How to Solve Your Problems With Lean Six Sigma (Free DMAIC Checklist)

Elisabeth Swan is the co-author of “The Problem-Solver’s Toolkit” and co-host of “The Just-in-Time Cafe Podcast.” She’s been a process improvement consultant, speaker, and innovator for over 30 years. She’s the Chief Learning Experience Officer for GoLeanSixSigma.com, a former cast member of ImprovBoston, and – if asked – may still be able to ride a unicycle.

Surgeon Atul Gawande made headlines when he told the world that a simple checklist could drastically reduce unnecessary deaths in The Checklist Manifesto .

Yet, checklists conjure images of forklift drivers on loading docks with clipboards counting boxes. How could they transform healthcare?

“ He has… produced a 90-second checklist which reduced deaths and complications by more than one-third in eight hospitals around the world – at virtually no cost and for almost any operation. ” – James Clarke, reviewing The Checklist Manifesto, Ulster Med J. 2011 Jan; 80(1): 54.

Aviation was transformed decades earlier when management and engineers at Boeing Corporation created the pre-flight checklist after the 1935 crash of the prototype Boeing B-17 at Wright Field in Dayton, Ohio. Checklists have become so essential to the airline industry that most crashes can be traced to the misuse or failure to complete a checklist.

A New York Times reviewer noted, “no matter how expert you may be, well-designed checklists can improve outcomes”. Since the purpose of process improvement is improving outcomes, Lean Six Sigma and checklists are natural companions.

To prove that, this Process Street blog post will show the relationship between checklists and lean six sigma, and provide you with a free DMAIC Improvement Project Tollgate Checklist that you can use right now.

Use the links below to jump to that section of the post:

Lean Six Sigma and the role of problem-solving

Lean six sigma & the checklist, introduction phase, define phase, measure phase, analyze phase, improve phase, control phase, checklists and lean six sigma, use process street to reduce error.

Or, if you just want the checklist, check it out below!

Let’s get started.

For those unfamiliar with Lean Six Sigma and process improvement, it is a structured approach for organizations to scrutinize how things are done, poke at data and processes to uncover waste and then cut out things like extra forms, out-dated approvals and other time-wasting steps.

It’s a customer-focused, 5-step problem-solving model that engages entire workforces to constantly seek a better way of doing things.

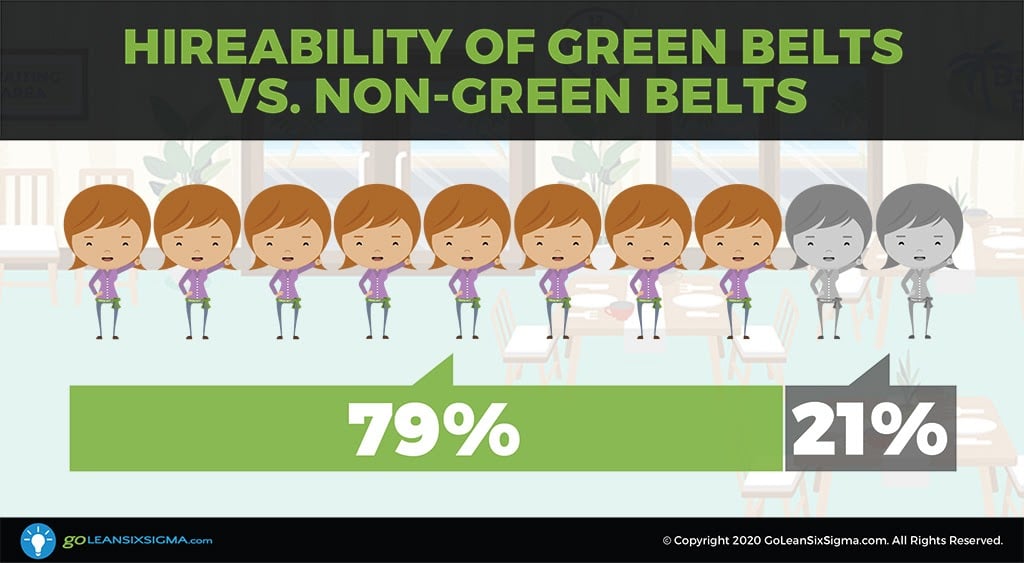

Proof of Lean Six Sigma’s influence is evident in today’s hiring practices. A poll by GoLeanSixSigma highlights that hiring managers prefer a person who is “ Green Belt Certified ” – having substantial Lean Six Sigma skills – by an almost 80% margin. In an interview with the former head of Twitter, problem-solving emerged as the top skill sought by today’s most influential hiring managers.

In other words, problem-solving (especially via Lean Six Sigma) is an absolutely vital skill.

If problem-solving is a must-have skill and checklists are key to good outcomes, then combining the two makes sense.

DMAIC – Define, Measure, Analyze, Improve & Control – is the 5-Step model for Lean Six Sigma and there’s a set of required tollgates at the end of each phase. These tollgates outline what has to be done in order to move the problem-solving process forward.

Using the tollgates as an outline, we created a dynamic Process Street template that you can use for free and run checklists from to track your progress!

Before you can start solving problems, you need a problem to solve.

Picking a process issue – and finding someone in leadership to support you – are two required tasks in this first tollgate. Scoping the project is important (bigger than a “just-do-it” and smaller than “solving world hunger”) but even more critical is finding a Sponsor.

Finding a Sponsor

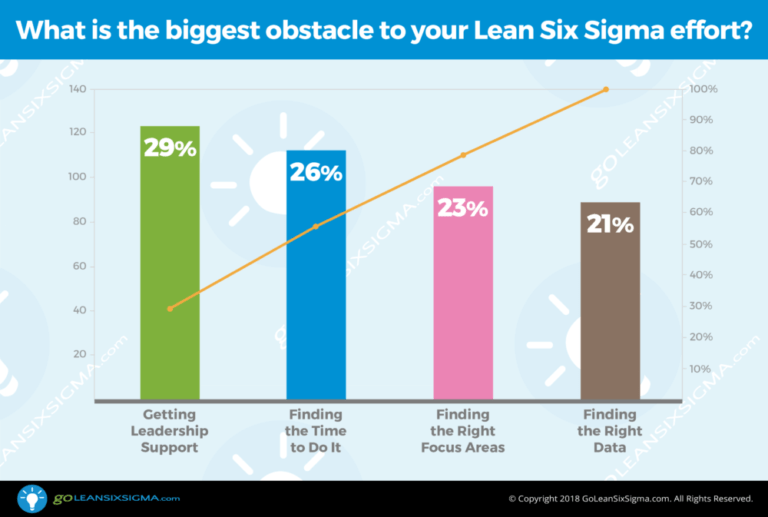

In a poll asking Lean Six Sigma practitioners what they considered the biggest obstacle to process improvement success, “Getting Leadership Support” accounted for almost a third.

When we coach team leads who tell us they can’t find someone to back their project, we let them know, “No Sponsor, no project”. If nobody in charge has any skin in the game, there’s no point in attempting the process fix. Find a different project that leadership supports.

One thing that helps when searching for leadership backing is being able to explain what Lean Six Sigma is and why it makes a difference. Since the checklist template is dynamic we inserted a video in the Define Phase within the checklist item, “Enlist a Project Champion/Sponsor who will support you and the project”. The team lead can share the video with managers or directors who they consider Sponsor candidates.

There’s also a Project Selection Guide Template embedded in the checklist so users can take a project idea and put it through a few screening questions. Is it a repeating problem? Is there a way to measure it? The checklist serves as a reminder, a source of templates, supporting videos and other just-in-time guidance.

The next set of tollgate tasks cover the Define Phase of DMAIC. This is where problem-solvers clarify the problem, the process impacted and customers of the process.

There is a journey of discovery during this phase as everyone agrees on the issue to solve. One of the big challenges is the tendency of ambitious team leads—or equally ambitious Sponsors—to try to “shoot the moon.”

Shooting the moon

They might want to reduce cycle time, reduce defects , improve margins, and increase customer satisfaction all by next Tuesday. But a project that focuses on everything accomplishes nothing. It’s okay to measure the cost reduction that results from reducing defects. But pick one of those to be the goal. Success is more possible if you focus on one goal at a time .

It takes practice and discipline to develop a manageable goal statement. Another moon shot is aiming for perfection out of the starting gate. When we see a goal statement that claims the team will, “reduce defects from 25% to 0%” then we know there is a sizable risk of failure and disappointment.

That’s why the Define Phase of the checklist includes a Goal Builder Template along with a blog providing tips on how to create well-crafted goal statements.

The primary focus of the Measure Phase is to baseline the process. If you’re trying to reduce defects, you need to know how you’re doing at that now. What’s your track record? You need to know the baseline of the process in order to measure whether or not you made a difference with your improvement when you get to the Improve Phase.

You need to know the gap, so you can close the gap.

The data’s in the system, somewhere…

One of the issues we run into in this phase is problem solvers assuming that data is sitting in a system somewhere waiting to be accessed. If they simply run a report, they’ll have the baseline. Check that off the list. But that rarely goes according to plan.

Maybe there’s system data, but was it entered with care? Is it reliable? We’ve seen teams struggle to use data that didn’t make sense. They could access cycle time data, but it didn’t take into account that the workday ended at 5:00. I had another team looking at why healthcare invoices had to be manually adjusted. They looked up the defect codes and the biggest category was “Other”. System data existed, but it was useless.

Most of the time, it helps to collect some data manually. In order to think through your approach, you need a Data Collection Plan. That involves listing the data you want and considering things like stratification factors—the “who, what, when, where” of data. If you’re looking at defects, should you collect data on defects by product? Defects by the fields on a form? Defects by customer type?

Within the task: “Develop a Data Collection Plan with Operational Definitions and create Check Sheets as Needed”, we’ve embedded a template (The Data Collection Plan) and a video to guide the process.

You’ll learn a lot by collecting the data firsthand, so if the perfect data set is not magically sitting in the system, it helps to have a plan.

Analyze is the crux of the DMAIC method. This is where learners drill down and discover the root cause of the process problem they’ve been chasing. Once you do that, you can solve the problem for good.

But if you have not determined the root cause then you might be solving a “symptom,” putting a bandaid on the problem or implementing a change based on a hunch. All of this means there’s a high likelihood the problem will remain and the efforts will have been in vain.

Finding the smoking gun

If you’ve always been told, “don’t bring me a problem, bring me a solution,” that’s an encouragement to jump right past this step into the fun of solutions. I’ve seen teams go with their assumptions regardless of what the data says or the process analysis reveals. I’ve seen Sponsors who tell teams what solutions they want to be implemented right from the get-go.

How do you stick with analysis long enough to find the smoking gun? The trick is to keep collecting the clues in the Cause & Effect Diagram , aka The “Fishbone Diagram”. It’s an aptly named tool, popularized by Dr. Ishikawa , which resembles a fish skeleton. Its construction allows teams to develop root cause theories around a problem as they build their knowledge of the process.

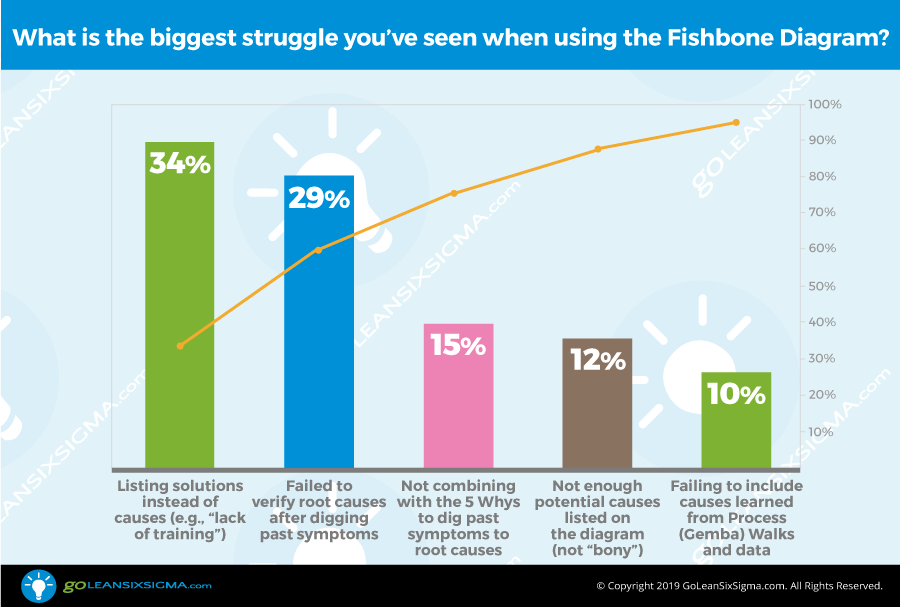

Each time they collect data, interview process participants on a Gemba Walk or map the process steps, they uncover potential reasons for defects. Making the most of the Fishbone Diagram is key but, during a poll, users reported where they fell short.

Solutions masquerading as problems

Over a third of respondents reported the issues of “listing solutions” on the Fishbone instead of causes. What we hear are phrases like, “the root cause is a lack of training”.

The problem with “lack of” anything is that it’s a sneaky way of putting a solution on the Fishbone.

The question is, “what is the training addressing?” Is it lack of user knowledge? If that’s the problem, could it be solved with helpful visuals, a simpler process? There are a lot of ways to address user knowledge before jumping to more employee training.

This is when you want to behave like the persistent detective – think Columbo, the classic 70’s TV icon. Every question helps you accumulate clues. People working through the process may have the answer without knowing it. The trick is to keep looking upstream until you find potential culprits. Dig past the symptoms.

To help with this phase, the checklist includes both a Fishbone Diagram Template as well as a video on how to get the most out of the Fishbone.

The Improve Phase is a long-anticipated step in the journey. It’s the step teams generally want to jump to from the start. Testing countermeasures, piloting solutions, watching the problem disappear, that’s the fun of process improvement. If you’ve done a proper job of Define, Measure, and Analyze, this phase falls nicely into place.

The ripple effect

The catch? Unintended consequences.

If you toss a stone into a lake you can see the ripples flow out from the center. The same principle holds true for process change. If you remove a step, change a form, skip an approval , will things fall apart? For that, we look to the Failure Modes & Effects Analysis or FMEA for short.

It’s a methodical way of assessing the potential for things to go wrong. It Involves deciding the potential severity and frequency of future problems and then mistake-proofing the process to prevent them. The technique originated at NASA since they couldn’t risk trial and error when sending men to the moon. By thinking through the risks of change they developed the kind of contingency plans you saw on display in movies like Apollo 13.

That’s why there’s an FMEA Template and a video on how to use it tucked into the main checklist from this post.

It’s okay to make changes. It’s simply key to think through the impact of those changes on other parts of the business.

Process Improvement can happen quickly and have a dramatic impact, but it’s critical to “stick the landing.” The Control Phase exists to see the improvement through to stability.

If teams move on and everyone takes their eyes off the ball, things may start to slip. What they need is the ability to continuously see the performance of the new process.

Sticking the landing

Have you ever tried to watch a game without a scoreboard? How would you know who was winning? Or how much time was left?

It’s the same with process work.

How does your team know how they’re doing? How do you stay aware of how the new process is performing?

By making the data visible.

Keeping an eye on Process Performance can be done with a single metric — you need to focus on one thing. If the goal was to reduce defects, then the single metric would be tracking the daily percentage of defects. A great way to measure success is with a Control Chart.

Control Charts are time charts. You might know them as Line Charts or Run Charts. They include a measure of variation so they are often referred to as “Run Charts that went to college”. They can be created in Excel , but they can also be drawn by hand.

Teams often set up whiteboards in the shared workspace to track things like defects. People can rotate responsibility for updating the chart. If people can see the measure and are responsible for it—they pay attention to it. What gets measured gets managed.

The Control Chart Template is embedded in the checklist for the Control Phase.

Process Improvement is a mainstay of Operational Excellence and checklists are simple but effective ways to make sure you get the outcomes you want. The following quote comes from the interim CEO/President of the Association for Manufacturing Excellence ( AME ).

“ I am a big fan of checklists for ensuring quality at the source. They serve an important purpose in reminding us of all that’s needed in a particular process or project. Without checklists, we risk missing or overlooking something by mistake. Checklists work best when ticking off items as they are completed, not en masse once the entire project is done. The key point is to use and follow them, not “pencil-whip” them from memory after the fact. While not foolproof, checklists can help us cover the details and result in more thorough, successful improvement efforts. ” – Jerry Wright , President, AME

Checklists have transformed healthcare, aviation, and countless other industries. Run this Process Street DMAIC Tollgate Checklist and make sure your next improvement effort gets great results.

Process Street is a powerful piece of workflow software that lets you crush the human error in your organization.

By creating process templates (like the free DMAIC checklist in this post) you can give your whole team a central location for them to see what they have to do, and how exactly they should do it.

No more confusion, no more errors.

Take advantage of our powerful feature set to create superpowered checklists, including:

- Form fields

- Conditional logic

- Variable user permission levels

- Exporting and printing templates

- And much, much more!

Check out our intro webinar to see the app in action!

Stop leaving the success of your processes up to chance. Get started with a free trial of Process Street today!

How do you manage quality control in your business? Let us know in the comments!

Get our posts & product updates earlier by simply subscribing

Ben Mulholland

Ben Mulholland is an Editor at Process Street , and winds down with a casual article or two on Mulholland Writing . Find him on Twitter here .

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Take control of your workflows today

- Consultancy

- Online Courses

SIGN UP TODAY

- Lean , Lean Wiki , Six Sigma

DMAIC Model | The 5 Phase DMAIC Process to Problem-Solving

- 5 mins to read

- July 1, 2020

- By Reagan Pannell

Summary: An Introduction to DMAIC

Dmaic – the dmaic model.

The 6 Sigma DMAIC model remains the core roadmap for almost all Lean Six Sigma problem-solving approaches that drive quality improvement projects. It is used to ensure a robust problem-solving process is followed to give the best chance of the best solution being found.

A note about the structure and the approach used in this article.

Our approach to DMAIC follows Quentin Brook’s book “Lean Six Sigma & Minitab” which for anyone wishing to study Lean Six Sigma is a must for the Green Belt Course and the Black Belt Course .

What is the DMAIC Model?

DMAIC is short for: Define, Measure, Analyse, Improve and Control. These are the key phases that each project must go through to find the right solution. This flow is the concept behind DMAIC Analysis of an issue and its the DMAIC cycle all projects must go through.

As you can quickly see from the 5 DMAIC phases they follow a logical sequence as we will go through in more detail below. But they also make sure you do not try to jump to implementing a solution before you have properly, defined and measured what you are going to be an improvement.

We all love to jump to solutions, but the DMAIC problem-solving structure helps us have a more rigorous approach so that we do not short cut the process and perhaps miss the best solution or perhaps implement the wrong solution as well. It can help companies better structure their problem-solving approaches and be more robust in their approach.

DMAIC – The 5 DMAIC Process Phases

The phases throughout the DMAIC model have and can be broken down in many different ways. One of the best approaches we have found is from Opex Resources which shows how to examine the existing processes, and with a project team, and the sigma improvement process, we can solve complex issues.

DMAIC Define Phase

The purpose of the Define phase is ultimately to describe the problems that need to be solved and for the key business decision-makers to be aligned on the goal of the project. Its about creating and agreeing the project charter .

All too often, teams have identified solutions without actually defining what it is they will actually be trying to do or perhaps not do. This can lead to internal confusion and often solutions which completely miss the business requirements and needs.

- Define the Business Case

- Understand the Consumer

- Define The Process

- Manage the Project

- Gain Project Approval

We can’t solve problems by using the same kind of thinking we used when we created them” Albert Einstein Tweet

DMAIC Analyse Phase

The goal of the DMAIC Analyse phase with the lean six sigma improvement process is to identify which process inputs or parameters have the most critical effect on the outputs. In other words, we want to identify the root cause(s) so that we know what critical elements we need to fix.

During this phase, the teams need to explore all potential root causes using both analytical approaches, statistical approaches or even graphical tools such as VSM’s and Process maps to uncover the most important elements which need to be changed/fixed.

The Analyse phase can be broken down into:

- Analyse the Process

- Develop Theories and Ideas

- Analyse the Data

- and finally, Verify Root Causes

DMAIC Improve Phase

The goal of the improvement phase is to identify a wide range of potential solutions before identifying the critical solutions which will give us the maximum return for our investment and directly fix the root cause we identified.

During this phase, the team brainstorm, pilot, test and validate potential improvement ideas before finally implementing the right solutions. With each pilot, the team can validate how well it improves the key measures they identified back in Define and Measure. When the team finally roll out the solution, the results should be seen if the right solution has been found and implemented correctly.

The Improve phase can be broken down into:

- Generate Potential Solutions

- Select the Best Solution

- Assess the Risks

- Pilot and Implement

DMAIC Control Phase

The final part of the DMAIC Model is the Control phase where we need to ensure that the new changes become business as normal and we do not revert to the same way of working as before.

During this phase, we want to ensure that we close the project off by validating the project savings and ensuring the new process is correctly documented. We also need to make sure that new measures and process KPI’s are in place and, finally that we get the business champion to sign off on both the project and the savings. We may need to redesign the workplace following the 5S principles .

The Control phase can be broken down into:

- Implement Ongoing Measurements

- Standardise Solutions

- Quantify the Improvement

- Close The Project

The key closing documents of the Control Phase is a Control Plan that documents all the changes and process steps with key risks, standard work instructions and the Project Close-Out document signed by the business owners to accept the change and the validated benefits.

Our approach to DMAIC follows Quentin Brook’s book “Lean Six Sigma & Minitab” which for anyone wishing to study Lean Six Sigma is a must for the Green Belt Course and the Black Belt Course .

The dmaic model vs. a3 management vs. 8d problem solving.

The DMAIC model is not the only project management roadmap. Two others which are important is the A3 format which originally comes from Toyota and is very Lean focused and the 8D which draws more of the DMAIC structure but with the 1-page idea of the A3.

Everyone has their own preference but each method is interchangeable. The DMAIC Structure lends its self naturally to a multi-slide Powerpoint presentation. Whereas the A3 is a single-page document which is perfect for internal communication and adding into War Rooms and Control Towers.

What’s important is that every problem-solving approach follows the PDCA (Plan, Do, Check and Act) Scientific Problem Solving format. The reset is just a preference or using the right tool in the right circumstances.

Our Newsletter

Reagan Pannell

Reagan Pannell is a highly accomplished professional with 15 years of experience in building lean management programs for corporate companies. With his expertise in strategy execution, he has established himself as a trusted advisor for numerous organisations seeking to improve their operational efficiency.

Our Training Courses

Fundamentals of lean.

- Lean Six Sigma White Belt Course

- Lean Thinking Business Course

- Lean Six Sigma Yellow Belt Course

- Lean Six Sigma Green Belt Course

- Lean Six Sigma Black Belt Course

Yellow Belt Course

View all courses

Recent articles.

Mastering the Art of Lean Manufacturing with an Online Degree

The Synergy of Antifragility and Lean Thinking

5 Essential Problem-Solving Strategies Every Business Leader Should Know

Unveiling the Secrets of Blue Ocean Strategy for Business Growth

The Difference Between Strategy and Strategic Execution

Small Steps, Big Gains: The Case for Incremental Improvement

View all articles, green belt course.

Other Articles

What is Lean?

Why are Control Plans Essential in Project Management

An Introduction to the Central Limit Theorem

What are some of the benefits of using Benchmarking in Lean Six Sigma?

Marrying Online Courses with Real-World Projects

Redefining Automation: Prioritizing Standardization and Optimization

What is the 1 Sample T-test?

Genchi Genbutsu – Get out and Go See for Yourself | Lean Principle 12

An Overview of the Pugh Matrix: What Is It and How Does It Work?

Principles of Persuasion to Manage Change in Organizations

DPMO: Defects per million opportunities explained

Best Recognized Lean Six Sigma Certification in the Middle East

Related articles.

5 Benefits and Power of A3 Problem Solving. Designed by Toyota

What is the Design of Experiments Tool

LeanScape launches the Online Lean Academy

The Critical to Quality Tool: What It Is & How to Use It

The Power of Hansei: Why Japanese Business Leaders Swear by this Concept

Lean six sigma online courses.

FREE COURSE | YELLOW BELT | GREEN BELT | BLACK BELT | MASTERCLASS | WORKSHOPS

Lean Accelerator Progam

A Lean Six Sigma Green Belt Masterclass

Ready to start your journey into the world of Lean with this free course?

FREE COURSE

Lean Thinking

A Lean focused continious improvement certification course

LSS Yellow Belt

Propel your career forward, tackle complex problems and drive change

LSS Green Belt

The ultimate fast-track for future leadership

LSS Black Belt

Become an expert in change management and complex problem-solving.

Subscribe to Newsletter

Keep up to date to the latest insights, courses, training, webinars and more. Join our newsletter today.

Lean Accelerator Program

Discover the power of problem-solving, 15 min per day | 3-months | only €999 | learn from experts.

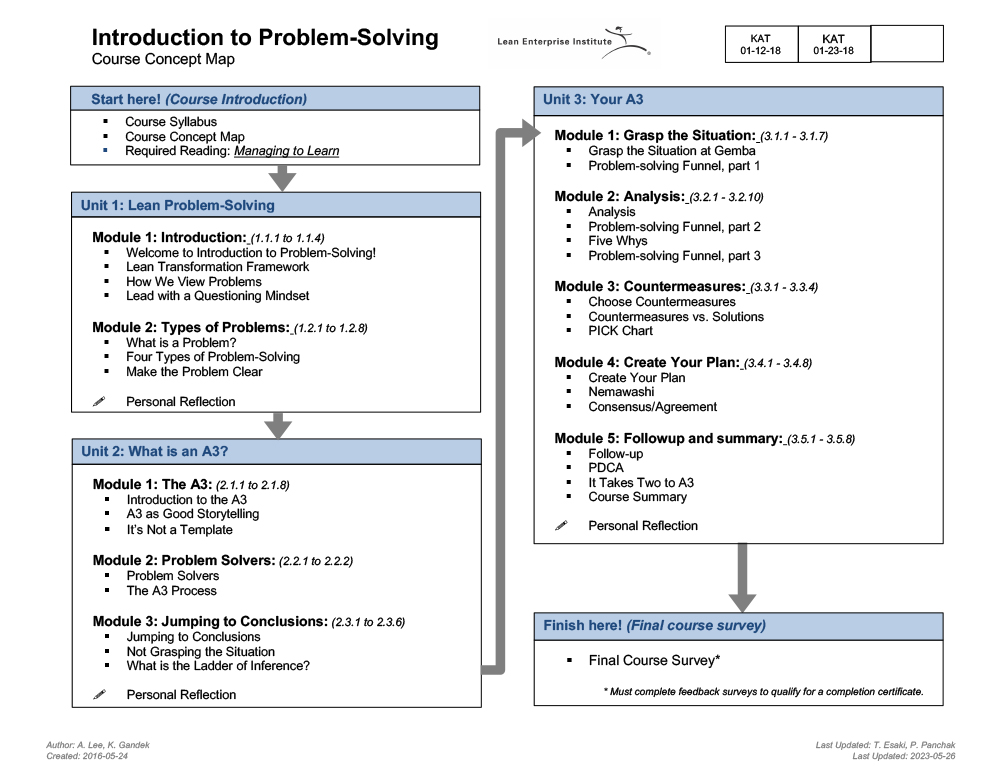

LEI's Learning Portal

Intro to problem solving.

Problem solving is critical to every position in every industry. In this course, you will learn to grasp the situation at the gemba (where the work is done) and use all your senses to understand what is truly happening.

All too often, people create countermeasures to perceived problems without digging deeper, asking the right questions, and thinking more.

Throughout the entirety of the course, we use a case example to illustrate the problem-solving approach as you are learning. In addition, you will deepen your understanding by applying this new way of thinking to a problem of your choice.

This course breaks down lean problem-solving concepts and techniques into simple, easily understood pieces.

How do you solve problems?

Learning objectives.

This course works for people new to the concepts of lean and continuous improvement, for individuals looking to improve their lean understanding and skills, and for organizations wanting to level set the lean knowledge of their workforce to speed progress.

Build a foundational understanding of problem types and problem solvingIdentify the four types of problems

Resolve business challenges by using scientific method, PDCA-based problem solving

Apply A3 thinking to solve problems

Clearly define problems, beginning with grasping the situation at gemba

Learn to break down vague problems to specific problems that can be solved to root cause

Time Estimates Per Unit*

*Actual times may vary.

| Unit 1: Problem Solving | 45 minutes |

| Unit 2: What is an A3? | 2 hours |

| Unit 3: Creating Your A3 | 6.5 hours |

| Work-based Activities | 10+ hours |

Course Units

Expand to view lessons

Course Introduction

0.1 Welcome!

0.2 Platform Tour (optional)

0.3 Copyright Acknowledgment

0.4 Curriculum Concept Map (Visual Syllabus)

0.5 Supplemental Textbook

Unit 1: Lean Problem Solving

1.1.1 | Welcome to Introduction to Problem Solving!

1.1.2 | Lean Transformation Framework

1.1.3 | How We View Problems

1.1.4 | Lead with a Questioning Mindset

1.2.1 | What's a Problem

1.2.2 | Problems Problems Problems

1.2.3 | Four Types of Problems

1.2.4 | Four Types of Problem Solving

1.2.5 | Make the Problem Clear

1.2.6 | Problem Breakdown Analysis

1.2.7 | Unit 1 Personal Reflection

Unit 2: What is an A3?

2.1.0 Helpful information for working on Your A3

2.1.1 | Introduction to A3

2.1.2 | A3 Basics

2.1.3 | Simple A3 Example

2.1.4 | A3 as Good Storytelling

2.1.5 | It's Not a Template

2.1.6 | 5-Step A3 Example

2.1.7 | Your A3: Title and Owner

2.1.8 | Introduction and Chapter 1 (optional)

2.2.1 | Develop Problem Solvers

2.2.2 | Developing Problem Solvers at Herman Miller

2.2.3 | The A3 Process

2.3.1 | Basic Thinking, Mindset, Assumptions

2.3.2 | Porter’s First A3: Rush to a Solution

2.3.3 | Rethinking Thinking by Trevor Maber

2.3.4 | What do I need to know

2.3.5 | Chapter 2: Grasp the Situation—Part 1 (optional)

2.3.6 | Unit 2 Personal Reflection

Unit 3: Your A3

3.1.1 | Grasp the Situation at the Gemba

3.1.2 | Gemba Is More than a Place from Managing to Learn (optional)

3.1.3 | Go See, Ask Why, Show Respect

3.1.4 | Chapter 2: Grasp the Situation—Part 2 (optional)

3.1.5 | Porter’s First Revised A3

3.1.6 | Problem-solving Funnel (Part 1)

3.1.7 | Your A3: Background & Current Condition

3.2.1 | Analysis (part 1)

3.2.2 | Problem-solving Funnel (Part 2)

3.2.3 | Chapter 3: Goals and Analysis—Part 1 (optional)

3.2.4 | Your A3: Background & Current Condition - update

3.2.5 | Analysis (part 2)

3.2.6 | The Five Whys

3.2.8 | The Five Whys Animation

3.2.9 | Problem-solving Funnel (Part 3)

3.2.10 | Your A3: Goal, Target and Analysis

3.3.1 | Choose Countermeasures

3.3.2 | Countermeasures vs. Solutions (optional)

3.3.3 | PICKing Countermeasures

3.3.4 | Your A3: Countermeasures

3.4.1 | Create a Plan

3.4.2 | Nemawashi from Managing to Learn (optional)

3.4.3 | Consensus/Agreement from Managing to Learn (optional)

3.4.4 | From Position Based Authority to Pull-Based Authority (optional)

3.4.5 | Chapter 5: Plan and Followup—Part 1 (optional)

3.4.6 | PDCA from Managing to Learn (optional)

3.4.7 | PDCA Improvement

3.4.8 | Your A3: Plan

3.5.1 | Followup

3.5.2 | Chapter 5: Plan and Followup—Part 2 (optional)

3.5.3 | Detailed A3 Template

3.5.4 | Your A3: Followup

3.5.5 | Conclusion and Getting Started (optional)

3.5.6 | Unit 3 Personal Reflection

3.5.7 | Course Summary

Final Course Survey and Certificate of Completion

Final Course Survey

Certificate of Completion

Continue Your Lean Learning

Extra Resources

More books from the Lean Enterprise Institute

A3 Thinking Questions

More learning experiences from the Lean Enterprise Institute

More on the 'Ladder of Inference'

More on 'Leading with a Questioning Mindset'

About this course

- 0.5 hours of video content

Senior Instructor John Shook

Shook co-authored Learning to See, the book that introduced the world to value-stream mapping. He also co-authored Kaizen Express, a bi-lingual manual of the essential concepts and tools of the Toyota Production System. With Managing to Learn, Shook revealed the deeper workings of the A3 management process that is at the heart of Toyota’s management and leadership.

Worth every minute spent!

Christy leite.

This training covers what other root cause training don’t: The Social-Technical system which is equally important to using problem solving tools when handlin...

This training covers what other root cause training don’t: The Social-Technical system which is equally important to using problem solving tools when handling a problem. Problem definition is where most teams fall short. This training covers that well with excellent application examples. Definitely worth taking!

Wish i learned this at the beginning of my career

Jonathan fairweather.

would have saved alot of headake on alot of problem solving arguements ect and got to the root problem

Outstanding

William butdorf.

Very organized and professionally delivered.

It's Not Just a Piece of Paper

You really have to try and put the simplest problem you think you have and see if you can fix or solve it with a sentence or paragraph about what you should ...

You really have to try and put the simplest problem you think you have and see if you can fix or solve it with a sentence or paragraph about what you should do. Then apply the A3 methodology... I bet you find it isn't one simple problem and you might just discover how complex the problem is, what else is affected that you never realized, or who else might be aware or impacted by it. It's just thinking outside the box and being open to solving the problem. I think to many people don't want to expose a problem because they don't know how to fix it or that it's a failure to have problem at all

Additional Courses

Learning to See Using Value Stream Mapping - with Live Coaching

This workshop shows you how to make and apply this fundamental and critical tool based on the Lean Enterprise Institute's groundbreaking value-stream mapping workbook, Learning to See, which has introduced the mapping tool to thousands of people.

NEW Intro to Lean Thinking & Practice

This online course serves as an introduction to the key concepts, philosophies, and tools associated with lean thinking and practice.

Lean Fundamentals Bundle

Buy all three fundamentals courses at reduced cost. Purchase for yourself or your entire enterprise.

Stay connected on all things lean thinking and practice.

Add your email to LEI's mailing list to get the latest updates.

Please enter a valid email address

Please check this box if you wish to proceed

Oops, something went wrong. Please try again with a different email address.

Lean Events and Training / Events / Intro to Problem-Solving

Intro to Problem-Solving

Learn a proven, systematic approach to resolving business and work process problems..

Online – On-Demand, Self-Paced

Why you should attend

Learn a proven, systematic approach to resolving business and work process problems, including how to overcome the shortcomings of most problem-solving efforts: not understanding the situation and jumping to conclusions.

$249, Users have access for 12 months

Register now on our eLearning platform

In this in-depth , self-paced learning experience, you’ll learn how to use A3 thinking and the plan-do-check-act (PDCA) improvement cycle — essential lean problem-solving practices that are effective at any level from the front line to the executive suite .

Too often, people jump to implement a “solution” to “fix” a problem only to see it recur and the firefighting cycle repeat. Learning and implementing the A3 thinking and PDCA improvement cycle will ensure you fully grasp the problem situation, identify the root cause, and try and test countermeasures, establishing a perpetual system for clearing obstacles keeping you or your team from achieving — or beating — your performance objectives.

Throughout this experience, narrated by John Shook, Toyota’s first American manager in Japan, Senior Advisor of the Lean Enterprise Institute, and Chairman of the Lean Global Network, you’ll follow a case example that illustrates and breaks down each step of the problem-solving approach into their simple, easily understood parts. You’ll engage with hands-on activities, videos, multimedia, PowerPoint presentations, articles, and book excerpts, including the best-selling Managing to Learn .

In addition, you will deepen your understanding of lean problem-solving concepts by applying this new way of thinking to a problem you’re currently wrestling with, using downloadable “tools,” such as the Problem Breakdown Analysis and Guided Gemba exercises and an A3 template.

This learning experience will enhance your ability to resolve work process problems — to get back on track after failing to achieve the standard targets or to achieve a higher performance target — a skill that is critical to every position in every industry , whether in a lean – thinking organization or not. As part of a lean journey, the experience will help you master an essential element of lean thinking and practice .

Who Will Benefit?

- Individuals who aim to enhance their career prospects by improving their problem-solving skills by adopting the A3 problem-solving process and the PDCA improvement cycle

- Lean practitioners who feel they must fill in learning gaps or refresh their A3 problem-solving and PDCA knowledge and skills

- Leaders, from mid-level managers to top executives, who are trying to level up their team’s knowledge of and adopt lean problem-solving processes as their standard approach, including continuous-improvement and human-resource leaders

What Will I Learn?

Upon completion, you will be able to:

- Build a foundational understanding of problem types and problem-solving.

- Identify the four types of problems.

- Resolve business challenges by using the scientific-method-based PDCA-based improvement cycle.

- Apply A3 thinking to solve problems.

- Clearly define problems, beginning with grasping the situation by gathering facts at the gemba.

- Break down general, vague problems into specific, actionable ones that you can solve at the root cause.

What Else Should I Know?

Get a head start or supplement your online learning. This ebook highlights and explains what you need to know about using this powerful lean practice to gain its most impactful benefits:

Also, though no prerequisite training or reading is required, having familiarity with lean management basics will be helpful. We recommend the following books:

This learning experience is based on the tested and proven methodology created for LEI’s popular Managing to Learn workbook , authored by John Shook , Toyota’s first American manager in Japan, Senior Advisor of the Lean Enterprise Institute, and Chairman of the Lean Global Network.

You might also find the book Four Types of Problems helpful in enhancing your problem-solving capabilities. The book explains how most business problems fall into four categories and describes the thought processes, management cadences, and improvement methods t hat will resolve each type.

Time Estimates Per Unit*

*Actual times may vary.

Download the Intro to Problem-Solving Concept Map and share it with your manager.

Senior Advisor, Lean Enterprise Institute

John Shook learned about lean management while working for Toyota for 11 years in Japan and the U.S., helping it transfer production, engineering, and management systems from Japan to NUMMI and other operations around the world. While at Toyota’s headquarters, he became the company’s first American kacho (manager) in Japan. In the U.S., Shook joined […]

Need to level set your team’s lean knowledge and skills? Choose the Lean Fundamentals Enterprise Subscription and gain unlimited access for everyone in your organization to three foundational lean learning experiences for three months.

Lean Fundamentals Bundle

Related events.

July 18, 2024 | Detroit, Michigan

The Future of People at Work Symposium

August 05, 2024 | Coach-Led Online and In-Person

Managing to Learn

September 06, 2024 | Coach-Led Online Course

Hoshin Kanri

Subscribe to get the very best of lean thinking delivered right to your inbox, privacy overview.

Lean leadership means achieving your goals by developing people, teaching them to create more value and learn to eliminate waste

Which side are you on?

12 April 2015 / article

Corporate functions were invented on the Taylorist notion that engineers devise the best system which is then taught to assembly line workers. As far as it goes, it makes sense, but what applied to immigrant manual labor in the late nineteenth century hardly applies to our reality now.

Lean shows there is a different way. By challenging and supporting line management (sales, engineering, production, procurement) to solve their own problems and learn first hand, it offers a method to solve the problem framed by Drucker. A lean system is, just as Taylor intended, a learning system, but the learning theory is radically different.

It’s based on developing every person’s kaizen mind, not asking them to thoughtlessly apply a best practice that was invented far from their real world. It’s about genchi genbutsu, kaizen, and respect. Read more here .

Comments are closed.

Guide: 5 Whys

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

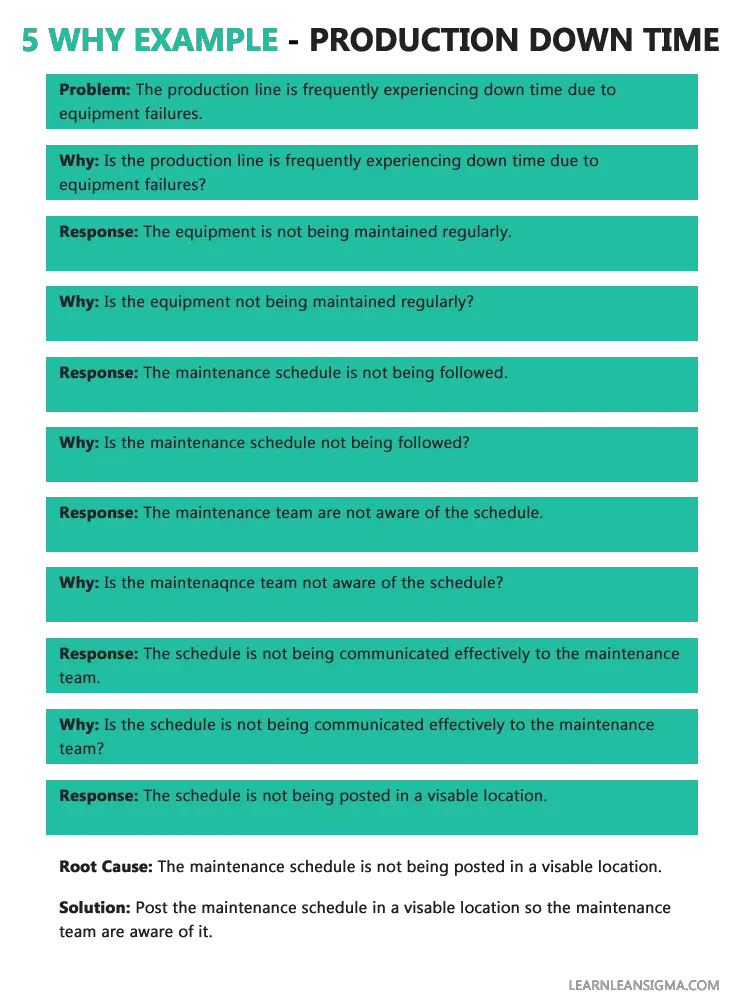

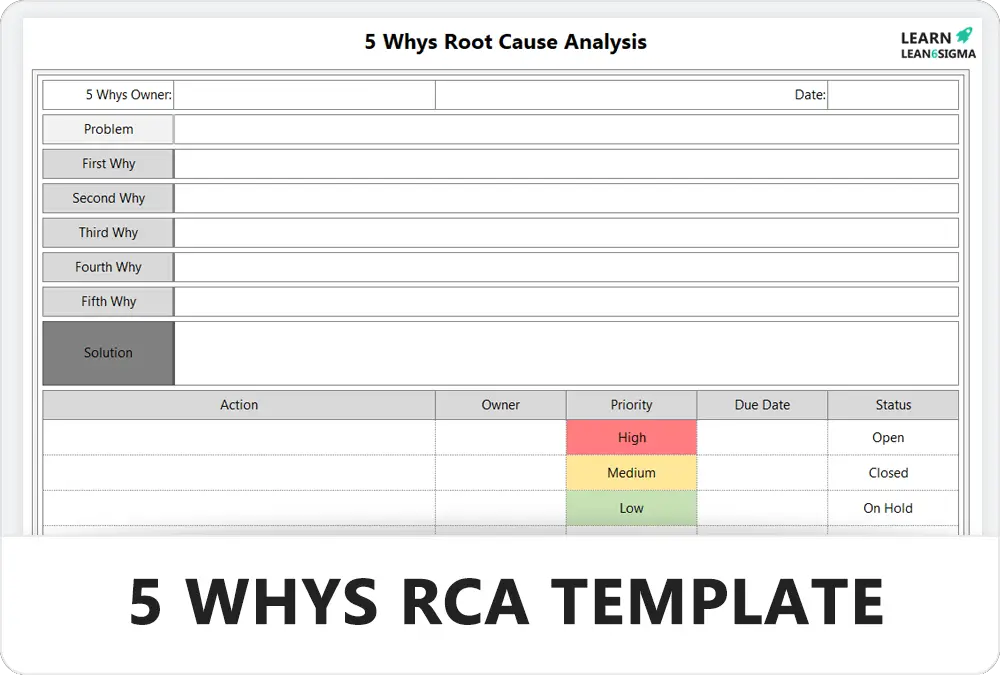

5 Whys is a problem-solving technique used to get to the root cause of problems by asking the question of Why multiple times, but often 5 times giving it the name “5 Whys”. This allows people to address the root cause of issues instead of the symptoms of the root causes which is often what is seen as the problem.

Like a doctor diagnosing an issue such as neck pain, a painkiller will only address the symptoms of the neck pain and not the root cause of the pain. By getting to the root cause you can ensure a long-term fix to the root cause of the neck pain which could be caused by seating positions and not taking painkillers which is a short-term fix.

What is the 5 Whys?

The 5 Whys is a root cause analysis problem-solving technique that aims to identify the root cause of a problem by repeatedly asking the question “Why?” five times or until the core issue is unveiled. Developed within the Toyota Production System , it’s one of fundamental tools in the Lean Six Sigma methodology.

Here’s how it works:

- Begin with a clear and concise problem statement.

- Ask “Why?” the problem occurred. Document the answer.

- If this answer doesn’t identify the root cause, ask “Why?” again and document the subsequent answer.

- Continue this process until you’ve either asked “Why?” five times or the root cause has been identified.

Lets go through an example, let’s say a machine stopped working:

- Why? – The machine’s fuse blew.

- Why? – The machine was overloaded.

- Why? – There wasn’t adequate training on machine capacity.

- Why? – Training materials were outdated.

- Why? – There’s no review process for updating training materials.

In this case, the root cause is the lack of a review process for training materials, and addressing this will prevent similar issues in the future. Only treating the symptom in this situation would have been to change the fuse, for it then to regularly blow and cause additional downtime.

This is a good example where a machine stopping working’s root cause is cause by an issue what would not be obvious is first glace at the symptom of the problem and provides a clear example that root cause analysis is important to ensure that solutions are not jumped to before a through root cause analysis is conducted.

Why is the 5 Whys Important?

Understanding the 5 Whys is important because identifying symptoms of a problem is not the same as uncovering its root cause. If you only address symptoms this provides only temporary solution to the problem. However, understanding and resolving the root cause can prevent the issue from reoccurring.

The 5 Whys Problem-Solving technique is also useful for:

- Problem Prevention: By identifying the root cause of the problem, businesses can implement long-term solutions, leading to more robust systems and processes and prevent the problem reoccurring.

- Cost-Efficiency: Addressing root causes is often more cost-effective in the long run as it prevents recurrence and the associated costs of repeated problem-solving which usually involves the same people constantly firefighting the same issues such as repeated machine breakdowns.

- Improved Processes: Regular use of the 5 Whys to identify the root causes of problems can highlight weaknesses in processes, leading to continuous improvement and optimization processes.

- Empowerment: The use of 5 Whys by individuals a positive culture that promotes a deeper understanding of systems and processes, empowering teams to take ownership and responsibility in addressing issues.

How to Conduct a 5 Whys Root Cause Analysis?

Step 1: define the problem.

This is an important step as if the problem is not defined effectively it could result in focusing in the wrong problem. A good method for this could be to use the 5W1H Is/Is Not Problem solving technique to gain a common understanding of that the problem is.

When stating the problem you are going to conduct a 5 Whys on it is important to be specific about the issue and avoid ambiguous descriptions. Additionally, where data and information is available this should be collected and used as evidence that points to the actual problem rather than opinions of the problem.

Step 2: Ask the First “Why?”

Now you have a clear problem definition you should ask the question “Why did that happen?” This should be done to understand the problem without making assumptions and should be done with supporting facts and data that backs up the initial answer to the question.

Step 3: Continue to Ask Why?

Now you should have an answer to the first why. This should form the next step and ask why did that happen. This ensures you dont settle for the inisital surface-level answer or symptoms of the real problem and pushes you to understand the underlying issues.

When you continue to ask why you should:

- Continuously question the previous answer

- Challenge answer that seem like assumptions and lack evidence to support them to avoid going down the wrong route.

Step 4: Continue the Process

- Keep the questioning focused on the problem

- If you feel the questioning is going off track revert back to what the initial problem definition.

- Ensure each answer provided logically leads to the next “Why?”

- The 5 Whys process then concludes when further questions leads to no further valuable answers are given or the when the root cause of the issues becomes clear.

Step 5 Implement Solutions

Once you have identified the root cause the you need to address it by implementing a solution to prevent the problem reoccuring.

This should be a case of developing an actionable solution that address the root cause of the issue and not preventing the symptoms as addressing the symptom will likely cause the issue to reappear elsewhere.

Make sure you test the solutions to ensure they are effective in addressing the root cause, you should then continue to monitor the process over time to confirm the problem did not reappear in the same place or elsewhere.

If the problem does not re appear congratulations you have solved the problem!

An Example of 5 Whys Analysis

Below is a good example of a 5 Whys analysis done in a situation where there was a production downtime.

To summarize, the 5 Whys process is an effective problem-solving tool that can assist businesses in identifying the root cause of a problem and developing effective solutions. Teams can delve deep into underlying issues and develop targeted solutions that address the root cause of the problem by asking “why” multiple times.

The five steps of the 5 Whys process – defining the problem, asking “why” once, asking “why” more times, developing a solution, implementing the solution, provide a clear framework for problem-solving and can help ensure that the problem is effectively resolved. The 5 Whys process encourages teams to think critically and systematically, resulting in long-term solutions that are effective, targeted, and sustainable.

- Benjamin, S.J., Marathamuthu, M.S. and Murugaiah, U., 2015. The use of 5-WHYs technique to eliminate OEE’s speed loss in a manufacturing firm. Journal of Quality in Maintenance Engineering , 21 (4), pp.419-435.

A: The 5 Whys technique is a problem-solving method that involves asking “why” multiple times to uncover the root cause of a problem or issue.

A: The 5 Whys technique involves repeatedly asking “why” to identify the underlying cause of a problem. After asking “why” five times or until the root cause is revealed, you can develop effective solutions to address the issue.

A: The primary purpose of the 5 Whys technique is to identify and address the root cause of a problem. It helps organizations and individuals go beyond surface-level symptoms and understand the deeper issues affecting their processes or systems.

A: The 5 Whys technique is best used when you encounter a problem or issue that needs to be resolved. It is particularly useful for complex problems, recurring issues, or situations where multiple factors contribute to the problem.

A: Yes, the 5 Whys technique can be applied to any industry or field. It is commonly used in manufacturing, engineering, healthcare, software development, project management, and various other sectors.

A: While the technique is called the “5 Whys,” the number of “whys” you need to ask may vary. The goal is to keep asking “why” until you reach the root cause of the problem, which may require more or fewer than five iterations.

A: Yes, there are a few limitations to consider when using the 5 Whys technique. It relies on the skill and knowledge of the people involved, and it may oversimplify complex problems. Additionally, it assumes a linear cause-and-effect relationship, which may not always be accurate.

A: Yes, the 5 Whys technique can be used in a group setting. In fact, involving multiple perspectives can enhance the effectiveness of the technique and lead to more comprehensive problem-solving.

Daniel Croft

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website www.learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Download Template

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Was this helpful?

What Are The 5 Whys?

- · April 4, 2023

Problem-solving is the bread and butter of most factories today, but not all organisations solve their problems the same way.

Today, we dissect the operating principles behind the 5 Whys method, exploring its advantages, use cases, and relevance.

What do the 5 Whys mean?

By definition, 5 Whys is a problem-solving technique that uses Root Cause Analysis (RCA) to understand the problem in detail and solve it permanently. It’s considered one of the most effective problem-solving techniques in lean management , and it works best to solve simple problems.

This method was developed by Sakichi Toyoda, founder of Toyota, and incorporated into the Toyota Production System (TPS).

The 5 Whys work best to solve relatively simple issues, as anything too complex will need more robust problem-solving tools such as 8D, Cause Effect Analysis, or QRQC .

How do the 5 Whys work?

This method is relatively straightforward. All you have to do is identify the problem and then ask why five times .

Sometimes, you might find the root cause before you reach your fourth line of inquiry.

Sometimes, you might have to ask why a few more times to reach the root cause.

To make the 5 Whys method really successful, there is a process you need to follow, and it goes like this:

Step 1 — Create a team

The more relevant people you include to find a solution to the problem, the faster and more effective the resolution will be.

When you’ve decided who will be part of your team, you should appoint a leader to guide the process and keep everyone on track.

This person is known as the 5 Whys Master .

Step 2— Identify the problem

The problem needs to be identified and clarified beyond any reasonable doubt . Your team should define the problem and explain it in a specific statement.

This keeps everyone focused on the problem, giving them a concise account of the situation.

Step 3 — Ask Why? five times

The first Why? is on your team.

The other four, on your 5 Whys Master .

Essentially, the team starts asking the first question, and then the 5 Whys Master leads the process through the rest of the questions.

Sometimes, you might need more than five whys to solve the issue.

Sometimes, you might need less.

However long it takes, you need to reach the root cause of the issue , which will always be linked to a management issue or a design flaw.

STEP 4 — Correct the problem

When the problem is identified, your team discusses actions or countermeasures to solve the issue.

The 5 Whys Master will then decide who does what, delegating responsibility among the team members.

STEP 5 — Keep track of your results & share them

Monitoring helps you see if the countermeasures you take to solve the issue are working.

It also gives you great insight into what you’re doing right, and what could be done better.

You also need to share your findings so that everybody can access them and learn from the process.

To make sure you’re using the 5 Whys method to its fullest extent, you need to make sure that you/your team:

- Know when to stop asking Why → when the answers you’re getting are no longer useful or don’t bring anything else to the process, you need to stop asking further whys and take another approach instead.

- Address the root cause(s) → finding the root cause it’s great, but not enough. Once you find it, you need to make sure you’re taking the appropriate measures to fix the issue and prevent it from happening again.

- Monitor your measures → once you take measures to address the issue, it’s fundamental that you monitor how the measures impact the issue. Are they effective? Could they be even more effective? When you monitor how your measures are performing, you’ll be able to solve the root cause faster and more efficiently.

- Share your results → keeping your results a secret helps nobody. When you find the root cause, you address it, and you fix it, you need to share your results with everybody, so they can learn from it. Even when the root cause isn’t fixed, you need to share your results to keep everybody on track regarding the issue and its current status.

5 Whys in real life

Here’s what a 5 Whys method looks like in real life:

In this particular instance, after finding the root cause, we then come up with a solution. In this case, it could be to make sure we train the workers on the standards regarding changing the pipes.

This example shows how easy and cost-effective it is to set up this problem-solving method to find the root cause of a problem in your factory.

Advantages of the 5 Whys methodology

This method brings with it a good number of advantages, and it might be exactly what you need to implement in your factory, some of which are:

- It helps your teams find, understand, and correct the root cause of the problem

- It fosters teamwork

- It’s very easy and flexible to implement

- You can use it alongside other problem-solving methods, such as Root Cause Analysis or Six Sigma

- It can be templated — just create a set structure and prompts that can be used whenever this method needs to come into play

mlean ® and the 5 Whys method

The 5 Whys method is a great problem-solving technique that helps you find the root cause of an issue and take measures to correct it quickly and efficiently.

But sometimes, this method alone isn’t enough to solve your problem.

Our mlean® Production System includes a wide range of problem-solving methods to ensure your issues are always dealt with using the right tools .

Our software is the most complete toolkit for digital industrial operations, integrating a variety of lean philosophies and processes like Kaizen or Hoshin Kanri .

mPS digitalises your factory processes, increases your workers’ safety and motivation, and increases revenue.

Book a demo and see for yourself!

Request a Demo Today

Blog category

- Deep dive (19)

- Digital transformation (14)

- How-tos (18)

- Industry Trends (14)

- mlean news (22)

The Kanban method for lean manufacturing

Production planning: Start reducing waste in your factory today

Ishikawa Fishbone Diagram: Problem-Solving Made Easy

Seeing is believing.

Book a demo to see the full power of the mPS.

Get the lastest from mlean . Subscribe to our newsletter and be the first to get updates, news and more

Running a factory is hard. We make it easy.

- Standard Work

- Shop Floor Management

- Start of production

- Maintenance

- Improvement Drivers

- mlean Hoshin Kanri

- Who benefits from the mPS?

- mlean product integrations

How we do it

- Success Stories

- Our philosophy

Let´s Work Together

- Become a partner

- 2024 © Mobile Lean S.L. All rights reserved.

- Privacy policy

- Legal Notice

- Information Security Policy

- Cookies Policy

- Complaints Channel

PROGRAMA INVESTIGO Proyecto financiado por el mecanismo de recuperación y resilencia.

MOBILE LEAN SL en el marco del Programa ICEX Next, ha contado con el apoyo de ICEX y con la cofinanciación del fondo europeo FEDER. La finalidad de este apoyo es contribuir al desarrollo internacional de la empresa y de su entorno.

MOBILE LEAN SL en el marco de su Programa de Internacionalización cuenta con el apoyo del Instituto para la Competitividad Empresarial de Castilla y León (ICE) y con la cofinanciación del fondo europeo FEDER.

- Privacy Summary

- Strictly necessary cookies

- Third party cookies

This website uses cookies so that we can offer you the best user experience possible. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website or helping our team understand which sections of the website you find most interesting and useful.

Strictly necessary cookies must always be activated so that we can save your cookie settings preferences.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, or the most popular pages.

Leaving this cookie active allows us to improve our website.

Please enable strictly necessary cookies first so we can save your preferences.

More information about our Cookies policy

Start exploring programs today. Fall classes start in August.

How one water-management company is using AI to unlock insights from its 100-year past

- Ecolab manages water-purification and water-treatment systems.

- The company, which has been around for a century, uses AI to inform new projects.

- This article is part of " CXO AI Playbook " — straight talk from business leaders on how they're testing and using AI.

For "CXO AI Playbook," Business Insider takes a look at mini case studies about AI adoption across industries, company sizes, and technology DNA. We've asked each of the featured companies to tell us about the problems they're trying to solve with AI, who's making these decisions internally, and their vision for using AI in the future.

Ecolab, a company headquartered in St. Paul, Minnesota, focusing on water management, hygiene, and infection prevention, works across 40 industries. Tens of thousands of its associates help optimize water use and maintain safe water environments for millions of customers in more than 170 countries.

Situation analysis: What problem was the company trying to solve?

Kevin Doyle, Ecolab's chief digital officer, told Business Insider that while Ecolab has deep institutional knowledge, digging into it to help clients can sometimes be tricky. "We've got water expertise that we've had for 100 years and have been out working with clients and customers assessing those operations and making recommendations" based on that history, he said.

Ecolab's business involves assessing a client's operations to understand their needs and challenges. Those findings are then used to develop plans to drive water and energy savings through tailored programs that include science-based chemistry, digital insights, and extensive expertise.

Ecolab's associates — generally chemical engineers — carry out these assessments and make recommendations to customers. Doyle said decades-old recommendations could be valuable for clients' current decision-making, but only if the company has access to them.

"That could have been lost on that person's hard drive or in that person's mind only," he said. "What's now happening is it's documented in a repository of data that we're then able to serve up" to associates using generative AI.

Key staff and partners

Ecolab's AI acceleration lab initiated the project, which is now used by thousands of employees working directly with customers and uploading data to the system . Doyle said those field associates also use generative AI to analyze information stored in the company's existing filing systems.

AI in action

The system started with a mobile application and a recommendation screen, and a chatbot was added later, Doyle said. "We could see either a recommendation based on best practices or what was contained in a knowledge repository, or somebody could ask a question, like, 'I'm trying to install water meters on this size pipe, what type of meter should I order?'" he said.

Adopting generative AI means Ecolab's representatives can harness information and insights from clients around the world.

"Maybe it's another person in southeast Iowa who goes into a similar-type plant, they have a similar customer with similar characteristics," he said. "It will make a recommendation based on the AI that will say, 'You could implement these programs and projects,' or 'Your peers have done this to create value: Is it something that's interesting to you?'"

Did it work, and how did leaders know?

Doyle said Ecolab had seen benefits from integrating generative AI in customer outreach, advisory, and briefing processes.

"It has enabled those out in the field to make decisions and ensures their on-the-ground insights are not lost within the organization," he said.

"We've seen increases already in the early stages of that program in the hundreds of millions of dollars of value creation and value potential," he added.

Doyle said AI will help the company make quicker decisions, which means "our existing team will be able to serve more customers and deliver greater value."

What's next?

Doyle said Ecolab's AI acceleration lab was testing further ways to use generative AI. "We're trying to apply that to even broader knowledge sets and certainly across all of our businesses," he said, referring to firms within the 40 industries Ecolab serves. Those broader knowledge sets include the nuanced processes in each industry, such as an associate's experience with supporting cooling water systems or identifying product quality issues.

By applying AI to new data, Doyle said they're able to take in more information to "get our people to the most impactful locations, whether that's to create value through a project or to fix something that's not operating as it should and causing other problems."

We want to hear from you. If you are interested in sharing your company's AI journey, email [email protected] .

- Main content

IMAGES

VIDEO

COMMENTS

In a lean management system, everyone is engaged in ongoing problem-solving that is guided by two characteristics: Everything described or claimed should be based on verifiable facts, not assumptions and interpretations. Problem-solving is never-ending; that is, it begins rather than ends when an improvement plan is implemented. ...

Problem-solving stands as a fundamental skill, crucial in navigating the complexities of both everyday life and professional environments. Far from merely providing quick fixes, it entails a comprehensive process involving the identification, analysis, and resolution of issues. This multifaceted approach requires an understanding of the problem's nature, the exploration of its various ...

A management discipline (or process): At a higher level, lean leaders, managers, and supervisors use "the A3" as a means by which they oversee and guide subordinates while simultaneously helping them develop their lean thinking and practice — particularly lean leadership and problem-solving — capabilities. With A3 management, leaders ...

A3 structured problem solving is a Lean Six Sigma methodology that has been designed and developed to support continuous improvement and solve complex business problems in a logical and structured process. ... Emphasized in Lean Management, A3 stresses understanding root causes, standardization across teams, team collaboration, and visual ...

Problem-solving is an important component of any business or organization. It entails identifying, analyzing, and resolving problems in order to improve processes, drive results, and foster a culture of continuous improvement. A3 Problem solving is one of the most effective problem-solving methodologies. A3 Problem solving is a structured and systematic approach to problem-solving that ...

DMAIC is the problem-solving approach that drives Lean Six Sigma. It's a five-phase method—Define, Measure, Analyze, Improve and Control—for improving existing process problems with unknown causes. DMAIC is based on the Scientific Method and it's pronounced "duh-may-ik.". Originally published on August 24th, 2017, this article was ...

8D Problem Solving is a systematic and structured approach used to solve business related problems. It names has been given by the fact there are 8 steps or 8 disciplines that are followed to identify, correct and eliminate recurring problems. ... Between quality management systems and lean six sigma there are several problem-solving ...

Step 1 - Define the Problem. The definition of the problem is the first step in effective problem solving. This may appear to be a simple task, but it is actually quite difficult. This is because problems are frequently complex and multi-layered, making it easy to confuse symptoms with the underlying cause.

Let's get started. Lean Six Sigma and the role of problem-solving. For those unfamiliar with Lean Six Sigma and process improvement, it is a structured approach for organizations to scrutinize how things are done, poke at data and processes to uncover waste and then cut out things like extra forms, out-dated approvals and other time-wasting steps.. It's a customer-focused, 5-step problem ...

Summary. The A3 problem-solving approach is a powerful tool used to identify, analyze and solve issues. It consists of a comprehensive template which can be used to effectively unlock improvements and gain deeper insights into various situations. This article will discuss how this versatile technique can be used to help individuals unlock their ...

The DMAIC Problem Solving Approach is a process improvement methodology based on the Six Sigma approach that helps to improve business processes and products. It is used to identify, analyze, and solve existing processes that are inefficient or ineffective. The approach breaks down into five phases: Define, Measure, Analyze, Improve and Control.

This course breaks down lean problem-solving concepts and techniques into simple, easily understood pieces. ... John Shook learned about lean management while working for Toyota for 11 years in Japan and the U.S., helping it transfer production, engineering, and management systems from Japan to NUMMI and other operations around the world. ...

unlocking employees' problem-solving capabilities. To underscore this point, we began using the term "lean management." And we explained that success rests on building from a small, isolated success story until it reaches the entire enterprise, including functions that once seemed too difficult to transform, such as IT,

Problem Solving. In a lean transformation or any process improvement effort, identifying and closing gaps between current and target conditions. In a lean management system, everyone is engaged in problem solving, guided by two key characteristics: Everything described or claimed in the problem-solving process (the problem itself; the target ...

Why problem-solving in a lean setting is a unique opportunity to think about how we think and develop expertise where it counts. Let's face it: we live in an illusion. That is to say, modern theories of cognition demonstrate that we do not really see what is around us. Instead, our eyes dart from one detail to the next to construct a ...

January 7, 2015. "Let's solve world peace" or "let's state our predetermined solution as a problem" aren't real problem statements, says Dave LaHote. Read why a good problem statement is so important, why it's harder than you think to come up with one, and learn how to write a better one. "Hey everybody, let's ' A3 '!".

112 The Lean Management nterprise A system for daily progress, meaningful purpose, and lasting value 2 Willingness to see problems wherever they may be Before you can acknowledge a problem, you have to be aware of it. Identifying problems, par-ticularly before they grow into a crisis, is a skill that can be learned. In lean thinking, all

Common lean practices. A Lean technique for determining the root cause of an issue, especially when there is likely to be a single root cause. It involves asking "Why" 5 times (or more, as needed). The A3 process is a team-collaborative, structured problem-solving practice that expands on PDCA.

2 Measure the current state. The second principle of Lean problem management is to measure the current state of the problem and the process. This means collecting data and facts that show how the ...

Solving Problems. By Josh Howell. February 8, 2023. A team learns what matters when it comes to problem-solving using lean thinking and practices. Becoming a lean enterprise isn't easy. Even individually, consistently thinking lean, especially in practice, isn't easy. Thankfully, our forebears have given us models like the TPS house and ...

Why you should attend. Learn a proven, systematic approach to resolving business and work process problems, including how to overcome the shortcomings of most problem-solving efforts: not understanding the situation and jumping to conclusions. Cost. $249, Users have access for 12 months. Register now on our eLearning platform. Register. Overview.

Lean shows there is a different way. By challenging and supporting line management (sales, engineering, production, procurement) to solve their own problems and learn first hand, it offers a method to solve the problem framed by Drucker. A lean system is, just as Taylor intended, a learning system, but the learning theory is radically different.

The 5 Whys Problem-Solving technique is also useful for: Problem Prevention: By identifying the root cause of the problem, businesses can implement long-term solutions, leading to more robust systems and processes and prevent the problem reoccurring. Cost-Efficiency: Addressing root causes is often more cost-effective in the long run as it prevents recurrence and the associated costs of ...

By definition, 5 Whys is a problem-solving technique that uses Root Cause Analysis (RCA) to understand the problem in detail and solve it permanently. It's considered one of the most effective problem-solving techniques in lean management, and it works best to solve simple problems.

Lean Project Management. Learning Agility. Planning. Problem Solving. Risk Management. Stakeholder Management. Strategic Thinking. View skill descriptions. Career Outlook. 883,422. Projected Project Management jobs in the next ten years. 10.0%. This career is growing faster than the national average.

Correct answers are reinforced with a brief explanation. Incorrect answers are linked to tutorials to help solve the problem. Crossing a white-eyed female and red-eyed male fly; Test cross of a red-eyed female fly; Predicting the offspring of a homozygous red-eyed female fly; Predicting genotype when phenotype is known

Ecolab, a water-management company, is using AI and a century's worth of data to help clients. Papatsorn Khunsaard/Getty Images Ecolab manages water-purification and water-treatment systems.