualifications and skills.

Training and Development : Invest in training programs to enhance the skills of your workforce and keep them updated with the latest industry trends and technologies.

Compensation : Offer competitive salaries and benefits to attract and retain skilled employees. Take into account industry standards and local market conditions when determining compensation packages.

By carefully considering the financial aspects of starting and operating a textile manufacturing business, you can develop a solid foundation for your venture. Conduct thorough research, create a detailed business plan, and ensure you have the necessary resources to support your operations. Keep in mind that costs can vary based on location, scale, and other factors, so it’s essential to tailor your financial planning to your specific business needs.

Marketing Strategies

In the competitive landscape of the textile manufacturing business, effective marketing strategies are essential to attract customers and establish a strong brand presence. This section will explore key marketing strategies, including market analysis, target customer identification, and competitive landscape analysis.

Market Analysis

Before diving into the textile manufacturing business, conducting a thorough market analysis is crucial. Market research plays a significant role in developing a comprehensive business plan by providing valuable insights into the industry, customer preferences, and market trends. Data collected from market research reports contribute to information about competitors, growth plans, target market, and more ( Market Research ).

A market analysis involves evaluating the size, growth potential, and segmentation of the target market. It helps identify opportunities and potential challenges within the industry. By understanding market dynamics, such as customer demands, trends, and purchasing behaviors, textile manufacturers can tailor their products and marketing strategies to meet the needs of their target audience.

Target Customer Identification

Identifying the target customer is a critical step in developing effective marketing strategies for a textile manufacturing business. Understanding the demographics, preferences, and needs of the target audience allows manufacturers to create products that resonate with their customers. Market research aids in developing effective advertising campaigns based on consumer insights ( Market Research ).