Optimize High-Energy Pumps With Improved Impeller Design

As new design and manufacturing technologies are developed, end users can affordably upgrade their systems and verify better performance..

Written by: Bob Jennings & Dr. Gary Dyson (Hydro, Inc.) Publisher: Pumps & Systems / August 2015

The rising cost of electrical power has caused many industrial plants to shift their focus to energy consumption. Plants often run pumping equipment continuously, and much research has pointed to opportunities for cost savings by optimizing pumping equipment.

When evaluating the potential for energy savings, end users cannot consider a pump in isolation. The suitability of the pump for the system within which it operates is vital. Even the best designed and most efficient equipment offers power-saving potential if it is run off its best efficiency point (BEP) in a system for which it is ill-applied.

Image 1. Much research has pointed to opportunities for cost savings by optimizing pumping equipment. (Images and graphics courtesy of Hydro, Inc.)

Many plants have been in operation for more than 40 years, and their operating philosophies have changed over time. Plant improvements have enabled higher throughput, often increasing production by as much as 125-150 percent. Unfortunately, little is done to improve or increase the performance of the support-service pumping equipment, such as cooling water pumps.

As system flow demands increase, the duty point of the pumps is forced to shift far to the right of the BEP, well outside the acceptable operating range (AOR). This causes efficiency and pump reliability to decrease dramatically.

Casting tolerances, surface finishes, and impeller/volute or impeller/diffuser geometry have all dramatically improved during the last 40 years. But because many pumps were installed when the plants were commissioned, the existing pumps were manufactured using techniques that would be considered obsolete today. The result is higher energy costs and reduced reliability and availability, which often cause production delays.

The Starting Point

Pumps react to changing system conditions. System demand (or system resistance) determines the flow and pressure at which a pump will operate. As system flow demand increases, the flow throughput of a pump also increases, causing it to operate further on the right-hand part of the performance curve.

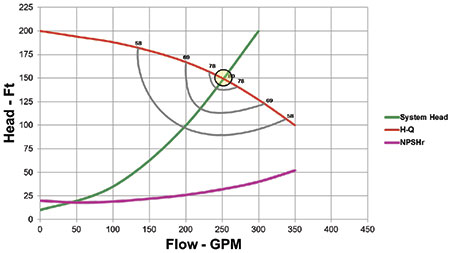

The system demand is graphically represented by plotting the system resistance curve as a function of flow. This curve enables the end user to quickly determine system flow for a given pump since the pressure and flow are determined by the intersection of the pump performance curve (red) with the system head curve (green). A process design engineer would ideally select a pump with an operating point that would have coincided with the BEP. This could yield a pump efficiency of 80 percent, as shown in Figure 1.

Figure 1. Pump and system curve interaction

However, many support pumping systems have exceeded their original design and have much higher flows to support the higher plant production. This is particularly common in cooling water applications, condenser water pumps, descale pumps or any application where water usage is proportional to production.

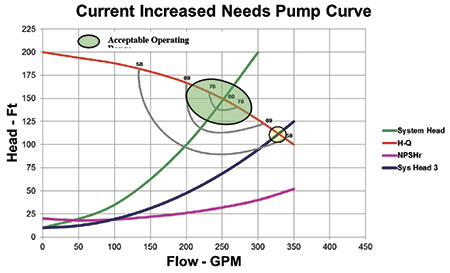

While the original design may have called for two-pump operation, present-day requirements may require 2 1/2 pumps online, with two pumps being insufficient and three pumps too many. As flows increase, the result is usually that system requirements have exceeded the AOR of the pumps (see Figure 2).

Figure 2. Pump Performance curve interaction based on different system requirements

Original Duty Point

The original system design for one processing plant’s service water pumps was to have three pumps operating in parallel with an installed spare as a standby. The total system requirement was 105,000 U.S. gallons per minute (GPM) (23,864 cubic meters per hour) at a pressure of 190 feet (57.9 meters) total dynamic head (TDH). Each pump was rated for 35,000 GPM (7,955 cubic meters per hour) at 190 feet (57.9 meters) TDH.

As production increased, more service water was required, causing the existing pumps to operate further out to the right of the performance curve. This caused the net positive suction head required ( NPSH R ) to exceed the NPSH available ( NPSH A ), leading to severe cavitation issues. To reduce cavitation problems, the plant ran four pumps in parallel and throttled each pump to keep the individual pump flows low enough to prevent cavitation.

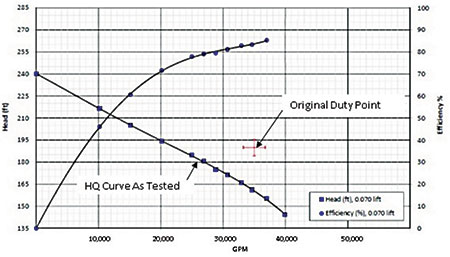

Figure 3. Pump performance test data illustrating performance degradation

Over time, the design of the impellers also drifted away from optimal because no testing or verification of the performance took place. Cavitation and insufficient service water continued until the pumping station could not keep up with plant demand. As Figure 3 shows, field pump assessments and subsequent individual performance tests conducted on the poorly replicated impellers showed that the pump performance had been dramatically compromised.

New Impeller Design

The technological advances made in recent years with reverse engineering, laser digitizing equipment, computation fluid dynamics (CFD) software and the ability to print 3-D foundry molds from computer-aided design/computer-aided modeling (CAD/CAM) software has revolutionized the aftermarket industry. Solutions that were cost-prohibitive five years ago are now within the realm of financial feasibility. The solution helped manufacturers and end users solve their energy optimization difficulties in three ways:

1. Capture system resistance data and operating conditions. The plant’s pumps operated at different flow conditions. Understanding how these flow requirements matched the system’s resistance enabled an optimized design flow to be derived that would ensure that head was not generated by the pump to be dissipated over a control valve, so the number of pumps running was optimized for the demand. 2. Capture the geometry of the existing impeller using advanced laser-scanning equipment and build a CFD model of this impeller. This allows design scenarios to be evaluated to get the optimized design for the newly established flow conditions. 3. Use additive manufacturing in the form of 3-D foundry sand printers and casting simulation software to drastically reduce lead-time and overhead normally associated with pattern/core box sand casting processes. The 3-D printing process directly from the design data ensures that the integrity of the design is completely captured. The high accuracy of sand printing means that vane-to-vane symmetry and vane shape is identical. Sand printing also offers improved casting surface finish. These manufacturing measures alone can lead to a 3 percent efficiency increase.

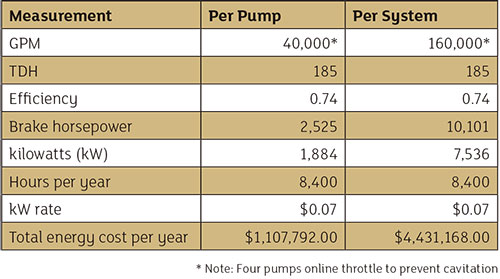

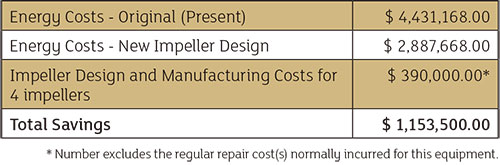

Tables 1-3 show the before and after energy usage, based on the projected energy audits.

Table 1. Original system

Table 2. Newly designed system

Table 3. Total projected energy savings for the system

In addition to energy savings, improved reliability and availability translates to extended mean time between repairs, significantly reducing maintenance costs.

Significant energy savings opportunities exist in every manufacturing facility worldwide, particularly with pumping systems that:

- use pumps driven by 200 horsepower and above

- are primarily providing cooling water

- include demands proportional to the plant throughput

- are used for batch operations

- have inherent delays or production slowdown

- currently use dump valves or bypass lines

- feature fluctuating system loading

In the past, pump upgrades or rerates tended to lie strictly with the OEM because they were the only party with access to cost-effective cast parts. However, with the technology revolution that is taking place in the aftermarket, upper tier service centers with on-staff hydraulic engineering support can often provide cost-effective, newly designed impellers or volutes with solutions specifically designed for the application.

With reverse engineering, laser digitizing equipment, CFD software and rapid prototyping coupled with the ability to print 3-D foundry molds directly from CAD/CAM software, the end user is no longer required to limp along with an obsolete pumping system. Solutions are readily available and well within the realm of financial feasibility.

– See more at: http://www.pumpsandsystems.com/pumps/august-2015-optimize-high-energy-pumps-improved-impeller-design

How to export a Word file as a PDF

- Click the Microsoft Office Button, point to the arrow next to Save As, and then click PDF

- In the File Name list, type or select a name for the document .

- In the Save as type list, click PDF .

- If you want to open the file immediately after saving it, select the Open file after publishing check box.

- Click Publish.

Report a problem

If you would like to be contacted regarding this issue, you can leave your details or, you can remain anonymous.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Thank you for reporting suspected misconduct, illegal acts, or failures to act within BGEN. We take these matters extremely seriously.

If you have provided contact details, we will respond back to you within 3 working days.

We support our clients in achieving not just exceptional projects but also exceptional business outcomes.

- Electrical & instrumentation

- LV assembly

- Systems integration

- Carbon & Energy Reduction

- Functional safety

- Digital engineering

- Mechanical design

- Electrical design

- Motor control centres & control panels

- Switchboards & substations

- 24/7 service and support

- Digitilisation

- Cybersecurity consultancy services

- Pump system optimisation

- Industrial networks

Optimising pump systems to help water companies meet their 2030 net zero carbon target

- Client: Utilities

- United Kingdom

Services provided

With water companies setting the bar for other infrastructure, utility and energy-intensive industries by aiming to achieve net zero carbon emissions by 2030, Andy O’Rourke, senior consultant at BGEN, explains the role control optimisation projects can have in helping the industry meet this ambitious target. He also gives examples of how Anglian Water has achieved significant carbon reduction savings in the field through optimising the control of pumping systems.

The race to 2030

In November 2020, UK water companies unveiled a ground-breaking plan to deliver a net carbon zero water supply for customers by 2030 in the world’s first sector-wide commitment of its kind1. Water UK has estimated this could save ten million tonnes of greenhouse gas by reaching net zero two decades ahead of the UK Government’s legally binding target of 2050.

The water industry is an energy intensive industry, with energy required to move and treat billions of litres of water per day, with each person in the UK consuming on average 142 litres1 per day. To meet the 2030 target, water companies are examining every facet of their operation to identify emission savings. This includes switching to low emission vehicles, realising water and energy savings, through to embracing renewable power and tackling process emissions.

Consequently, water companies are embracing new strategies to tackle leakage and examining their entire operation to identify energy saving opportunities. Pumps, an emitter of emissions, are one such area where water companies are looking for efficiencies and process improvements.

Pumps are fundamental in the water industry. They regulate the pressure in pumping mains to ensure water reaches its final destination, whether that be a storage reservoir or direct to customers. Pumps also remove and enable treatment of wastewater.

One of the key ways to improve the efficiency of pumping systems and reduce energy consumption is through effective control optimisation. An intelligent control system will pump only the required water when needed, and at the optimum pressure. This steady approach will also improve the treatment process and resilience through reduced leakage and bursts.

Realising control optimisation improvements at Anglian Water

Anglian Water, keen to look at how it could reduce its pump-related emissions across its operations, contacted BGEN to assist in meeting its 2030 target.

Anglian Water is the largest water and water recycling company in England and Wales by geographic area. The water company supplies water and water recycling services to almost seven million people in the East of England and Hartlepool. BGEN is a specialist, multi-discipline engineering solutions business. It has a dedicated team, providing engineering services across the utilities industry.

In delivering control improvements at Anglian Water, BGEN was responsible for a range of projects from conception to completion. Prior to each project taking place, BGEN gathered and analysed historical data from several sources to determine current and potential performance. A business case was then built to secure funding and upon approval the project was implemented in-house. Finally, the project was closed-out by verifying the delivered energy reduction against predicted savings.

The majority of the activity involved control modifications or re-designs, and offered leakage and process benefits alongside a reduction in CO2.

Three examples of optimising control systems are highlighted below:

Intake raw water pumping station

A desktop study was undertaken to evaluate the efficiency and energy reduction opportunities at an intake raw water pumping station. It had been identified that a lack of automation was impacting on performance. The pumps were also split between low- and high-pressure units. The low-pressure units were inefficient at high pressures and vice versa.

To deliver the energy savings, a PLC was installed to provide automated control of the pumps, band-screens and valves to manage river and reservoir levels. This enabled calculation of the optimum target flowrate and the selection of the most efficient pump numbers and combinations (large or small).

Pressure optimisation

An intelligent control philosophy was designed by BGEN to smooth the demand on a major transfer pumping main. Modern variable speed drives were installed so that the pumps can reduce flow overnight (instead of completely stopping) to eliminate pressure surge and to better manage reservoir levels. This also reduced peak day flowrates and facilitated an optimised pressure/flow relationship, where the controlling pressure was calculated dynamically based on requirements.

Raw water pumping station

At another raw water pump station, it was identified that the existing control was inefficient and not making optimal use of the available assets. Due to the complexity of the system, a Front-End Engineering Design study was conducted to further analyse the system and verify potential savings.

To improve the efficiency of the station, BGEN used its Pump System Optimisation software which offers reduced energy consumption potential and storage volume management. As a result, the team optimised pump system flowrates, flow control and pump scheduling, which led to significant energy savings.

Making a difference

Through a number of control optimisation projects BGEN has achieved substantial carbon and cost savings for Anglian Water by reducing total emissions by 5,858 tonnes of embodied CO2 and total operating costs by £3 million. The projects were recognised at the Anglian Water Supplier Awards, where BGEN was awarded honours for Sustainability and Efficiency. Projects currently in delivery are set to realise further savings of 975 tonnes of embodied CO2, and circa £600,000 of savings per annum.

By water companies embracing the potential of optimising controls, they can make significant strides in their mission to achieve net zero emissions by 2030.

Get in touch

Whether you have a specific project in mind or would like to explore how we might work together in future, please just contact us.

* Fields are required

IMAGES

VIDEO

COMMENTS

The case studies presented in this blog post demonstrate the importance of industrial pumps in different sectors, highlighting the benefits of upgrading existing pumping systems with new, …

The weight ratio of gear pumps (of the corresponding specific flow) for high pressures (ZPB.F#. and etc.) was analysed by analysing the weights of the starting (raw) and …

This paper focuses on the development of a small-scale and affordable pumped-storage powerplant. To do so, a survey was conducted to find existing reservoirs, such as the ones used for artificial snow or irrigation, in …

Pumps react to changing system conditions. System demand (or system resistance) determines the flow and pressure at which a pump will operate. As system flow …

SOLUTION. By using ANSYS Fluent CFD software, Neptuno Pumps® has been able to design and validate several vertical turbine pump models, optimizing impeller and bowl geometry in …

Case study: Planning at High Performance Pumps Introduction High Performance Pumps is a small, successful manufacturing organization that specializes in manufacturing a range of …

A High-Performance Cleaning Program that addresses staffing, training of maintenance personnel, the use of chemical concentrates, the use of sustainable cleaning materials, the use …

To improve the efficiency of the station, BGEN used its Pump System Optimisation software which offers reduced energy consumption potential and storage volume management. As a …